果园风送喷雾机导流板角度对气流场三维分布的影响

吕晓兰,张美娜,常有宏,雷哓晖,杨青松

果园风送喷雾机导流板角度对气流场三维分布的影响

吕晓兰1,张美娜1,常有宏2※,雷哓晖1,杨青松2

(1. 江苏省农业科学院农业设施与装备研究所,南京 210014;2. 江苏省农业科学院园艺研究所,南京 210014)

风送喷雾条件下,雾滴是在空气流携带下进入果树冠层的各个部位,所以喷雾机气流场的运动和分布对雾滴的分布和穿透非常重要。为了研究果园风送喷雾机导流板角度变化对外部气流速度场三维空间分布的影响,该文采用ICEM建立几何模型,并进行全结构网格划分,采用k-ε湍流模型和CFX求解器进行数值求解。通过变换上导流板角度(30°、45°、60°、90°)与下导流板角度(0°、10°、20°、30°),来模拟分析风机外部流场在各工况下的空间稳态流场、湍流状态,以及对气流场空间分布的影响。结果表明,下导流板角度由0°增加至30°过程中,由于地面摩擦阻力对气流的影响逐渐减小,同时地面摩擦阻力与两侧空气阻力形成的夹角越来越大,因此单一气流束逐渐分成3条气流束,这样的气流分布优于单一方向气流对果树枝叶的吹动效果,有利于气流携带雾滴进入果树冠层;上下导流板导向气流主要集中在导流板指向区域,因此,导流板的角度设置应根据树冠高度、树干高度来调整。通过设置合理的导流板角度,使得风场分布与果树冠形相吻合,达到仿形喷雾效果。对于行距4 m、树高3.0~3.2 m的果园喷雾,上、下导流板角度均为30°;对于棚架果园,上导流板角度为90°(或卸掉上导流板),下导流板为30°。该研究有利于指导田间喷雾作业、喷雾参数调整,可达到更好的喷雾效果、减少环境污染。

农业机械;喷雾;计算机仿真;风送式喷雾机;导流板;气流分布;三维

吕晓兰,张美娜,常有宏,雷哓晖,杨青松. 果园风送喷雾机导流板角度对气流场三维分布的影响[J]. 农业工程学报,2017,33(15):81-87. doi:10.11975/j.issn.1002-6819.2017.15.010 http://www.tcsae.org

Lü Xiaolan, Zhang Meina, Chang Youhong, Lei Xiaohui, Yang Qingsong. Influence of deflector angles for orchard air-assisted sprayer on 3D airflow distribution[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2017, 33(15): 81-87. (in Chinese with English abstract) doi:10.11975/j.issn.1002-6819.2017.15.010 http://www.tcsae.org

0 引 言

果园风送喷雾作业中,农药雾滴是在辅助气流携带下进入树冠的各个部位,风机气流场的空间分布与扩散对雾滴在果树冠层中的穿透、沉积有显著影响。因此,国内外许多研究人员对不同风送式喷雾机的气流场速度分布、药液沉积分布及影响因素进行了试验研究,结果发现:不同结构的风送式喷雾机,其气流速度空间分布特性有很大差异,同样条件下产生的药液沉积分布特性也有很大的差异[1-2]。然而,施药过程受很多因素影响,尤其受不可控的田间自然风、空气温度和相对湿度等因素的影响[3-4]。采用传统试验方法研究有很大困难,而采用CFD技术进行研究,则可克服田间试验中不可控因素对试验结果的干扰,实现各个参数按要求改变,获得任意条件下的试验结果。目前国内外研究均已证实采用CFD模拟技术能较好的模拟分析风送喷雾内外气流场分布与雾滴沉积规律[5-8]。

气流特性是衡量果园风送喷雾机性能的主要技术指标,特别是寻求与果树冠层参数匹配的风机出口气流场分布是研究的重点和难点。目前国际上主要利用基于非结构化网格的有限元方法求解N-S方程和湍流方程,并结合试验数据,获得喷雾机内外流场的气动特性,并建立了多种风机气流场CFD模型。Endalew等[9-12]建立了一个新的果园风送喷雾CFD 模型,研究了喷雾机风速与方向对喷雾气流的影响,证实气流逆向线性衰减。Delele等[13-15]建立了不同类型果园风送喷雾机风场模型,用以评价喷雾机作业性能。Dugaa等[16-20]建立了果园风送喷雾田间飘失CFD模型,该模型能预测并减少漂移距离50%。García-Ramos等[21]采用3D超声波风速计针对双风机果园喷雾机进行了地面之上4 m空间内气流速度来验证以风机进风量为主要参数的CFD模型,模拟值与测量值相关系数达0.859,具有良好的相关性。Salcedoa等[22]将柑橘树体简化成多孔介质,建立二维CFD模型,该CFD模型能够重现树冠周围的气流行为,且具有相同的湍流结构。祁力钧等[23-24]采用CFD 模拟技术建立了果园风送喷雾机二维雾流场分布模型与温室轨道式弥雾机的气流速度场分布模型,并对模拟结果进行了验证。傅泽田等[25]基于CFD模拟建立了果园风送式喷雾机气流场速度分布模型,研究了果园风送式喷雾机气流速度场速度分布特性及各因素的影响规律,揭示果园风送式喷雾机的工作机理。王景旭等[26]则研究了靶标周围气流场分布以及对冠层内雾滴沉积分布影响规律。周良富等[27-29]采用试验方法与计算机模拟相结合,研究了圆盘雾化器最佳的工作转速,不同转速下圆盘雾化器的气流速度场,并进行试验验证。丁天航等[30]模拟分析了单、双层流道设计对果园风送喷雾机双侧流场对称性的影响。

上述研究结果均显示建立的CFD模型能够直观反应气流场特性,且实测值与模拟值吻合度高,具有极高的可信度。得出喷雾机外流场的气流速度在垂直和水平2个方向呈梯度减小趋势;有效风速的距离和有效风场半径都随喷雾机出口气流速度增大而增大;气流靶标点的速度与喷雾机风量和行驶速度有关。雾滴的穿透性、雾滴在作物冠层中的沉积量与风机风量正相关等重要结论。但是这些研究没有充分展示三维气流场随不同作业参数变化而发生改变的规律,特别是导流板角度对三维风场的分布的影响。目前国内果园风送喷雾机主要以传统轴流风机风力辅助喷雾为主,气流调节依靠导流板,因此本文通过模拟分析上下导流板不同角度、不同三维截面上气流场分布规律,以期有效指导实际田间作业时导流板的合理调整。

1 几何模型建立

1.1 几何模型

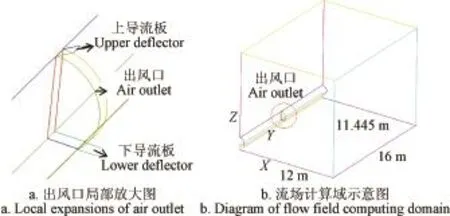

本文针对Hardi Zaturn 1000型牵引式果园风送喷雾机进行研究。如图1所示,风机轴线距离地面高度为0.915 m,出风口弧面宽度为0.16 m,弧面半径为风机外壳半径0.53 m,风扇外壳底部(下导流板水平位置)距地面高度为0.52 m。因此,本文将风机出风口简化成一宽度为0.16 m的弧面,并在弧面上部和下部分别设置导流板;考虑到几何模型具有对称特性,因此只考虑几何模型的一半作为研究对象。考虑后续模拟研究中将加入一排果树模型,研究侧向风对雾滴飘失的影响规律等,风机最上端出风口的高度为1.445 m,设定风机的顶端射程10 m,因此风机上部流场高度可达11.445 m,同时该喷雾机左右侧有效射程(以2 m/s 为边界)为10~15 m,因此建立外流场计算域,长度为16 m,宽度为12 m,高度为11.445 m,如图2所示。

图2 三维流场计算区域设置Fig.2 Setting of 3D flow field computing domain

1.2 网格划分

由于本文研究上导流板角度α和下导流板角度β(角度均为导流板与地面的夹角)的不同组合对风送喷雾机外部气流场的影响,因此需要根据导流板与水平面角度的变化建立多个几何模型,共计16组模型,导流板角度变化规律如表1所示。

表1 上下导流板角度组合Table 1 Angle settings of upper and lower deflectors

本文采用ICEM CFD对每个几何模型的计算域进行全结构化网格划分,在导流板和出风口附近区域进行网格加密,并在长、宽、高方向由近及远对网格节点进行比例缩放,全局网格节点约为156万。

2 流体计算模型

2.1 控制方程

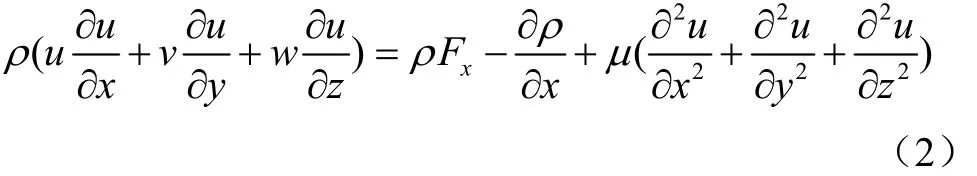

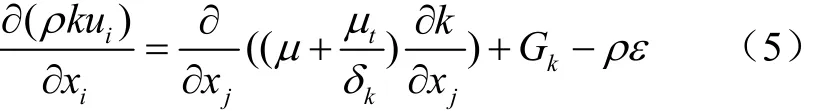

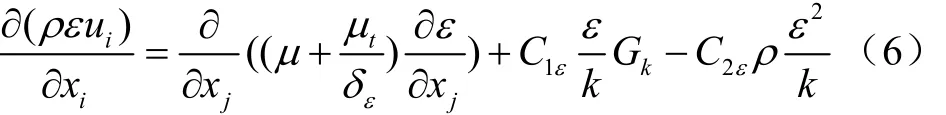

根据风机实际作业时出口风速范围15~35 m/s,本文中风机出口风速设置为20 m/s,由于空气流速不大,将空气视为不可压缩流体,其密度为1.185 kg/m3,参考大气压力为1个大气压。本文采用CFX来计算各工况稳态流场,其基本控制方程如式(1)~式(4)所示。在实际工程中,流体基本处于紊流状态,本文选择κ-ε湍流模型来描述湍流,控制方程如式(5)~式(6)所示[31]。

1)质量守恒方程

2)动量守恒方程

式中x,y,z为坐标轴长度,m;u,v,w为3个坐标轴对应的速度,m/s;ρ为密度,kg/m3;μ为黏度,kg/(m·s);Fx,Fy,Fz为作用在流体元上单位质量力所在3个坐标轴的分力,m/s2。

3)湍流动能方程

4)湍流动能耗散率方程

式中μt为湍流黏性系数,Pa·s;xi、xj为2个方向的长度距离,m;Gk是由平均速度梯度引起的湍动能产生项;C1ε、C2ε为经验常数;δk和δε分别为与湍动能k和耗散率ε对应的Prandt l数,ui为速度,m/s。

2.2 边界条件

根据风机产生气流工况,设置各边界条件,如下所示:1)进口:速度入口,方向垂直弧面;2)出口:压力出口,相对压力为0;3)地面及导流板:Wall壁面,无滑移;4)对称面:Symmetry对称面。

3 气流场模拟分析与讨论

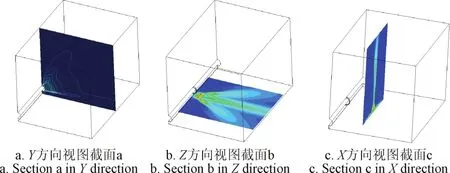

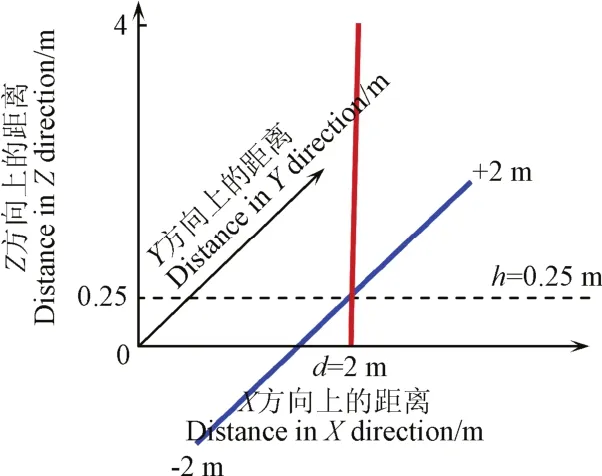

气流场三维截面的选取示意图如图3所示,在风机外部空间流场内以3种方向来选取截面,以显示速度场空间分布情况。截面a:与风机轴线垂直,经风机出口中心的竖直平面;截面b:与地面平行的水平面,且距地面0.25、0.915(风机轴线高度)、1.5、2.0 m 4个截面;截面c:与风机轴线平行垂直平面,且距离风机轴线1、2、3、4 m位置垂直面。

图3 气流场三维截面的选取示意图Fig.3 Three sections were selected in airflow 3D field

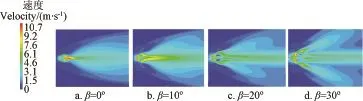

3.1 上、下导流板角度变化对截面a风场分布的影响

图4为上、下导流板角度变化时,风场在截面a上分布的变化。如图4所示,上导流板角度由90°变为30°的过程中,气流在导流板的导向作用下,气流扩散区域逐渐减小,同时导向气流主要集中在导流板指向区域,上下导流板调整角度时,对中间区域气流无明显影响。因此上下气流调整应以树冠高度为依据。因此,调整导流板角度时,可采用长飘带来标识气流方向,上下导流板各系上2 m长飘带,飘带指向树冠顶端及偏下20 cm即可,下飘带则应指向树冠底端[29]。对于棚架种植的果树喷雾时,由于树冠枝叶集中在上层且交叉,上导流板角度应设为90°,下导流板角度设为30°及以上,以确保气流和雾滴向上喷撒到枝叶上。对于中国常规种植果园,果树高度3.0~3.2 m,定干高度0.6 m左右,行距4 m,冠形多为纺锤形,上导流板角度设置为30°,下导流板设置为30°,可有利于农药雾滴集中向冠层喷施。

图4 上下导流板角度变化对截面a内气流分布的影响Fig.4 Changes of air velocity distributions in section a with upper and lower deflector angle

由于本研究所用喷雾机下导流板距离地面0.52 m,当导流板角度为0°时,由于地面摩擦阻力与外围气流反向卷吸作用,导流板导向气流多扩散至地面区域。因此可认为,下导流板角度较小时,下部气流多扩散至地面,这是引起农药雾滴地面流失的重要因素。当导流板角度慢慢增加至30°时,导流板导向气流主要扩散方向慢慢提升至水平及以上区域。由于不同地区、不同果树品种定干高度有差异,果园行距有大小,因此下导流板角度设置应根据具体的果园条件来调整,以风机底端气流脱离地面摩擦,且气流指向冠层底端方向为宜。

3.2 上、下导流板角度变化对截面b风场分布的影响

图5为不同高度的截面b内气流分布的变化,随着高度的增加,气流场在水平面内最高风速减小的同时,射流区域逐渐变窄,说明喷雾机上部气流量小于下部气流量。

图6中下导流板角度由0°增加至30°过程中,由于地面摩擦阻力对气流的影响逐渐减小,同时地面摩擦阻力与两侧空气阻力形成的夹角越来越大,因此气流束逐渐分成3条气流束,这样的气流分布优于单一方向气流对果树枝叶的吹动效果,有利于气流携带雾滴进入果树冠层。

图5 不同高度的截面b内气流分布的变化Fig.5 Changes of air velocity distributions in section b at different height

图6 下导流板角度变化对0.25 m高度截面b内气流分布的影响Fig.6 Changes of air velocity distribution in section b at height of 0.25 m with different lower deflector angles

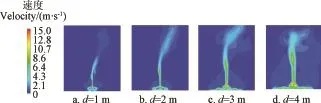

3.3 上、下导流板角度变化对截面c风场分布的影响

图7为不同距离d的截面c内气流分布,图8为下导流板角度变化时,距离风机轴线不同距离的垂直方向气流垂直分布变化规律。如图7、8所示,在距离风机轴线1、2、3、4 m的垂线上,风速分布高风速区域主要集中在0.5~4.0 m之间。

图7 距风机轴线不同距离的截面c内气流分布Fig.7 Changes of air velocity distribution in section c at different distances from fan axis

下导流板角度逐渐增加时,最高风速点出现在导流板指向区域和角度,在风机出口风速20 m/s时,下导流板角度为30°时,距离风机轴线距离1 m垂直线上,最高风速出现在0.8 m高度,最高值为25.5 m/s,高风速其他区域数值几乎无差异。这就意味着,最高风速点出现的位置低于现有果树冠层最厚高度位置,为进一步优化风送气流分布特性,使其风速垂直分布曲线与果树冠层外形曲线在高度方向上吻合。需进一步优化风机出口导流板设置,在风机出口区域,除上、下导流板外,中间区域同样设置导流板,对气流进行多重调整[2]。

图8 下导流板角度变化时距离风机轴线不同距离截面c中垂线上气流分布变化规律Fig.8 Changes of air velocity distribution on vertical line cross section c at different distances from fan axis with different lower deflector angles

4 气流场分布试验验证

4.1 试验设计

为验证模拟结果的可靠性,试验设置条件与模拟试验相同,测量了距离风机轴线距离d=2 m垂直线,以及距离地面高度h=0.25 m水平线上的气流速度分布。风机外部气流速度实测试验在福田雷沃重工集团车间进行,风机出口15 m内无障碍物。采样点设置示意图如图9所示,垂直线测量高度为4 m,水平线测量长度为4 m,即以风口为中心前后各2 m的距离。采样点分别沿垂直、水平两条线间隔0.2 m设置。风速分布实地测量如图10所示,以4.5 m 高杆作为定位标杆,从地面向上以0.2 m为间隔在杆上做出标识,沿坐标位置移动高杆,实现风速采样点快速定位。拖拉机PTO 设定540 r/min转速,风机挂高速挡,此时风机出口平均风速在19.76 m/s。本试验采用台湾SENTRY热球式风速仪ST-732对采样点进行风速测量,记录每个采样点最大风速值。

图9 采样点设置示意图Fig.9 Diagram of samples setting

图10 风速分布实地测量Fig.10 Measurement of wind velocity distribution in field

4.2 试验结果与分析

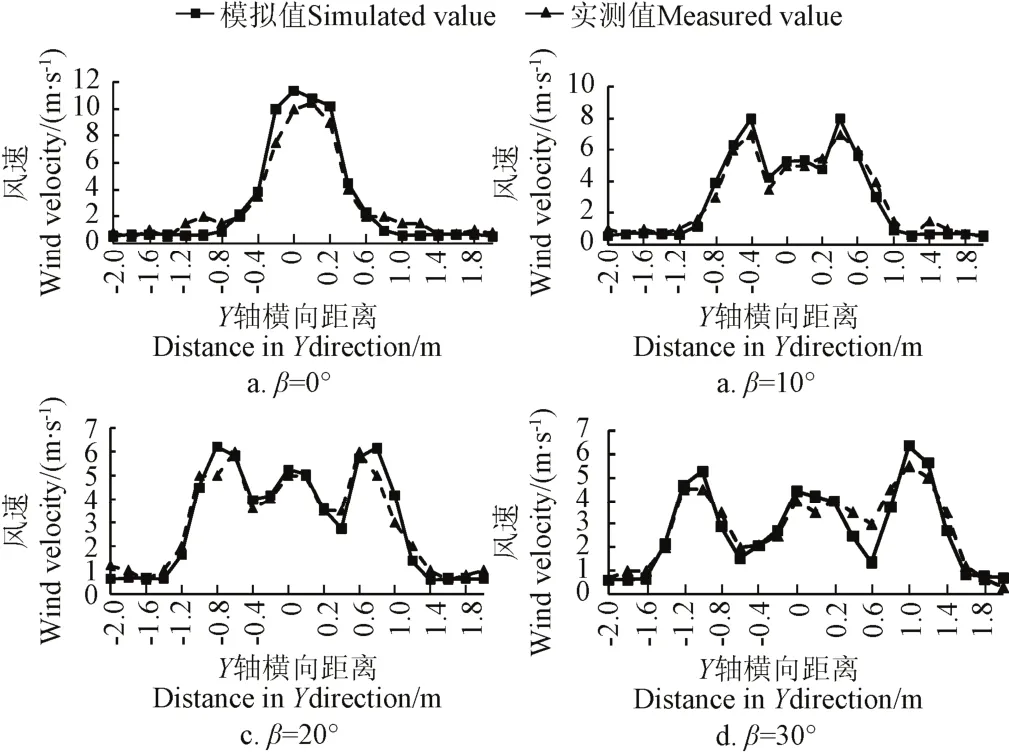

如图11所示,实测风速在距离风机轴线2 m的垂直线上分布曲线特性与CFD模拟结果吻合较好,呈单边纺锤形,祁力钧等[23]亦提出相同结论。水平方向气流分布如图12所示,实测风速在距离风机轴线2 m,距离地面0.25 m的平面b内的分布曲线特性与CFD模拟曲线趋势吻合,均随着下导流板角度由0°增加至30°过程中,单一气流束逐渐分成3条气流束,相对高速区逐渐扩大,气流场厚度的增加有利于风机外部空间与冠层内空气的推动置换,便于枝叶的充分扰动。

图11 风速垂直分布Fig.11 Air velocity distribution in vertical direction

图12 水平方向气流分布Fig.12 Air velocity distribution in horizontal direction

由于部分采样点的瞬时气流不稳定,造成采集的最大风速不是真正某一时段的最大风速,因此风速的CFD模拟值普遍略大于实测值,特别是在低风速段(≤2 m/s),部分采样点的风速模拟值与实测值差异性较大,这是由于气流速度已经淹没于环境自然风速中,受周边气流扰动显著,造成实测值与模拟值之间的差异。然而在高风速区域(±0.60 m区间),风速实测值与模拟值平均相对误差小于10%。综上表明,本文CFD 模拟结果能够较准确模拟出风送式喷雾机气流速度三维分布的特征区域,模拟结果的正确性可信。

5 结论与讨论

1)基于CFD模拟建立的Hardi Zaturn 1000型果园风送式喷雾机外部气流速度场三维空间分布模型能够直观反映了3个视角平面内气流场的分布,以及各参数变化对气流场影响的规律,气流三维分布特征曲线模拟值与实测值吻合较好,模拟结果的正确性可信。

2)上下导流板角度变化对气流扩散的中间区域无明显影响,仅仅使上下区域的气流集中在导流板指向区域,增加了局部气流速度,因此,导流板角度应根据树冠高度、树干高度做调整。

3)下导流板角度变化对下部气流分布影响显著,当下导流板角度由0°增加至30°,气流受地面摩擦力逐渐减小,且地面摩擦阻力与气流束两侧空气阻力形成的夹角越来越大,因此气流束逐渐分成3条气流束,这样的气流分布优于单一方向气流对果树枝叶的吹动效果,有利于气流携带雾滴进入果树冠层。

4)通过全因素模拟分析可知,上下导流板角度合理设置可有效减少气流在地面区域和高空区域的无效流失。由于不同地区、不同果树品种定干高度有差异,果园行距有大小,因此下导流板角度设置应根据具体的果园条件来调整,以树高为依据调整上导流板角度,以树干高度来调整下导流板角度,以风机底端气流脱离地面摩擦,且气流指向冠层底端方向为宜。

基于本文结论,建议在风机出口区域,除上、下导流板外,中间区域设置导流板,对气流进行多重调整,有利于使风速垂直分布与树冠仿形。风机出口导流板优化设置有待进一步研究。

[1] Ashenafi T D, Kris R, Donald D, et al. Spray deposition profiles in pome fruit trees: Effects of sprayer design, training system and tree canopy characteristics[J]. Crop Protection, 2015, 1(67): 200-213.

[2] Almbauer R A, Lind K , Matzer W. Determination of the influence of the driving speed on the application parameters of orchard sprayers[C]//Proceeding of Fifth European Workshop on Standard Procedure for the Inspection of Sprayers-SPISE 5, Julius Kühn Archiv, 2015, No.449.

[3] 吕晓兰,傅锡敏,吴萍,等. 喷雾技术参数对雾滴沉积分布影响试验[J]. 农业机械学报,2011,42(6):70-75.

Lü Xiaolan, Fu Ximin, Wu Ping, et al. Influence of spray operating parameters on droplet deposition[J]. Transactionsof the Chinese Society of Agricultural Machinery, 2011, 42(6): 70-75. (in Chinese with English abstract)

[4] 吕晓兰,傅锡敏,宋坚利,等. 喷雾技术参数对雾滴飘移特性的影响[J]. 农业机械学报,2011,42(1):59-63.

Lü Xiaolan, Fu Ximin, Song Jianli, et al. Influence of spray operating parameters on spray drift[J]. Transactions of the Chinese Society of Agricultural Machinery, 2011, 42(1): 59-63. (in Chinese with English abstract)

[5] 周良富,薛新宇,贾卫东,等. CFD技术在果树风送喷雾中的应用与前景分析[J]. 排灌机械工程学报,2014,32(9):776-782.

Zhou Liangfu, Xue Xinyu, Jia Weidong, et al. Application of CFD technology in air-assisted spraying in orchard and analysis of its prospects[J]. Journal of Drainage and Irrigation Machinery Engineering (JDIME), 2014, 32(9): 776-782. (in Chinese with English abstract )

[6] 孙国祥,汪小旵,丁为民,等. 基于CFD 离散相模型雾滴沉积特性的模拟分析[J]. 农业工程学报,2012,28(6):13-19.

Sun Guoxiang, Wang Xiaochan, Ding Weimin, et al. Simulation analysis on characteristics of droplet deposition base on CFD discrete phase model[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2012, 28(6): 13-19. (in Chinese with English abstract)

[7] Baetens K, Nuyttens D, Verboven P, et al. Predicting drift from field spraying by means of 3D computational fluid dynamics model[J]. Computers and Electronics in Agriculture, 2007, 56(2): 161-173.

[8] 王景旭,祁力钧,夏前锦. 靶标周围流场对风送喷雾雾滴沉积影响的CFD模拟及验证[J]. 农业工程学报,2015,31(11):46-53.

Wang Jingxu, Qi Lijun, Xia Qianjin. CFD simulation and validation of trajectory and deposition behavior of droplets around target affected by air flow field in greenhouse[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2015, 31(11): 46-53. (in Chinese with English abstract)

[9] Endalew A M, Debaer C, Rutten N, et al. A new integrated CFD modelling approach towards air-assisted orchard spraying—Part I: Model development and effect of wind speed and direction on sprayer airflow[J]. Computers and Electronics in Agriculture, 2010, 71(1): 128-136.

[10] Endalew A M, Debaer C, Rutten N, et al. A new integrated CFD modelling approach towards air-assisted orchard spraying—Part II: Validation for different sprayer types[J]. Computers and Electronics in Agriculture, 2010, 71(1): 137-147.

[11] Endalew A M, Debaer C, Rutten N, et al. Modelling the effect of tree foliage on sprayer airflow in orchards[J]. Boundary-Layer Meteorology, 2011, 138(1): 139-162.

[12] Dekeyser D, Foque D, Endalew A M, et al. Assessment of orchard sprayers using laboratory trials[J]. Aspects of Applied Biology, 2012, 114: 395-403.

[13] Delele M A, Jaeken P, Debaer C, et al. CFD prototyping of an air-assisted orchard sprayer aimed at drift reduction[J]. Computers and Electronics in Agriculture, 2007, 55: 16-27.

[14] Delele M A, Moor A D, Sonck B, et al. Modelling and validation of the air flow generated by a cross flow air sprayer as affected by travel speed and fan speed[J]. Biosystems Engineering, 2005, 92(2): 165-174.

[15] Delele M A, Moor A D, Verboven P, et al. CFD modelling of air flow patterns from an air assisted orchard sprayer[J]. Aspects of Applied Biology, 2004, 71(2): 303-310.

[16] Dugaa A T, Delelea M A, Ruysenc K, et al. Development and validation of a 3D CFD model of drift and its application to air-assisted orchard sprayers[J]. Biosystems Engineering, 2017, 154:62-75.

[17] Dugaa A T, Dekeyser D, Ruysenc K, et al. Numerical analysis of the effects of wind and sprayer type on spray distribution in different orchard training systems[J]. Boundary-Layer Meteorology, 2015, 12(157): 517-535.

[18] Duga A T, Ruysen K, Dekeyser D, et al. CFD based analysis of the effect of wind in orchard spraying[J]. Chemical Engineering Transactions, 2015, 44: 289-294.

[19] Duga A T, Defraeye T, Nicolai B, et al. Training system dependent optimization of air assistance and nozzle type for orchard spraying by CFD modeling[C]// Association of Applied Biologists, 2014, 122: 453-458.

[20] Dekeyser D, Dugaa A T , Verbovenb P, et al. Assessment of orchard sprayers using laboratory experiments and computational fluid dynamics modeling[J]. Biosystems Engineering, 2013, 2(114): 157-169.

[21] García-Ramos F J, Malón H, Aguirre A J, et al. Validation of a CFD model by using 3D sonic anemometers to analyze the air velocity generated by an air-assisted sprayer equipped with two axial fans[J]. Sensors 2015, 15(2): 2399-2418.

[22] Salcedoa R, Granella R, Palaub G, et al. Design and validation of a 2D CFD model of the airflow produced by an airblast sprayer during pesticide treatments of citrus[J]. Computers and Electronics in Agriculture, 2015, 116(8): 150-161.

[23] 祁力钧,王虎,张建华,等. 温室轨道式弥雾机气流速度场三维模拟与试验[J]. 农业机械学报,2013,44(2):69-74.

Qi Lijun, Wang Hu, Zhang Jianhua, et al. 3-D numerical simulation and experiment of air-velocity distribution of greenhouse air-assisted sprayer[J]. Transactions of the Chinese Society for Agricultural Machinery, 2013, 44(2): 69-74. (in Chinese with English abstract)

[24] 祁力钧,赵亚青,王俊,等. 基于CFD 的果园风送式喷雾机雾滴分布特性分析[J]. 农业机械学报,2010,41(2):62-67.

Qi Lijun, Zhao Yaqing, Wang Jun, et al. CFD simulation and experimental verification of droplet dispersion of air-assisted orchard sprayer[J]. Transactions of the Chinese Society of Agricultural Machinery, 2010, 41(2): 62-67. (in Chinese with English abstract)

[25] 傅泽田,王俊,祁力钧,等. 果园风送式喷雾机气流速度场模拟及试验验证[J]. 农业工程学报,2009,25(1):69-74.

Fu Zetian, Wang Jun, Qi Lijun, et al. CFD simulation and experimental verification of air-velocity distribution of air-assisted orchard sprayer[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2009, 25(1): 69-74. (in Chinese with English abstract)

[26] 王景旭,祁力钧,夏前锦. 靶标周围流场对风送喷雾雾滴沉积影响的CFD 模拟及验证[J]. 农业工程学报,2015,31(11):46-53.

Wang Jingxu, Qi Lijun, Xia Qianjin. CFD simulation and validation of trajectory and deposition behavior of droplets around target affected by air flow field in greenhouse[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2015, 31(11): 46-53. (in Chinese with English abstract)

[27] 周良富,张晓辛,吕晓兰,等. 圆盘雾化器风力性能竖直模拟与试验[J]. 农业机械学报,2012,43(10):72-75.

Zhou Liangfu, Zhang Xiaoxin, Lü Xiaolan, et al. Numerical simulation and experimental study on the wind performance of the disc atomizer[J]. Transactions of the Chinese Society for Agricultural Machinery, 2012, 43(10): 72-75. (in Chinese with English abstract)

[28] 陈发元,汪小旵,丁为民,等. 果树喷雾用圆盘风扇三维气流速度场数值模拟与验证[J]. 农业机械学报,2010,41(8):51-55.

Chen Fayuan, Wang Xiaochan, Ding Weimin, et al. Numerical simulation and experimental verification of 3-D air velocity field of disk fan used in orchard sprayer[J]. Transactions of the Chinese Society for Agricultural Machinery, 2010, 41(8): 51-55. (in Chinese with English abstract)

[29] Balsari P, Herbst A, Langenakens J. Advice for bush and tree crop sprayer adjustment[C]//Proceedings of the 6th workshop on Standardized Procedure for the Inspection of Sprayers in Europe(SPISE6). Quedlinburg Germany: Julius Kuhn Institute Press, 2016: 4-14.

[30] 丁天航,曹曙明,薛新宇,等. 果园喷雾机单双风机风道气流场仿真与试验[J]. 农业工程学报,2016,32(14):62-68.

Ding Tianhang, Cao Shuming, Xue Xinyu, et al. Simulation and experiment on single-channel and double-channel airflow field of orchard sprayer[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2016, 32(14): 62-68. (in Chinese with English abstract)

[31] 王福军. 计算流体动力学分析-CFD 软件原理与应用[M].北京:清华大学出版社,2004.

Influence of deflector angles for orchard air-assisted sprayer on 3D airflow distribution

Lü Xiaolan1, Zhang Meina1, Chang Youhong2※, Lei Xiaohui1, Yang Qingsong2

(1. Institute of Agricultural Facilities and Equipment, JAAS, Nanjing 210014, China; 2. Institute of Horticulture, JAAS, Nanjing 210014, China)

Air-assisted orchard sprayers are characterized by a strong airflow that carries the pesticide droplets to the target canopy and assists the plant parts to move so as to allow the whole tree penetrated with pesticide droplets. The airflow distribution and movement characteristics are key parameters of sprayer for droplet deposition on target canopy. In order to study the 3D (three-dimensional) spatial distribution of airflow field from an air-assisted orchard sprayer, this article used ICEM CFD (Integrated Computer Engineering and Manufacturing code for Computational Fluid Dynamics) to establish a geometric model, whose whole structure was meshed, and the k-ε turbulence model and CFX solver were adopted. The effect of different environmental systems on airflow 3D distribution for air-assisted orchard sprayer was estimated, in which the upper deflector angle was set as 30°, 45°, 60°, and 90°, and the lower deflector angle was set as 0°, 10°, 20° and 30°, respectively. Results show that the 3D spatial distribution model of the airflow from air-assisted orchard sprayer can reflect the airflow distribution directly, and the simulated values of airflow characteristic curve are in good agreement with the measured values. However, in the low airflow velocity region (the velocity below 2 m/s), the simulated velocity values of some sampling points are quite different from measurements. That is caused by the perturbation of the natural wind. In the high airflow velocity region with 1.2 m width, the average relative error between the measured value and the simulated value of wind speed is less than 10%. That can confirm that the simulation results are credible. Meanwhile, airflow guided by deflectors is mainly focused in the area the deflectors pointed to, with no obvious effect on airflow diffusion in the middle area, only increasing the airflow velocity and letting airflow gather near deflector area. So the adjustment of deflector angle should be based on the height of canopy and tree trunk, through setting lower deflector angle to fit the foliage limit of the orchard, and setting upper deflector angle to point at position which is little lower than the topmost of tree canopy in the orchard. For further research, to change airflow velocity of the fan has no significant effect on airflow distribution in the airflow field, and merely increases airflow diffusion region. When the lower deflector angle increases from 0° to 30°, the effect of ground friction resistance on the airflow decreases gradually, and the angle between ground friction resistance and air resistance on both sides increases constantly, so one single air current is divided into 3 air currents gradually. This kind of air distribution on horizontal plane has advantages on blowing branches and leaves and penetrating droplets into fruit tree canopy. The airflow velocity distribution in the vertical direction considerably affects the distribution of spray droplets in canopy. The vertical profile of the airflow velocity should be even along the whole vegetation wall, and matched with the canopy shape curve. But the deflector can only adjust the upper and lower airflow, some deflectors are suggested to be fixed in the middle area for adjusting airflow distribution in vertical direction. This study found that a better effect could be achieved by setting the upper and lower deflectors angle as 30° for spraying in the Chinese general orchard where fruit trees had 3.0-3.2 m height and were planted with 4 m row spacing, and by setting the upper deflector angle of 90° (or removing), and the lower deflector angle of 30° for spraying in trellised orchard. The results can provide the reference for the spraying in the orchard, and the higher spraying efficiency and the reduction of environmental pollution can be achieved through the calibration of sprayer operational parameters.

agricultural machinery; spraying; computer simulation; air assisted sprayer; deflector; airflow velocity distribution; three dimensional

10.11975/j.issn.1002-6819.2017.15.010

S49

A

1002-6819(2017)-15-0081-07

2017-03-21

2017-06-12

国家梨产业技术体系(CARS-29-18),国家自然科学基金项目(31301687),江苏省农业自主创新资金项目(CX(15)1023)

吕晓兰,女,研究员,主要从事植保机械与施药技术研究。南京江苏省农业科学院农业设施与装备研究所,210014。

Email:lxlanny@126.com

※通信作者:常有宏,男,研究员,博士生导师,主要从事果园设施与农机具研究。南京 江苏省农业科学院园艺研究所,210014。

Email:cyh@jaas.ac.cn