Preparation and Tribological Properties of Lanthanumdoped Muscovite Composite Particles as Lubricant Additives in Lithium Grease

(Logistical Engineering University, Chongqing 401311)

Preparation and Tribological Properties of Lanthanumdoped Muscovite Composite Particles as Lubricant Additives in Lithium Grease

Du Pengfei; Chen Guoxu; Song Shiyuan; Zhao Litao; Wu Jiang; Cheng Peng; Yang Xiao

(Logistical Engineering University, Chongqing 401311)

Lanthanum-doped muscovite (MC) composite particles (hereinafter abbreviated as La-MC) were prepared by the mechanical solid-state-chemistry-reaction method, followed by surface modi fi cation with oleic acid. The microstructure of materials was characterized by SEM, XRD, EDS and FTIR. Furthermore, the friction-reduction and anti-wear properties of MC and La-MC as lubricant additives in lithium grease were evaluated using a four-ball friction and wear tester. The results showed that La(OH)3nanoparticles were coated on the surface of muscovite. Both MC and La-MC can effectively improve the friction-reduction and anti-wear properties of lithium grease and La-MC presents better tribological properties than MC. The excellent tribological properties of La-MC can be attributed to the formation of the adsorbed La-MC fi lm and the chemical reaction fi lm mainly composed of Fe2O3and SiO2on the worn surface, as well as the catalysis of lanthanum element during the friction process.

muscovite; composite particles; lubricant additives; friction-reduction and anti-wear mechanism

1 Introduction

Phyllosilicates have gained an increasing interest as lubricant additives in recent years. It is found that most of these phyllosilicates with layered structures possess good antioxidation, high fl exibility and sliding properties and good reducibility[1-2]. Some phyllosilicates have been investigated and proven to be potential lubricant additives for mechanical components. Yu[3-5]and Zhang[6]investigated the tribological properties of serpentine particles as lubricant additive by using the friction and wear testers. The serpentine could signi fi cantly improve the friction-reduction and anti-wear performance of lubricating oil and the excellent tribological properties were attributed to the formation of a tribofilm of multiaperture oxide layer. Nan[7-9]added surface-modified attapulgite powder into mineral lubricating oil and found a smooth and compact tribofilm formed on the tribosurfaces. Yuan[10]and Wang[11]showed that with the proper addition of muscovite particles, the friction coefficient and wear rate of lubricating oil were greatly decreased. However, previous researches mainly focused on the tribological properties of phyllosilicates powder in lubricating oil, little research has been done on the tribological performance of phyllosilicates in lubricating grease.

In addition,it is well known that rare earth materials have also been widely used as the catalyst in the metallurgical industry and as lubricant additive in the fi eld of tribology thanks to their some special physiochemical properties. Xu[12]and Zhang[13]reported that La compounds could reduce the thermodynamic and structural stability of serpentine and facilitate the segregation and enrichment of C, O, and Si elements on the friction surface. Therefore, La compounds may also have a positive effect on the tribological properties of Si- and O-rich muscovite, since the crystal structure and chemical composition of muscovite are similar to those of serpentine. However, no report is currently available about La compound-doped muscovite composite particles used as lubricant additive.

In this work,the lanthanum-doped muscovite composite particles were prepared by the mechanical solid-statechemistry-reaction method, which involved coating the micro-muscovite particles with La(OH)3nanoparticles. The tribological properties of MC and La-MC used as lubricant additives in lithium grease were investigated and compared using a four-ball friction and wear tester. The tribo fi lm formed on the worn surface was characterized by SEM, EDS and XPS to explore the friction-reduction and anti-wear mechanism of La-MC. This work is believed to be helpful for providing theoretical and practical guide for research on the tribological properties of La-MC additives in lubricating grease.

2 Experimental

2.1 Preparation and characterization of materials

The muscovite (MC) powder was purchased from the GERA Minerals Corporation (Anhui Province, China). The 6% La-doped muscovite composite particles were prepared by the mechanical solid-state-chemistry-reaction method at room temperature. The muscovite powder, lanthanum nitrate, hexahydrate and oxalic acid were premixed according to required proportions and then ground continuously for 4 h using a Fritsch planetary ballmilling machine with a certain amount of ethanol serving as the grinding agent. The La-doped muscovite composite particles (La-MC) were obtained in a pump filter and calcined at 700 ℃ for 2 h in a muf fl e furnace. The Zeiss Supra 550 SEM and Shimadzu 6100 XRD were utilized to characterize the morphology and phase structure of MC and La-MC. The Microtrac S3500 laser diameter analyzer was used to measure the diameter distribution of MC and the AMETEK EDS was employed to analyze the elemental composition of La-MC. To provide good dispersing stability in lithium grease, MC and La-MC were ultrasonically oscillated for 1 h at 60 ℃ with oleic acid (5%) to modify their surfaces followed by being cleaned with petroleum ether prior to measurements by a PerkinElmer 400 FTIR spectrometer.

2.2 Friction and wear test

The laboratory-made lithium grease with a drop point of 203 ℃ and a penetration (0.1 mm) index of 274 was used as the base grease[14]. MC and La-MC after modi fi cation were separately added to lithium grease at different mass fractions and were fully mixed by a triple-roller mill. The friction-reduction and anti-wear properties of the grease containing different samples were evaluated by a MMW-1 four-ball friction and wear tester under a load of 392 N, a.rotation speed of 1 200 r/min, and a time duration of 30 min at room temperature. GCrl5 bearing steel balls with a diameter of 12.7 mm and a hardness of 59—61 HRC were adopted to assemble the friction pair. The friction coef fi cient curve was recorded automatically by a computer connected to the tester. Moreover, the wear scar diameter (WSD) of the balls was measured by an optical microscope and the average WSD was calculated. At the end of each test, the worn steel balls were rinsed ultrasonically with petroleum ether for 10 min and the morphology, elementary and phase composition of worn steel surface were characterized by SEM, EDS and XPS (Thermo ESCALab-250; exciting source: Al Kα radiation; reference, contaminated carbon: C1s, 284.80 eV).

3 Results and Discussions

3.1 Materials

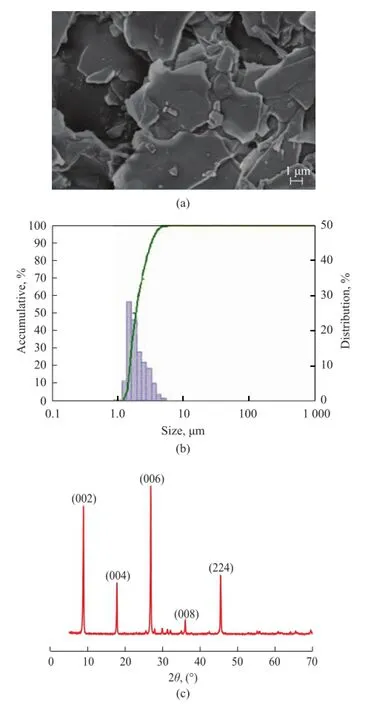

Figure 1 presents the SEM morphology, size distribution and XRD pattern of the muscovite. It can be observed from Figure 1a that the muscovite particles are lamellar with their size ranging from 1 mm to 4 mm, which is in good agreement with the size distribution as shown in Figure 1b. The diffraction peaks in Figure 1c all comply with the index of zinnwaldite (JCPDS: No.86-1403, one kind of muscovite), indicating that raw muscovite sample is very pure.

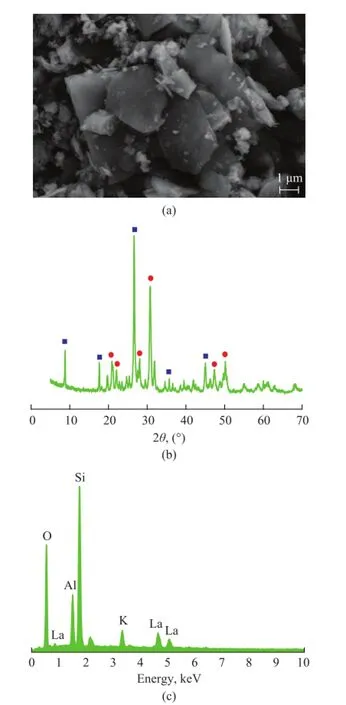

Figure 2 presents the SEM morphology, XRD pattern and EDS image of La-MC. The La-MC composite particles are seen in the form of lamellar morphology, and lanthanum compound nanoparticles are coated on the surface of muscovite as shown in Figure 2a. The XRD pattern in Figure 2b shows that the main phase compositions in the sample cover muscovite and La(OH)3, and there are no other impurities, suggesting that the La-MC composite particles with high purity are obtained. The presence of La element in Figure 2c denotes the existence of La(OH)3.

Figure 1 SEM morphology (a), size distribution (b) and XRD pattern (c) of muscovite

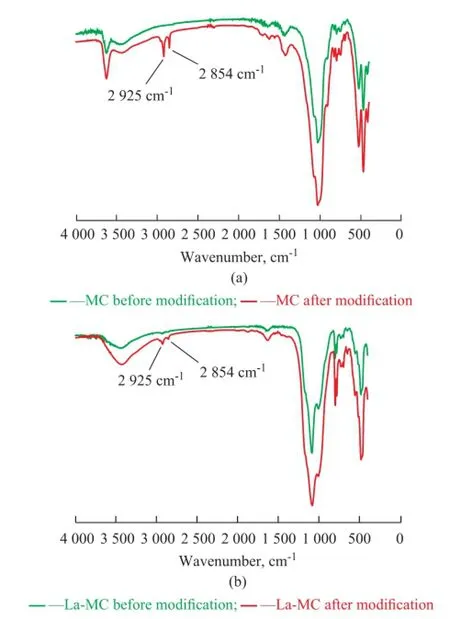

Figure 3 displays the FTIR spectra of MC and La-MC before and after modi fi cation. It can be seen from Figure 3 that both MC and La-MC present new absorption peaks at 2 925 cm-1and 2 854 cm-1after modification, which are assigned to the asymmetric and symmetric stretching vibrations of C—H bonds, respectively. And both of the peaks belong to the nonpolar carbon chain characteristic absorption in oleic acid[15]. Therefore, it can be inferred that an organic layer formed on the surface of MC and La-MC and accordingly the dispersion capacity of the samples in lithium grease is greatly increased.

Figure 2 SEM morphology (a), size distribution (b) and XRD pattern (c) of muscovite

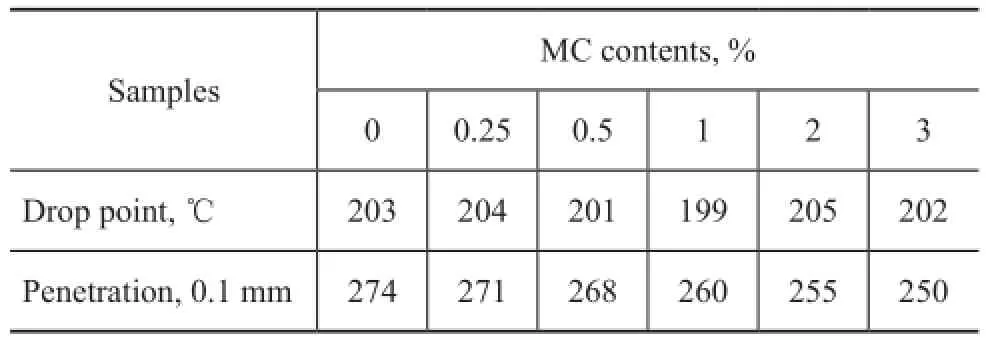

In general, adding solid powder into lubricating grease will affect the property of the grease. In this work, the drop point and penetration (usually regarded as two crucial factors) were measured to evaluate the effect of MC addition on lithium grease, as listed in Table 1. It can be seen that the penetration decreases with the increase of the addition amount. This means that MC can increase the consistency of grease to a certain degree. Meanwhile, the drop point of all grease samples was around 200, which implies that MC has little influence on the soap fiber structure of lithium grease.

Figure 3 The FTIR spectra of MC (a) and La-MC (b) before and after modi fi cation

Table 1 The drop point and penetration of lithium grease samples

3.2 Friction and wear properties

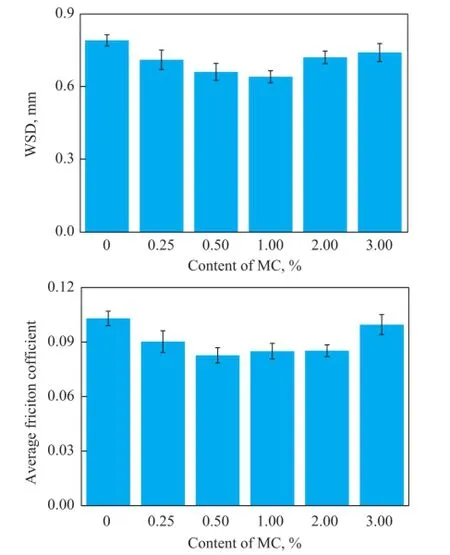

The average WSD and friction coefficient of lithium grease with different contents of MC are presented in Figure 4. It can be seen from Figure 4 that WSD is relatively large and is equal to 0.79, when the balls are lubricated with lithium grease alone. With an increased addition of MC into lithium grease, the WSD decreases at fi rst and then increases in the range of 1%—3%. The WSD reaches a minimum value of 0.64 at a MC content of 1%, which is decreased by 19% as compared to the value achieved by the lithium grease alone. The trend of variation in average friction coef fi cient is similar to that of WSD. It also fi rst decreases to a minimum value and then increases. The lithium grease containing 1% of MC exhibited the best friction-reduction property, which is reduced by 21.1% as compared to the value achieved by the lithium grease alone.

Figure 4 The WSD and average friction coef fi cient oflithium grease with different content of MC

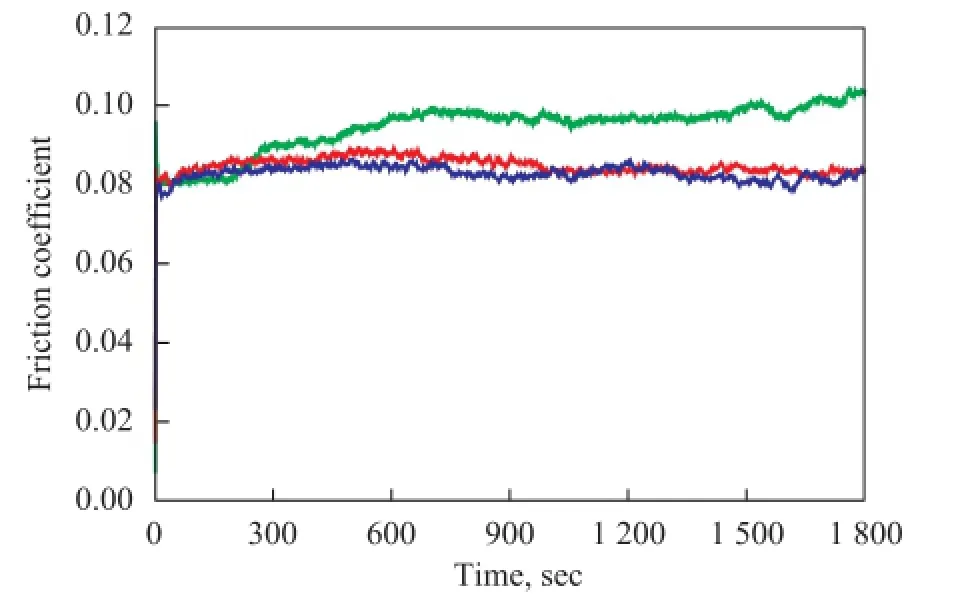

In order to compare the tribological properties of MC and La-MC, the lithium grease with an optimum content of 1% of MC was chosen as the comparison object, the experimental study of the tribological properties of lithium grease containing 1% of La-MC was carried out. Figure 5 displays the friction coefficient-time curve of the lithium grease, and lithium grease containing 1% of MC and 1% of La-MC, respectively. The friction coefficient lubricated with the lithium grease increases along with the friction time and fi nally reaches a value of 0.105, indicating that the friction-reduction performance is not very good. On the contrary, the grease containing MC exhibits a lower friction coefficient as compared to that of lithium grease, indicating that muscovite can improve the friction-reduction ability of the base grease. Moreover, the friction coef fi cient lubricated with lithium grease containing La-MC is further reduced and becomesmore stable in comparison with the grease containing muscovite, attesting to the better friction- reduction ability of La-MC.

Figure 5 Friction coef fi cient-time curve of different samples

Figure 6 presents the SEM morphology of wear scar surface lubricated with different grease samples. Obviously, the wear scar diameter is relatively large and there are deep furrows and some plastic deformations on the worn surface upon being lubricated with lithium grease alone, indicating to a severe wear. In contrast, the worn surface is quite smooth with few shallow furrows and the wear scar diameter is decreased under the lubrication of the grease containing MC. In particular, the surface is much smoother and the boundary of the wear scar is much neater upon being lubricated with lithium grease containing La-MC. All these results demonstrate that MC and La-MC can markedly improve the anti-wear ability of base grease, which is especially effective by using La-MC. Therefore, it can be deduced that La element in La-MC composite particles is conducive to enhancing the tribological ability of muscovite in lithium grease.

Figure 6 The SEM morphology of different worn surface lubricated by: lithium grease (a), lithium grease +MC (b), lithium grease +La-MC (c)

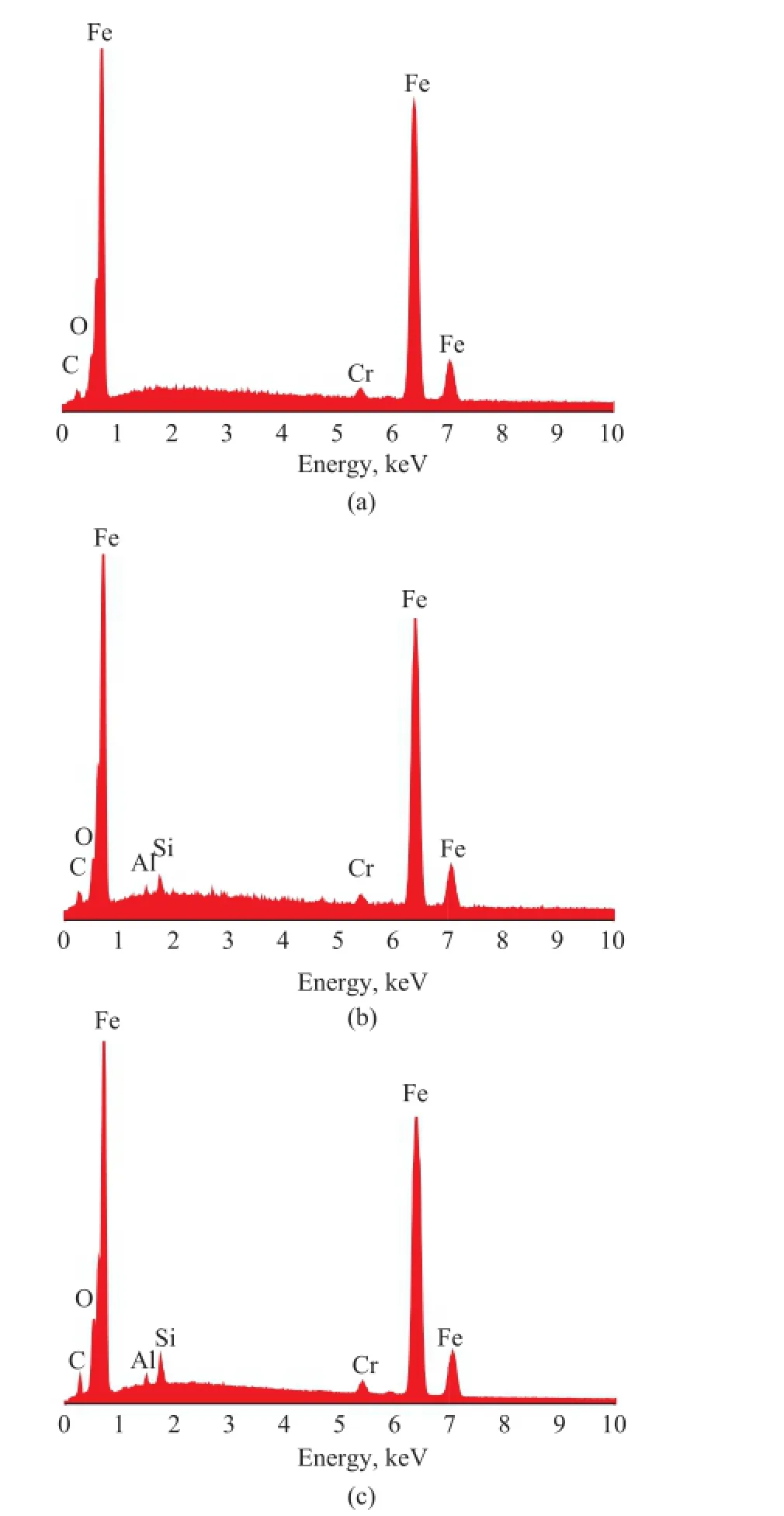

Figure 7 The EDS image of different worn surface lubricated by: lithium grease (a), lithium grease+MC (b), lithium grease +La-MC(c)

The EDS patterns of the worn surface lubricated with the lithium grease, the grease containing MC, and the grease containing La-MC, respectively, are displayed in Figure 7. The main elements of worn surface lubricated with lithium grease cover C, O, Fe, and Cr (Figure. 7a). Besides C, O, Fe and Cr elements, a certain amount of Si and Al elements, which can be only contained in muscovite, also exist on the worn surface, suggesting that MC and La-MC directly participate in the physicochemical interactions so that a tribo fi lm mainly consisting of O, Fe, Si and Alelements is formed on the worn surface. Meanwhile, the worn surface lubricated with lithium grease containing La-MC has a higher content of O and Si elements than that of lithium grease containing muscovite, but La element is not found on the worn surface. The La element could not detected for two reasons: the first reason is that La element may act as a catalyst to accelerate the physicochemical reactions and consequently facilitate the segregation and enrichment of O and Si elements onto the friction surface[12-13]. The second reason is that the proportion of La in the composite particles is too low to be detected. In addition, the higher content of O and Si elements on the worn surface may be responsible for the better friction-reduction and anti-wear properties of La-MC.

Figure 8 The XPS pattern of worn surface lubricated with grease containing 1%La-MC: C1s(a), Fe2p3/2 (b), Si2p (c), Al2p (d), O1s (e)

In order to ascertain the phase composition of tribofilm and explore the friction-reduction and anti-wear mechanism of La-MC, the worn surface lubricated with grease containing 1 wt% of La-MC was analyzed by XPS, as presented in Figure 8. The C1s peak at 285 eV and288.5 eV can match with those of carbon and carbides[16](Figure 8a). The Fe2p3/2 peaks at 710.8 eV imply that iron is oxidized into Fe2O3[17-18](Figure 8b). The peak position of Si2p has a little shift compared with the standard spectral peak, indicating that Si exists not only in the form of SiO2, but also in the form of silicate[18](Figure 8c). Because of a low portion of Al elements on the worn surface, the spectral peaks of Al2p was not very obvious, it might exist in the form of silicate according to the existence of a certain amount of Si elements in silicate. The O1s peaks appear to be widened and uneven, the peaks at 529.8 eV and 531.9 eV correspond to the chemical state of oxygen in Fe2O3, SiO2and silicate[16], respectively, which is attributed to the chemical reaction or adsorption of La-MC on the worn surface.

3.3 Friction-reduction and anti-wear mechanism

Based on the above-mentioned surface analysis, it can be reasonably concluded that the excellent friction-reduction and anti-wear properties of La-MC composite particles are mainly ascribed to the formation of the adsorption film and chemical reaction film on the worn surface. On the one hand, the La-MC has a high speci fi c surface area and there exists a certain amount of active groups on the surface of La-MC, which provides La-MC with high surface activity and adsorption ability[19]. During the friction process, the La-MC suspended in lithium grease can be absorbed and deposited onto the contact surface, acting as the polishing particles to improve the flatness and hardness of worn surfaces[7]. On the other hand, as one kind of phyllosilicates, muscovite has the crystal structure and chemical composition similar to those of serpentine. The crystal structure consists of tetrahedral laminae of Si-O bonds and octahedral laminae of Al-O bonds in the form of TOT. The main binding force between each lamina is connected by the van der Waals forces, while the binding within each lamina is strongly covalent. This structure makes it easy for muscovite to slide between each lamina and cause the structural instability when it is subjected to shear force during the friction process and can accordingly result in the release of a certain amount of active oxygen atoms and Si-O bonds[7,20]. And then the active oxygen atoms with higher chemical energy can react with the matrix Fe to form Fe oxides under high pressure and fl ash temperature. In the meantime, Si-O bonds also participate in physicochemical reaction to generate SiO2[8], during which La element probably functions as a catalyst to accelerate physicochemical reactions. In the end, an induced layer of tribo fi lm mainly composed of the adsorption fi lm of La-MC and the chemical reaction fi lm mainly consisting of SiO2and Fe2O3are generated on the worn surface, which can avoid the direct contact of friction pair to enhance the friction-reduction and anti-wear properties of lithium grease.

4 Conclusions

1) La-MC composite particles were prepared through the mechanical solid-state-chemistry-reaction method, in which La(OH)3nanoparticles were coated on the surface of muscovite.

2) Both MC and La-MC can effectively improve the friction-reduction and anti-wear properties of lithium grease, and La-MC exhibited a better tribological performance than MC.

3) The La-MC composite particles can directly participate in the physicochemical reaction, and a tribo fi lm composed of the adsorption fi lm and a chemical reaction fi lm mainly consisting of Fe2O3and SiO2are generated on the worn surface, during which La element probably functions as a catalyst.

Acknowledgement: This research was supported by the Postdoctoral Science Foundation of China (XM2013018) and Logistics Project Foundation of China (Oil 20070209)

[1] Zhang B, X Y, Li X Y, et al. Tribological modification of nano-attapulgite powders on wear surface[J]. Materials Science and Engineering of Powder Metallurgy, 2012,17(4): 514-521 (in Chinese)

[2] Mookhrjee M, Stixrude L, et al. Structure and elasticity of serpentine at high-pressure[J]. Earth Planet Sc Lett, 2009, 279: 11-19

[3] Yu H L, Xu Y, Shi P J, et al. Microstructure, mechanical properties and tribological behavior of tribo fi lm generated from natural serpentine mineral powders as lubricant additive[J]. Wear, 2013, 297(1/2): 802-810

[4] Yu H L, Xu Y, Shi P J,et al. Effect of thermal activation on the tribological behaviours of serpentine ultrafine powder as an additive in liquid paraf fi n[J]. Tribology International, 2011,44(12): 1736-1741

[5] Yu H L, Xu Y, Shi P J,et al.Tribological behaviors of surface-coated serpentine ultrafine powders as lubricant additive[J]. Tribology International, 2010, 43(3): 667-675

[6] Zhng B S, Xu Y, Gao F, et al. Sliding friction and wear behaviors of surface-coated natural serpentine mineral powders as lubricant additive[J]. Appl Surf Sci, 2011, 257(7): 2540-2549

[7] Nan F, Xu Y, Xu B S, et al. Tribological behaviors and wear mechanisms of ultrafine magnesium aluminum silicate powders as lubricant additive[J]. Tribology International, 2015, 81: 199-208

[8] Nan F, Xu Y, Xu B S, et al. Effect of natural attapulgite powders as lubrication additive on the friction and wear performance of a steel tribo-pair[J]. Appl Surf Sci, 2014, 307: 86-91

[9] Nan F, Xu Y, Gao F, et al. Tribological property of attapulgite powder as lubricant additive[J]. Journal of the Chinese Ceramic Society, 2013, 41(6): 836-841 (in Chinese)

[10] Yuan K, Wang C B, Yue W, et al. Study on tribological property of muscovite as mineral lubricating oil additive[J]. Lubrication Engineering, 2008, 33(8): 61-65 (in Chinese)

[11] Wang L, Zhu D C, Chen G X. The studies of preparation and tribological behaviors of muscovite /CeO2compound particles[J]. Surface Technology, 2015(5): 72-76 (in Chinese)

[12] Xu Y, Zhang B S, Xu B S, et al. Thermodynamic characteristics and tribological properties of lanthanum/ serpentine composite lubricating material[J]. Materials Science and Engineering of Powder Metallurgy, 2011, 16(3): 349-354 (in Chinese)

[13] Zhang B S, Xu B S, Xu Y, et al. Effect of nano-scale lanthanum on phase transformation behavior of ultrafine serpentine powder[J]. Transactions of Materials and Heat Treatment, 2013, 34(12): 18-23 (in Chinese)

[14] Chen H L, Chen G X, Du P F, et al. Tribology of nanotungsten disulfide powder as an lubricating additive for lithium grease[J]. Tribology, 2015, 35(6), 651-657 (in Chinese)

[15] Gao Y J, Chen G X, Ou Y P, et al. Study on tribological properties of oleic acid-modified TiO2nanoparticle in water[J]. Wear, 2002, 252(5/6): 454-458

[16] Wang L M, Xu B S, Xu Y, et al. Tribological properties of attapulgite clay as lubricant additive for steel-steel contacts[J]. Tribology, 2012, 32(5): 493-499 (in Chinese)

[17] Gu K C, Chen B S, Wang X M, et al. Preparation, friction and wear behaviors of cerium-doped anatase nanoparticles in rapeseed oil[J]. Ind Eng Chem Res, 2014, 53(15): 6249-6254

[18] Chen W G, Gao Y Z, Zhang H C, et al. Anti-wear mechanism of the serpentine powder as self-repairing additive[J]. Tribology, 2008, 28(5), 463-468 (in Chinese)

[19] Ju C X, Wang J, Ma Jing, Wang X L, et al. Study on surface modification of muscovite[J]. Plastics Additives, 2008(1): 40-44 (in Chinese)

[20] Wang L M, Xu Y, Gao F, et al. Tribological properties of attapulgite clay as lubricant additive for steel–steel contacts[J]. Materials Science and Engineering of Powder Metallurgy, 2012, 17(5): 657-663 (in Chinese)

Received date: 2016-01-08; Accepted date: 2016-03-23.

Professor Chen Guoxu, E-mail: chen_ guoxu@21cn.com; Telephone: +86-23-86731417.

- 中国炼油与石油化工的其它文章

- Study on Preparation and Properties of Grease Based on Ultra fi ne Bentonite Powder

- Preparation and Tribological Behavior of Hydrophobic Lanthanum Borate Nanosheets in Rapeseed Oil

- Synthesis and Evaluation of Environmentally Friendly Calcium Isostearate Detergent with Excellent Oil Solubility

- Experimental and Molecular Simulations for Evaluating the Effect of Lubricity Improvers on the Property of Jet Fuel

- Analysis and Modeling of Wangqing Oil Shale Drying Characteristics in a Novel Fluidized Bed Dryer with Asynchronous Rotating Air Distributor

- Modeling of Isobutane/Butene Alkylation Using Solid Acid Catalysts in a Fixed Bed Reactor