基于正交误差对准的MEMS陀螺测控电路设计

陈华+来强涛+郭桂良+郭江飞+韩荆宇

摘 要:传统MEMS(Micro-Electro-Mechanical System)陀螺的相干检测基于驱动位移和科氏位移的相位关系,依赖于陀螺的工作模式,解调载波相位抖动大,不易相位对准.为解决此问题,本文提出了一种基于正交误差对准的不依赖陀螺工作模式的相干解调系统.解调载波取自驱动电路的PLL(Phase-Locked Loop)输出,相位抖动小,仅作载波使用,不代表驱动位移信息.检测通路插入移相器,使正交误差相位滞后解调载波90°,则科氏位移信号与解调载波同相,完成检测.为验证该方法,本文研究了陀螺器件与接口电路之间的信号传递特性并进行建模,设计了锁相环、C/V(Capacitance/Voltage)转换、移相器等核心电路,实现了一款完整的MEMS陀螺测控电路.测试结果表明:陀螺驱动正常,检测正确,刻度因数为1.415 mV/(°.s),零偏不稳定度为108 °/h.结果验证了该检测方法的有效性,并为后续进一步提升性能提供了基础.该检测方法也适用于其他振动式MEMS陀螺的测控系统.

关键词:相干检测; 正交误差; 读出系统; 陀螺; MEMS传感器

中图分类号:TN911.7 文献标志码:A

Design of MEMS Gyroscope Interface Circuit Based onQuadrature Error Alignment

CHEN Hua1,2,LAI Qiangtao1,GUO Guiliang1,,GUO Jiangfei1,HAN Jingyu1

(1,Institute of Microelectronics of Chinese Academy of Sciences,Beijing 100029,China;

2.University of Chinese Academy of Sciences,Beijing 100049,China)

Abstract:Traditional synchronous demodulation of MEMS (Micro-Electro-Mechanical System) gyroscope is based on phase relationship of drive and sense positions. This relationship depends on the work mode of gyro. Moreover,the phase jitter of drive displacement is large,which makes the phase alignment of demodulator hard. To solve these problems,a new demodulation method based on quadrature error alignment was proposed,which is independent on work mode of gyro. Demodulator reference was extracted from PLL (Phase-locked loop) output,which has low jitter. Phase shifter of sense channel was used to delay quadrature error by 90°,compared with the reference signal. Therefore,Coriolis signal and the reference were automatically in-phase,and successful demodulation was achieved. To demonstrate this method,drive-mode and sense-mode circuits were elaborately implemented,and several critical blocks were care fully de signed. The demodulation of MEMS gyro shows that the vibration oscillation is stable and the operation of sense channel is correct. The scale factor is 1.415 mV/(°·s),and the bias instability is 108°/h. Moreover,the measurement results verify the validity of the demodulation method,providing solid foundation for further research. The method is also applicable to other vibratory MEMS gyroscopes.

Key words:coherent demodulation; quadrature error; readout systems; gyroscopes; MEMS sensors

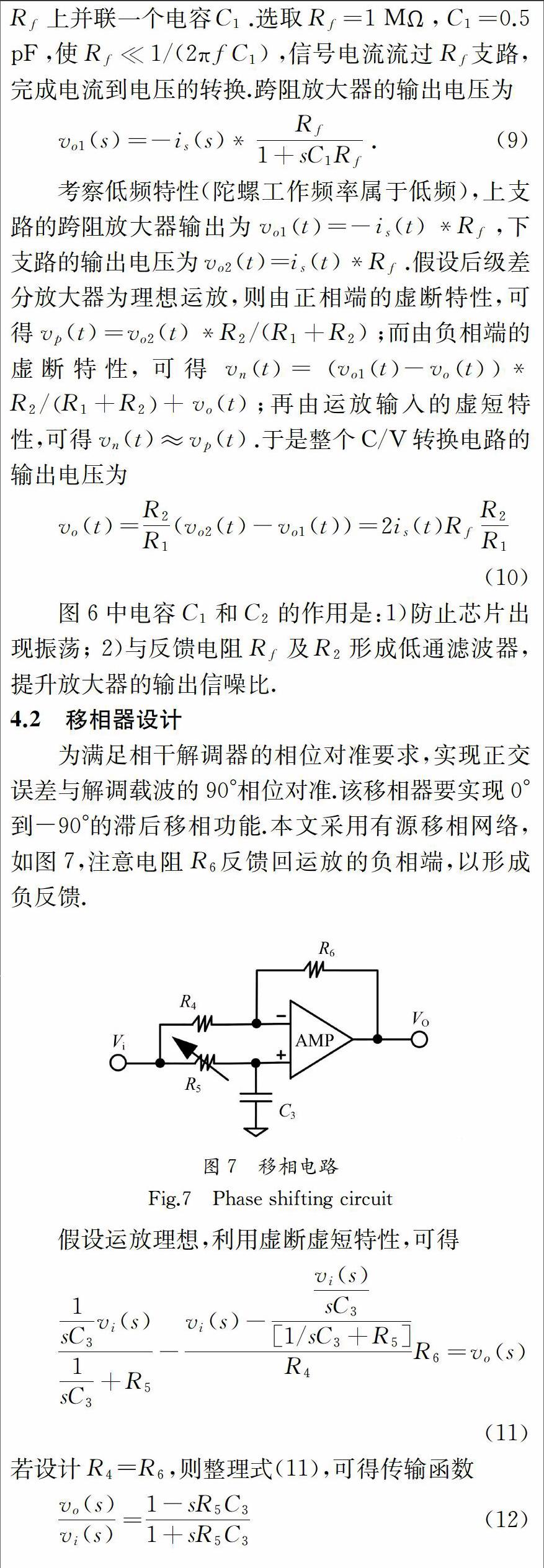

相對于传统陀螺仪,硅MEMS陀螺具有低成本、小尺寸、低功耗和高可靠性等优势,在消费电子、汽车、工业控制及国防军事等领域有着广泛的应用[1-2].近年来,随着研究的不断深入,MEMS陀螺性能已逼近惯导级[3-5],并且成功地应用于惯性测量单元中[6-8].由于加工误差等非理想因素,陀螺驱动模态和检测模态之间存在比较严重的弹性耦合,使得在没有输入角速度时,检测模态仍然有较大的正交误差输出.为抵抗各种扰动,陀螺一般工作于低通区而非模态匹配区,这就造成科氏信号极其微弱.为了有效地检测科氏信号,文献[9-11]做了正交误差消除工作,然后尽可能地将科氏信号放大,提升机械信噪比.消除正交误差的方法有:在驱动方向设计校准梳指;在检测方向的检测电极上施加校准力;对检测方向的输出电学信号进行补偿.后两种方法会引入噪声,污染检测梳齿上的微弱科氏信号,所以高性能陀螺一般采用第一种方法.而本文研究对象由其他单位提供,没有设计正交误差校正梳指,所以本文要探索在正交误差存在时怎样将微弱的科氏信号较好地检测出来.endprint