马丁·劳奇访谈

马丁·劳奇,张利

尚晋 译

马丁·劳奇访谈

马丁·劳奇,张利

尚晋 译

1 起点

张利:夯土几乎是您一手在当代建筑中打造起来的。我想这不是您第一次被问到整个夯土事业是从哪里起步的。您是在何时何地下决心将余生献给夯土建筑的呢?夯土的什么品质让您走上了这条道路?

马丁·劳奇:我是在福拉尔贝格的一个小村庄长大的。父亲是教师、艺术家。父母拥有一座小农场。从孩提时代起我就迷上了生土材料。我喜欢在外面玩,而大自然就是我的玩具。那时几乎所有的村子都有自己的壤土i窑,整个社区都会从那里取壤土盖房子或作日用。它的用途非常广泛:从围泉水、密封、造炉子,到家用热敷治疗。对这种材料和制作器物工艺的亲身接触让我决定去当造火炉的学徒,后来又到维也纳艺术学院研习陶瓷艺术。在研习中我开始建造自己的柴窑,并熟悉了烧瓷所需的技巧。从这时开始我就问自己,何时何处需要加热烧造材料?什么时候发挥原材料的优势更合理?最后,我创作出了最早的夯土画和雕塑,并逐渐走向可居住、有供暖的房间和建筑。不过一开始显然是艺术而非建筑的手法。

我的一些兄弟姐妹活跃在国际领域。在这种环境下,我的目光投向了全球生土建筑。当然那不只是壤土屋,还有宫殿、集市、宗教场所以及完全由生土建造的城市。生土建筑能高达数层的特性令我尤为着迷。我对夯土建筑情有独钟,它与其他生土建筑技术相比有两个明显的优势:它能够轻松造出承重建筑,且无需外包材料就能抵御风雨。这就是圆满之处。夯土建筑应从外观上就能识别出来。我希望这种材料以最纯粹的方式表达自身。这就是与现代建筑相通的重要关联。夯土建筑具有一种坦诚的结构真实性和雄壮的美。

2 全球/本土

张利:夯土由于用了本地的土就被认为在本质上是本土的。但您最近采用了一种更工业化的夯土制造方法,甚至是预制。大多数人会认为手工艺是本土的,工业的则意味着全球的。那工业化预制会危害夯土作为本土、乡土材料的名声么?

劳奇:首先这种矛盾并不真的存在。预制可以有非常本土的建造方式。比如利口乐草药中心,加工厂离建筑场地只有3km——原材料都来自建筑半径10km以内的场地。目前我们正在德国有机食品生产商Alnatura新总部办公楼的建筑场地直接制造。这样预制的砌体离安装地点和最终位置都不过几米远。我们的预制工厂基本上是移动的。对于较大的建筑项目,将工厂迁到建筑场地也是更经济、更生态的,而不应长途运输预制构件。

预制与现场制造是互补的。预制的好处在于制造不受天气影响,并能减少现场施工的时间。众所周知,今天的建筑周期越来越紧。当然,预制也会更多地使用机器,从而提高效率。但从另一方面看,也有可能完全抛弃机器。比如,在沙特阿拉伯的阿卜杜勒阿齐兹国王世界文化中心,有时最多会需要150名工人来填充材料、制作模板和对预制构件进行夯筑和定位。

通过预制,夯土的应用领域得到了显著拓展。这不仅改善了前面提到的建筑周期和造价,还提高了技术可行性。如果没有预制,我的很多项目是不可能完成的。

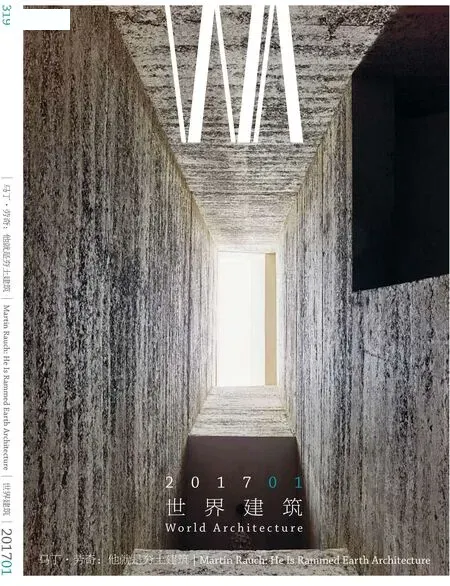

1 夯土细部/Detail of rammed earth

是在本地开采、使用壤土和生土材料,还是像很多其他产品一样全球运输,取决于我们的选择而不是预制的模式。是否重新尊重并欣赏人工完全取决于我们。

3 审美

张利:让我们直面这个问题。很多人都陶醉于夯土的美。您的建筑和家用品就是有力的证明。而这种美也吸引着模仿者。最近在中国,有些建筑在尝试用手工混凝土板模仿夯土的材质,并得到了赞赏。您对此的看法是什么?

劳奇:我并不想评论其他项目或建筑技术。但我要指出夯土建筑的两个重要方面:第一,一切要名副其实。如果混合了水泥、石灰和其他人工强化剂,那它就肯定不再是生土建筑了。很多好的属性——与壤土的水溶性直接相关——在水泥和CO的使用中被削弱、甚至彻底消除了:调节湿度、易于修复、完全可回收,即材料全部回归自然的可能性等。最近我读到一篇关于掺土混凝土建筑的文章:“混合土经特殊处理以避免因吸收湿气而软化”。这不仅以拙劣的方式掩盖了混合物是用水泥强化的事实,作者还以剥夺壤土天然的优良属性而骄傲。我们需要理解并承认壤土的柔软和可溶性是它最大的优点。

由于水泥的额外属性通常是不需要的,所以就更是如此了。夯土墙能够承受一座住宅的重量,并保护住户免遭风雨寒暑的环境侵袭。因此我们必须以准确的名称来表达它:假如在混合土中加入6%、8%或10%的水泥,就会得到很差的掺土混凝土,而不是天然的泥建筑。

使用水泥往往也是出于方便。混合物对于工程师和工匠更便于计算,而且更好处理。混合土强化后,工人就无需深入熟悉这种材料的知识,水泥本身消除了壤土的优缺点。而这丧失的是对材料和自身工艺的信任。

生土建筑的一大障碍就是易受侵蚀、变形和变质。在我看来,这些担心应该加以讨论,并积极面对,但其中很多问题都被夸大了。在夯土建筑上只需注意几个施工问题:合适的基础、全面的覆盖和用水平防蚀障减缓水流。防蚀障可由陶瓦(如劳奇自宅)或粗面凝灰砂浆(如利口乐草药中心)组成。尽管如此仍会有一定程度的侵蚀,需要从技术和设计上予以考虑。但我相信,天然的夯土墙历经沧桑后的风韵美胜过许多其他建筑材料。当表面完全磨光后,

1 How it started

ZHANG Li (LZ):You have make rammed earth what it is in contemporary architecture, almost single-handedly. I guess this is not the first time that you have been asked about how this whole rammedearth thing started.When and where did you make up your mind that you will spend the rest of your life doing rammed-earth buildings? What were the qualities of rammed-earth that moved you onto such a path?

Martin Rauch (MR):I grew up in a small village in Vorarlberg. My father was a teacher and artist. My parents owned a small farm together. Already as a child I was fascinated by earthen materials. I loved playing outside, my toys were nature and my hands. In those days, nearly all villages still had their own loam pits, from which the whole community used to draw their loam for building and daily needs. Potential uses were very broad: from encasing springs, sealing, in the construction of ovens, up to the application in home medicine for warm compresses. This personal involvement with the material and the handicraft production of things prompted me to do an apprenticeship in furnacebuilding and later to take up studies in ceramic arts at the academy of arts in Vienna. During my studies I also started building my own, wood-fired potterykilns, and realized how much energy was needed to produce ceramics. This was the start for me to ask myself, when and where it was useful and needed to fire and heat material and when it was more logical to have the raw material show its advantages? As a result, I produced the first rammed earth pictures and sculptures which gradually evolved into accessible and heatable rooms and buildings. At the beginning however it clearly was an artistic and not an architectural approach.

Some of my siblings are active in international development work. In this context my attention caught on to global earthen architecture. Of course there are not only simple loam huts, but palaces, bazaars, places of worship and entire cities built of earth. I was also especially fascinated by the fact that earthen buildings could be built several stories high. My attention was particularly drawn towards rammed earth construction which clearly has two advantages in comparison with other earthen building techniques: you can very well build loadbearing constructions and they can be exposed to weather conditions without external cladding. This is where the full circle closes. A rammed earth building should be recognized as such from the outside. I wanted the material to speak for itself in the purest way possible. This is where a very important connection to modern architecture comes in. There is a profound structural truth and great beauty in rammed earth constructions.

2 Global/Local

LZ:Rammed-earth is believed to be inherently local by the use of local soil.Yet you are recently working on a more industrialized method of making rammed-earth,even prefabs. Most people would consider hand-craft as local,and industrial means global. Is there a danger that industrialized fabrication will hurt the name of rammed-earth as a local,vernacular material?

MR:At first this contradiction doesn't really exist. In prefabrication one can build very locally. At the Ricola Kräuterzentrum for example, the production facility was just 3 km away from the building site -the raw materials all came from sites within a 10 km radius of the finished building. At the moment we are producing directly at the building site of the new administrative head offices of the German organic-food producer Alnatura. The prefabricated blocks thus have only few meters from production site to their mounting place and final position. Our prefabrication plant is largely mobile. In the case of larger building projects it is also more economical and ecological to bring the facility to the building site, rather than transporting the pre-fab elements over long distances.

Prefabrication supplements on-site production. Prefabrication benefits consist in production being independent from weather conditions and in reducing construction time at the site. It is well-known that buildings schedules nowadays are becoming increasingly tight. Prefabrication of course, also allows a more intensive use of machinery resulting in increased efficiency. But on the other hand it also possible to cut down on machinery almost completely. At the King Abdulaziz Center for World Culture in Saudi Arabia, at times up to 150 workers were employed for the filling of material, formwork, ramming and positioning of the prefab elements.

Through the prefabrication process, the application fields of rammed earth have widened considerably. That does not only concern building schedules that can be better planned, as mentioned above, and the costs, but also technical feasibility. Many of my projects would not have been possible without prefabrication.

It depends on us and not on the prefabrication model whether we excavate and use loam and earthen material locally or send it around the globe as we do with many other products. It definitely depends on us whether we value and appreciate human labor again.

3 Aesthetics

LZ:Let's face it.There are many,many people who are lured into rammed-earth by its sheer beauty. Your buildings and domestic objects are solid evidences of that. This beauty encourages imitations. Recently in China, there are buildings trying to use hand-made concrete panels to simulate the texture of rammed-earth and have been applauded.What is your comment on it?

MR:I do not in any way want to criticize other projects or building techniques. I rather I argue for two very important aspects of building with rammed earth: first, one has to call everything by its honest and full name. If I mix in cement, lime and other artificial stabilizers then it is definitely not an earthen construction any more. Many of the positive properties - which are intrinsically linked to the water solubility of loam, are diminished through the use of cement and CO, or are lost entirely: the moisture-regulating effects, the easy reparability, the complete recyclability or rather the possibility to return the material entirely back to nature. Just recently I read an article on earthen-concrete我能一眼看到每个瑕疵。在这个意义上,壤土和夯土要柔韧得多。例如,瑞士巴塞尔的埃托沙馆,在P37,图4中可以看到它的入口。顶篷正下方有一处渗漏;因此雨水会比其他地方更容易侵蚀墙体。客户对此赞赏有加,以至不愿翻修。成千上万的人每年穿过这座建筑。当然有一些更小的破损,特别是在边角处。但它们都很难察觉。

所以我们必须消除顾虑。换言之——这是第二个关键点——我想鼓励每一个人用无强化的生土进行建造。中国有着多姿多彩的泥和夯土建筑传统。在此基础上,通过前面提到的施工细部改良,生土建筑在未来会有广阔的天地。

还有两点。在世界的很多地方几乎没有适合做混凝土的砾石,例如在整个非洲就极其稀少。这就是水泥业现在探索“强化生土建筑”的原因之一。他们一下看到了销路更好的另一个市场——通过“壤土”“生态”和“社会”等标签。但建筑师也应在初步设计阶段就考虑壤土和生土等替代材料的内在属性和条件。钢和混凝土建筑技术发展至今给建筑语言带来了强烈的影响。那为什么生土建筑技术就不能形成相同的潮流呢?

4 土壤

张利:夯土以土壤为原材料。在中国,寸土寸金。我们不得不用上所有的土地才能供养庞大的人口。人们会担心夯土建筑将夺去土地。您如何回答这个问题?

劳奇:壤土/粘土到底是什么?壤土/粘土是破碎、侵蚀、分解和沉积的岩石。水、霜、风和构造运动造成的侵蚀是构成我们地球的决定性可持续因素。壤土淤泥、沙子、砾石和碎渣是这一过程的直接结果。这些物质可以在全球所有的混合物中找到,而且几乎是取之不尽的。相反,农业需要“腐殖质”,即含有机养分的土壤。这种表土不适合夯土建筑,它需要这层肥沃的表土之下的无机沉积物。

在中国,这种侵蚀后的物质当然也是用之不竭的,所以绝不会与农业用土有任何冲突。从世界上看,生土材料有近40种不同的建筑技术,都是根据各地方的壤土形成的。合适的生土类型非常广泛。对于夯土建筑,不可用于砖或水泥业的生土和砾石类型是最合适的。

另一个非常重要的方面是无强化的生土建筑完全可回收。壤土、粘土和生土建筑材料可以无限次反复使用,而品质不会降低。从这个角度看,土建筑材料是无穷无尽的。

5 成本

张利:鉴于中国的人力成本很低,混凝土是目前建筑施工成本效益最佳的选择。夯土也需要大量人力。所以很想问问您如何比较夯土和混凝土在中国的成本。

劳奇:有一点,混凝土建筑材料成本效益这么好,主要是因为水泥的原材料和生产它所需的能耗很便宜。但这不是关于成本的全部事实。此外,水泥业虽不需要大量工人,但在生产和运输的过程中会释放大量CO2。另一方面,夯土建筑技术是高度劳动密集的。低薪水也是生土材料建筑的优势。倘若加上巨大的能耗以及破坏环境的实际成本,水泥和混凝土就会贵得多了。

混凝土建筑类型在过去100年中统治着建筑业。传统生土建筑技术的发展和必要的研究全被忽视。假如只投入用在混凝土建筑技术上的一部分研究,我们就能带来惊人的变化和生土建筑技术的革命。我们今天就会具备创造成本效益更高的生土建筑类型和作品的技术手段,从而以可持续的方式将生土建筑作为未来人类和环境最健康的建筑材料。尤其在中国,卓越的土建筑传统在多数地区依然在延续,其潜力是巨大的。我们应当发扬这一传统,同时使之现代化。就像前面所说,我确实从中看到了创造高成本效益和高品质住宅的道路。

6 挑战

张利:为何生土建筑技术在建造业中仍是一个缺口?为什么没有其他能像您这样用生土进行大规模建造的公司?夯土建筑更广阔发展的最大障碍和挑战是什么?

劳奇:前面已经提到,主要的障碍之一是对水溶性的担心。但还有其他因素。时至今日,工业化一直是影响最深远的变革之一。在铁路和其他发明问世之前,只能就地取材。今天全球物流的能力几乎超越了任何界限。直到今天,土建筑材料都是危机时刻或世界贫穷人口的选择。这不仅是因为这种材料垂手可得,它还是一种无与伦比的、能够自我发挥的材料。不过,数百年来这些特征被证明既是优点也是缺点。至少在中欧就从未有过生土建筑的技术行会。当时有木匠、砖匠、铁匠、石匠,可从来没有土匠。相反:权威的建筑工艺却抵制生土建筑技术——说它是脏东西、废物、垃圾。虽然这种材料的知识世代相传,却从未进一步发展。顺便提一下,这也是让生土建筑更吸引我的地方:这种材料还有极大的发展潜力。

说到这里我要讲下最后一个障碍。生土建筑是一种有挑战性的非标准化建筑技术。这也让很多人认为生土不是一种建筑材料。我不仅把建造业的官僚泛滥视为推高造价的一大因素,更关键的在于它是创新的阻力。另一方面,夯土没有任何建筑规范,这激发着我不断向前进,去面对风险,并尝试这种材料。

如果生土建筑技术要大规模进步,这种材料最终必须在我们培养建筑师和工匠的建筑学校中有一席之地。理解这种材料的人更勇于接受创新的风险。

或许中国具备绝无仅有的机遇,能够继承丰富的生土建筑传统,并用属于自己的生土创造出在技术和建筑上都具有高品质的生土建筑。

还有一点我认为很重要的是,大量施工公司和工匠要走出来,承认生土建筑技术的经济前景,并通过创造生土建筑树立全新的形象。同时需要建立相应的框架条件,实现可持续的经济发展。

7 技术

张利:您从非洲和欧洲的工作中积累了诸多夯土技术经验。您认为中国是否蕴藏着不为人知的夯土技术?如果有,最可能是在哪些方面?

劳奇:在中国,和全世界一样,人们都有生土建筑的经验,并仍在实践。当然,我也看到了这种技术宝藏,尤其是在中国。对于生土技术和添加的人造材料已有很多讨论,但很少谈论壤土和生土材料本身。混合土本身是多种多样的,而这是一大优点。最重要的是,生土建筑艺术以这种材料的知识和属性为基础,并熟悉它的特性,知道如何在建筑中充分利用。在我们这个以数字支配的世界中,通常要依靠大量精细的试验——找到精确的参数并规定下来。不过这永远也比不上材料的属性和多样性。人要通过触摸感受这种材料,去尝试它,并开拓实践。这绝不是可以从书本中学到的东西,也不可能写成书就一劳永逸。我们需要去尝试各种生土材料,从实践中学习,接受并探索,与创新和新方法一同进步。

正如前面谈到的,中国的过去和现在都有大量生土建筑。人们这种传统的、内源而直观的知识需要发掘和传承。□

编注/Editor's Note

i 指壤土颗粒组成中粘粒、粉粒、沙粒含量适中的土壤。质地介于粘土和砂土之间。其成因请见本文问题4/Loam is soil composed mostly of sand, silt, and a smaller amount of clay. See Q4 for detail.construction: "… the earthen mixture was especially treated to prevent it from softening through soaking moisture". Not only is this an inapt way to try to hide the fact that the mixture was stabilized by cement, but the author is indeed proud of depriving the loam of one of its substantial positive properties. We need to understand and recognize that the softness and solubility of loam is ultimately its greatest virtue.

Particularly so, as the additional properties of the cement are often not needed. A rammed earth wall can bear the weight of a home and can shelter its inhabitants from the environmental impacts like rain, cold and heat. Hence one must call the topic by its proper name: if you add 6, 8 or even 10% of cement to an earthen mixture, you get a poor earthconcrete and not a natural mud construction.

Often the use of cement also comes for the sake of convenience. The mixture becomes more calculable for the engineer and the craftsman and is easier to handle. By stabilizing the earth mixture the workers don't need to get acquainted so deeply with the knowledge of the material, the cement as it were, levels out the positive and negative properties of the loam. What is simply missing here is the trust in the material and one's own craftsmanship.

A big impediment to earthen construction is the fear of erosion, fear of alteration and quality loss. It's important to me to make these fears subject of a discussion and to confront them actively. Much of these is exaggerated. In rammed earth building only a few constructional precautions need to be observed: proper foundations, a thorough top coverage and a slight deceleration of the water flow through horizontal erosion barriers. These barriers can consist in fired tiles (e.g. at the House Rauch), or in trasslime mortar (e.g. the Ricola Kräuterzentrum). However there will still be a certain level of erosion which needs to be taken into account both in technically and with respect to design. I am convinced however, that a natural rammed earth wall ages a lot more dignified and with a lot more beauty than many other building materials. With surfaces trimmed to perfection, I can see every fault immediately. Loam and rammed earth is in this sense much more pliable. For example at the Etosha House in the Zoo Basel, in Switzerland. In the fig.4 on page 37 you can see the entrance, where there was a leakage directly underneath the coverage; therefore the rainwater could erode the wall somewhat more than the rest. The client appreciated it so much, that he didn't want to have it refurbished. Many tens of thousands people move through this building every year. Of course there are some smaller damages, especially on edges. But also those are hardly noticeable.

So we must relieve the anxieties. With other words - and this is the second crucial point - I want to encourage everyone to build with non-stabilized earth. In China there is a rich mud and rammed earth building tradition. On the basis of this, and improved by the constructive details mentioned above, earthen buildings have a great chance in the future.

2 位于奥地利施林斯的工作室/Studio of Lehm Ton Erde Baukunst GmbH, Schlins, Austria

Two short additional remark. In many regionsof the world there is hardly any or very little gravel suitable for making concrete. In the whole of Africa for example, it is very scarce. This is one of the reasons why the cement industry is currently discovering "stabilized earthen construction". They simply see another sales market in which they can sell even better - through labels like "loam" "ecological" and "social". But also architects should consider alternative materials like loam and earth with their inherent specifications and conditions, already in the preliminary design stage. The development of steel and concrete building techniques have strongly influenced architectural language up until today. Why shouldn't a similar trend not be possible for earthen building techniques?

4 Soil

LZ:Rammed-earth uses soil as raw materials. In China,soil is a valued commodity. We have to make use of almost all the available soil to feed our huge population.People may question that rammed-earth buildings would compete with agriculture for soil.

What is your answer to such a question?

MR:What actually is loam/clay? Loam/clay is fractured, eroded, decomposed and sedimentated rock. Erosion through water, frost, wind and tectonic earth movement is the determinant element that forms our earth sustainably and decisively. Loam silt, sand, gravel and debris are direct consequences of this process. These materials are found in all kinds of compositions all over the globe and in near endless quantities. In contrast, agriculture needs "humus", that is soil which is enhanced by organic nutrients. This topsoil is not suitable for rammed earth constructions. It needs the inorganic sediments underneath this fertile topsoil.

Also in China, this eroded material is surely available in such incredible quantity that there will never be any competition with agricultural uses. Worldwide, there are nearly 40 different building techniques with earthen materials, which have developed according to respective local loamoccurrences. The spectrum of suitable earth types is very broad. For rammed earth constructions, especially those types of earth and gravel types are best suited that can't be used in the brick or cement industry.

3 天然土壤/The soil from nature

Another very important aspect is the uncompromising recyclability of non-stabilized earth constructions. The building materials of loam, clay and earth can be reused endless times without quality losses. From that angle, earthen building materials are infinite.

5 Cost

LZ:Given the low human labor cost in China,concrete is currently the most costeffective for building construction. Rammed-earth also involves a lot of human labor. So it might be interesting to ask your perspective of cost comparison between rammed-earth and concrete in China.

4 夯土混合物/Rammed earth mixture(1,3-4 图片来源/Copyright: Ricola AG,摄影/Photos: Markus Bühler-Rasom)

MR:Not least, concrete building material is so cost-effective mainly because the raw resources for cement and the energy needed for its production are so cheap. But this does not tell the cost-truth entirely. In addition, the cement industry does notentirely. In addition, the cement industry does not require a lot of work force but emits vast amounts of CO2in the production process and transportation. On the other side, the rammed earth building technique is very labor intensive. Low wages also profits building with earthen materials. Would there be true-cost pricing for the vast energy consumption and the environmental consequential damages, cement and concrete would need to be a lot more expensive.

The triumph of concrete building types has dominated the building industry in the last 100 years. The enhancement of traditional earthen building techniques and the necessary research involved was completely neglected. Would we only invest a fraction of the research put into concrete building techniques, we could create incredible change and revolutionize earthen building techniques. We would possess the technological means today for creating much more cost-effective earthen building types and constructions in order to sustainably establish earthen architecture as the healthiest building material for the future of man and environment. Especially in China, with its profound earthen building tradition still present in a lot of its regions, there is an enormous potential. It is important to build on this tradition and at the same time modernize it. As said before, I do see here a crucial solution approach for creating costeffective and high-quality housing.

6 Challenges

LZ:How is it that earthen building techniques are still a niche in the construction sector? Why are there no other companies like yours that can build with earth in a larger scale? What are the biggest obstacles and challenges for a broader development of building with rammed earth?

MR:As mentioned already, one of the major obstacles are concerns about water-solubility. But there are other factors as well. Until today, industrialization has been one of the most farreaching changes. Before the advent of railways and many other inventions, it was necessary to make do with what was available locally. Today's global logistic possibilities have hardly any boundaries. Up until today, earthen building materials were and are used in times of crisis or by the poorer parts of world population. This is not only due to the fact that the material that is freely available. It is also a material which lends itself to do-it-yourself construction like no other. However, over the centuries these aspects have proved not only advantageous but also disadvantageous. At least in central Europe there was never a craftsmanship guild developed around earthen construction. There were carpenters, bricklayers, blacksmiths, masons, but never any earth-builders. On the contrary: the established building crafts fought against earthen building techniques - calling it filth, muck and grime. Though the knowledge of the material was passed on from one generation to the next it was never being further developed. By the way, this is something which makes earthen architecture even more appealing to me: there is still so much development potential in the material.

With that I'll come to the last hurdle. Building with earth is defiantly a widely un-standardized building technique. This also keeps many from considering earth as a building material. Not only do I generally perceive the exuberant bureaucratization in the construction industry as a major cost driver, but above all, also as a potential preventor of innovation. On the other hand, the fact that rammed earth is not subject to any building norms gave me with stimulus and chances to always go a step further, take risks and try out the material.

If earthen building techniques are to be further developed on a grand scale, the material must eventually find its place in our schools for construction where architects and craftsmen are taught and trained. For those who understand the material, are more likely prepared to take a certain risk for innovation.

Perhaps there is a chance in China - like nowhere else - to link up with its rich earthen building tradition and pound out of its own earth both technically and architecturally profoundly high-quality earthen buildings.

What I consider also very important is that construction companies and craftsmen in sizable numbers step up and recognize their economic future in earthen building techniques and by realizing earthen buildings implement a completely new image. In parallel, respective framework conditions need to be created that allow sustainable economic development.

7 Know-how

LZ:You gained most of your expertise with rammed-earth through working in Africa and Europe. do you think there is some hidden knowhow in doing rammed-earth in China? If so,what are the mostly likely aspects?

MR:In China, as all over the world - people have built with earth and still do. As a matter of course I also see a great treasure of know-how particularly in China. We have spoken a lot about techniques and artificial materials sometimes added, but hardly about the material of loam and earth itself. Earthen mixtures themselves are varied and this is good. Above all, the art of earthen buildings rests with the knowledge of the material and its properties, recognizing its specific qualities and realizing how best to use and implement it in a building. In our world which is dictated by figures, we often rely on doing extensive and elaborate lab testssetting narrow parameters and codifying them. This however will never match up to the material properties and diversities. One has to haptically feel the material, work with it, and practically try it out. This will never be something you can learn from just reading nor can it be written down once and for all. We need to work with earthen materials, learn by doing, recognize and discover, and progress with new innovations and solutions.

As said before - in China, there was and is much earthen architecture. This traditional, partly endogenous and intuitive knowledge of the people needs to be tapped into and utilized.□

Interview with Martin Rauch

Martin Rauch, ZHANG Li

Translated by SHANG Jin

马丁·劳奇,壤土-粘土-泥土建筑艺术股份有限公司张利,清华大学建筑学院/《世界建筑》

2016-12-08