A heuristic approach for petrochemical plant layout considering steam pipeline length☆

Yan Wu,Yufei Wang,Xiao Feng

State Key Laboratory of Heavy Oil Processing,China University of Petroleum,Beijing 102249,China

1.Introduction

Plant layout is an important aspect in the design of petrochemical factory and a good layout will provide an effective way to increase economic benefits and reduce heat and mass losses.To various objective functions for layout design,the design is normally carried out with expert experience.A lot of work on petrochemical plant layout design is based on practical experience[1,2],concluding safety[3],device characteristic[4-6],heat integration[7],space requirements[8],maintenance and operational considerations[9],and so on.No systematic methodology has been proposed.The plant layout of petrochemical factory is a branch of facility layout problem(FLP),which has been extensively studied in the area of industrial engineering[10].FLP is to determine the most effective department arrangement in a facility,to minimize material handling costs[11].A facility may be a production factory,an administrative building or service facility[12].To solve an FLP,various methods have been proposed including heuristic approaches and mathematical programming methods.Hillier has developed a pairwise exchange heuristic[13].Skorin-Kapov has applied the tabu search heuristic[14].Chandratre and Nandurkar have used genetic algorithm[15].FLP is widely applied in the areas such as hospitals[16],ship cabin[17],and autonomous material handling system such as mobile robot or automated guided vehicle[18].

However,these methods are hardly applied to petrochemical plant layout.This is mainly due to the characteristics of petrochemical enterprises,such as high-risk,large-scale,strong continuity and massive energy consumption,especially the complexity of material and heat flows.Nowadays,there is no effective methodology to simultaneously satisfy different objective functions and multiple constraint conditions.Only single objective function is involved,such as safety[19]and pipe network length of heat exchanger(heat integration)[20].

To reduce the pipeline investment,material flow pipeline network has been taken into consideration in the design of petrochemical plant layout.In this paper,both material and heat flows are considered in the design of plant layout for the first time.The major pipeline network of heat flow is steam system in a petrochemical plant.By considering the length of steam pipeline,conventional layout design method for petrochemical plants is more economical and reasonable.

2.Methodology

In order to obtain the shortest length of pipe network,heuristic method is used to optimize plant layout in this work.Practical factors such as material flow,steam consumption,technological process,transportation,environment and safety are considered.

This section consists of three methods for layout designs with different objective functions:(1)the shortest length of material flow pipelines,(2)the shortest length of steam pipelines,and(3)the shortest total length of material and steam pipelines.

2.1.Method 1

This method is used to design plant layout for shorter material flow pipeline.A number of principles are developed on the basis of Chemical Engineering Design[21],Preliminary Chemical Engineering Plant Design[22],and Code for layout design of petrochemical plant(GB 50984-2014)[23].The content is as follows.

(1)For safe operation and less energy consumption,the plants using hydrogen at high temperature and high pressure,such as gas oil hydrocracking and residue hydrotreating,are close to the hydrogen production installment.

(2)The units include aromatic hydrocarbons,isomerization,continuous reforming and naphtha hydrotreating are placed jointly because of their upstream and downstream relationship.Sulfur recovery and delayed cokerare close to each other.Fluid catalytic cracking plant is the most close to its upstream installment residue hydrotreating.

(3)Crude oil fractionation unit is near crude oil storage,which is its upstream facility.Processes for finalproducts,such as diesel,kerosene and gasoline,are preferred to stay together and close to the storage devices.

(4)The power station is located at the edge of the factory,near the railway and delayed coker.This layoutnotonly reduces the environment pollution caused by coal dust,but also facilitates the supply of fuel coal and petroleum coke.

(5)The utility such as air separation unit,air compressor station,desalt water station and water treatment is close to the main users,shortening pipeline and avoiding heat loss.Air separation and air compressor plant is far away from the power station for a good air environment,which is beneficial in improving equipment operation.

(6)Sewage treatment is in low-lying areas of the re finery,preventing sewage from flow backward and helping environmental protection.To reduce the pipeline investment,sulfur recovery unit,which produces a great deal of waste-water,should be close to sewage farm.

(7)Comprehensive administrative zone locates in the higher ground for safety and is close to downtown and highway to avoid potential safety hazards for commuting of employees.

These principles are listed according to the decreasing order of importance.They may give some contradictions.In the design process the designer should meet the principles in the front of the list and meet the requirements of production process and environmental protection simultaneously as far as possible.

2.2.Method 2

Method 2 is to minimize the length of steam pipeline network.

In general,the steam system of petrochemical plants consists of three levels of steams(ignore other grades used in some special devices or cases),i.e.,high pressure steam(3.5 MPa),medium pressure steam(1.0 MPa)and low pressure steam(0.4 MPa).The steam pipeline investment cost increases sharply from low pressure steam to high pressure steam.For pipeline arrangement,high pressure steam is preferred and low pressure steam is considered last.Power station is an important process to produce steam,so its location is determined firstin the layout design.The rules are as follows.

(1)It is better for the power plant to locate at the edge of the factory based on Method 1(4).To increase its effective connection area,it is better not to put the power station and storage together.Otherwise it will increase the length of steam pipeline due to large storage area.

(2)High pressure steam usersare close to the powerstation,especially those with large steamconsumption.This arrangementcan reduce the length and diameter of high pressure steam pipeline,reducing the investment,the loss of steam pressure and temperature.

(3)On the premise of shortest high pressure steam pipeline,large medium pressure steam users are near the power station as far as possible,by adjusting the locations of small users with high pressure steam consumption,to reduce the medium pressure pipe diameter and length.

(4)Low pressure steam pipe network do not need to be near the power station.For less pipeline length,the plants producing low pressure steam and steam users are put together.

(5)The lastthree points(5,6,and 7)in Method 1 should be considered.

The principles in Method 2 are also listed according to the decreasing order of importance.When principles conflict each other,arrange the workshops to obtain the shortest high pressure steam pipeline length as far as possible.

2.3.Method 3

This method considers material and heat flows simultaneously,including almost all the contents of Methods 1 and 2.Some other points that should be referenced are also listed according to the decreasing order of importance.

(1)Determine the location ofpowerstation.Find the large consumption users of high pressure steam,put them close to the power station,and determine their relative position preliminarily.

(2)According to material flow directions, find the plants that should be combined with the large consumption users of high pressure steam.Adjust their locations properly in the light of their lower pressure steam consumption.

(3)Medium pressure steam pipeline network,throughout almost the

whole factory,has the mostusers.Changing the locations of plants has small effect on the length of pipeline.Therefore,small users of medium pressure steam do not have to be near the power station.By contrast,shorter material pipeline should be in higher priority.

When these factors conflict,the plants with large consumption for three levels of steam may not be close to the power station.They can be near the plants producing a large amount of steam for steam usage.When a plant does not need any level of steam and has few material flows,it can stay at the end of steam pipeline.This extends the material flow pipeline slightly,while greatly shortens the length of steam pipe network.

3.Case Study

A case is used to illustrate the three methods.It is a simplified plant layout of a real petroleum re finery,and the original layout scheme is presented(CASE 1).The objective of CASE 1 is to minimize the total length of material flow pipeline by using Method 1.Another plant arrangement scheme(CASE 2)is presented by using the Method 2,which prioritizes steam usage without considering material flows.Finally,both material and steam flows are considered in accordance with the requirements of technological process,and the final optimized scheme(CASE 3)is put forward using Method 3.

3.1.Data acquisition

Twenty-three plants are included in this case.They are railway transport department(RTD),sewage treatment area(STA),power station(PS),sulfur recovery(SR),delayed coker(DC),aromatic combine(AC),is omerizati on unit(IU),gas separation(GS),continuous reforming(CR),naphtha hydrotreating(NH),diesel hydrotreating(DH),catalytic gasoline hydrotreating(CGH),gas oil hydrocracking(GOH),residue hydrotreating(RH), fluid catalytic cracking(FCC),kerosene hydrotreating(KH),hydrogen production(HP),crude oil fractionation(COF),air compression and air separation(ACAS),water treatment works(WTW),storage(STO),central control room(CCR),and laboratory centre(LC).

The material flow direction among plants is shown in Table 1.They are used to guide the design of process stream pipelines.

Table 1Material flow directions among plants

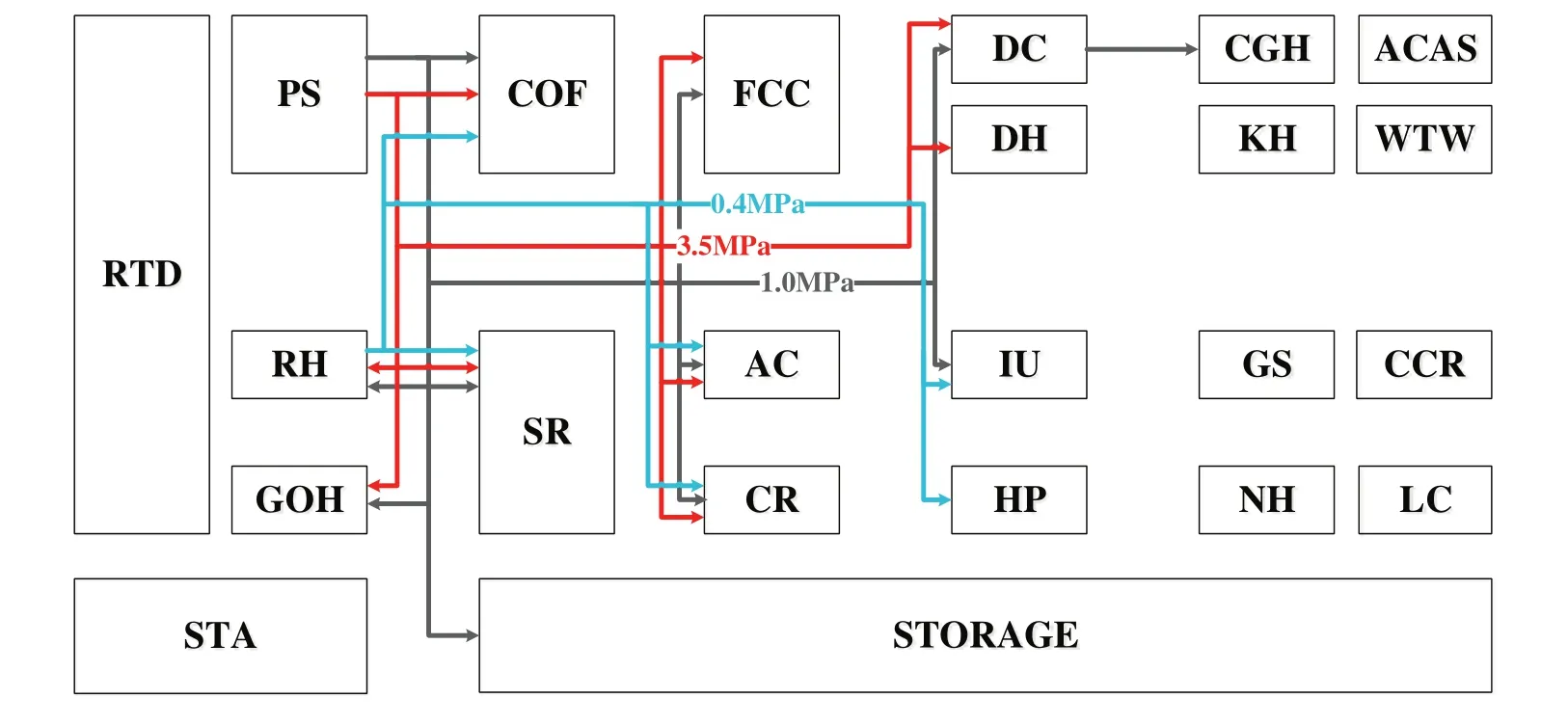

The steam system balance for the petroleum re finery is illustrated in Fig.1.It is used to guide the design of steam pipelines.

3.2.Calculation for pipeline length

We simplify the calculation of the length of pipe network.Each plant is a point,ignoring its size.Some jointunits such ascrude oilfractionation,fluid catalytic cracking and sulfur recovery,occupy the position of two plants.The distance between two plants is set to be 100 m and the length from plant to the pipe rack is neglected.Draw the material and steam flows in the general arrangement of plants using arrows representing the direction,and the total pipeline length is the sum of arrow lengths,which are the distance between plants,an integer times 100 m.

3.3.Results

CASE 1 is designed by simplifying and adjusting an existing plant layout of petrochemical re finery according to Method 1.Fig.2 shows the optimal plant layout for material flow pipeline.The numbers on the line represent the material flows in Table 1.The total length for the material flow pipe is 5500 m.Fig.3 shows the steam pipelines,with a total length of 3700 m.The pipeline length for different levels of steam is 1300 m(3.5 MPa),1400 m(1.0 MPa)and 1000 m(0.4 MPa).

CASE 2 is designed using Method 2.The specific layout steps are as follows.

According to the situation of railway,RTDisin the westof the re finery.PS is at the edge of the factory,connected to RTD to facilitate the fuel transportation and reduce the dust pollution.To be close to more workshops simultaneously,it locates in the northwest,without linking with the large tank farm of steam consumption.COF,FCC,RH,GOH,SR,AC and CR are large users of 3.5 MPa and 1.0 MPa steams,so they are near the power plant according to the usage of steam level.Among them,FCCisthe largestgas producer,so itmay be moved eastward appropriately for providing steam to other plants,as well as reducing the pressure drop loss.AC and CR use the most 3.5 MPa steam and are close to FCC.COF needs a lot of three levels of steam,so it is also near PS.In addition,RH and GOH are near PS as far as possible because they also need lots of high pressure steam.Other high pressure steam users,DC and DH,are in the vicinity of FCC to make the high pressure steam pipe shortest.For medium pressure steam users IU and CGH,they are near AC and CR.For 0.3 MPa steam users,HP is near CR.IU and HP are near AC and CR,CGH is near DC.This layout can give the shortest length of medium pressure steam and low pressure steam network.Storage covers a large area and uses medium pressure steam,so it is in the broad south of re finery.STA should be on the edge of re finery with low-lying area,so it is in the southwest.CCR and LC are on the east of the factory,near the roads.GS and NH should be far away from dust,so they are near CCR and LC.Other plants,KH,ACAS,and WTW,are in the rest of positions.

Fig.1.Steam system balance diagram.

Fig.2.Material flow pipeline system for CASE 1.

Fig.3.Steam pipeline system for CASE 1.

Fig.4.Material flow pipeline system for CASE 2.

Fig.5.Steam pipeline system for CASE 2.

The optimized plant arrangement scheme of CASE 2 is shown in Figs.4 and 5.Fig.4 shows the material flow pipeline network.Compared with CASE 1,the material flow pipeline network of CASE 2 is more complicated,with a total length of 6900 m.The total length of steam pipe is much shorter,as shown in Fig.5.It is 2900 m.These results are in accordance with the expectation.Besides,the pipeline length for different levels of steam is 1000 m(3.5 MPa),1300 m(1.0 MPa)and 600 m(0.4 MPa).

CASE 3 is designed using Method 3.The specific layout steps are as follows.

Adjust the layout of Figs.4 and 5.Keep the positions for RTD,STA,STO,CCR,LC,ACAS and WTW,which have less material and steam flows.The location of PS is the optimal and does not need adjustment.Then combine the related plants according to upstream and downstream relationship of material flow and safety factor in Method 1.GOH and RH should be near HP;AC,IU,CR and NH are close to each other;SR and DC,FCC and RH are as close as possible;DH,KH and CGH are also adjacent to each other and better near HP.In this way,the length of material pipeline is reduced.Considering the steam usage,adjust the positions of binding plants according to Figs.4 and 5 for appropriate steam pipeline length.Following the above methods,several layouts are obtained by comparing a variety of schemes.

The final layout plan of CASE 3 is shown in Figs.6 and 7.Fig.6 displays the material flow pipeline network.The total length is 5500 m,which is smaller than 6900 m in CASE 2.The same value in CASE 1 and CASE 3 shows very good optimized result.Fig.7 displays that steam pipelines of different levels are as simple as that in CASE 2.The total length of steam pipelines in CASE 3 is 3000 m.The pipeline length for different levels of steam is 1000 m(3.5 MPa),1200 m(1.0 MPa)and 800 m(0.4 MPa).

3.4.Discussion

Table 2 summarizes the results.When only the material flow pipeline network is optimized in CASE 1,steam pipeline stretches a lot,which is 3700 m.In CASE 2,the length of material flow pipeline is larger,6900 m.Thus optimizing only one type of pipeline is not comprehensive.The total length of pipeline in CASE 3(8500 m)is smaller than that in CASE 1(9200 m),so the optimization of both material and steam pipelines do reduce the overall pipeline cost.In particular,for 3.5 MPa steam pipeline,whose investment is large,the length in CASE 3(1000 m)is equal to that in CASE 2 and less than that in CASE 1(1300 m).The layout plan of CASE 3 achieves the best result,which is 8500 m,although the total length of steam pipeline(3000 m)is a little longer than that of CASE 2(2900 m).Besides the reduction in pipeline investment,the loss of steam pressure and temperature can be also reduced due to the reduction in pipeline length.Therefore,Method 3 has more application prospects.

4.Conclusions

This paper develops a complete set of principles to consider the length of both process stream pipeline and steam pipeline in the design of plant layout.Method 1 and Method 2 are proposed to determine the layout with the shortest process stream pipeline and steam pipeline,respectively.Method 3 shortens the total pipe length for material and steam flows.For three cases,the total length of material and steam pipeline is 9200,9800 and 8500 m.In CASE 3,the length of material pipeline

Fig.6.Material flow pipeline system for CASE 3.

Fig.7.Steam pipeline system for CASE 3.

Table 2Summary for pipeline lengths

is 5500 m,which is equal to that in CASE 1,and the length of steam pipeline is 3000 m,only a little longer than that in CASE 2(2900 m).Therefore,CASE 3 is considered to be the optimized scheme,which can significantly increase the economic bene fit.The results of three cases show that the steam pipe network optimization in process plant layout is very meaningful.The methodologies proposed can help to put forward optimized plant layout plan.Further work is needed to optimize the layout of petrochemical plants with steam system using mathematical programming method.

[1]F.F.House,An engineer's guide to process-plant layout,Chem.Eng.76(16)(1969)120-128.

[2]R.Kern,How to manage plant design to obtain minimum cost,Chem.Eng.84(11)(1977)130-136.

[3]M.L.Kaura,Plot plans must include safety,Hydrocarb.Process.59(7)(1980)183-194.

[4]R.Kern,Layout arrangements for distillation columns,Chem.Eng.84(17)(1977)153-160.

[5]R.Kern,Arrangements of process and storage vessels,Chem.Eng.84(24)(1977)93-99.

[6]R.Kern,How to get the best process-plant layouts for pumps and compressors,Chem.Eng.84(26)(1977)131-140.

[7]R.Kern,How to find the optimum layout for heat exchangers,Chem.Eng.84(19)(1977)169-177.

[8]R.Kern,Space requirements and layout for process furnaces,Chem.Eng.85(5)(1978)117-122.

[9]R.Kern,Instrument arrangements for ease of maintenance and convenient operation,Chem.Eng.85(9)(1978)127-134.

[10]M.C.Georgiadis,S.Macchietto,Layout of process plants:A novel approach,Comput.Chem.Eng.Suppl.21(1997)S337-S342.

[11]H.Tarkesh,A.Atighehchian,A.S.Nookabadi,Facility layout design using virtual multi-agent system,J.Intell.Manuf.20(4)(2009)347-357.

[12]A.R.Mckendall,J.Shang,S.Kuppusamy,Simulated annealing heuristic for the dynamic facility layout problem,Comput.Oper.Res.33(8)(2006)2431-2444.

[13]F.S.Hillier,Quantitative tools for plant layout analysis,J.Ind.Eng.14(1)(1963)33-40.

[14]J.Skorin-Kapov,Tabu search applied to the quadratic assignment problem,ORSA J.Comput.2(1)(1990)33-45.

[15]K.V.Chandratre,K.N.Nandurkar,Applying genetic algorithm to dynamic layout problem,Int.J.Appl.Oper.Res.1(3)(2011)1-9.

[16]Q.L.Lin,H.C.Liu,D.J.Wang,L.Liu,Integrating systematic layout planning with fuzzy constraint theory to design and optimize the facility layout for operating theatre in hospitals,J.Intell.Manuf.26(1)(2015)87-95.

[17]X.Luo,Y.M.Yang,Z.X.Ge,X.S.Wen,Maintainability-based facility layout optimum design of ship cabin,Int.J.Prod.Res.5(3)(2015)677-694.

[18]A.S.Tubaileh,Layout of flexible manufacturing systems based on kinematic constraints of the autonomous material handling system,Int.J.Adv.Manuf.Technol.74(9—12)(2014)1521-1537.

[19]F.D.Penteado,A.R.Ciric,An MINLP approach for safe process plant layout,Ind.Eng.Chem.Res.35(4)(1996)1354-1361.

[20]Y.F.Wang,W.Wang,X.Feng,Heat integration across plants considering distance factor,Chem.Eng.35(2013)25-30.

[21]R.K.Sinnott,X.F.Song,Chemical engineering design,fourth ed.China Petrochemical Press,Beijing,2009 657-668(in Chinese).

[22]W.D.Bassel,Preliminary chemical engineering plant design,Elsevier North Holland,New York,1980 141-158.

[23]GB50984-2014,Code for layout design of petrochemical plant,China Planning Press,2014(in Chinese).

Chinese Journal of Chemical Engineering2016年8期

Chinese Journal of Chemical Engineering2016年8期

- Chinese Journal of Chemical Engineering的其它文章

- Computational chemical engineering - Towards thorough understanding and precise application☆

- A review of control loop monitoring and diagnosis:Prospects of controller maintenance in big data era☆

- Experimental and numerical investigations of scale-up effects on the hydrodynamics of slurry bubble columns☆

- The heat transfer optimization of conical fin by shape modification

- The steady-state and dynamic simulation of cascade distillation system for the production of oxygen-18 isotope from water☆

- Experimental mass transfer coefficients in a pilot plant multistage column extractor