Microstructure and pitting corrosion of armor grade AA7075 aluminum alloy friction stir weld nugget zone-Effect of post weld heat treatment and addition of boron carbide

P.VIJAYA KUMAR,G.MADHUSUDHAN REDDY,K.SRINIVASA RAO*

aDepartment of Mechanical Engineering,R.I.T.,Visakhapatnam,India

bDefence Metallurgical Research Laboratory,Hyderabad,India

cDepartment of Metallurgical Engineering,Andhra University,Visakhapatnam,India

Microstructure and pitting corrosion of armor grade AA7075 aluminum alloy friction stir weld nugget zone-Effect of post weld heat treatment and addition of boron carbide

P.VIJAYA KUMARa,G.MADHUSUDHAN REDDYb,K.SRINIVASA RAOc,*

aDepartment of Mechanical Engineering,R.I.T.,Visakhapatnam,India

bDefence Metallurgical Research Laboratory,Hyderabad,India

cDepartment of Metallurgical Engineering,Andhra University,Visakhapatnam,India

Friction stir welding(FSW)of high strength aluminum alloys has been emerged as an alternative joining technique to avoid the problems during fusion welding.In recent times FSW is being used for armor grade AA7075 aluminum alloy in defense,aerospace and marine applications where it has to serve in non uniform loading and corrosive environments.Even though friction stir welds of AA7075 alloy possess better mechanical properties but suffer from poor corrosion resistance.The present work involves use of retrogression and reaging(RRA)post weld heat treatment to improve the corrosion resistance of welded joints of aluminum alloys.An attempt also has been made to change the chemical composition of the weld nugget by adding B4C nano particles with the aid of the FSW on a specially prepared base metal plate in butt position. The effects of peak aged condition(T6),RRA and addition of B4C nano particles on microstructure,hardness and pitting corrosion of nugget zone of the friction stir welds of AA7075 alloy have been studied.Even though RRA improved the pitting corrosion resistance,its hardness was slightly lost.Significant improvement in pitting corrosion resistance was achieved with addition of boron carbide powder and post weld heat treatment of RRA.

FSW;AA7075;Post weld heat treatment;Pitting corrosion

1.Introduction

High strength aluminum alloys are utilized extensively in the defense,aerospace,automotive and structural applications. AA7075 alloy is a high strength aluminum alloy of the 7000 series family based on Al-Zn-Mg system,in which Mg combines with Zn,and forms the strengthening precipitates,such as MgZn2and Mg3Zn,contribute to the improvement inmechanical properties.Their strength is derived from the precipitation of η′phase(semi-coherent MgZn2)in the grain interiors and of η phase(non-coherent MgZn2)along the grain boundaries[1,2].The attributes such as high durability,low density,superior cryogenic properties and response to age hardening made these alloys as a safe choice for fabricating armor plates,transportable bridges,girders,vehicles for military and railway transport systems,storage tanks,naval and marine applications.The fusion welding of AA7075 alloys is unattractive as the weld nugget shows poor microstructural and mechanical properties due to the presence of brittle dendritic structure,porosity,distortion and residual stresses,alloy segregation,hot cracking and hydrogen entrapment.Friction stir welding(FSW)is an autogenous solid state weldingtechnique where the joints are produced in solid state.The problem with fusion welded joints is overcome by using the FSW as there is no melting and recasting of the base material. Even though the joints of FSW show better mechanical properties than the fusion welded joints,the nugget zone(NZ)suffersfromsofteningandpoorcorrosionresistance. Abnormal grain growth and thermal cycles,wide precipitatefree zones(PFZs)and coarse precipitates are the causes for poor corrosion resistance of NZ.The dissolution of grain boundary phases along the grain boundaries in the weld nugget zone where the Cu-Zn rich precipitates exists also contributes to corrosion in NZ.The onion ring bands that are created during FSW cause microstructural discontinuities in NZ leading to corrosion.

The literature review[3-10]revealed that the post weld heat treatments(PWHT)have been in use for improving the mechanical properties and corrosion resistance of NZ of friction stir welded(FSWed)joint in the high strength aluminum alloys.As-welded joints of 7xxx series aluminum alloys were treated in peak-aged condition(T6)for improving the strength and hardness but suffer from poor corrosion resistance due to precipitate free zones(PFZs)at the grain boundaries.Retrogression and reaging(RRA)is a specially developed heat treatment and has been studied by many authors for improving the corrosion resistance of FSWed AA7075 alloys[11,12]. With RRA treatment,corrosion resistance is improved due to reduced dislocation density in the nugget,increased grain boundary precipitate size,spacing and the presence of high volume fraction of η′with small amounts of η precipitates[13].The dissolution of GP zones during retrogression and the segregation of η′phase during subsequent re-aging reduce the hardness,but the rupture toughness is improved[14-16].The η′particles are responsible for the strength of the alloy while the η precipitates located at grain boundaries are responsible for the corrosion resistance of alloy.The corrosion resistance of the alloy improves with the increase in volume fraction of grain boundary precipitates.Dissolution of grain boundary precipitates during retrogression and re-precipitation in the matrix during re-aging improve the corrosion resistance.RRA of FSWed AA7075 alloy shown improved corrosion resistance,but with the expense of the joint strength[17].As the 7xxx series aluminum alloy products are used in the harsh environments like military,marine and aerospace,further improvement of corrosion resistance and strength of the joints is needed.The mechanical properties and corrosion resistance of the aluminum alloy were improved by changing the chemical composition of the weld nugget.This can be achieved by the introduction of nano sized ceramic particles with the aid of FSW process.The literature on this research area of FSW is limited.Many authors reported that post weld heat treatments like peak aging(T6),retrogression and reaging(RRA)improve weld properties with modification of size,shape and distribution of secondary strengthening particles[18].The present study is significant as the studies related to microstructure and pitting corrosion of armor grade AA7075 aluminum alloy friction stir weld nugget zone effected by post weld heat treatment and addition of boron carbide have notbeen reported so far.In view of the above facts,the present work has been aimed to improve the pitting corrosion resistance and mechanical properties of the friction stir welds of AA7075 alloy by using post weld heat treatments viz.T6,RRA and addition of boron carbide(B4C)nano particles.B4C was chosen for reinforcement due to its density(2.52 g/cm3)and elastic modulus of(427 GPa).

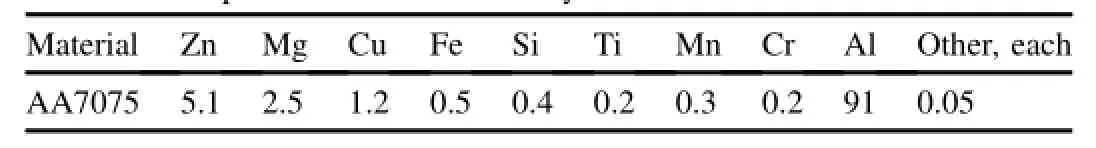

Table 1 Chemical composition of AA7075 Alloy.

2.Experimental details

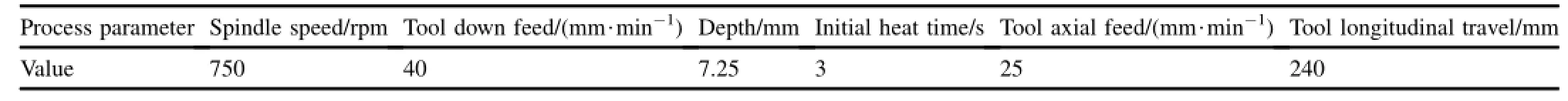

30 μm-sized B4C powder was ball-milled in a high energy planetary ball mill in wet mode using toluene as a liquid medium for 15 h.After the ball milling,the particle size was measured with XRD and was found to be 60 nm.The material used in this study was AA7075 alloy rolled plates with 8 mm thickness.Chemical composition of the base metal is given in Table1.Thedimensionsoftheplateswere 240 mm×150 mm×8 mm.The top surface of the plate was drilled with 1 mm diameter drill at a distance of 2 mm in a zigzag form,as shown in Fig.1.The holes are drilled along the length of the tool travel on the plates.The depth of the holes was 4 mm.The 60 nm-sized B4C powder was filled in the drilled holes made on the plates.Initially the powder-filled holes of the plates were closed with the help of friction stir processing(FSP)tool.After processing with FSP tool,the processed region was then friction stirred with FSW tool.The FSP and FSW tools used for making the joint with the nano powder are shown in Fig.1.The schematic representation of plates with holes for FSW is shown in Fig.1.The optimum process parameters used for FSWare given in Table 2.Friction stir welding of same alloy was performed under the same welding conditions without the addition of the B4C particles for comparative study.The samples were extracted from the welded plates for metallography,hardness measurement,andcorrosion studies.All the samples are heat treated to T6 and RRA conditions.Heat treatment procedure is given in Table 3. Optical and electron microscopy studies are carried out to study the microstructural features of base metal and friction stir welded samples.The Vicker's hardness of the samples was measured with 1 kgf load and 15 s as dwell time.

Fig.1.Preparation of plates and tools used for FSW.

Table 2 Process parameters of friction stir welding.

Table 3 Post weld heat treatment procedures.

Software based electrochemical system of GILL AC was used to perform potentiodynamic polarization tests to study the pitting corrosion behaviors of the AA7075 aluminum alloys before and after friction stir welding.The potential at which current increased drastically was considered to be the critical pitting corrosion potential Epit.Specimens exhibiting relatively more positive potential were considered to have better pitting corrosion resistance.All the above tests were conducted in 3.5%NaCl and the polarization graphs were recorded.

3.Results and discussion

3.1.Microstructure

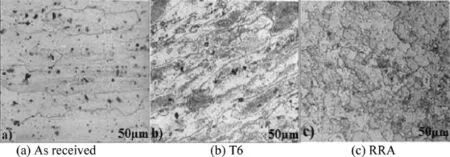

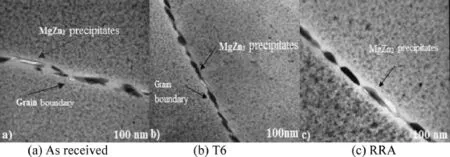

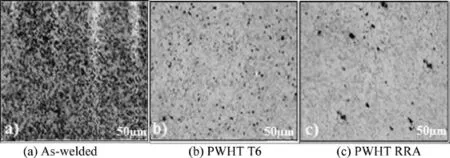

Fig.2 shows the optical micrographs of grain structure developed in the base AA 7075 aluminum alloy and clearly reveals the elongated pancake shaped grains.The TEM micrographs of AA 7075 aluminum alloy in different tempers are given in Fig.3.Grain boundary precipitates(MgZn2)are observed in all three conditions with different morphologies. In T6 condition,the microstructure has relatively coarse and closely spaced precipitates along the grain boundaries and fine precipitates within the grains.On the other hand,in RRA the grain boundary precipitates are continuous and coarser than those of T6 condition due to the formation of additional grain boundary precipitates during the initial phase of retrogression. The optical micrographs of nugget zone without boron carbide are given in Fig.4.The fine and equiaxed recrystallized grain structure in the nugget was developed due to tool stirring action and temperature.The grain structure shows finer grains compared to the base metal.

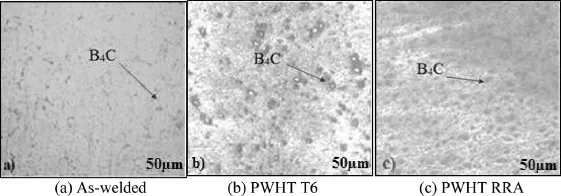

The microstructure of the nugget zone with carbide powder reinforcement(Fig.5)shows the dynamic recrystallization due to severe plastic deformation.The finely dispersed B4C particles are accumulated at the grain boundaries of the welds. These reinforcement particles at the grain boundaries along with the strengthening precipitates(MgZn2,Mg3Zn)are the main contributors to the improvement of hardness and corrosion resistance.The movement of dislocations in the matrix is arrested more effectively by the nano B4C particles.The size of the B4C particles was further reduced due to the tool force and the stirring action.These finer particles also restrict the grain growth in the nugget zone.

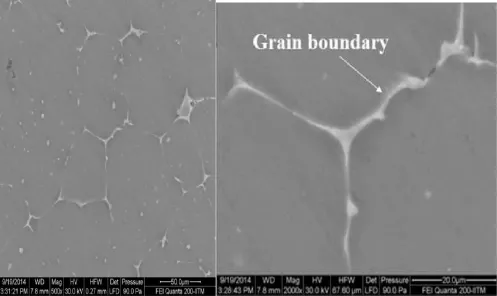

Figs.6-8 shows the SEM images of the nugget zone in aswelded,T6 and RRA conditions.The As welded nugget zone in the Fig.6 shows dynamically recrystallized structure due to the frictional heat and the presence of B4C nano particles. There was no significant grain growth in the nugget zone as the reinforcement particles acted as barriers to the grain boundary migration.The fine grain structure in the nugget zone was observed due to the presence of low angle boundaries and B4C reinforcements which supports the nucleation of fine grains.Agglomeration of B4C particles at the grain boundaries was also observed in the as welded nugget zone.

Fig.2.Optical micrographs of AA7075 alloy base metal.

Fig.3.TEM photographs of AA7075 alloy base metal.

Fig.4.Optical micrographs of nugget zone without B4C powder.

In T6 condition(Fig.7),a uniform and continuous grain structure was observed.The continuous fine grain structure and thepresenceofparticlerichandstrengtheningprecipitatesatthe grain boundaries are the causes of increased hardness.In RRA post weld condition,the grain boundaries were discontinuous and the reinforcement particles were dispersed around thegrain boundaries.Grain coarsening was also evident,as shown in Fig.8.The particle rich and particle free regions were observed intheRRAsampleduetothedevelopmentofnonuniformgrain structure.The particle free region undergoes the grain growth and the particle rich region resists the grain growth.

3.2.Hardness measurements

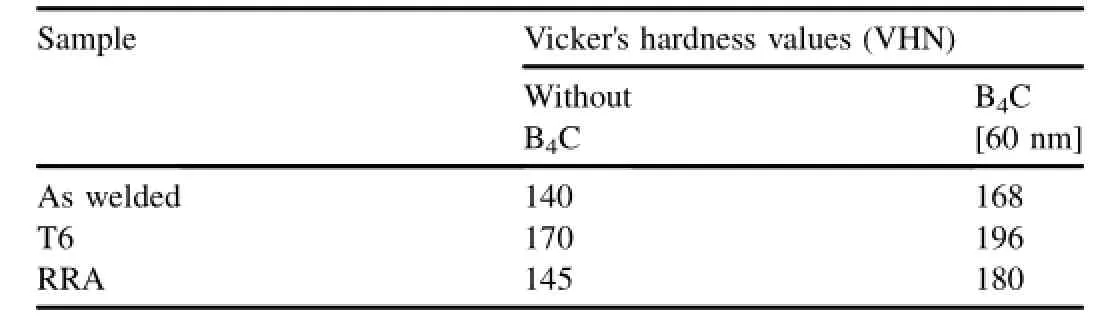

From Table 4 and Fig.9,the hardness of nugget zone is relatively low and may be attributed to the softening of the nugget zone and the dissolution and distribution of strengthening precipitates.It is evident that,after PWHT,the hardness was high in peak aged condition(T6)in the nugget zone of the welds.The hardness was improved significantly with the addition of nano B4C powders in the nugget zone(NZ).These B4C particles acts as reinforcement particles in NZ and are agglomeratedatthegrainboundaries,leadingtothe improvement of the hardness.With RRA treatment on FSW AA7075 alloy without B4C particles,there was a slight reduction in the hardness values.The reduction in hardness may be due to the dissolution of GP zones during retrogression and growth and segregation of η′phase during subsequent reaging.

Fig.5.Optical micrographs of nugget zone with the addition of B4C.

Fig.6.SEM photographs of nugget zone with the addition of B4C in as-welded condition.

Fig.7.SEM photographs of nugget zone with the addition of B4C in PWHT T6 condition.

Fig.8.SEM photographs of nugget zone with the addition of B4C in PWHT RRA condition.

Table 4 Vicker's hardness values.

Fig.9.Variation of hardness in nugget zone.

The hardness difference between the T6 and RRA conditions in NZ with the addition of B4C nano particle was very less.Refs.[19-23]reported on FSW and FSP of aluminum metal matrix composites with an aim to improve the mechanical properties and to improve the surface characteristics. During FSW of aluminum composites,the dispersoids or strengthening particles in the matrix are distributed uniformly throughout the weld nugget region due to the stirring action of the tool.

When hard nano particles are added to the base aluminum alloy with the aid of FSW,the fine particles are expected to be agglomerated and uniformly distributed in the nugget region of the joint.In the present investigation,the reinforcement of B4C nano particles in the weld nugget improved the hardness significantly,and the hardness in RRA condition is very close to that in T6 condition.

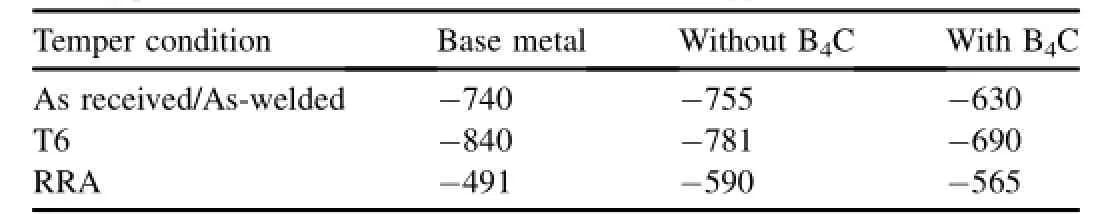

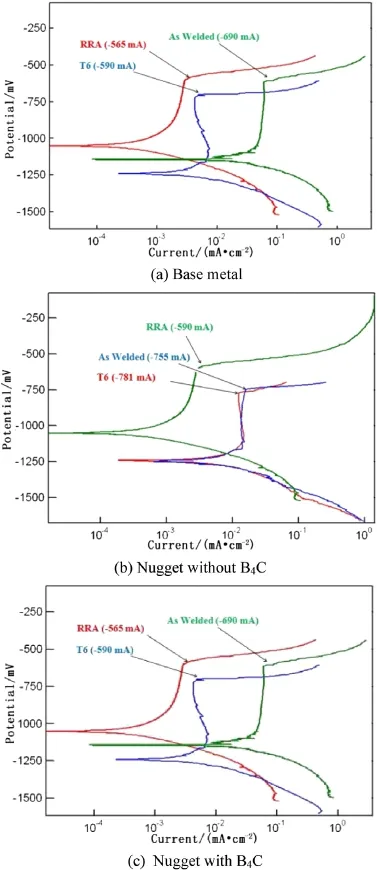

3.3.Pitting corrosion

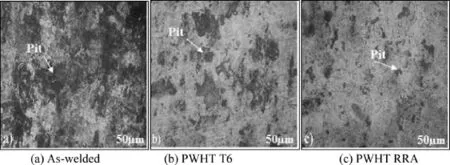

The pitting potential values of weld nugget zone with and without B4C nano powder are given in Table 5.Potentiodynamic polarization curves are shown in Fig.10(a)-(c). The resistance to pitting corrosion was improved in the weld nugget formed by reinforcing B4C particles.The hard particles act as insulators and prevent the galvanic coupling between the matrix and the precipitates,thereby improving the resistance to pitting corrosion.The pitting corrosion resistance was found to be improved significantly by the addition of B4C nano particles.The density of finer particles also increases the chances of segregation at the grain boundaries,thereby improving the resistance to pitting corrosion.There was asignificant improvement of pitting corrosion resistance in RRA condition due to the combined effect of reinforcements and microstructural changes of the nugget to RRA treatment. Redistribution of grain boundary precipitates,elimination of PFZs and more number of coherent precipitates in the matrix are the microstructural features that help in improving the pitting corrosion resistance.Fig.11 shows the optical micrographs of specimens after pitting corrosion testing.It is evident that the pit formation is less in the RRA sample compared to as-welded and T6 samples,which is clear indication of improved pitting corrosion resistance.

Table 5 Pitting potential values(mV)of base metal and nugget zone.

Fig.10.Potentio-dynamic polarization curves.

Fig.11.Optical micrographs of nugget zone with B4C after pitting corrosion test.

4.Conclusions

1)Friction stir welding of AA7075 alloy with the addition of boron carbide powder resulted in the improved hardness and refinement of microstructure in nugget zone.

2)Microstructure of nugget zone was found to be responsive to the post weld heat treatments of peak-aging(T6),retrogression and RRA.

3)RRA treatment with the addition of boron carbide powder resulted in improvement in hardness of weld nugget and the increased hardness is attributed to the uniform distribution of strengthening precipitates in the matrix and particle strengthening.

4)Pitting corrosion resistance of friction stir weld nugget was significantly improved in RRA condition of the weld nugget with the addition of B4C powder.

5)Optimum combination of strength and corrosion resistance of armor grade AA7075 alloy friction stir weld can be achieved by the addition of B4C powder and post weld heat treatment of retrogression and re-aging.

Acknowledgments

The authors would like to thank Dr.A.Ghokale,Director,Defense Metallurgical Research Laboratory,Hyderabad,India for his continued encouragement and permission to publish this work.

[1]Fuller Christian B,Mahoney Murray W,Calabrese Mike.Evolution of microstructure and mechanical properties in naturally aged 7050 and 7075 Al friction stir welds.Mater Sci Eng A 2010;527(9):2233-40.

[2]BahramiMohsen,DehganiKamran,GiviMohammadKazem Besharati.A novel approach to develop aluminum matrix nanocomposite employing friction stir welding technique.Mater Des 2014;53:217-25.

[3]Sharma Chaitanya,Dwivedi Dheerendra Kumar,Kumar Pradeep.Effect of welding parameters on microstructure and mechanical properties of friction stir welded joints of AA7039 aluminum alloy.Mater Des 2012;36:379-90.

[4]Azimzadegan T,Khalaj GH,Kaykha MM,Heidari AR.Ageing behavior of friction stir welding AA7075-T6 aluminum alloy.Comput Eng Syst Appl 2011;Vol.II:183-7.

[5]Venugopal T,Srinivasa Rao K,Prasad Rao K.Studies on friction stir weldedAA7075aluminumalloy.TransIndianInstMetals 2004;57(6):659-63.

[6]Pumchan Wichai.The influences of the friction stir welding on the microstructure and hardness of aluminum 6063 and 7075.In:2011 International Conference on Advanced Materials Engineering IPCSIT15;2011.p.31-5.

[7]Choi Don-Hyun,Kim Yong-Il,Kim Dae-Up.Effect of SiC particles on microstructure and mechanical property of friction stir processed AA6061-T4.Trans Nonferrous Metal Soc China 2012;22(s3):s614-8.

[8]Mahoney MW,Rhodes CG,Flintoff JG.Properties of friction-stir-welded 7075 T651 aluminum.Metallurgical Mater Trans A 1998;29A:1955.

[9]Srinivasa Rao K,PrasadRao K.Pitting corrosion of heat-treatable aluminium alloys and welds:a review.Trans Indian Inst Metals 2004;576:593-610.

[10]Hassan KHz AA,Norman AF,Price DA.Stability of nugget zone grain structures in high strength Al alloy friction stir welds during solution treatment.Acta Mater 2003;51(7):1923-36.

[11]Holt RT,Raizenne MD,Wallace W.RRA heat treatment of large Al 7075-T6 components.In:RTO AVT Workshop on“New Metallic Materials for the Structure of Aging Aircraft”;1999.7:1-7:12.

[12]Karaaslan A,Kaya I,Atapek H.Effect of aging temperature and of retrogression treatment time on the microstructure and mechanical propertiesofalloyAA7075.MetalSciHeatTreat 2007;49(9-10):443-7.

[13]Yeni C,Sayer S,Ertugrul O,Pakdil M.Effect of post-weld aging on the mechanical and microstructural properties of friction stir welded aluminum alloy 7075.Archives Mater Sci Eng 2008;34(2):105-9.

[14]Su Jian-Qing,Nelson Tracy W,Sterling Colin J.Microstructure evolution during FSW/FSP of high strength aluminum alloys.Mater Sci Eng A 2005;405(1-2):277-86.

[15]Gan Yong X,Solomon Daniel,Reinbolt Michael.Friction stir processing of particle reinforced composite materials.Materials 2010;3(1):329-50.

[16]Ramesh R,Murugan N.Microstructure and metallurgical properties of aluminium 7075-T651 alloy/B4C 4%vol.surface composite by friction stir processing.Adv Mater Manuf Charact 2013;3(1):301-6.

[17]Zaid HR,Hatab AM,Ibrahim AMA.Properties enhancement of Al-Zn-Mg alloy by retrogression and re-aging heat treatment.J Min Metal 2011;47(1).B:31-35.

[18]Kashani-Bozorg SF,Jazayeri K.Formation of Al/B4C surface nano composite layers on 7075 Al alloy employing friction stir processing. AIP Conf Proc 2008;1136(1):715-9.

[19]Cioffi F.Friction stir welding of thick plates of aluminum alloy matrix composite with a high volume fraction of ceramic reinforcement. Compos Part A 2013;54:117-23.

[20]Shafiei-Zarghani A.Microstructures and mechanical properties of Al/ Al2O3 surface nano-composite layer produced by friction stir processing. Mater Sci Eng A 2009;500:84-91.

[21]Bahrami Mohsen,Givi Mohammad Kazem Besharati.On the role of pin geometry in microstructure and mechanical properties of AA7075/SiC nano-composite fabricated by friction stir welding technique.Mater Des 2014;53:519-27.

[22]Kalaiselvan K.Role of friction stir welding parameters on tensile strength of AA6061-B4C composite joints.Trans Nonferrous Mater Soc China 2013;23:616-24.

[23]Bisadi Hossein,Abasi Asghar.Fabrication of Al7075/TiB2 surface composite via friction stir processing.Am J Mater Sci 2011;1(2):67-70.

27 September 2014;revised 27 November 2014;accepted 15 January 2015

Available online 16 March 2015

.

E-mail addresses:vijayakumarrit@gmail.com (P.VIJAYA KUMAR),gmreddy_dmrl@yahoo.com(G.MADHUSUDHAN REDDY),arunaraok@ yahoo.com(K.SRINIVASA RAO).

Peer review under responsibility of China Ordnance Society.

http://dx.doi.org/10.1016/j.dt.2015.01.002

2214-9147/Copyright©2015,China Ordnance Society.Production and hosting by Elsevier B.V.All rights reserved.

Copyright©2015,China Ordnance Society.Production and hosting by Elsevier B.V.All rights reserved.

- Defence Technology的其它文章

- Effect of tool pin profile on microstructure and tensile properties of friction stir welded dissimilar AA 6061-AA 5086 aluminium alloy joints

- Multiobjective optimization of friction welding of UNS S32205 duplex stainless steel

- Variation of chemical composition of high strength low alloy steels with different groove sizes in multi-pass conventional and pulsed current gas metal arc weld depositions

- Friction stir surfacing of cast A356 aluminium-silicon alloy with boron carbide and molybdenum disulphide powders

- Theoretical study of BTF/TNA cocrystal:Effects of hydrostatic pressure and temperature

- Microstructure and pitting corrosion resistance of AA2219 Al-Cu alloy friction stir welds-Effect of tool profile