层层自组装功能化涂层及其生物应用研究进展

江兵兵,宋琼芳,陈明,陈学琴

(1.湖北大学材料科学与工程学院,湖北 武汉 430062;2.有机化工新材料湖北省协同创新中心(湖北大学),湖北 武汉430062)

层层自组装功能化涂层及其生物应用研究进展

江兵兵1,2,宋琼芳1,陈明1,陈学琴1

(1.湖北大学材料科学与工程学院,湖北 武汉 430062;

2.有机化工新材料湖北省协同创新中心(湖北大学),湖北 武汉430062)

层层自组装作为一种新颖的材料制备技术,具有制备条件可控,适用于多种物质,具备产业化前景等诸多优点.探讨层层自组装技术的优势及其近几年的生物医学应用(构建生物相容性界面,改性组织工程支架表面,药物载体的制备)和功能化涂层应用,重点详述用层层自组装技术制备功能化涂层并使其具有不同响应性的研究进展.

层层自组装技术;功能化涂层;响应性;应用

0 引言

现代医学的进步与生物材料的发展密不可分.从外科整形、心血管植入支架,到人体骨科置换和修复、生物组织工程,再到药物传递系统,医用生物材料遍及生物医学的各个领域[1].

层层自组装技术,作为一种新颖的制备纳米膜的技术,由德国科学家Decher、Hong等在 1991年正式提出[2-3],并于1997年将详细技术首次发表于《Science》[4],在过去的20多年内得到了迅猛的发展.经典的层层自组装驱动力是静电作用力[5-6],除此之外,氢键[7-8]、疏水[9-10]、共价键[11-12]、主客体[13-14]、电荷转移[15]等作用力同样可以用类似的原理形成交替的多层膜.张希课题组[16]和Rubner课题组[17]在1997年几乎同时提出以氢键作为驱动力形成多层膜;Crooks课题组[18]也在1997年提出了以共价键为驱动力构建薄膜.

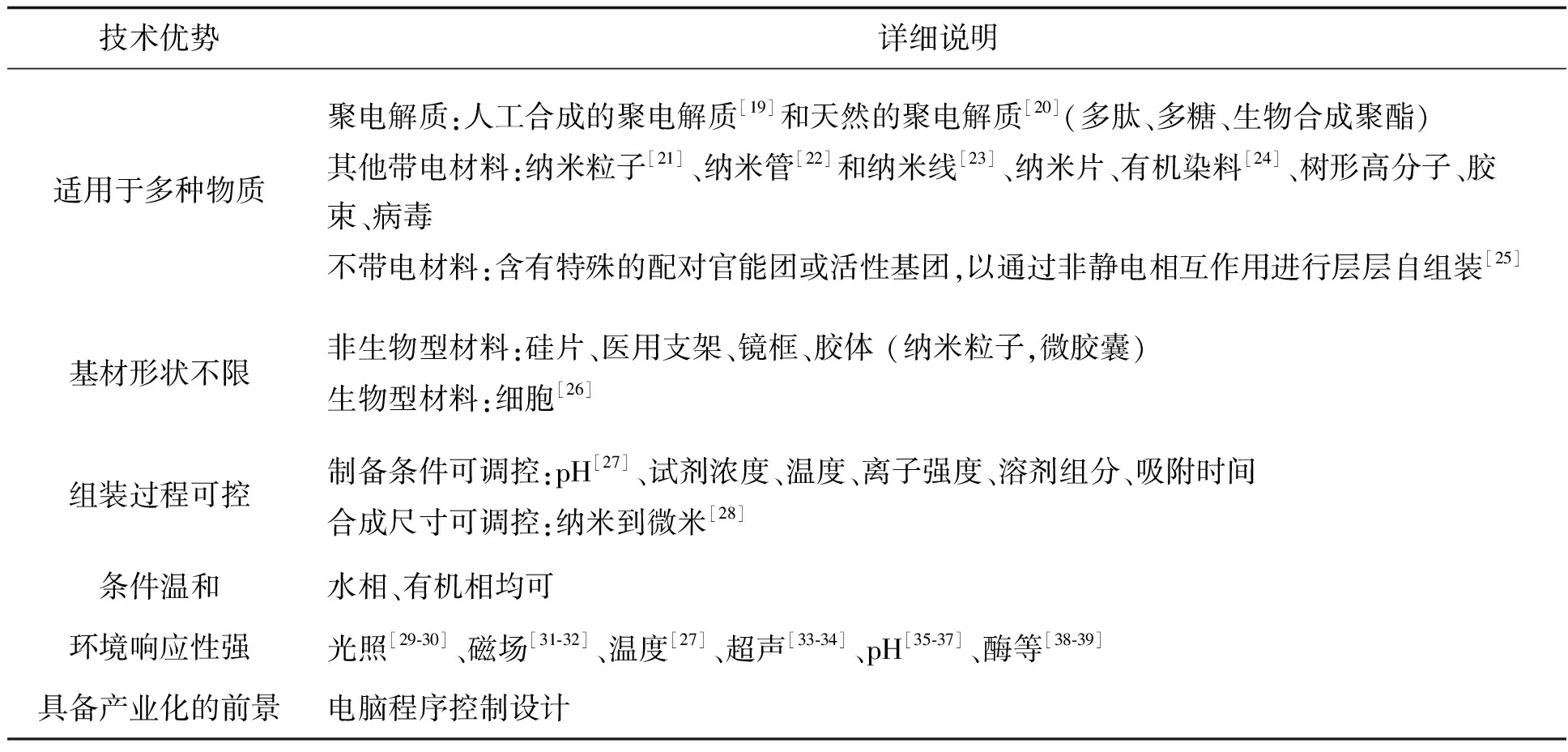

层层自组装技术拥有其独特的优势,如表1所示.该类多层膜的物理、化学性质可以很容易通过改变自组装多层膜的层数以及聚电解质的种类进行调控.这些特点极大扩展了层层自组装多层膜的应用范围,使得层层自组装技术成为了医学材料中构筑复合功能性薄膜和药物载体不可或缺的方法.由此可见,层层自组装技术在21世纪初便得到广泛应用也便不无道理.

表1 层层自组装的优势

1 层层自组装的生物医学应用

1.1构建生物相容性界面层层自组装技术基于表1中的种种优势而被广泛用于构建生物相容性界面,减小生物材料和人体的排斥反应,使细胞能更好地附着在材料表面并进行增殖.谭琦[40]等用层层自组装技术使肝素和壳聚糖在去细胞质基质表面进行层层自组装,并进行化学交联.结果显示,其生物力学性能和生物相容性明显优于单纯去细胞质基质,该层层自组装材料具备良好的内皮细胞粘附能力及增殖能力.Wu等[41]将肝素和氧化石墨烯通过静电作用自组装于纳米纤维表面.结果表明用该复合膜改性后的纳米纤维其亲水性得到改善,细胞粘附性能更好,还在一定程度上抑制了炎症的产生.余森等[42]通过层层自组在静电层层自组装在TiO2薄膜表面引入肝素-白蛋白多层复合膜.结果表明,经表面肝素-白蛋白复合涂层修饰处理后,其表面更为光滑、平整,同时材料表面的溶血率显著降低,试样表面无凝血块出现,且粘附的少量血小板,激活反应轻微,且材料的抗凝血性能和血液相容性均得到了明显的改善.

上述结果均表明,用层层自组装技术构建生物相容性界面之后,材料本身的性能没有降低,还能缓解人体对材料的免疫反应,和材料起协同作用,在生物体内发挥更好的作用.

1.2组织工程支架表面改性层层自组装技术同样被用于组织工程支架领域.经多层膜改性的组织工程支架可为细胞和组织生长提供更为适宜的环境,利于激活细胞特异的基因表达.用于研究组织工程结构的材料需要具备良好的生物相容性和降解性,因此大多我们选取天然聚电解质之类的材料.沈家骢等[43]将静电层层自组装的技术引入制备好的聚乳酸(PLLA)多孔支架材料中.成功地在支架上制备出硫磺软骨素/胶原(CS/COL)多层膜.与未改性的PLLA相比,经多层膜改性的PLLA材料表面细胞的黏附率、增殖率和活性都得到了显著的改善,细胞边缘清晰完整,尺寸正常,而且细胞分布均匀,细胞密度大,基本铺满培养板基底.Matthew等[44]以氧化锌(ZnO)纳米粒子和聚苯乙烯磺酸钠(PSS)为组装基元制备了多层膜.该多层膜能在一定程度上防止细菌感染.

1.3微胶囊型药物载体层层组装所形成的功能化涂层应用广泛,主要应用于药物的载入和释放.其载药方式可分为前载药[45]和后载药[46-47]两种:(1)前载药即在装载的过程中进行载药[48];(2)后载药即通过后处理的方式进行载药:已制备好的多层膜体系,浸入含有药物分子的溶液中进行载药,通过分子间的识别和物理吸附的方法包埋药物,较前一种方法载药量较低,但该种载药方式能保持较高的药物活性.李峻柏等[49]则利用N-异丙基丙烯酰胺(PNIPAAm)和Alg之间的氢键作用制备了层层自组装微胶囊.当温度高于PNIPAAm的低临界溶解温度(LCST)时,PNIPAAm由亲水物质转变成疏水性物质,导致了分子链紧的收缩,继而改变囊壁的通透性.通过改变温度,可以很好的控制药物的包裹和释放.Sukhorukov等[50]合成了一种带负电的侧链为偶氮苯的聚合物(PAzo),通过与PAH 和聚磺酸基乙烯(PVS)进行层层自组装制备出(PAH/PAzo)3PAH/PV S 微胶囊药物载体.这种微胶囊在不同光照的情况下会因为偶氮苯构象的变化而发生体积和膜渗透性的可逆变化,从而可以实现药物控释.

2 功能化涂层及其响应性

2.1功能化涂层以薄膜基材制备功能型多层膜,由于其丰富的组装基元、优越的薄膜调控功能,被广泛研究和应用.我们[51]使用聚赖氨酸(PLL)和聚(L-谷氨酸)(PLGA)制备聚多肽多层膜,并在膜中引入了IL-12细胞因子,从而自发激活人体免疫系统进行杀菌,该方法不仅可以有效地避免医疗器械植入所引起的感染同时也不会产生耐药性问题.我们[52]还采用不同聚电解质修饰的碳酸钙胶体微粒为载体与多肽材料进行组装.研究表明,在37 ℃,pH=7.4条件下,释放周期长达数周.该方法大大提高了药物的活性,为多层膜的药物负载提供了广阔的设计空间.Saibom等[53]首先将不带电的聚乙二醇-聚乳酸共乙醇酸(PEG-PLG)胶束为载体与聚电解质透明质酸(HA)进行混合,随后与聚电解质LPEI进行交替层层组装.结果显示,HA多层膜具有良好的生物相容性;而载有紫杉醇(PTX)药物的多层膜在对人平滑肌细胞的抗粘附测试则表明,PTX的缓释可以通过改变组装的层数达到理想效果,当组装层数为20层时,PTX释放周期长达14 d,对防止手术后的再感染具有重要的意义.

在过去的研究发展历程中,不仅实现了疏水的有机小分子等非水溶性物质的层层组装膜的构筑,也成功地在同一体系中负载多种不同药物,通过材料对某些特定信号或者生物体内某种特定信号的响应[54].根据材料的性质,选取不同的材料可以达到不同的响应效果.同时,在外界条件刺激下,智能型多层膜能够实现物质的选择性包埋,并对药物进行智能化控释.这样既可以减少药物在人体内的毒性作用,也可以维持药物浓度在有效治疗浓度范围内,延长其在体内/体外的作用时间.根据释放机制的不同可以将这些响应手段分为物理和化学两大类.物理手段主要包括温度[27]、光[29-30]、磁场[31-32]和超声变化[33-34]等使层层组装体系解离释放药物,而化学方法主要包括pH[35-37]和酶[38-39]等.

2.2温敏性响应温度响应是用来控释药物的常见手段之一.自组装体系具有了温敏响应性后,多层膜在各研究领域有更广泛的应用.其中,最为常见的温度敏感型高分子材料N-异丙基丙烯酰胺(PNIPAAm).PNIPAAm被广泛引入层层自组装体系,既适用于微胶囊体系,又可以作为组成薄膜的片段.除了上文所述的微胶囊体系,PNIPAAm还能组装为温敏响应的功能性薄膜,Quinn等[55]率先将PNIPAAm与聚丙烯酸(PAA)通过氢键作用结合成多层膜并负载染料进行测试,实验表明通过对温度的调节可以控制染料的装载和释放.除了PNIPAAm外,Vincent等[56]以温敏型阳离子嵌段聚合物和光敏染料为原料,用层层自组装技术制备了多层膜.(2-二甲基氨基)甲基丙烯酸乙酯嵌段共聚2-(乙二醇)甲基醚甲基丙烯酸酯(PDMAEMA59-b-PDEGMA318, PDD)表现出明显的温度依赖性,在26 ℃时PDD/PSS的双层膜厚度约为(2.65±0.02) nm,而31 ℃则仅为(1.34±0.02) nm,使之成为传感装置中极有潜力的温敏材料.

2.3光敏响应用光为刺激手段进行智能化控制是一种比较温和的手段.光敏物质使多层膜增加了孔结构,与无孔的多层膜相比,其比表面积更大,通透性更好,应用更多元化.以卟啉为例,卟啉是一种被广泛应用于医疗和其他领域的光敏剂,在光照下可以激发出具有强氧化力的活性氧自由基(ROS).光照下卟啉产生的具有强氧化能力的活性氧自由基能够解离两种成膜聚合物的分子链,从而使多层膜变成多孔结构,增加薄膜通透性.Volodkin等[57]报道一种由HA与PLL作为聚电解质,并负载了金纳米粒子的多层薄膜.薄膜中的金纳米粒子在近红外照射下变得活跃,经表征显示薄膜局部的温度上升,该现象主要是因为光能转化成热能.李草[58]分别选用了两种具有良好生物相容性的材料,卟啉封端的聚赖氨酸(APP-PLL)以及鲱鱼精DNA作为聚阳离子和聚阴离子进行层层自组装,薄膜通过控制光照时间来控制多孔膜上孔洞的数量和大小.

2.4pH响应pH响应的物质能调控多层膜的结构,使其在不同的pH下呈现不同的特性,以达到某些特定的效果.参与静电层层组装的膜材料很多是弱聚电解质,这类层层组装体系具有pH敏感性的特性,如聚阳离子材料聚烯丙胺盐酸盐(PAH) 就是一种弱电解质(pKa=8.7)聚多碱材料.对于这种聚多碱膜材料组装得到的多层膜,当外环境的pH 值高于它们的pKa时,多层膜就会发生解离.同样的对于聚多酸弱电解质膜材料组装得到的多层膜体系,当外环境的pH值低于它们的pKa时,聚电解质质子化使多层膜解离.

Kainourgios等[59]制备了pH敏感型聚电解质多层膜微球.该微球由聚二甲基二烯丙基氯化铵/聚苯乙烯磺酸钠(PDADMAC/PSS)多层膜和交联聚乙二醇组成,并在微球中载入DNR,于不同的pH值下测定其释放行为.结果显示,在pH值为4时,启释放量仅为15%,而在pH值为7.4的环境下,DNR呈爆发性释放,一小时内其释放量约为65%.此特性使该微球载体能应用于一定的pH环境.

2.5其他响应方式除却上述响应方式,磁性响应,酶响应等响应手段也有一定的研究进展.Wang等[60]用层层自组装技术在Fe3O4@SiO2纳米微球表面包裹聚烯丙基胺-葡聚糖微凝胶,形成复合微球并用来负载布洛芬.结果显示,该载体能在0.9%的NaCl溶液中持续释放药物,微球外层的交联膜有很好的溶胀能力,而且其表面有大量质子化氨基团,能使该复合载体有很好的.Baumert等[61]则将带负电的si-RNA与带正电的PEI进行复合,形成正电复合体PEI-siRNA、并同HA、CHI进行层层自组装,制备出对丙型肝炎病毒有很好抑制作用的多层膜.该薄膜通过细胞透明质酸酶对薄膜裂解的作用,siRNA不断被释放出来,达到治疗的效果.

层层自组装的功能化涂层,由于组装物质的多元化,其功能也不尽相同,应用广泛.随着科学技术的发展,层层自组装多层膜会有更多不同种类的功能.

3 展望

层层自组装是基于物质间的相互作用力的,通过物质的交替沉积而形成纳米结构的多层膜一种手段.这种新型技术涉及物理、化学、生命科学和材料科学、药理学和工程学等方面知识,在各研究领域中扮演着重要的角色.从不可降解性物质,发展到可降解,继而多功能性选择,层层自组装取得了跨越式发展,从无机相到有机相,浸涂到喷涂,技术也在不断的成熟.通过设计负载多种药物的功能性薄膜并在不同的环境下进行响应控释,仍是当前及以后的研究热点.层层自组装在基础性研究中取得突破性进展的同时,将基础性研究的成果逐步进行体内/外效果测试、评价,并运用于临床,其研究与开发对拓展高性能生物医用材料具有重要的理论意义和现实价值.

[1] 高长有. 医用高分子材料[M]. 北京:化学工业出版社, 2006.

[2] Decher G, Hong J D. Buildup of ultrathin multilayer films by a self-assembly process, 1 consecutive adsorption of anionic and cationic bipolar amphiphiles on charged surfaces[J].Makromolekulare Chemie Macromolecular Symposia,1991, 46(1):321-327.

[3] Decher G, Hong J D, Schmitt J, et al. Buildup of ultrathin multilayer films by a self-assembly process(III):consecutively alternating adsorption of anionic and cationic polyelectrolytes on charged surfaces[J].Thin Solid Films,1992, 210/211(2):831-835.

[4] Decher G. Fuzzy nanoassemblies: toward layered polymeric multicomposites[J]. Science, 1997, 277(5330):1232-1237.

[5] 徐扬子, 张候. CdS包覆SiO2核/壳和空腔结构纳米球制备及发光性能[J].湖北大学学报(自然科学版), 2015(3):257-261.

[6] Velk Natalia, Uhlig Katja, Vikulina Anna,et al. Mobility of lysozyme in poly(l-lysine)/hyaluronic acid multilayer films[J]. Colloids and Surfaces B:Biointerfaces, 2016(1):343-350.

[7] Eugenia K, Veronika K, Sukhishvili S A. Layer‐by‐layer hydrogen‐bonded polymer films: from fundamentals to applications[J]. Advanced Materials, 2009, 21(21):3053-3065.

[8] Yu C, Wei H. Synthesis and characterization of glucocorticoid functionalized poly(N-vinyl pyrrolidone): a versatile prodrug for neural interface[J]. Biomacromolecules, 2010, 11(5):1298-1307.

[9] Xu L, Zhu Z, Sukhishvili S A. Polyelectrolyte multilayers of diblock copolymer micelles with temperature-responsive cores.[J]. Langmuir, 2011, 27(1):409-415.

[10] Alhariri L A, Reisch A, Schlenoff J B. Exploring the heteroatom effect on polyelectrolyte multilayer assembly: the neglected polyoniums[J]. Langmuir, 2011, 27(7):3914-3919.

[11] Hu X, Ji J. Covalent layer-by-layer assembly of hyperbranched polyether and polyethyleneimine: multilayer films providing possibilities for surface functionalization and local drug delivery[J]. Biomacromolecules, 2011, 12(12):4264-71.

[12] Such G K, Quinn J F, Quinn A, et al. Assembly of ultrathin polymer multilayer films by click chemistry[J]. Journal of the American Chemical Society, 2006, 128(29):9318-9319.

[13] Suzuki I, Egawa Y, Mizukawa Y, et al. Construction of positively-charged layered assemblies assisted by cyclodextrin complexation[J]. Chemical Communications, 2002, 13(2):164-165.

[14] Crespobiel O, Dordi B, Reinhoudt D N, et al. Supramolecular layer-by-layer assembly: alternating adsorptions of guest-and host-functionalized molecules and particles using multivalent supramolecular interactions[J]. Journal of the American Chemical Society, 2005, 127(20):7594-7600.

[15] Wang F, Ma N, Chen Q, et al.Halogen bonding as a new driving force for layer-by-layer assembly[J]. Langmuir, 2007,23(19): 9540-9542.

[16] Wang L, Wang Z, Zhang X, et al. A new approach for the fabrication of an alternating multilayer film of poly(4-vinylpyridine) and poly(acrylic acid) based on hydrogen bonding[J].Macromolecular Rapid Communications,1997,18(6):509-514.

[17] Vainas T, Stassen F R M, Bruggeman C A, et al.Molecular-Level processing of conjugated polymers. 4. layer-by-layer manipulation of polyaniline via hydrogen-bonding interactions[J]. Macromolecules, 1997, 30(9):2717-2725.

[18] Liu Y, Bruening M L, Bergbreiter D E, et al. Multilayer dendrimer-polyanhydride composite films on glass, silicon, and gold wafers[J]. Angewandte Chemie International Edition, 1997, 36(19):2114-2116.

[19] Jiang X, Chen Z, LV D, et al. Basic law controlling the growth regime of layer-by-layer assembled polyelectrolyte multilayers[J]. Macromolecular Chemistry & Physics, 2007, 209(2):175-183.

[20] Paterno L G, Constantino C J L, Oliveira O N, et al. Self-assembled films of poly(o-ethoxyaniline) complexed with sulfonated lignin[J]. Colloids & Surfaces B:Biointerfaces, 2002, 23(4):257-262.

[21] Chandrawati R, Koeverden M P V, Lomas H, et al. Multicompartment particle assemblies for bioinspired encapsulated reactions[J]. Journal of Physical Chemistry Letters, 2011, 2(20):2639-2649.

[22] Hou S, Harrell C C, Trofin L, et al. Layer-by-layer nanotube template synthesis[J]. Journal of the American Chemical Society, 2004, 126(18):5674-5675.

[23] Liao L, Lin Y C, Bao M, et al. High-speed graphene transistors with a self-aligned nanowire gate[J]. Nature, 2010, 467(7313):305-308.

[24] Zhao W, Tong B, Shi J, et al. Fabrication and optoelectronic properties of novel films based on functionalized multiwalled carbon nanotubes and (Phthalocyaninato)Ruthenium(II) via coordination bonded layer-by-layer self-assembly[J]. Langmuir, 2010, 26(20):16084-16089.

[25] Dorokhin D, Hsu S H, Tomczak N, et al. Fabrication and luminescence of designer surface patterns withβ-cyclodextrin functionalized quantum dots via multivalent supramolecular coupling[J]. Acs Nano, 2010, 4(1):137-142.

[26] Swiston A J, Cheng C, Um S H, et al. Surface functionalization of living cells with multilayer patches[J]. Nano Letters, 2009, 8(12):4446-4453.

[27] Kim B S, Park S W, Hammond P T. Hydrogen-bonding layer-by-layer-assembled biodegradable polymeric micelles as drug delivery vehicles from surfaces[J]. Acs Nano, 2008, 2(2):386-392.

[28] Such G K, Quinn J F, Quinn A, et al. Assembly of ultrathin polymer multilayer films by click chemistry[J]. Journal of the American Chemical Society, 2006, 128(29):9318-9319.

[29] Volodkin D V, Madaboosi N ,Blacklock J, et al. Surface-supported multilayers decorated with bio-active material aimed at light-triggered drug delivery?[J]. Langmuir, 2009, 25(24):14037-14043.

[30] Liu J, Zhang Y, Wang C, et al. Magnetically sensitive alginate-templated polyelectrolyte multilayer microcapsules for controlled release of doxorubicin[J].The Journal of Physical Chemistry C,2010, 114(17):7673-7679.

[31] Liu J, Zhang Y, Wang C, et al. Magnetically sensitive alginate-templated polyelectrolyte multilayer microcapsules for controlled release of doxorubicin[J].The Journal of Physical Chemistry C, 2010, 114(17):7673-7679.

[32] Katagiri K, Nakamura M, Koumoto K. Magnet responsive smart capsules formed with polyelectrolytes, lipid bilayers and magnetic nanoparticles[J]. ACS Applied Materials & Interfaces, 2010, 2(3):768-773.

[33] Song W, He Q, Mchwald H,et al. Smart polyelectrolyte microcapsules as carriers for water-soluble small molecular drug[J]. Journal of Controlled Release, 2009, 139(2):160-166.

[34] Shchukin D G, Gorin D A, Mchwald H. Ultrasonically induced opening of polyelectrolyte microcontainers[J]. Langmuir, 2006, 22(17):7400-7404.

[35] Jiang B, Li B. Tunable drug loading and release from polypeptide multilayer nanofilms[J]. International Journal of nanomedicine, 2009, 4:37.

[36] Kim B S, Park S W, Hammond P T. Hydrogen-bonding layer-by-layer-assembled biodegradable polymeric micelles as drug delivery vehicles from surfaces[J]. Acs Nano, 2008, 2(2):386-392.

[37] Wang B, Liu P, Jiang W, et al. Yeast cells with an artificial mineral shell: protection and modification of living cells by biomimetic mineralization[J]. Angewandte Chemie International Edition, 2008, 47(19):3560-3564

[38] Sakr O S, Borchard G.Encapsulation of enzymes in layer-by-layer structures: latest advances and applications[J]. Biomacromolecules, 2013, 14(7):2117-2135.

[39] Serizawa T, Yamaguchi M, Akashi M. Alternating bioactivity of polymeric layer-by-layer assemblies: anticoagulation vs procoagulation of human blood[J]. Biomacromolecules, 2002, 3(4):724-731.

[40] 谭琦, 刘又年, 陈万松, 等. 化学交联层层自组装结构提高去细胞基质生物相容性研究[C].中国功能材料及其应用学术会议,2010.

[41] Wu K, Zhang X, Yang W, et al. Influence of layer-by-layer assembled electrospun poly (l-lactic acid) nanofiber mats on the bioactivity of endothelial cells[J]. Applied Surface Science,2016,390:838-846.

[42] 余森, 于振涛, 牛金龙, 等. 医用钛合金Ti-3Zr-2Sn-3M0-25Nb表面自组装抗凝血复合涂层的构建及其血液相容性研究[C].中国有色金属工业协会钛锆铪分会2011年会, 2011.

[43] Gong Y, Zhu Y, Liu Y, et al. Layer-by-layer assembly of chondroitin sulfate and collagen on aminolyzed poly(l-lactic acid) porous scaffolds to enhance their chondrogenesis[J]. Acta Biomaterialia, 2007, 3(5):677-685.

[44] Mcguffie M J, Jin H, Bahng J H, et al. Zinc oxide nanoparticle suspensions and layer-by-layer coatings inhibit staphylococcal growth[J]. Nanomedicine Nanotechnology Biology & Medicine, 2015, 12(1):33-42.

[45] Ma N, Zhang H, Song B, et al. Polymer micelles as building blocks for layer-by-layer assembly: an approach for incorporation and controlled release of aateriInsoluble dyes[J]. Chemistry of Materials, 2005, 17(20):5065-5069.

[46] Volodkin D V, Madaboosi N, Blacklock J, et al. Surface-supported multilayers decorated with bio-active material aimed at light-triggered drug delivery[J]. Langmuir the Acs Journal of Surfaces & Colloids, 2009, 25(24):14037-14043.

[47] Liu J, Zhang Y, Wang C, et al. Magnetically sensitive alginate-templated polyelectrolyte multilayer microcapsules for controlled release of doxorubicin[J]. Journal of Physical Chemistry C, 2010, 114(17):7673-7679.

[48] Wei C, Wang A, Jie Z, et al. Layer by layer assembly of albumin nanoparticles with selective recognition of tumor necrosis factor-related apoptosis-inducing ligand (TRAIL)[J]. Journal of Colloid & Interface Science, 2015, 465(12):11-17.

[49] Wang A, Cheng T, Yue C, et al. Assembly of environmental sensitive microcapsules of PNIPAAm and alginate acid and their application in drug release[J]. Journal of Colloid & Interface Science, 2009, 332(2):271-279.

[50] Bédard M, Skirtach A G, Sukhorukov G B. Optically driven encapsulation using novel polymeric hollow shells containing an azobenzene polymer[J]. Macromolecular Rapid Communications, 2007, 28(15):1517-1521.

[51] Li B, Jiang B B, Boyce B M, et al. Multilayer polypeptide nanoscale coatings incorporating IL-12 for the prevention of biomedical device-associated infections[J]. Biomaterials, 2009, 30(13):2552-2558.

[52] Jiang B, Defusco E, Li B. Polypeptide multilayer film co-delivers oppositely-charged drug molecules in sustained manners[J]. Biomacromolecules, 2010, 11(12):3630-3637.

[53] Park S, Bhang S H, La W G, et al. Dual roles of hyaluronic acids in multilayer films capturing nanocarriers for drug-eluting coatings[J]. Biomaterials, 2012, 33(21):5468-5477.

[54] Pavlukhina S, Sukhishvili S. Polymer assemblies for controlled delivery of bioactive molecules from surfaces[J]. Advanced Drug Delivery Reviews, 2011, 63(9):822-836.

[55] Quinn J F, Caruso F. Facile tailoring of film morphology and release properties using layer-by-layer assembly of thermoresponsive materials[J]. Langmuir, 2004, 20(1):20-22.

[56] Joseph V S, Kim S, Zhang Q, et al. Multilayer films composed of a thermoresponsive cationic diblock copolymer and a photoresponsive dye[J]. Polymer, 2013, 54(18):4894-4901.

[57] Volodkin D V, Madaboosi N, Blacklock J, et al. Surface-supported multilayers decorated with bio-active material aimed at light-triggered drug delivery[J]. Langmuir the Acs Journal of Surfaces & Colloids, 2009, 25(24):14037-14043.

[58] Li C, Zhang J, Yang S, et al. Controlling the growth behaviour of multilayered films via layer-by-layer assembly with multiple interactions[J]. Physical Chemistry Chemical Physics, 2009, 11(39):8835-8840.

[59] Kainourgios P, Efthimiadou E K, Tziveleka L A, et al.Comparative study of LBL and crosslinked pH sensitive PEGylated LBL microspheres: Synthesis,characterization and biological evaluation[J]. Colloids & Surfaces B Biointerfaces, 2013, 104(3):91-98.

[60] Wang L, Liao R, Li X. Layer-by-layer deposition of luminescent polymeric microgel films on magnetic Fe3O4@SiO2, nanospheres for loading and release of ibuprofen[J]. Powder Technology, 2013, 235(2):103-109.

[61] Dimitrova M, Affolter C, Meyer F, et al. Sustained delivery of siRNAs targeting viral infection by cell-degradable multilayered polyelectrolyte films[J]. Proceedings of the National Academy of Sciences of the United States of America, 2008, 105(42):16320-16325.

Advancedprogressoflayerbylayerself-assemblyfunctionalcoatinganditsapplicationinbiology

JIANG Bingbing1,2,SONG Qiongfang1,CHEN Ming1,CHEN Xueqin1

(1.Faculty of Materials Science and Engineering, Hubei University, Wuhan 430062, China; 2.Hubei Collaborative Innovation

Center for Advanced Organic Chemical Materials(Hubei University), Wuhan 430062,China)

As a novel material preparation technology, the layer-by-layer(LBL) technique has many advantages, such as controlled preparation conditions, suitable for a variety of material and great industrialization prospects. This paper discussed the advantages of LBL self-assembly technology as well as its biomedical applications-synthesis of biocompatible interface, surface modification tissue engineering scaffolds, preparation of drug carrier-and functional applications, focusing on progress of the functional coatings and its different response.

layer-by-layer technique;functional coatings;responsiveness ;application

2017-01-08

国家自然科学基金(51503060)和湖北省自然科学基金(2014CFB549)资助

江兵兵(1972-),男,博士,教授;陈学琴,通信作者,讲师,E-mail:51545457@qq.com

1000-2375(2017)06-0639-07

O631

A

10.3969/j.issn.1000-2375.2017.06.014

(责任编辑 胡小洋)