Enhancement of seal life through carbon composite back-up rings under shock loading conditions in defence applications

Shnkr BHAUMIK,A.KUMARASWAMY*,S.GURUPRASAD

aR&DE (Engrs.),Pune 411015,Maharashtra,India

bDefence Institute of Advanced Technology (DU),Pune 411025,Maharashtra,India

Enhancement of seal life through carbon composite back-up rings under shock loading conditions in defence applications

Shankar BHAUMIKa,A.KUMARASWAMYb,*,S.GURUPRASADa

aR&DE (Engrs.),Pune 411015,Maharashtra,India

bDefence Institute of Advanced Technology (DU),Pune 411025,Maharashtra,India

The life of Nitrile Butadiene Rubber(NBR)O-ring seal having shore hardness ofA70 andA90 under shock loading conditions was investigated by a specially designed pneumo-hydraulic shock test rig.Shock tests have been carried out on bare seals,seal with conventional polytetraf l uoroethylene (PTFE)back-up rings and seal with newly developed carbon composite back-up rings to study its behaviour under different operating conditions until failure.Experiments were conducted by varying annular gap ranging from 0.3 to 0.5 mm,oil temperature from 30 °C to 70 °C and rate of pressure rise from 600 to 2400 MPa/s.Signif i cant enhancement in seal life was observed with carbon composite back-up ring at reduced annular clearances compared to seal life with conventional PTFE back-up ring and without back-up rings.

Hydraulic seal;O-rings;Shock load;Seal extrusion;Pneumo-hydraulic shock absorber;Back-up rings

1.Introduction

Hydraulic seals are used in a variety of critical applications involving machinery and are several times more expensive compared to seals.The critical importance of the seal can be quantif i ed by the failure of a static O-ring due to cold temperature freezing,causing catastrophe of NASA space shuttle“Challenger1986”.Therefore,the precise design and evaluation of reciprocating hydraulic seals are of supreme importance to avoid such costly mistakes.

O-rings are the simplest and most versatile seals among various types and cross sections of hydraulic seals having wide applications involving static and dynamic loading conditions. O-rings are employed in reciprocating hydraulic actuators involving long stroke and large diameter seals.The most important application includes the use of O-rings in reciprocating hydraulic rod and piston seals.The life of reciprocating dynamic O-ring seals is inf l uenced by extrusion,spiraling,f i nish of sliding surface and hardness of the seal.

Shock is def i ned as a non-periodic excitation of a system characterized by sudden relative displacement in a system.Allstructures in general and aerospace structures in particular experience shock loads of different magnitudes throughout their service life.Shock is generally measured through time histories expressed in seconds and amplitude expressed in g's of the shock event.Shock can also be measured in terms of velocity,displacement,force,pressure,etc.Shock testing is commonly performed by imparting kinetic energy to the system by drop hammering,impact,shaker,pyro-shock,etc.The failures caused by shock include crack or deformation of structural elements,failure of weld joints,hydraulic seal failure,etc.

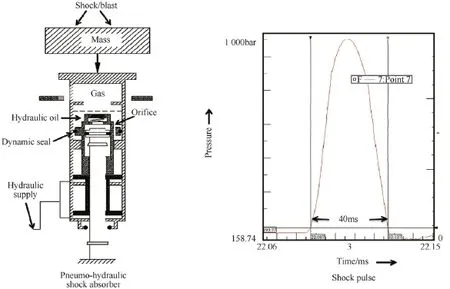

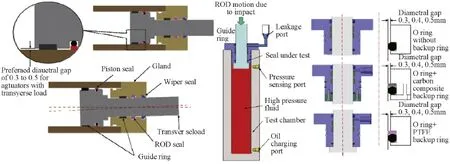

High pressure hydraulic seals are the common and most critical elements of any hydraulic system.Many of the defence equipment experiences shock/blast loads during deployed conditions.These blast/shock loads create short duration peak pressures,which are several times higher than the system operating pressure that will affect the seal life and in turn affect the reliability of the system.Shock isolators/dampers are generally used to isolate the shock loads and safeguard the delicate components of the system.One such pneumo-hydraulic shock absorber is shown in Fig.1,in which the dynamic seals experience a short duration pressure surge of 1000 bar during shock load isolation.

Fig.1.Effect of shock load on pneumo-hydraulic shock absorber.

Experimental research on hydraulic seals has been in progress for several decades.Over the years,theoretical and experimental investigation of tribological characteristics of reciprocating hydraulic seals such as leakage,friction,wear and extrusion has been carried out by numerous researchers. Numbers of test rigs have been built and various methods were employed for determination of tribological characteristics. Nikas,Müller,Field and Nau investigated the leakage and friction of reciprocating hydraulic seals [1-4].Hirano and Kaneta investigated the friction characteristics of f l exible seals for reciprocating motion [5].Nau determined the friction of oil lubricated sliding seals by conducting a number of experiments[6].Iwanami and Tikamori experimentally determined leakage from O-ring packing [7].Kawahara et al. [8]and Kaneta [9]also contributed to the experimental investigation of tribological characteristics of reciprocating hydraulic seals.Nikas formulated algebraic equations to describe the shape and contact pressure of the extruded part of the seal with the rod [10]. Signif i cant theoretical work was carried out by Salant[11-13],Nikas [14-17],Fatu and Hajjam [18]to determine the tribological characteristics of reciprocating hydraulic seals.Bhaumik et al.investigated the contact mechanics in reciprocating hydraulic U-seals for defence applications [19].Thatte and Salant developed a transient numerical model for reciprocating hydraulic seals to take account of the varying rod speeds [20]. However,no theoretical or experimental data to assess the inf l uence of shock/blast load on hydraulic seals were found in the literature.Therefore,in order to quantify the performance of hydraulic seals under severe operating conditions,it is necessary to design a test rig capable of generating shock pressure peaks to test the sealing elements of the hydraulic system.

In view of the above,in the present investigation,a special test rig has been developed and seal life as a function of parameters such as annular gap,rate of pressure rise,seal hardness,oil temperature,etc.,was investigated with and without the use of back-up rings.It was observed that the seal life was enhanced signif i cantly with carbon composite back-up ring at reduced annular clearances compared to seal life with conventional PTFE back-up ring and without back-up rings.

2.Pneumo-hydraulic test rig for hydraulic seals subjected to shock loading

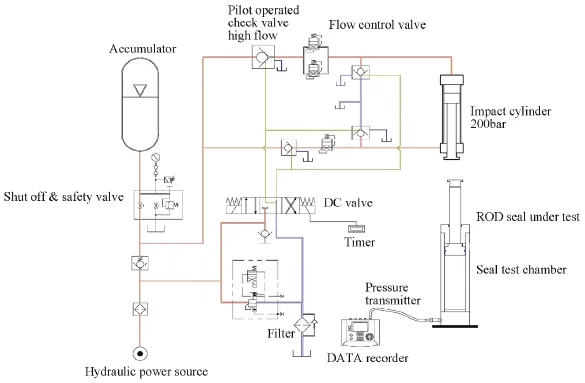

The test rig [21]capable of generating various types of shocks pulses by variation of parameters such as peak pressure,pulse duration,pulse shape,etc.,shown in Fig.2 has been developed to simulate the performance of static and dynamic hydraulic seals.The test rig is integrated with a data acquisition system for capturing test data for further analysis.The shock test rig will generate controlled hydraulic pressure pulse in a test chamber.The test chamber having bore diameter of 63 mm,rod diameter of 36 mm and stroke length of 300 mm is similar to a hydraulic cylinder integrated with rod/piston seal to be tested under dynamic conditions.The schematic of hydraulic system for the test rig consisting of hydraulic power pack,hydro-pneumatic accumulator,controlled valves,impact cylinder,test chamber,transducers and data recorder is shown in Fig.3.The hydraulic power source consists of 2 cc/rev,30 MPa,f i xed displacement radial piston pump driven by an electric drive unit.The accumulator of 50 L capacity is charged by a hydraulic power source to the desired pressure depending on the peak test pressure.After charging the accumulator to relief pressure setting,the pump f l ow is by-passed to the reservoir of 60 L capacity through the maximum pressure set relief valve and a return line f i lter.The pump pressure isalso available to the DC valve for operation of pilot operated check valves provided in the circuit for forward and reverse motion of impact cylinder of bore diameter of 125 mm,rod diameter of 90 mm and stroke length of 500 mm.The DC valve solenoids are energized by a power supply through a timer to control the pressure pulseduration.The rate of pressure rise and pressure drop is controlled by hydraulic f l ow control valves.A set of parallel f l ow control valves of 600 L/min has been provided to cater for high f l ow rate to the piston side of impact cylinder;the low oil volume from annular side is drained into the reservoir through a smaller pilot operated check valve.The pressure prof i le and peak pressure in the chamber may be controlled by hydraulic control valves and accumulator charge pressure.The accumulator sizing is done to meet the impulse pressure prof i le requirements.

Fig.2.Pneumo-hydraulic shock test rig.

All of the test parameters can be controlled by hydraulic system accumulator,control valves and timer based switching of the DC valve.The peak-test pressure up to 120 MPa can be maintained,which is three times the working pressure of a mobile hydraulic high-pressure system with an extra load factor of 20%.

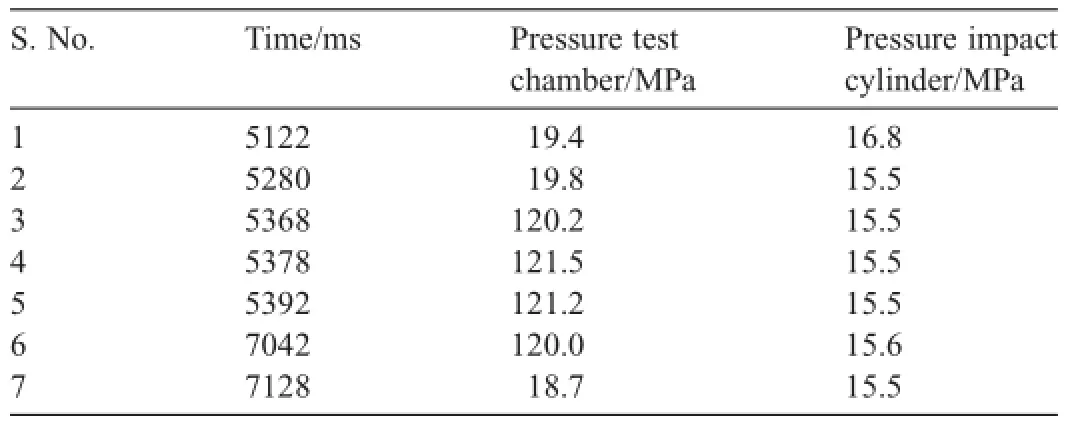

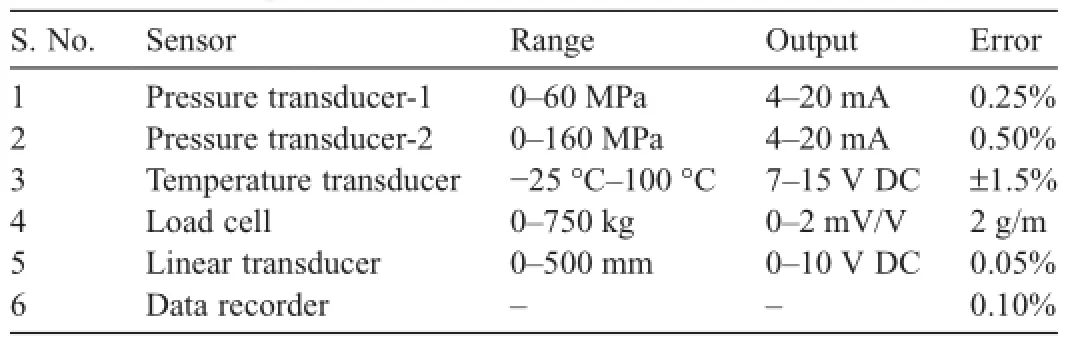

With a rate of pressure rise of 1200 MPa/s,i.e.,120 MPa pressure rise in 100 ms,a total impulse cycle duration of 1800 ms can be achieved.The impulse data generated using the test rig are given in Table 1.Cyclic impulse test may be carried out by controlling hydraulic valves using a timer.The test chamber is f i tted with pressure and temperature transducers,which are connected to a data recorder.Test at elevated temperature is controlled by wrapping a heating strip around the test chamber and a controller to maintain the test temperature. The test chamber is f i tted with pressure sensor (160 MPa)andtemperature sensor (100 °C)connected to a data recorder,which is capable of capturing data within a span of 2 ms. Different types of sensors along with their specif i cations are given in Table 2.

Fig.3.Schematic of hydraulic system.

Table 1Impulse data generated on shock test rig.

Table 2Sensors and their specif i cations.

3.Experimental

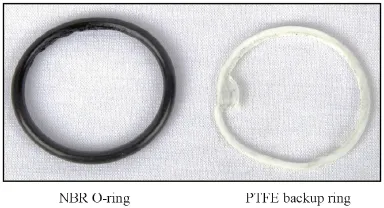

Nitrile Butadiene Rubber (NBR)O-ring seal of 36 mm internal diameter and 3.53 mm cross-sectional diameter with shore hardness ofA70 andA90,with and without back-up ring under shock loading conditions,has been considered in the current investigation.Shock tests have been carried out on (a)bare O-ring seals,(b)O-ring seal with PTFE back-up rings and (c)O-ring seal with carbon composite back-up rings to study seals under different operating conditions until failure.The shock load test arrangement for three conf i gurations is shown in Fig.4.Tests were carried out by varying annular gap/clearance,temperature and rate of pressure rise.

The stroke length of rod during shock test was kept at 100 mm.A hydraulic mineral oil conforming to the ISOVG 68 specif i cation was used during the test.The test chamber was initially charged to a pressure of 20 MPa.The rod surface f i nish(Ra)and the rod speed were 0.2 μm and 2 m/s,respectively.A white colored pure PTFE back-up ring having tensile strength of 28 MPa was used.Specially developed black colored carbon composite of carbon f i ber plus resin and ring machined out of composite sheet having tensile strength of 135 MPa was used in the current investigation.All of the above parameters are generally used in a typical hydro-pneumatic shock absorber.

3.1.Variation of annular clearance

Linear actuators involving longer strokes and larger diameters will experience large dynamic/shock loads.Therefore,the annular/diametral clearance/gap should be large enough to avoid metal to metal abrasion in the system.Depending on the size and type of seal in linear actuators under dynamic loading conditions,0.3 mm annular gap is recommended.However,in the case of linear actuators subjected to shock loads that are transferred between rod and gland,annular gap of the order of 0.3-0.5 mm is preferred.Annular gap less than 0.3 mm could cause metal to metal contact at rod/gland or piston/tube interface,thus damaging seal sliding surfaces.On the other hand,annular gap more than 0.5 mm results in seal extrusion.Therefore,in the present work,annular gap ranging between 0.3 mm and 0.5 mm has been considered to study seal behavior.A schematic of annular clearance in test cylinder for shock load is illustrated in Fig.4.

3.2.Results and discussion

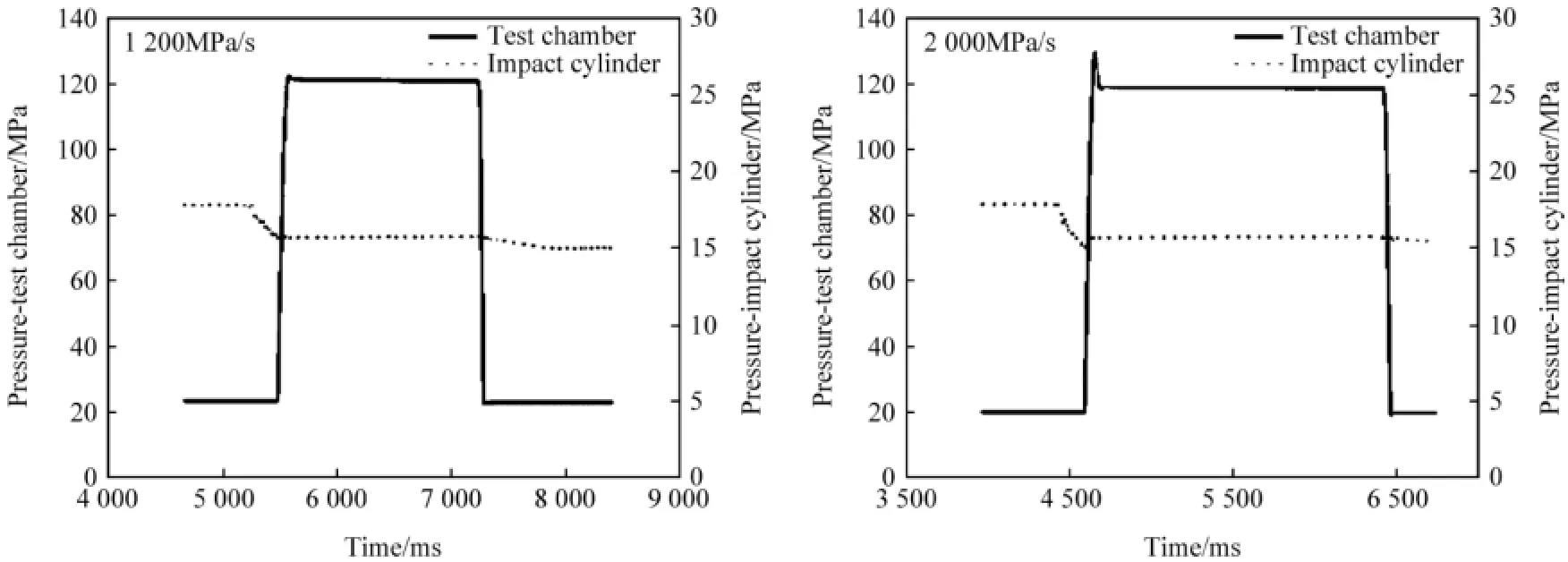

The pressure in the test chamber due to impact load is built up to 120 MPa and the rate of pressure rise in the test chamber is 1200 MPa/s as shown in Fig.5.The peak pressure is attained in 100 ms and is maintained for 1695 ms duration.This addedpressure for impact load is obtained from the accumulator into the impact cylinder.

Fig.4.Schematic of annular/diametral clearance in the test cylinder for shock load.

Fig.5.Pressure in the test chamber.

It may also be noted that there is a sudden drop of pressure in the impact cylinder as the impact load is applied.A rate of pressure rise at 2000 MPa/s in the test chamber can also be obtained by applying impact load as shown in Fig.5.The peak pressure of 130 MPa is obtained in the test cylinder in 50 ms,then reduced to 120 MPa and remained constant for 1350 ms. The pressure was reduced to 4 MPa upon removal of the load and the cycle was continued until seal failure takes place.

3.3.Effect of annular clearance on seal life

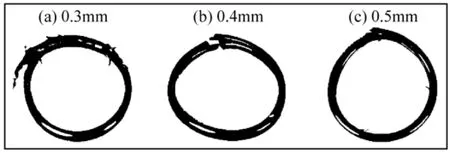

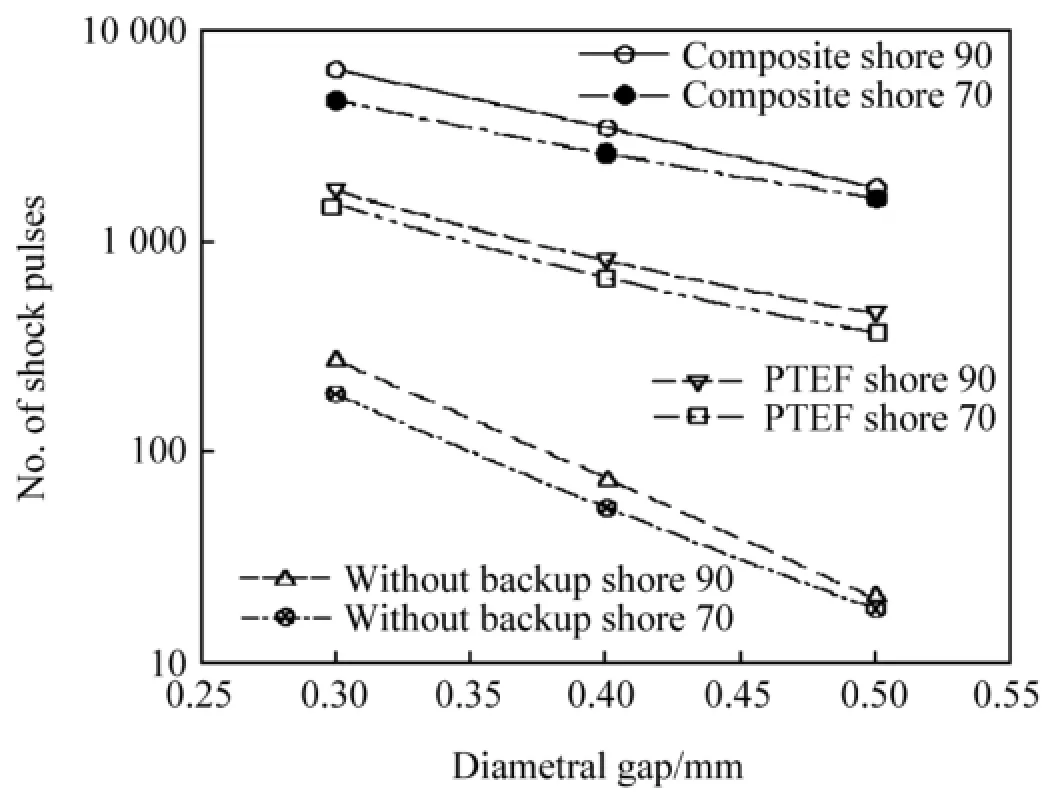

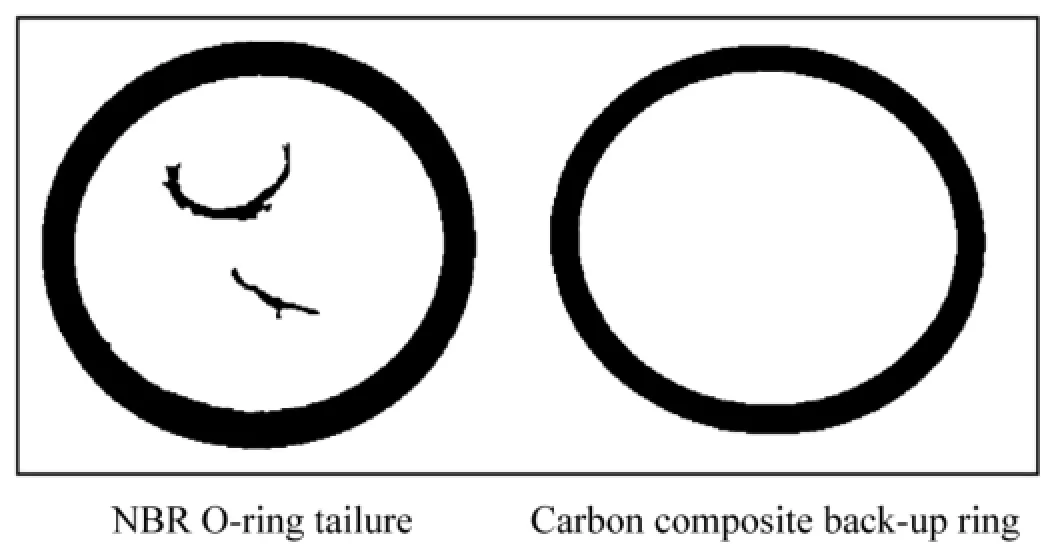

Shock tests were carried out on a set of three similar NBR O-ring seals (made of the same material duly inspected for dimensional tolerances chosen from the same manufacturing lot)to ascertain repeatability of results,considering diametric clearance of 0.3,0.4 and 0.5 mm.The number of shock pulses,which the seal can sustain before failure,is plotted in Fig.6 and the extent of seal damage is shown in Fig.7.It was observed that seal without back-up ring at a lower annular gap of 0.3 mm was capable of sustaining oil pressure up to 275 ± 25 repeated shock pulses,while seal ceased to function satisfactorily at increased annular gaps (0.4 mm:75 ± 25 shock pulses and 0.5 mm:only 20 shock pulses).

3.4.Effect of back-up rings on seal life

Fig.7.Extent of seal damage with annular/diametral gap (without back-up ring).

Fig.8.Seal extrusion under shock load.

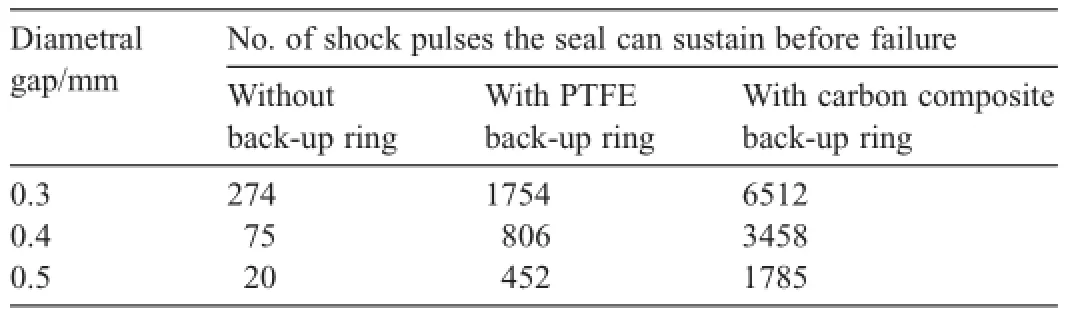

Table 3No.of shock pulses the seal can sustain before failure (shore hardness:A90).

Shock load experiments were conducted on O-ring hydraulic seals of shore hardness A70 and A90 using conventional PTFE and carbon composite back-up rings considering annular/ diametral gap of 0.3,0.4 and 0.5 mm.The number of shock pulses,which the seal can sustain before failure with and without back-up rings,is plotted as a function of diametral gap as shown in Fig.8 and listed in Table 3.The number of shock pulses the seal could sustain before failure followed a regression type of second-order polynomial.It was observed that use of high strength conventional PTFE back rings delayed the seal failure due to extrusion and back-up rings failed due to higher frictional force before the seal failure as shown in Fig.9.Motivated by these observations,the analysis was further extended to investigate the seal life with carbon composite back-up rings possessing high strength,low load-to-def l ection ratio,low friction,high resistance to wear and self-lubricating properties.It is interesting to note that the life of the sealing system was enhanced by 4-5 times compared to seal life with conventional PTFE back-up ring as seen in Fig.10.

3.5.Effect of rate of pressure rise and oil temperature on seal life

Fig.9.Improved seal life with PTFE back-up ring.

Fig.10.Enhanced seal life with carbon composite back-up ring.

Fig.11.Effects of rate of pressure rise and oil temperature on seal life without back-up ring (shore hardness A90).

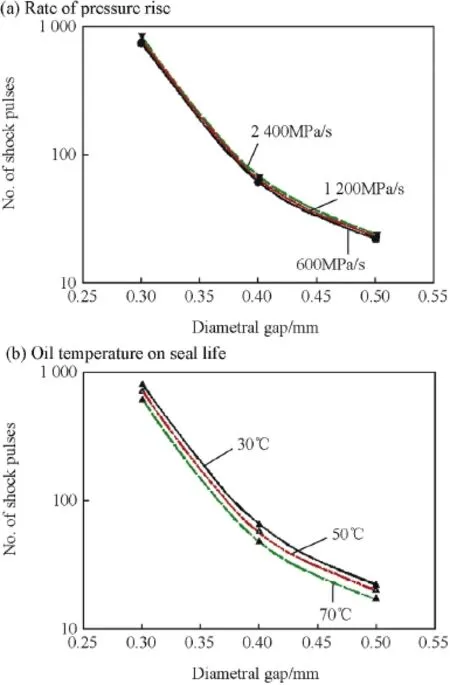

The effect of rate of pressure rise on seal life under shock loading was investigated by conducting tests on O-ring seals of shore hardness A90 with annular gaps of 0.3,0.4 and 0.5 mm and rate of pressure rise of 600,1200 and 2400 MPa/s.It can be seen in Fig.11 that the seal life with rate of pressure rise of 2400 MPa/s is slightly inferior compared to the rate of pressure rise of 600 MPa/s,indicating that seal life is weakly affected by the rate of pressure rise.

The effect of oil temperature on seal life under shock load was investigated by conducting tests on O-ring seals of Shore hardness A90 with annular gaps of 0.3,0.4 and 0.5 mm and temperatures of 30 °C,50 °C and 70 °C.It may be observed from Fig.11 that the number of shock pulses that the seal could sustain before failure decreased with an increase in temperature due to swelling of seal at elevated temperatures.It may be noted that the effect of pressure rise on seal life is not as much as the effect of temperature.The number of shock pulses the seal can sustain was reduced with an increase in annular gap from 0.3 to 0.5 mm in both cases as described in the previous sections.

4.Conclusions

1)Catastrophic seal failure has taken place within 20-50 shock pulses with annular gap of 0.5 mm withoutback-up ring,while seal failure was delayed (up to 300 shock pulses)when the annular gap was reduced to 0.3 mm.

2)The seal life was enhanced signif i cantly with carbon composite back-up ring at reduced annular clearances compared to seal life with conventional PTFE back-up ring and without back-up rings.

3)The seal life at higher rate of pressure rise is slightly inferior compared to lower rate of pressure rise,indicating that seal life is weakly affected by the rate of pressure rise.

4)The number of shock pulses that the seal could sustain before failure decreased with an increase in temperature due to swelling and hardening of seal.Further,the effect of the rate of pressure rise on seal life is not as much as the effect of temperature.

Acknowledgments

The authors would like to extend thanks to Mr.Rakesh,Mr. Abhishek Kumar,Mr.CKWaghmare and Mr.Manoj Bhujbal of R&DE (Engrs),Pune,India,for providing assistance during the course of the work.One of the authors,Shankar Bhaumik,would like to thank Vice Chancellor,DIAT (DU),Pune for permitting him to do PhD.

[1]Nikas GK,Almond RV,Burridge G.Experimental study of leakage and friction of rectangular,elastomeric hydraulic seals for reciprocating motion from-54 to+135°C and pressures from 3.4 to 34.5 MPa.Tribol Trans 2014;57(5):846-65.

[2]Cheyney LE,Müller WJ,Duval RE.Frictional characteristics of O-rings with a typical hydraulic f l uid.Trans ASME 1950;291-7.

[3]Müller HK.Leakage and friction of f l exible packings at reciprocating motion with special consideration of hydrodynamic f i lm formation.In: Proc 2nd Int Conf Fluid Seal;1964.p.13-28.

[4]Field GJ,Nau BS.An experimental study of reciprocating rubber seals. In:Proc.1972 Symposium on EHD lubrication,Leeds University;1972. p.29-36.

[5]Hirano F,Kaneta M.Experimental investigation of friction and sealing characteristics of f l exible seals for reciprocating motion.In:Proc 5th Int Conf Fluid Seal;1971.p.17-32.

[6]BS.Friction of oil lubricated sliding seals.In:Proc 5th Int Conf Fluid Seal;1971.p.81-96.

[7]Iwanami S,Tikamori N.Oil leakage from an O-ring packing.In:Proc 1st Int Conf Fluid Seal;1961.

[8]Kawahara Y,Ishiwata H,Ichikawa Y.An experimental investigation of dynamical characteristics of U-seal in reciprocating motion.In:Proc 6th Int Conf Fluid Seal;1973.p.33-43.

[9]Kaneta M.Sealing characteristics of double reciprocating seals.J JSLE Int Ed 1986;7:141-6.

[10]Nikas GK.Analytical study of the extrusion of rectangular elastomeric seals for linear hydraulic actuators.J Eng Tribol 2003;217:365-73.

[11]Salant RF,Maser N,Yang B.Numerical model of a reciprocating hydraulic rod seal.ASME J Tribol 2007;129:91-7.

[12]Yang B,Salant RF.Numerical model of a reciprocating rod seal with a secondary lip.Tribol Trans 2008;51:119-27.

[13]Salant RF,Maser N,Yang B.Elasto hydrodynamic model of a reciprocating hydraulic rod seal.In:5th International Conference on Tribology,Parma,Italy;2006.

[14]Nikas GK,Sayles RS.Nonlinear elasticity of rectangular elastomeric seals and its effect on elastohydrodynamic numerical analysis.Tribol Int 2004;37:651-60.

[15]Nikas GK,Sayles RS.Computational model of tandem rectangular elastomeric seal for reciprocating motion.Tribol Int 2006;39:622-34.

[16]Nikas GK.Theoretical study of solid back-up rings for elastomeric seals in hydraulic actuators.Tribol Int 2004;37:689-99.

[17]Nikas GK.Transient elastohydrodynamic lubrication of rectangular elastomeric sealsforlinearhydraulic actuators.J Eng Tribol 2004;217:461-73.

[18]Fatu A,Hajjam M.Numerical modelling of hydraulic seals by inverse lubrication theory.J Eng Tribol 2011;225:1159-73.

[19]Bhaumik S,Kumar SR,Kumaraswamy A.Experimental investigation and FE modelling of contact mechanics phenomenon in reciprocating hydraulic U-seals for defence applications.Appl Mech Mater Trans Tech Publicat 2014;592-594:1950-4.

[20]Thatte A,Salant RF.Transient EHL analysis of an elastomeric hydraulic seal.In:Proceeding of the 13th Nordic Symposium on Tribology,Tampere,Finland;2008.

[21]Bhaumik S,Kumarswamy A,Guruprasad S.Design&development of test rig for investigation of contact mechanics phenomena in reciprocating hydraulic seals.Proced Eng 2013;64:835-43.

Received 8 March 2015;revised 30 July 2015;accepted 7 August 2015 Available online 7 September 2015

Peer review under responsibility of China Ordnance Society.

*Corresponding author.Tel.:+912024304191.

E-mail address: akswamy@diat.ac.in, adepu_kswamy@yahoo.com(A.KUMARASWAMY).

http://dx.doi.org/10.1016/j.dt.2015.08.003

2214-9147/© 2015 China Ordnance Society.Production and hosting by Elsevier B.V.All rights reserved.

© 2015 China Ordnance Society.Production and hosting by Elsevier B.V.All rights reserved.

- Defence Technology的其它文章

- Effect of f i bre orientations on the mechanical properties of kenaf-aramid hybrid composites for spall-liner application

- Studies on impact sensitivity of nanosized trinitrotoluene (TNT)conf i ned in silica processed by sol-gel method

- Optimization of three-loop missile autopilot gainunder crossover frequency constraint

- Ballistic behavior of boron carbide reinforced AA7075 aluminium alloy using friction stir processing-An experimental study and analytical approach

- Friction assisted solid state lap seam welding and additive manufacturing method

- Azo-bridged triazoles:Green energetic materials