Preparation of antioxidant flm from Musa sapientum Linn.peel extract and fruit

Siriwtjnee KtsilSrn PnyjiAnongnrt Kmkew Pdungkwn Chitrops

aSchool of Pharmaceutical Sciences,University of Phayao,Phayao 56000,Thailand

bFaculty of Pharmaceutical Sciences,Khon Kaen University,Khon Kaen 40002,Thailand

Preparation of antioxidant flm from Musa sapientum Linn.peel extract and fruit

Saengrawee Sutthiparinyanonta,*,Nutthiya Panrattanasukkula, Siriwatjanee Katasilaa,Saran Panyajaia,Anongnart Kamkeawa, Padungkwan Chitropasb

aSchool of Pharmaceutical Sciences,University of Phayao,Phayao 56000,Thailand

bFaculty of Pharmaceutical Sciences,Khon Kaen University,Khon Kaen 40002,Thailand

A R T I C L E I N F O

Article history:

Available online 25 November 2015

Musa sapientum Linn

Kluai Namwa

Biopolymer flm

Musa sapientum Linn.(commonly called Kluai Namwa;KNW) is a herbaceous plant of the Musaceae family,which is extensively cultivated throughout Thailand.Peel of green KNW contains various effective compounds of tannins and favonoids,which provide usefulness in antibacterial,antioxidant activities[1].Fruit starch from green KNW is also useful in the thickeners,binding,especially biopolymer agents[2,3].

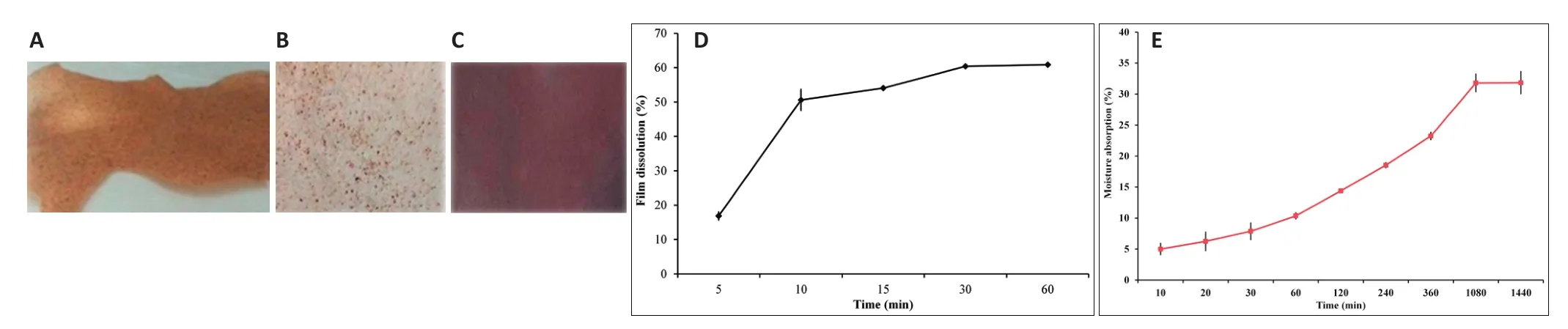

Antioxidant flm was formulated by using starch from green KNW fruit as flm forming agent,and consisting antioxidant agent from peel extract.Conditions of starch flm preparation were optimized by varying heating time of starch solution as 1,2 and 3 h,and starch concentration as 2%,3%and 4%(w/v). Physicochemical of KNW flm was carried out by visual appearance,thickness,water uptake,and dissolution.Increasing of heating time could increase strength and homogeneity, average thickness was about 0.18 mm,but not reduce brittleness,water uptake and dissolution of flm properties.Uniaxial orientation of densely starch molecule at the highest content could have an effect on change of physicochemical properties of flm,especially strength improvement.The suitable condition of flm preparation was 2%(w/v)KNW starch,heated at 70°C for 3 h,and dried to be flm at 50°C.Concentration effect of glycerol(Gly)as a plasticizer was then studied at 50%, 70%and 100%(w/w).Each sample of KNW flms with plasticizers was more clear,homogenous,and tough than that of original one.The increasing of Gly could increase the thickness,moisture uptake,dissolution,but decrease puncture strength of flm properties.Similarly,water uptake and elongation were decreased with the increasing of Gly.KNW peel extract was added into starch flm with 70%Gly,resulting in dark-brown color(Fig.1),tough,homogeneity,pH 5.63±0.01, 0.19 mm of thickness,31.8%moisture uptake,65.6%water uptake,60.8%dissolution.Mechanical properties were 0.92 MPa of puncture strength,and 37.7%elongation,which were signifcantly different(P<0.05)from original flm without the extract(2.93 MPa and 21.5%elongation).The flm also presented antioxidant activity at IC50=182.1 μg/mL which has signifcantly lower activity from crude extract about 3 times (P<0.05).Consequently,KNW native starch could be used as biopolymer to form KNW flm as well as additional peel extractprovided the benefcial antioxidant product.It could therefore be applied for topical applications and other uses.

Fig.1–KNW flm(A),KNW flm with Gly(B),KNW flm with Gly and peel extract(C),dissolution(D)and moisture absorption(E)of KNW flm.

Acknowledgements

The authors acknowledge School of Pharmaceutical Sciences, University of Phayao,and Faculty of Pharmaceutical Sciences, Khon Kaen University,for encouragement in carrying out our work.The English version was clarifed by Assist.Prof.Dhittima Kaweera,University of Phayao.

R E F E R E N C E S

[1]Kumar KP,Bhowmik D,Duraivel S,et al.Traditional and medicinal uses of banana.J Pharmacogn Phytochem 2012;1(3):51–63.

[2]Zhang P,Whislter RY,Bemiller JN,et al.Banana starch: production,physicochemical properties and digestibility-a review.Carbohydr Polym 2005;59:443–458.

[3]Sothornvit R,Pitak N.Oxygen permeability and mechanical properties of banana flms.Food Res Int 2007;40:365–370.

*E-mail address:saengrawees@yahoo.com.

Peer review under responsibility of Shenyang Pharmaceutical University.

http://dx.doi.org/10.1016/j.ajps.2015.11.099

1818-0876/©2016 Production and hosting by Elsevier B.V.on behalf of Shenyang Pharmaceutical University.This is an open access article under the CC BY-NC-ND license(http://creativecommons.org/licenses/by-nc-nd/4.0/).

Asian Journal of Pharmacentical Sciences2016年1期

Asian Journal of Pharmacentical Sciences2016年1期

- Asian Journal of Pharmacentical Sciences的其它文章

- Determination of the antidepressant effect of mirtazapine augmented with caffeine using Swiss-albino mice

- Photosafety testing of dermally-applied chemicals based on photochemical and cassette-dosing pharmacokinetic data

- Biopharmaceutics classifcation system(BCS)-based biowaiver for immediate release solid oral dosage forms of moxifoxacin hydrochloride (Moxifox GPO)manufactured by the Government Pharmaceutical Organization(GPO)

- Bioequivalence study of abacavir/lamivudine (600/300-mg)tablets in healthy Thai volunteers under fasting conditions

- Evaluation of cytotoxic and infammatory properties of clove oil microemulsion in mice

- Analytical method development of pregabalin and related substances in extended release tablets containing polyethylene oxide