Preparation and physical properties of itraconazole-loaded nanoemulsions using pineapple starch as co-emulsifer

,Knit Boontr,Tnpourn Teerprstkul, Wris Yngngm,Vipluk Ptomchiviwt,b, Pornsk Srimornsk,b,Suchd Piriyprsrth,b,

aDepartment of Pharmaceutical Technology,Faculty of Pharmacy,Silpakorn University,Nakhon Pathom 73000, Thailand

bPharmaceutical Biopolymer Group(PBiG),Faculty of Pharmacy,Silpakorn University,Nakhon Pathom 73000, Thailand

Preparation and physical properties of itraconazole-loaded nanoemulsions using pineapple starch as co-emulsifer

Su Su Latta,Kanit Boontaraa,Tanapourn Teeraprasatkula, Warisa Yangngama,Vipaluk Patomchaiviwata,b, Pornsak Sriamornsaka,b,Suchada Piriyaprasartha,b,*

aDepartment of Pharmaceutical Technology,Faculty of Pharmacy,Silpakorn University,Nakhon Pathom 73000, Thailand

bPharmaceutical Biopolymer Group(PBiG),Faculty of Pharmacy,Silpakorn University,Nakhon Pathom 73000, Thailand

A R T I C L E I N F O

Article history:

Available online 24 November 2015

Pineapple starch

Pectin

Co-emulsifer

Polysorbate 80

Itraconazole

Nanoemulsions

Pineapple plant(Ananascomosus L.Merr.)is a leading edible member of the Bromeliaceae family[1].Nanoemulsions containing itraconazole,a poorly water-soluble drug using pectin as a polymeric emulsifer,are currently under investigation [2].The physicochemical and rheological properties as well as structural characterizations of cassava and mungbean starches have been reported[3].However,the application of pineapple starch as co-emulsifer of pharmaceutical excipients for pharmaceutical industry has not been investigated.

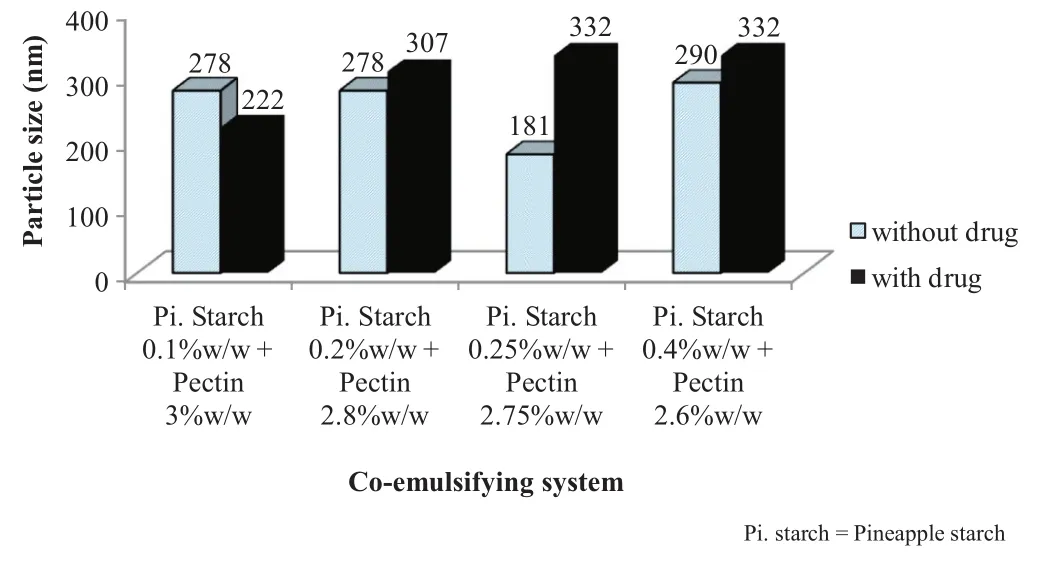

Nanoemulsions were prepared by simple homogenization method using homogenizer with speed of 20,000 rpm for 30 minutes to avoid high pressure conditions.In this study,polysorbate 80 was used as emulsifer,whereas high methoxy pectin or Pattawia pineapple starch were employed as co-emulsifers. Castor oil was used as internal phase.Itraconazole,a poorly water-soluble drug was used as a model drug.The selected formulations were evaluated for particle size,zeta potential, viscosity and%creaming.The composition of optimized formulations was 20%w/w polysorbate 80,2.6–3.0%w/w high methoxy pectin and 0.1–0.4%w/w pineapple starch as shown in Fig.1.The particle size of the formulations was within the range of 100 to 500 nm.The zeta potential and viscosity were in the range of−15.71 to−21.46 mV and 5003 to 5101 mPa.s, respectively.The formulations provided the most stable nanoemulsions when they were kept at 2–8°C for 14 days.When the prepared nanoemulsions were subjected to temperature cycling test(4°C for 24 hours and 40°C for 24 hours),they were stable for 3 cycles.The results suggested that pineapple starch, naturally occurring polysaccharide,biodegradable,edible and harmless biopolymer,could be applied as co-emulsifer in nanoemulsions for pharmaceutical application.

Fig.1–Effect of co-emulsifying system on particle size of nanoemulsions.

Acknowledgments

The authors gratefully acknowledged Silpakorn University Research and Development Institute through research program on“The study of starch from stalks and stems of pineapples and development as pharmaceutical excipients”for fnancial support.

R E F E R E N C E S

[1]Tran A.Chemical analysis and pulping study of pineapple crown leaves.Ind Crops Prod 2006;24:66–74.

[2]Burapapadh K,Kumpugdee-Vollrath M,Chantasart D,et al. Fabrication of pectin-based nanoemulsions loaded with itraconazole for pharmaceutical application.Carbohydr Polym 2010;82:384–393.

[3]Kittipongpatana O,Jakkapan S,Laenger R.Preparation and physicochemical properties of sodium carboxymethyl mungbean starches.Carbohydr Polym 2006;63:105–112.

*E-mail address:piriyaprasarth_s@su.ac.th.

Peer review under responsibility of Shenyang Pharmaceutical University.

http://dx.doi.org/10.1016/j.ajps.2015.11.102

1818-0876/©2016 Production and hosting by Elsevier B.V.on behalf of Shenyang Pharmaceutical University.This is an open access article under the CC BY-NC-ND license(http://creativecommons.org/licenses/by-nc-nd/4.0/).

Asian Journal of Pharmacentical Sciences2016年1期

Asian Journal of Pharmacentical Sciences2016年1期

- Asian Journal of Pharmacentical Sciences的其它文章

- Determination of the antidepressant effect of mirtazapine augmented with caffeine using Swiss-albino mice

- Photosafety testing of dermally-applied chemicals based on photochemical and cassette-dosing pharmacokinetic data

- Biopharmaceutics classifcation system(BCS)-based biowaiver for immediate release solid oral dosage forms of moxifoxacin hydrochloride (Moxifox GPO)manufactured by the Government Pharmaceutical Organization(GPO)

- Bioequivalence study of abacavir/lamivudine (600/300-mg)tablets in healthy Thai volunteers under fasting conditions

- Evaluation of cytotoxic and infammatory properties of clove oil microemulsion in mice

- Analytical method development of pregabalin and related substances in extended release tablets containing polyethylene oxide