H2气氛对采用MOCVD法在Si衬底上外延生长AlN薄膜性能的影响*

杨美娟,林云昊,王文樑,林志霆,李国强,2

1.华南理工大学发光材料与器件国家重点实验室,广东 广州 510640;

2.华南理工大学广东省半导体照明与信息化工程技术研究中心,广东 广州 510640

H2气氛对采用MOCVD法在Si衬底上外延生长AlN薄膜性能的影响*

杨美娟1,林云昊1,王文樑1,林志霆1,李国强1,2

1.华南理工大学发光材料与器件国家重点实验室,广东 广州 510640;

2.华南理工大学广东省半导体照明与信息化工程技术研究中心,广东 广州 510640

摘要:采用金属有机化合物气相沉积法(MOCVD)在Si(111)衬底上外延生长AlN薄膜,用高分辨X射线衍射、扫描电子显微镜和原子力显微镜对外延生长所得AlN薄膜的性能进行表征,并研究了适量H2的引入对AlN薄膜的晶体结构和表面形貌的影响.结果表明:在Si衬底上外延生长AlN薄膜过程中引入适量H2,有利于提高AlN岛间愈合程度,薄膜表面缺陷减少,表面粗糙度由4.0 nm减少至2.1 nm;适量H2的引入可使AlN薄膜的(0002)和(10-12)面的X射线摇摆曲线的半峰宽(FWHM)值从0.7及1.1分别减小到0.6和0.9,即刃型穿透位错密度和螺型穿透位错密度减少.

关键词:Si衬底;AlN薄膜;H2;MOCVD

在现存半导体材料中AlN具有超过6 eV的最宽直接带隙,且其载流子饱和迁移率、热导率、压电性能及耐高温抗辐射能力,相比其他很多半导体材料有着不可替代的优势[1-2].因此,AlN在深紫外探测器、抗辐射器件、大功率器件等领域中有着广阔的应用前景[3-4].目前,常用于生长AlN薄膜的衬底材料有蓝宝石、SiC和Si等.但蓝宝石衬底不导电,使用范围有限;SiC衬底价格偏高;Si衬底相比前两者成本低、尺寸大、导热导电性好及加工方便等诸多优势受到广泛关注.在Si衬底上外延生长AlN薄膜,已成为研究界和产业界的焦点[5-6].采用金属有机化合物气相沉积法(MOCVD),在Si衬底上制备AlN薄膜是目前主要的研究方向.想要在Si衬底上获得高质量的AlN薄膜依然存在以下问题[7-9]:AlN与Si衬底间存在较大的晶格失配(19.3%),容易因为较大的失配应力而产生大量位错与裂纹;Al元素化学性能活泼,容易与O及C等杂质元素发生反应,难以获得高质量的AlN薄膜.研究者已经对AlN薄膜的生长速率、反应温度、反应室气压等工艺条件进行了深入地研究,以提高AlN薄膜的质量而获得高性能的器件[10-12].对于反应腔内气氛,其对AlN膜生长至关重要[13-14],特别是H2载气对AlN薄膜性能影响的研究却不多见.

本文采用MOCVD技术在Si(111)衬底上外延生长AlN薄膜,研究了反应腔内通入适量H2载气对AlN薄膜晶体结构和表面形貌的影响,并详细讨论引入适量H2载气的作用机理.这是对高质量AlN薄膜生长研究的进一步完善,为获得高性能AlN基器件奠定基础.

1实验部分

用Veeco公司研制的K465i型MOCVD设备外延生长AlN薄膜,以三甲基铝(TMAl)和氨气(NH3)作为Al源和N源,材料中不进行任何故意掺杂.在生长前,用酸性溶液(浓度为98%的H2SO4、浓度为30%的H2O2和H2O,其比例为3:1:1)和浓度为5%的HF,对尺寸为101.6 mm的Si衬底进行清洗,以除去表面的污染物.衬底放入反应室后,在H2气氛压力为6666.1 Pa高压下再次进行衬底清洁.本实验准备了两组样品,样品A是只采用N2为载气而得到的AlN薄膜,样品B是通入适量H2和N2混合气体为载气而得到的AlN薄膜.除此之外,两个样品的生长温度均为1100 ℃,压力为6666.1 Pa,生长厚度为110 nm.

用高分辨X射线衍射仪(HRXRD,Bruker D8,Cu K1X射线源=1.5406Å)、扫描电子显微镜(SEM)、原子力显微镜(AFM)对样品进行测试.

2结果与讨论

2.1通入适量H2对AlN薄膜表面形貌的影响

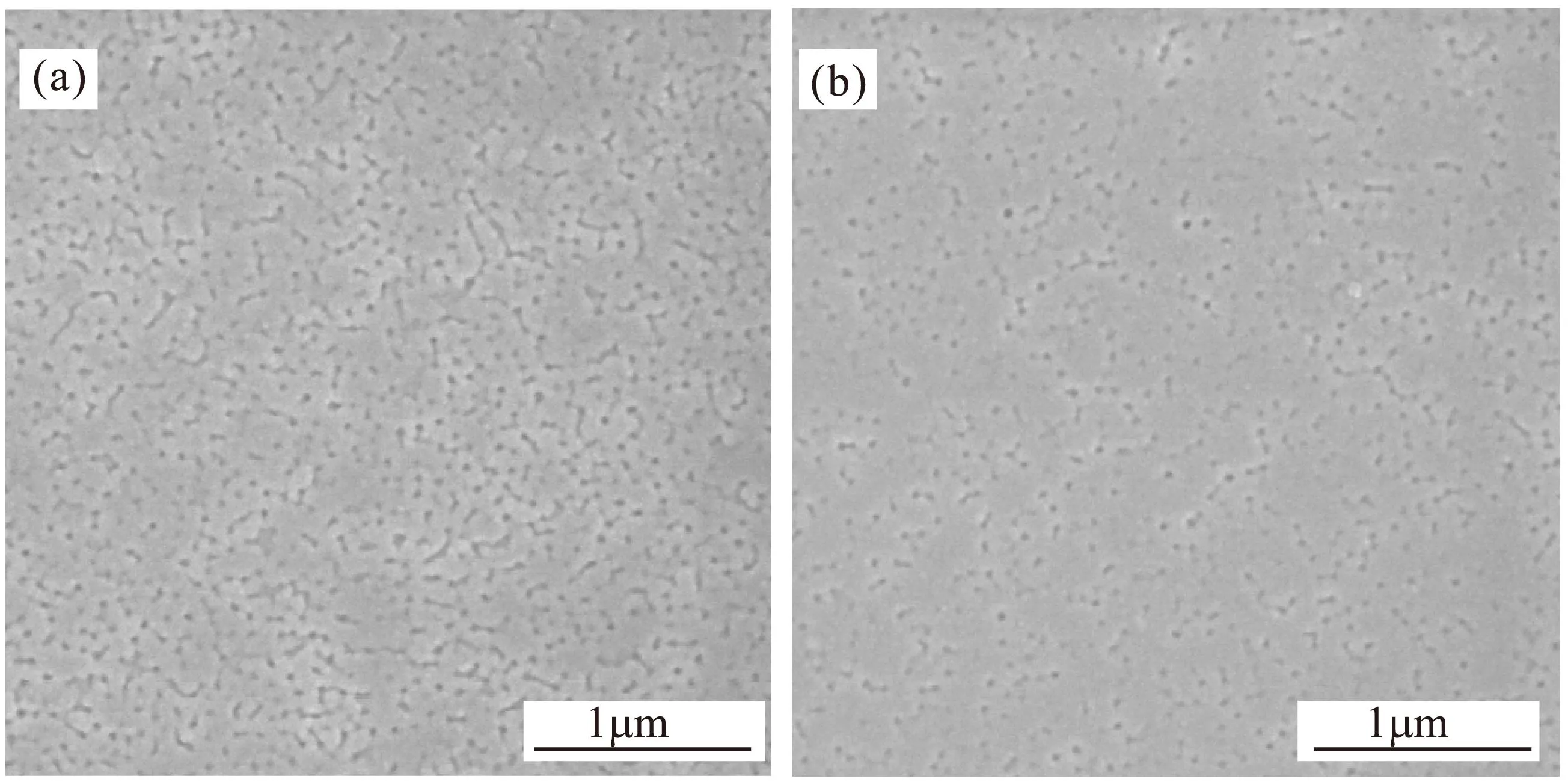

图1 AlN薄膜的SEM图样品A;(b)样品BFig.1 SEM images for AlN films (a) sample A;(b) sample B

对样品A和B的表面进行SEM表征,结果如图1所示.从图1(a)可见,AlN薄膜表面存在大量凹坑,尺寸不一,且没有合并的AlN孤岛.从图1(b)可见,AlN薄膜表面凹坑逐渐愈合,凹坑数量显著减少.表明通入适量H2有利于AlN逐渐成膜,并且呈现2D层状生长模式.进一步对两个样品进行AFM测试,图2为样品A和B的表面三维形貌,扫描面积为5m×5m.从图2可见:样品A及样品B对应的表面粗糙度分别为4.0 和2.1 nm;样品A表面的岛密度较大且形状尖锐不一,这增加了表面的起伏程度,从而导致表面粗糙度较大;样品B中AlN岛的纵向生长速度较样品A的慢,但AlN岛的横向生长速度较快并开始愈合,这说明适量H2的引入促进了AlN岛的愈合,加快了AlN从3D生长模式向2D的转变,与SEM测试结果相吻合.这是由于AlN与Si衬底间存在较大的晶格失配(19.3%),且Al原子在衬底表面的原子迁移率低,从而导致AlN很容易以岛状形式生长[15].在反应腔体内总气压不变的情况下,通入适量H2后降低了NH3的分压,使反应界面附近的气体分子密度有所下降,从而使反应物扩散距离较长,缓解了AlN的岛状生长并有利于AlN岛的横向生长与合并成膜[16].

2.2通入适量H2对AlN薄膜结构性能的影响

图2 AlN薄膜的表面三维形貌图(a)样品A;(b)样品BFig.2 3D images for the surface of AlN films (a) sample A; (b) sample B

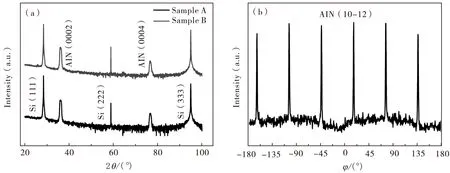

图3 样品A和B的2θ-ω和φ的扫描图(a)2θ-ω扫描图;(b)φ的扫描图Fig.3 XRD 2θ-ω measurements and XRD φ scans for sample A and sample B(a) XRD2θ-ω measurements;(b) XRD φ scans

图3为样品的2θ-ω和φ扫描图.从图3(a)可见:当2θ分别为36.02和76.40时,对应的是AlN(0002)和AlN(0004)晶面的衍射峰;当2θ分别为28.40,58.5和94.90时,分别对应Si(111),(222)和(333)晶面衍射峰,此外无其他的衍射峰.这表明,两个样品均具有良好的c轴择优取向.对两个样品(10-12)晶面进行φ扫描(图3(b))发现,两个样品均表现出面内六次旋转对称,说明生长的AlN薄膜和Si衬底具有良好的面内对称关系.因此,结合X射线的面外和面内扫描结果可知,本实验外延生长的AlN薄膜为单晶薄膜.为了进一步研究通入适量H2后对AlN薄膜晶体质量的影响,对两个样品进行了对称(0002)面和非对称(10-12)面的X射线摇摆曲线(RC)扫描.由于(0002)面RC扫描对于螺位错的分布密度较敏感,(10-12)面RC扫描代表刃位错和混合位错的分布情况,因此可利用不同晶面的RC扫描半峰宽(FWHM)的大小研究薄膜晶体的质量[17-18].RC扫描FWHM值越小,意味着晶体生长的质量越好.表1为样品A和样品B中AlN薄膜的(0002)面和(10-12)面的RC扫描FWHM值.由表1可以看出,在Si衬底上外延AlN薄膜过程中引入适量H2可使AlN薄膜的(0002)和(10-12)面的RC曲线的半峰宽值(FWHM)分别从0.7和1.1减小到0.6和0.9.通过公式D=β2/9b2[19-20],对AlN薄膜的刃型位错和螺型位错分别进行计算,其中D代表位错密度,β代表RC曲线半峰宽,b代表位错的伯氏矢量大小.经计算样品A的螺位错密度、刃位错和混合位错密度,分别是样品B的1.17和1.22倍.结果再一次表明,通入适量H2后AlN薄膜位错大大减少,晶体质量得到提高.通入适量H2有利于AlN岛的横向生长及合并成膜,穿透位错也在AlN横向生长过程中发生弯曲闭合,使其在继续生长的过程中不能延伸至薄膜表面.同时,H2在反应过程中可以与O及C等杂质元素反应,有利于减少外延生长中的非故意掺杂,从而减少点缺陷和位错的形成[21].H2相对分子质量小、黏度小、纯度高及携带灵活,也容易使杂质成分散出.

表1 AlN薄膜(0002)和(10-12)面RC扫描半峰宽值对照表

2.3通入适量H2对AlN薄膜界面性能的影响

X射线小角度反射(GIXR)是一种小角度(2θ15)的θ/2θ测量方式,探测得到的是X射线的强度随入射角的变化曲线,并可运用X射线动力学理论对实验测量曲线进行数值模拟,获得有关薄膜厚度、表面与界面特性等方面的信息.X射线在界面各处发生反射是由于各层介质对X射线的折射率不同,故GIXR曲线对表面/界面的粗糙度很敏感.如果是粗糙或者扩散的表面/界面会增加散射矢量和角度,表面/界面越粗糙反射强度下降越快,并会影响到曲线的振荡性[22].因此,常用GIXR曲线来研究Si衬底上外延生长AlN薄膜的表面/界面情况[23-24].

在MOCVD高温高压的生长条件下,Si原子容易从衬底中逃逸.一方面,Si原子会与N及Al发生化学反应,形成原子排列混乱的粗糙界面层[25];另一方面,Si原子的逸出造成了衬底与外延层更大的晶格失配,在后续薄膜生长中因失配应力而产生更多位错和裂纹,对薄膜的晶体质量产生不利的影响[26].图4为样品A与样品B的GIXR曲线.从图4可见:样品A的GIXR曲线强度下降较快,且低于样品B的GIXR曲线强度;样品A的GIXR曲线振荡性不如样品B.这表明样品A的表面/界面性能较差,粗糙度高于样品B.

3结论

对在Si(111)衬底上采用MOCVD技术外延生长AlN薄膜,通入适量H2对AlN薄膜性能的影响进行了探讨.结果表明,在Si衬底上生长AlN薄膜过程中,通入适量H2,AlN薄膜的表面形貌、晶体质量及界面性能均有所改善.适量H2的引入有利于AlN岛的横向生长与合并成膜.H2能与杂质元素反应并携带其散出,减少外延生长过程中的非故意掺杂.

参考文献:

[1] KONG Susu,WEI Hongyuan,YANG Shaoyan,et al. Morphology and structure controlled growth of one-dimensional AlN nanorod arrays by hydride vapor phase epitaxy[J]. RSC Adv,2014 (4):54902.

[2] WANG Wenliang,LIU Zuolian,YANG Weijia,et al. Nitridation effect of theα-Al2O3substrates on the quality of the GaN films grown by pulsed laser deposition[J]. RSC Adv,2014(4):39651.

[3] MOHD YUSOFF M Z,MAHYUDDIN A,HASSAN Z,et al. AlN/GaN/AlN heterostructures grown on Si substrate by plasma-assisted MBE for MSM UV photodetector applications[J]. Materials Science in Semiconductor Processing,2015,29:231.

[4] ZHOU J,DEMIGUEL-RAMOS M,GARCIA-GANCEDO L,et al. Characterisation of aluminium nitride films and surface acoustic wave devices for microfluidic applications[J]. Sensors and Actuators B:Chemical,2014,202:984.

[5] LIN Kungliang,CHANG E Y,HSIAO Y L,et al. Growth of GaN film on 150mm Si (111) using multilayer AlN/AlGaN buffer by metal-organic vapor phase epitaxy method[J]. Appl Phys Lett,2007,91:222111.

[6] LIN Yunhao,ZHOU Shizhong,WANG Wenliang,et al. Performance improvement of GaN-based light-emitting diodes grown on Si(111) substrates by controlling the reactor pressure for the GaN nucleation layer growth[J]. Journal of Materials Chemistry C,2015(3): 1484.

[7] BOURRET A,BARSKI A,ROUVIRE J L,et al. Growth of aluminum nitride on Si (111): Microstructure and interface structure[J]. J Appl Phys,1998,83,2003.

[8] LI Xiaohang,WANG Shuo,XIE Hongen,et al. Growth of high-quality AlN layers on sapphire substrates at relatively low temperatures by metalorganic chemical vapor deposition[J]. Phys Status Solidi:B,2015,252:1089.

[9] SIGNORE M A,TAURINO A,VALERINI D,et al. Role of oxygen contaminant on the physical properties of sputtered AlN thin films[J]. J Alloy Compds,2015,649:1267.

[10] MATSUMOTO K,TACHIBANA A. Growth mechanism of atmospheric pressure MOVPE of GaN and its alloys: gas phase chemistry and its impact on reactor design[J]. J Crystal G rowth,2004,272:360.

[11] MENG Jianping,LIU Xiaopeng,FU Zhiqiang,et al. Thermal stability of AlN films prepared by ion beam assisted deposition[J]. Appl Surf Sci,2015,347:109.

[12] TOMOAKI F,KAZUMA S,REMI O,et al. Fabrication and Characterization of AlN/InN Heterostructures[J]. Appl Phys Express,2009(2):011002.

[13] BAO Q,ZHU T,ZHOU N,et al. Effect of hydrogen carrier gas on AlN and AlGaN growth in AMEC prismo D-blue® MOCVD platform[J]. J Crystal Growth,2015,419:52.

[14] JUMPEI T,CHIKASHI E,RIE T,et al. Carrier gas dependence at initial processes forα-plane aln growth onγ-plane sapphire substrates by hydride vapor phase epitaxy[J]. Jap J Appl Phys,2011,50:055501.

[15] SHELDON B W,RAJAMANI A,BHANDARI A,et al. Competition between tensile and compressive stress mechanisms during volmer-weber growth of aluminum nitride films[J]. J Appl Phys,2005,98:043509.

[16] WANG H X,AMIJIMA Y,ISHIHAMA Y,et al. Influence of carrier gas on the morphology and structure of GaN layers grown on sapphire substrate by six-wafer metal organic chemical vapor deposition system[J]. J Crystal Growth,2001,233:681.

[17] HEINKE H,KIRCHNER V,EINFELDT S,et al. X-ray diffraction analysis of the defect structure in epitaxial GaN[J]. Appl Phys Lett,2000,77:2145.

[18] WANG Wenliang,YANG Weijia,WANG Haiyan,et al. Epitaxial growth of GaN films on unconventional oxide substrates[J]. Journal of Materials Chemistry C,2014(2):9342.

[19] LUO Weike,LI Liang,LI Zhonghui,et al. Influence of the nucleation layer annealing atmosphere on the resistivity of GaN grown by metalorganic chemical vapor deposition[J]. J Alloys Compds,2015,633:494.

[20] WANG Wenliang,YANG Hui,LI Guoqiang. Growth and characterization of GaN-based LED wafers on La0.3Sr1.7AlTaO6substrates[J]. Journal of Materials Chemistry C,2013(1): 4070.

[21] AMBACHER O,ANGERER H,DIMITROV R,et al. Hydrogen in gallium nitride grown by MOCVD[J]. Phys Status Solidi:A,1997,159:105.

[22] MORAM M A,VICKERS M E. X-ray diffraction of III-nitrides[J]. Rep Prog Phys,2009,72:036502.

[23] LI Guoqiang,WANG Wenliang,YANG Weijia,et al. Epitaxial growth of group III-nitride films by pulsed laser deposition and their use in the development of LED devices[J]. Rep Prog Phys,2015,70:380.

[24] WANG Wenliang,YANG Weijia,LIU Zuolian,et al. Interfacial reaction control and its mechanism of AlN epitaxial films grown on Si(Ⅲ) substrates by pulsed laser deposition[J]. Sci Rep,2015(5):11480.

[25] WANG Yuanzhang,LI Jinchai,LI Shuping,et al. X-ray reflectivity and atomic force microscopy studies of MOCVD grown AlxGa1-xN/GaN superlattice structures [J]. J Semicon, 2011,32:043006.

[26] LOSURDO M, CAPEZZUTO P,BRUNO G,et al. Interfacial reactions during GaN and AiN epitaxy on 4H-6H-SiC(0001)[J]. Appl Phys Lett,2005,86:021920.

Effect of hydrogen atmosphere on the properties of AlN films epitaxially grown on Si substrate by MOCVD

YANG Meijuan1,LIN Yunhao1,WANG Wenliang1,LIN Zhiting1,LI Guoqiang1,2

1.StateKeyLaboratoryofLuminescentMaterialsandDevices,SouthChinaUniversityofTechnology,Guangzhou510640,China;2.EngineeringResearchCenteronSolid-StateLightinganditsInformationisationofGuangdongProvince,SouthChinaUniversityofTechnology,Guangzhou510640,China

Abstract:AlN epitaxial films were grown on Si(111) substrates by metal-organic chemical vapor deposition (MOCVD). The surface morphology, crystalline quality, and interfacial property of as-grown AlN films have been investigated systematically, and the effect of hydrogen atmosphere on the properties of AlN films were studied in detail. The results reveal that the root-mean-square (RMS) roughness of ~110 nm-thick AlN films is greatly reduced from 4.0 nm to 2.1 nm, and the full-width at half-maximum (FWHM) value of X-ray rocking curve of AlN(10-12) is dramatically decreased from 1.1 to 0.9 by introducing a certain amount of hydrogen when compared with that grown without hydrogen.

Key words:Si substrates;AlN films;hydrogen;MOCVD.

中图分类号:TN304.2

文献标识码:A

文章编号:1673-9981(2016)01-0010-06

作者简介:杨美娟(1992-),女,福建省平潭县人,硕士研究生.

*基金项目:国家优秀青年科学家基金(51422203);广东省杰出青年科学家基金(S2013050013882);广东省重大科技专项资助项目(2014B010119001)

收稿日期:2015-11-11