Multivariable Model Predictive Control of p-Xylene Oxidation Process Based on Aspen Dynamics

TAO Li-li,HU Zhi-hua

(School of Intelligent Manufacturing and Control Engineering,Shanghai Second Polytechnic University, Shanghai 201209,P.R.China)

Multivariable Model Predictive Control of p-Xylene Oxidation Process Based on Aspen Dynamics

TAO Li-li,HU Zhi-hua

(School of Intelligent Manufacturing and Control Engineering,Shanghai Second Polytechnic University, Shanghai 201209,P.R.China)

Terephthalic acid(TPA)is one of the main raw materials used to produce polyester.In industry,most of TPA is produced by the liquid-phase catalytic oxidation of p-xylene(PX).PX oxidation process is a multivariable,strong-coupling, nonlinear and complicated system.On the basis of the steady-state model established previously,a dynamic model with PID controllers was established and the dynamic responses of the process have been studied.Due to the deficiency of the traditional single input single output(SISO)PID control,the multivariable model predictive control is implemented on the dynamic model.Simulation results of the control system show that model predictive control(MPC)based on mechanism model can greatly reduce production fluctuation and realize a smooth running process.This can serve as the foundation of the smooth operation and advanced control strategy of this process.

Aspen Dynamics;p-xylene oxidation process;multivariable model predictive control

0 Introduction

Terephthalic acid(TPA)is one of the main raw materials used to produce polyester,including polyester fibre,polyethylene terephthalate(PET)bottle resin and polyester film[1].Until 2014,global TPA markets had been growing strongly at rates of around 7%—9%per year.Inindustry,mostofTPAisproducedbytheliquidphase catalytic oxidation of p-xylene(PX).Figure 1 shows the simplified flow-sheet of a Mitsui PX oxidation process in a PTA plant.Since p-xylene oxidation process is a multivariable,strong-coupling,nonlinear and complicated system,control and optimization of this process have been widely concerned by many researchers[2].Onthebasisofthesteady-statemodelestablished previously[3],a dynamic model with PID controllers was established and the dynamic responses of the process have been studied.Due to the deficiency of the traditional single input single output(SISO)PID control,the multivariable model predictive control is implemented on the dynamic model.At present,most advancedcontrolmodelsaredevelopedbytheindustrial test data which are time-consuming and expensive,thus cannot be applied at other conditions.Because the dynamic model used in this paper is on the basis of the reaction mechanism,to some extent,it can reflect the real industry process.Based on our previous work[4-7],design and simulation of advanced control scheme of the PX oxidation reaction process are investigated in this paper.

Industrial PX oxidation process is a complex multi-scale and multivariable system.Worth to be noticed,a multivariable system is quite different from many single-variable systems.The easiest operating point of the system is generally in the center of the operating area,and the response time of the disturbanceat this time is the largest.However,the system optimal operating point is often located at several constraint boundaries(as shown in Fig.2).In fact,it is difficult for the traditional PID control system to make the process operating at several constraint boundaries.Besides,it is unrealistic for the operator to monitor many variables all the time.The multivariable predictive control algorithm can realize the overall control of complex industrial processes.In a multivariable control system, usually all the input can influence each output in different degree.The degree of the effect depends on the dynamic characteristics of the system for each channel or the priority levels of the output variables set by the controller.In this way,the entire industrial system can operate safely and economically.

Fig.2 The optimal operating range and the safe operating range

1 Dynamic Matrix Control(DMC) Multivariable Model Predictive Control for PX Oxdiation Process

1.1DMC Multivariable Model Predictive Control

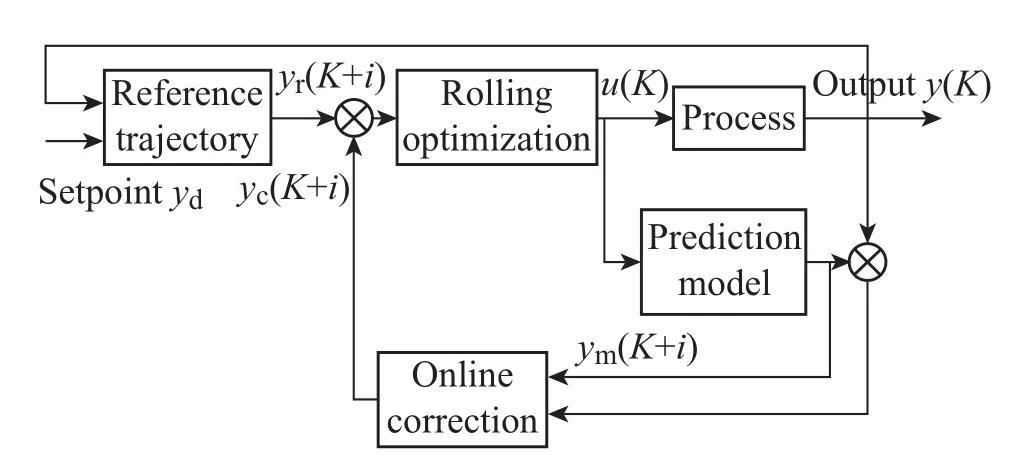

The principle of multivariable predictive control and single-variable predictive control is almost the same,involving three basic characteristics:prediction model,rolling optimization and feedback correction[8]. The predictive control system structure is shown in Fig.3.

Fig.3 The figure of the predictive control

The prediction model is the foundation of the multivariable predictive control.The main function of the model is forecasting the process output in a future time domain according to the history information and the future input.There are many kinds of prediction model, such as:the transfer function,state equations and step response,etc.

The optimization strategy of the predictive control is the rolling finite horizon optimization.This means that the optimization is not achieved through a simple offline optimization but continuous online optimization time after time.The disadvantage of the finite timedomain optimization is that it can only obtain the local optimal solution.However,the continuous rolling optimization can overcome the uncertainty caused by the model mismatch,disturbances and time-varying problems.Therefore,it is more suitable for complex industrial processes.

The prediction errors between the predictive output and the actual output are widely exist because of the model mismatch and disturbances.This problem can usually be solved by means of the feedback correction.

DMC is an advanced control algorithm established on the basis of step response.DMC are widely used in the industrial process because of several reasons:the step response in the industry is usually easy to obtain, it can overcome the impact of various uncertainties and does not require complex model identification.A model predictive software(DMCplus)was developed by AspenTech company by combining the steady-state optimization and composite linear programming.

In the DMCplus software,the process controlled variables can be controlled in a constraint range.If the system disturbances occur,DMCplus can figure out both the current and future moving direction and magnitude of the manipulated variables.During each control operation,DMCplus utilizes linear programming to solvethe optimal solution of operating variables.It contains the following features.

(1)The robustness of the controller can be strengthened by the track section control,singular value analysis of dynamic matrix and the design of robust parameters.

(2)The architecture includes a two-layer design (steady-state optimization layer and dynamic control layer)and three models(model prediction,steady-state optimization and dynamic control).

(3)Steady-state optimization includes:estimation of initial feasible solution,adjustment of soft constraints,economic optimization and so on.

(4)It can solve the problems such as the regulating valve saturation and the instrument failure.

(5)It can handle the non-square system and the change of freedom,etc.

1.2Multivariable Model Predictive Control Simulation of PX Oxidation Process Based on Aspen Dynamics

In our previous work,a dynamic model with PID controllers was established.With respect to the air feed, the inlet gas is flow controlled.During the design of advancedcontrol scheme,cascade control scheme is introduced.The O2concentration in the off-gas is controlled by the flowrate of air feed.According to the analysis of previous work and the requirements of the real industrial process,the input and output variables of the controllers and the variation ranges are shown in Table 1.

Tab.1 The range of the manipulated variable and the controlled variable

The effect of an model predictive control mainly depends on the accurate predition model.In an model predictive control(MPC)project,testing and identification of the model is the most complex and timeconsuming work.In this paper,DMCplus is used to identify the model.The accurate of the model identification will directly affect the design of the control system and the correctness and confidence of the system simulation.

Currently,DMCplus mainly contains two identification methods:finite identification response(FIR) and subspace identification.The FIR method has been widelyusedinindustrybecauseithasmanyadvantages:there is no need to assume the model order,it is unbi-ased and consistent,and it is able to handle complex dynamic characteristics[9-10].Meanwhile FIR method also has some shortcomings.For example,many“glitches”can exist in the response curve of the identification due to the industrial noise.If they are applied to the process control,big fluctuation will occur,whereas the operating point of the process is generally smooth[11].To solve this problem,a penalty term is usually added to the criterion function.In DMCplus,the smoothing factor is introduced to solve this problem.In addition,the relationship between the data length and the model parameters has a great influnce on the identification of FIR[12].More identification parameters requires longer length of the corresponding input and output data.If the data length is not long enough,big identification error will occur.Generally,the range of model parameters is 30—120.Another important parameter in the FIR method is the steady-state time.If the steady-state time is chosen improperly,steady-state error will appear. Usually,in an industrial process,we take the minute as the unit of the sampling time.Since the process often includes many sub-processes,the steady-state time for the whole process should be the longest one of all the sub-processes.In DMCplus,a linear parameter model is obtained by the FIR method and it can be expressed in an incremental form as follows[13-15].The advantage of the incremental expression is that it can reduce the influence of the unmeasured disturbances[16].

where U is the manipulated variable vector,Y is the manipulated variable vector,X is the state variable vector and V is the measurable disturbance vector,εkis the immeasurable disturbance.

The first step of the simulation of the PX oxidation process based on the DMCplus is step response tests of the process dynamic model.Step tests of a series of single-variable are usually carried out in industrial model identification.According to the characteristics of the reaction process,the pre-design test signals of the reactor liquid feed flow control valve,the reactor air feed flow control valve and the valve position of the water outflow are imposed on the dynamic model, respectively.At the same time,the other manipulated variables are kept constant.The test signals mentioned above are shown in the Fig.4.

Fig.4 The test signal plot

Step responses of the controlled variables are shown in Fig.5.

In DMCplus,the correlation degree between the the control variables and controlled variables are obtained by the use of“case”.In the“case”section, you can set the identification parameters of control variables,controlled variables and other model variables.And results of model identification at different conditions can be achieved by the“predication”section.The predication results of the PX oxidation process of three manipulated variables are shown in Fig.6.On the basis of the prediction results the identification model is finally obtained and can be seen in Fig.7.The offline design and simulation of the advanced control are carried out on the basis of the model.In DMCplus,a series of LP/QP(Linear programming/Quadratic programming)are used to solve the local steady-state optimization problem.This means in each control cycle, the controller make efforts to minimize the deviation between the actual value and the target value of the controlled variables.If the controller cannot meet all the targets of the system,it will give up some control objectives according to their importance.And the importance degree of the controlled variables can be set by giving them different weights.Then the controller gives up some control targets due to their weights.The“rank”is used to distinguish the importance level of the controlled variables during the parameter tuning of the DMC controller.The controller must first make sure the controlled variables with the high level rank(ie,small values)is under control.With respect to the PX oxidation process,the main control requirements are as follows:

(1)O2concentration in the off-gas is controlled in a given range.

(2)On the premise of guarantee the stability of the O2concentration,try to control the temperature within a given range.

(3)On the premise of guarantee the first two conditions,try to control COxoncentration within a given range.

Fig.5 The response curve of the test signal

Fig.6 The predication result of the DMCplus

Fig.7 The result of the model identification

Finally,the DMCplus multivariable predictive control system based on the Aspen Dynamics dynamic model are developed,as shown in Fig.8.The PID controllers of the process are replaced by the DMC-plus controller.In order to verify the control efficiency of multivariable predictive control,several tests will be done with the O2concentration in the off-gas and the reaction temperature in violation of constraints.

Fig.8 The flow-sheet of the DMC multivariable predictive control based on Aspen Dynamics(FC1101:PX feed;FC1102:HAC and catalyst feed;FCPX:PX flow controller;FCAIR:air flow controller;FCHAC:ratio controller;FI1209:air feed;TC1 and TC2:temperature controllers;LC1 and LC2:level controllers;WG:off-gas;OUTFLOW:TA product;B1-B27:valves.)

The control quality of the process when the O2concentration constraint is violated is shown in Fig.9. A 0.7%margin step disturbance(0.1%exceed the upper bound)from the initial steady state is imposed on the O2concentration,and the controller pulled the O2concentration back to the allowable range by increasing the load,reducing the air feed and increasing the outflow water.The new steady-state data(steady-state 2) are given in Table 2.Then a-2%margin step disturbance(0.8%exceedthelowerbound)isimposedontheO2concentration,and the controller still can pull the O2concentration back to the allowable range by all means. The new steady-state data(steady-state 3)are given in Table 2.

Fig.9 The control quality of the disturbance of the O2in the off-gas

Tab.2 The steady-state results of the simulation

The control quality of the process when the reactor temperature constraint is violated is shown in Fig.10. A 1.2°C margin step disturbance(0.2°C exceed the upper bound)from the initial steady state is imposed on the the reactor temperature,and the controller has enough freedom to pull the temperature back to the allowable range.The new steady-state data(steady-state 2)are given in Table 3.Then another 1.2°C margin step disturbance(1.2°C exceed the upper bound)is imposed on the the reactor temperature.Since the constraint violation is too severe,the O2concentration reach the constraint boundary and try to pll back the temperature. Unfortunately,it still cannot overcome the disturbance. So the controller give up the temperature.The new steady-state data(steady-state 3)are given in Table 3. The simulation results show that the O2concentration and the temperature can influence each other,so they should be set in a reasonable range.

Fig.10 The control quality of the disturbance of the temperature

Tab.3 The steady-state results of the simulation

2 Conclusions

The optimization and control of the PTA production process has been widely concerned by many researchers.The test of dynamic characteristics should be carried out before the implementation of the advanced control scheme.At present,most advanced control models are developed by the industrial test data which are time-consuming and expensive,thus cannot be applied at other conditions.Because the dynamic model used in this paper is on the basis of the reaction mechanism,to some extent,it can reflect the real industryprocess.Based on our previous work,design and simulation of advanced control scheme of the PX oxidation reaction process are investigated in this paper.The simulation results showed that the proposed multivariable predictive control method can provide operating guidance on the smooth operation of the industrial process.

References:

[1]LI X,XIE G,HUA W Q.Key problems and research program for PTA process domestic development[J].Polyester Industry,2001,14(1):1-7.

[2]LI S.Influence of p-xylene(PX)accumulation on the operation of Pure Terephthalic Acid(PTA)Solvent Dehydratic Distillation Column[J].Industrial&Engineering Chemistry Research,2009,48(13):6358-6362.

[3]TAO L L,QIAN F.Design and control of a p-xylene oxidation process[J].Chinese Journal of Chemical Engineering, DOI:10.1016/j.cjche.2015.09.009,2015.

[4]QIAN F,TAO L L,SUN W Z,et al.Development of a free radical kinetic model for industrial oxidation of p-xylene based on artifical network and adaptive immune genetic algorithm[J].Industrial&Engineering Chemistry Research, 2012,51(8):3229-3237.

[5]TAO L L,KONG X D,ZHONG W M,et al.Modified selfadaptive immune genetic algorithm for optimization in the combustion side reaction of p-xylene oxidation[J].Chinese Journal of Chemical Engineering,2012,20(6):1047-1052.

[6]TAO L L,ZHONG W M,LUO N,et al.Adaptive weighted least square support vector machine regression with application to estimate kinetic parameters for industrial oxidation of p-xylene[J].CIESC Journal,2012,63(12):3943-3950.

[7]TAO L L,HU Z H,XU B.Optimization of operating conditions for industrial p-xylene oxidation process based on a novel adaptive immune genetic algorithm[C]//The 11th World Congress on Intelligent Control and Automation (WCICA2014).Shenyang,China:Institute of Electrical and Electronics Engineers,2014.

[8]HENSON M A.Nonlinear model predictive control:Current status and future directions[J].Computersa&Chemical Engineering,1998,23(2):187-202.

[9]NIKOLAOU M,VUTHANDAM P.FIR model identification:parsimony through kernel compression with wavelets [J].AIChE Journal,1998,44(1):141-150.

[10]DAYAL B S,MACGREGOR J F.Identification of finite impulse response models:Methods and robustness issues [J].Industrial&Engineering Chemistry Research,1996, 35(11):4078-4090.

[11]WANG Z,DAI L K.FIR model identification:The algorithms based on the polynomial interpolation[J].Mechanical and Electrical Engineering Magazine,2000,17(2):90-93.

[12]HONG Y P.FIR Model identification algorithm with applications[D].Zhejiang:CollegeofInformationEngineering, Zhejiang University of Technology,2011.

[13]FEDELE G.A new method to estimate a first-order plus time delay model from step response[J].Journal of the Franklin Institute,2009,346(1):1-9.

[14]SO H.On time delay estimation using an FIR filter[J].Signal Processing,2001,81(8):1777-1782.

[15]ZHANG Y,YANG H Z,DING F.System identification method for colored noises[J].Journal of Nanjing University of Aeronautics&Astronautics,2006,38(B07):167-171.

[16]CUTLER C,YOCUM F.Experience with the DMC inverse for identification[C]//Proceedings of the 4th International Conference on Chemical Process Control.Amsterdam:Amsterdam TX,1991.

1001-4543(2015)04-0317-08

2015-03-26

陶莉莉(1983—),女,江苏人,讲师,博士,主要研究方向为复杂工业过程的建模、优化与控制。电子邮箱lltao@sspu.edu.cn。

上海第二工业大学重点学科建设项目(No.XXKPY1308)、上海第二工业大学校基金(No.EGD14XQD02)、上海高校青年教师培养资助计划(No.ZZegd14013)资助

基于Aspen Dynamics的对二甲苯氧化反应器的多变量预测控制

陶莉莉,胡志华

(上海第二工业大学智能制造与控制工程学院,上海201209)

精对苯二甲酸(Pured Terepthalic Acid,PTA)作为工业上生产聚酯的重要原料,主要是由对二甲苯(p-xylene,PX)在高温下液相催化氧化获得。PX氧化的生产过程是一个多变量、多尺度、动态、强耦合、非线性的复杂系统,而目前工业上应用较多的传统单回路PID(比例、积分、微分)控制在处理复杂的多变量系统时存在很多不足。为此,在所建立的基于Aspen Dynamics的PX氧化反应器动态模型基础上,采用动态矩阵多变量预测控制(DMC)方法对反应器的平稳控制进行仿真研究。仿真结果表明,由于该动态模型是基于机理建立的,能够较好反映实际工业反应过程,以此为基础建立的DMC多变量预测控制方法对对PX氧化反应过程的平稳控制具有良好的效果,可以作为指导工业预测控制实施的依据。

Aspen Dynamics;对二甲苯氧化反应器;多变量预测控制

TP29

A