Microstructure and pitting corrosion resistance of AA2219 Al-Cu alloy friction stir welds-Effect of tool profile

Ch VENKATA RAO,G.MADHUSUDHAN REDDY,K.SRINIVASA RAO,*

aDepartment of Metallurgical Engineering,Andhra University,Visakhapatnam,India

bDefence Metallurgical Research Laboratory,Hyderabad,India

Microstructure and pitting corrosion resistance of AA2219 Al-Cu alloy friction stir welds-Effect of tool profile

Ch VENKATA RAOa,G.MADHUSUDHAN REDDYb,K.SRINIVASA RAOa,*

aDepartment of Metallurgical Engineering,Andhra University,Visakhapatnam,India

bDefence Metallurgical Research Laboratory,Hyderabad,India

AA2219 Al-Cu alloy is widely used in defence and aerospace applications due to required combination of high strength-to-weight ratio and toughness.Fabrication of components used for defence always involves welding.Even though the mechanical properties of the base metal are better,but the alloy suffers from poor mechanical and corrosion properties during fusion welding.To overcome the problems of fusion welding,friction stir welding(FSW)is recognized as an alternative solid state joining method aimed to improve the mechanical and corrosion properties. Tool profile is one of the important variables which affect the performance of the friction stir weld.In the present work the effect of tool profile on the microstructure and pitting corrosion of AA2219 aluminium-copper alloy was studied.Electron backscattered diffraction results established that the grain size and orientation of weld nugget of triangle profile is finer than that of conical profile.Differential scanning calorimetric results show the evidence of precipitate dissolution during FSW.It was found that the microstructure changes,such as grain size and its orientation precipitate dissolution during FSW influence the hardness and corrosion behaviour.Pitting corrosion resistance of friction stir welds of AA2219 was found to be better for triangle profile tool compared to conical profile which is attributed to material flow and strengthening precipitate morphology in various zones.Higher amount of heat generation during FSW made using triangle profile tool may be the reason for greater dissolution of strengthening precipitates in nugget zone and coarsening in thermo mechanically affected zone(TMAZ)and heat affected zone(HAZ).

AA2219 Al-Cu alloy;Friction stir welding;Microstructure and pitting corrosion

1.Introduction

Friction stir welding(FSW),an innovative solid state welding technique,has found widely used in defence and aerospace applications[1].This environment-friendly and energy-efficient technique can be used to join high strength aluminium alloys and other metallic materials that are difficultto join using conventional welding processes.In FSW,a rotating tool produces frictional heat causing local plastic deformation[2].Functions of two main parts of the tool,shoulder and pin are to generate heat for material softening and material flow control for defect free weld.Generally it is considered that the final microstructure in a given zone of friction stir weld is strongly influenced by the peak temperature and material flow.It is also a known fact that the age hardenable AA2219 Al-Cu alloy is sensitive to the microstructure changes during welding.Understanding of effect of material flow on microstructure changes is very limited with respect to aluminium alloys[3-6].Tool pin profile strongly influences the change of microstructure in various zones offriction stir welds and thus plays an important role in corrosion behaviour.Microstructure heterogeneity in the friction stir welds is significant in determining the corrosion properties of AA2219 alloy owing to the galvanic coupling between the noble CuAl2 precipitate and the surrounding matrix.Any attempt to improve corrosion resistance generally affects the mechanical properties of aluminium alloy welds[7-10].Most of the previous investigations on the design of tool geometry were focused on optimizing the tool pin profile with respect to microstructure and mechanical properties[11-14].However the studies related to the effect of tool profile on the microstructure and corrosion behaviour of welds are scarce[15]. Keeping in view of the above facts,the present investigation is aimed at studying the microstructure changes in various zones and the pitting corrosion behaviour of AA2219 alloy FS welds made using two tool profiles,smooth type conical and flat type triangle.

Table 1 Chemical composition of AA2219 alloy.

2.Material and methods

In the present investigation,the high-strength aluminiumcopper alloy AA2219-T87 rolled plates of which dimensions are 240 mm×160 mm×7 mm were used for friction stir welding experiments.The chemical composition of the parent metal is given in Table 1.The plates were welded in single pass,normal to the rolling direction,by using the conical and triangle pin profile tools(Fig.1)on a position controlled friction stir welding machine.Fig.2 shows the weld beads of conical and triangle profiles.

Fig.1.Geometry of tool profiles.

Fig.2.Weld beads of FS welds of both profiles.

Keller's reagent is used for etching polished surfaces and theopticalmicrographsarerecorded.Studiesonthe strengthening precipitates were carried out using a 120 kV transmission electron microscope(TEM).The electron backscattered diffraction(EBSD)imaging was carried out using high resolution scanning electron microscope(SEM)equipped with TSL and EBSD system.The EBSD was operated at an accelerating voltage of 20 kVand imaging was performed at a step size of 0-1.0 μm.Line intercept method was employed for measurement of grain size.Vickers hardness testing of the weld joints was carried under the load of 2 kgf.Differential scanning calorimetry(DSC)was carried out for the welds by extracting 10 mg of metal from the stirred region.The extracted metal/sample was subjected to heating rate of 10°C/ min in the range from ambient temperature(35°C)to 550°C to estimate the fraction of precipitates dissolved during friction stir welding.The DSC was also carried out for the base metal for comparison,by following a similar procedure. Potentiodynamic polarization tests were carried out to determine the critical pitting corrosion potential Epitfrom the recoded polarization curve.

3.Results and discussion

3.1.Microstructure

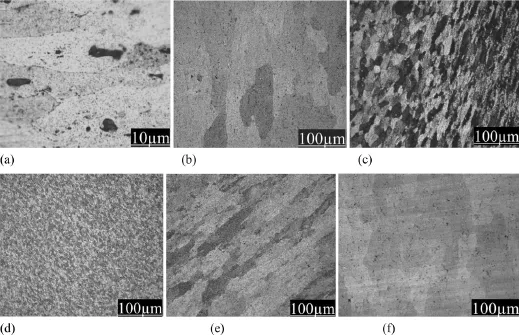

Optical micrographs of AA2219 friction stir welds with base metal are shown in Figs.3 and 4.Base metal microstructure(Fig.3(a))reveals the elongated grain characteristics of the rolled plate with some dark intermetallic particles.The optical micrographs of three microscopically distinct regions,viz WN(weld nugget),TMAZ and HAZ on the advancing side(AS)and the retreating side(RS)of weld made using conical tool,are given in Fig.3.The nugget region has experienced high temperatures and extensive plastic deformation and is characterizedbydynamicallyrecrystallizedgrains.The deformation extent of the plastic material and the flow of the material affect the microstructure and the properties of the nugget.Pin geometry affects the weld nugget microstructure significantly.Specifically the weld made using triangle toolprofile(Fig.4)shows very fine grain distribution compared to the weld made using conical tool profile.

Fig.3.Optical micrographs of AA2219 FS welds with conical tool profile.(a)Base material,(b)AHAZ,(c)ATMAZ,(d)Weld nugget,(e)RTMAZ,(f)RHAZ.

TMAZ is characterized by a highly deformed structure which may result from the insufficient deformation strain,temperature and recrystallization resistance of the base alloy. One of the important characteristics of FSW is the different relative speeds of plastic material on advanced side and retreating side,which results in the different structures.

It can be seen that the microstructures change smoothly from nugget to TMAZ.In the weld made using triangle tool,the nugget grain experienced high temperatures and turbulent material flow resulting in severe plastic deformation.Very fine grains are formed due to dynamic recrystallization compared to weld nugget made using conical tool(Figs.3(d)and 4(d)). The triangle tool has little influence on the material flowing out of diameter of the pin,so the pin speed between nugget and TMAZ is very high.The material flow is insufficient in TMAZ.The temperature and plastic deformation in TMAZ is not as much as those in nugget.Therefore the shape of the weld nugget and the TMAZ zone is only dependent on the shape and the geometry of welding tool and not on the welding parameters.

Fig.4.Optical micrographs of AA2219 FS welds with triangle tool profile.(a)Base material(b)AHAZ(c)ATMAZ,(d)Weld nugget,(e)RTMAZ(f)RHAZ.

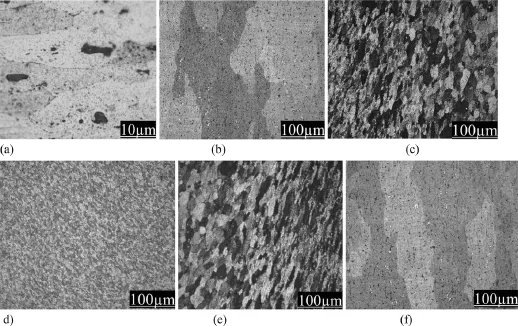

Fig.5.Transmission electron micrographs of AA2219 FS welds with conical profile.(a)Base material,(b)AHAZ,(c)ATMAZ,(d)Weld nugget,(e)RTMAZ,(f)RHAZ.

Transmission electron micrographs of various zones of friction sir welds of AA2219-T87 alloy made using the triangle and conical profile tools are shown in Figs.5 and 6 θ′and θ′′phases of the densely distributed plate-like semicoherent and coherent strengthening precipitates are observed in TEM micrographs of base metal.TEM studies clearly reveal the morphology of precipitates(CuAl2)in weld nugget,TMAZ and HAZ.It can be seen that the relative precipitate coarsening occurs in the HAZ and TMAZ of weld made using triangle profile compared to the weld made using conical profile.Similarly relative higher rate of dissolution of precipitates was observed in the nugget zone of weld made using triangle tool compared to the weld made using conical profile tool.Higher amount of heat generation in the preparation of FS welds using triangle profile tool may be the reason for greater dissolution of precipitates in nugget zone and coarsening of precipitates in TMAZ and HAZ zones.

3.2.Electron backscattered diffraction study

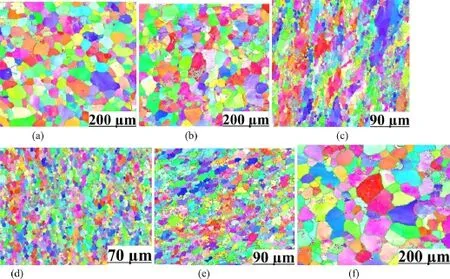

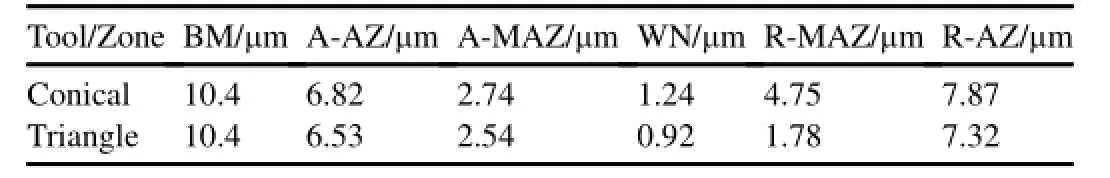

The grain sizes obtained in the welds,produced by two tool pin profiles,were measured using EBSD through the line intercept method,and the EBSD images are shown in Figs.7 and 8.Grain size of weld nugget with triangle profile was found to be finer(0.67 μm)compared to that with conical profile(3.6 μm).This may be attributed to higher amount ofheat produced in triangle profile.Grain sizes of various zones are given in Table 2.And similar trend is also observed in the other regions of the weld.High stacking fault energy materials,such as aluminium alloy,undergo continuous dynamic recrystallization during high temperature deformation.Figs.9 and 10 show the SEM/EBSD images of grain boundary misorientation in the five identified weld zones of conical and triangle tools,respectively.The dynamic recrystallization is caused by local frictional heating and severe plastic strain.

Fig.6.Transmission electron micrographs of AA2219 FS welds with triangle profile.(a)Base material,(b)AHAZ,(c)ATMAZ,(d)Weld nugget,(e)RTMAZ,(f)RHAZ.

Fig.7.EBSD images of AA2219 FS welds with conical profile.(a)Base material,(b)AHAZ,(c)ATMAZ,(d)Weld nugget,(e)RTMAZ,(f)RHAZ.

Fig.8.EBSD images of AA2219 FS welds with triangle profile.(a)Base material,(b)AHAZ,(c)ATMAZ,(d)Weld nugget,(e)RTMAZ,(f)RHAZ.

Table 2 Average grain sizes of different regions of AA2219 FS welds.

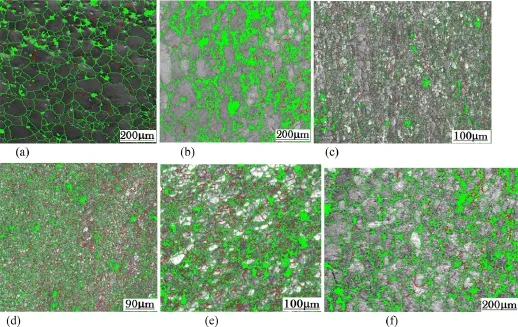

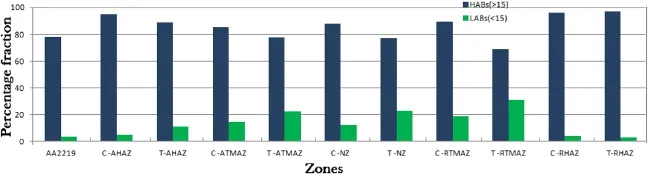

Grain boundary misorientation is divided into two classes,namely Low Angle Grain Boundary LAGB (misorientation<15 deg.)and High Angle Grain Boundary HAGB(misorientation>15 deg.).The values for different zones are given in Fig.11.It is very clear that there is a substantial increase in the number of LAGBs in TMAZ of triangle tool profile compared to conical profile.The increase of LAGBs in TMAZ can be attributed to dynamic recovery,whereby a large number of sub grains with low angle intergranular boundaries are formed.

Fig.9.Grain boundary misorientation images of AA2219 FS welds with conical tool profile.(a)Base material,(b)AHAZ,(c)ATMAZ,(d)Weld nugget,(e)RTMAZ,(f)RHAZ.

Fig.10.Grain boundary misorientation images of AA2219 FS welds with triangle tool profile.(a)Base material,(b)AHAZ,(c)ATMAZ,(d)Weld nugget,(e)RTMAZ,(f)RHAZ.

Fig.11.Grain boundary misorientation distribution in FS welds(C-Conical,T-Triangle).

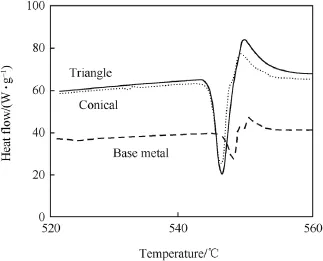

Fig.12.DSC traces for weld nugget.

Table 3 Percentage of precipitates dissolved in FSW.

3.3.Differential scanning calorimetry(DSC)

DSC studies were carried out to quantify the amount of precipitates dissolved in nugget zone during friction stir welding and also in base metal for comparison purpose.The difference between the areas under the endothermic peaks of the base metal and welded metal,divided by the area under the endothermic peak of base metal,gives the fraction of precipitates present after welding(x).From this,the fraction of second phase dissolved during welding for a given tool pin profile weld is calculated by subtracting_x_from unity[10]. The DSC traces of two tool pin profile welds and the base metal are shown in Fig.12.The graph clearly reveals that the endothermic peaks are obtained at temperatures between 542°C and 544°C,which correspond to the complete dissolution of precipitates as may be observed from phase diagram. The amount of precipitates dissolved was estimated from DSC traces by considering the area within the endothermic peak corresponding to the precipitate dissolution for the particular tool pin profile weld.The amount of precipitates dissolved during FSW is presented in Table 3.The calculation shows that the dissolution is relatively higher in the case of triangle tool pin profile welds as compared to other tool pin profile weld.This may be due to relatively higher peak temperature.

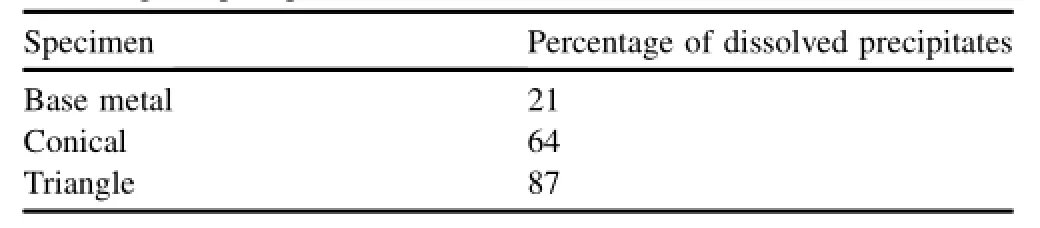

3.4.Hardness study

Hardness values of various zones of welds are given in Table 4.An examination of the data clearly demonstrates that the hardness values are considerably affected by the geometryof tool pin.This may be attributed to fine grain microstructure in triangle tool profile due to sufficient heat and material flow available compared to that of weld made using conical tool profile.This result is in agreement with optical,TEM observations and the results of grain size and orientation measurement using EBSD.

Table 4 Vickers hardness values(VHN)of 2219 Al-T87 alloys FS welds.

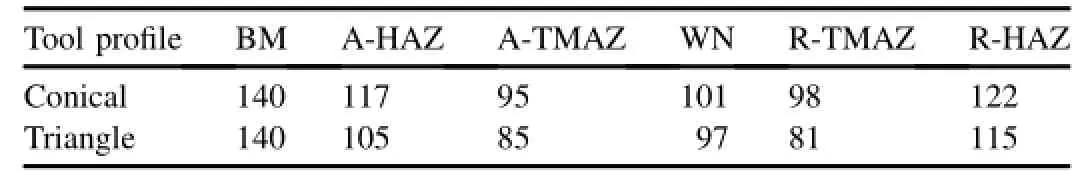

3.5.Pitting corrosion study

The potentiodynamic polarization curves of the welds in the various regions are shown in Fig.13.The intermetallics are the initiation sites for pitting in Al-Cu alloys.The pitting is due to a local dissolution of the matrix due to galvanic coupling between intermetallics and surrounding matrix.The intermetallics containing Cu and Fe are cathodic with respect to the matrix and promote the dissolution of the matrix.Better corrosion resistance of TMAZ/HAZ and the weld nugget regions in 2xxx series aluminium alloys have been reported earlier[16].The dissolution of precipitates in the weld nugget and the coarsening of precipitates in the TMAZ/HAZ regions seem to be the factors responsible for the improved corrosion resistance as well as the nobler corrosion potentials in these two regions.The Epitvalues(mV)of nugget zone(NZ),and the advancing(A)and retreating(R)sides of TMAZ and HAZ are given in Table 5.The weld nugget seems to have turned into a cathode and was completely protected from corrosion damage.It is clearly noticed that the relatively low positive Epitvalues are recorded in NZ,TMAZ and HAZ of the friction stir weld of triangle tool profile.Comparatively uniform pitting corrosion resistance was observed throughout the cross section of the both tool profiles resulted.This is attributed to the dissolution/coarsening of the strengthening precipitates in the nugget region and finely disintegrated eutectics which are evenly distributed in the TMAZ of triangle profile.The typical micrographs after pitting corrosion are shown in Fig.14.Pit density of weld nugget is higher for conical profile compared to that for triangular profile,which is in agreement with the observed pit potential values.

4.Conclusions

1)EBSD analysis indicated a continuous dynamic recrystallization process leading to the formation of equiaxed grain structure in the weld nugget of triangle profile.Selection of tool profile is important in achieving the better combination of mechanical properties and corrosion resistance of AA2219 aluminium-copper alloy friction stir welds.

Fig.13.Potentio-dynamic polarization of AA2219 FS welds in different zones.(a)Base metal,(b)A-HAZ,(c)A-TMAZ,(d)Weld Nugget,(e)R-TMAZ,(f)R-HAZ.

Table 5 Epit Values of AA2219-T87 Al alloy FS welds.

2)DSC study established that the rate of heat generation as well as the peak temperature is relatively higher in the case of triangle pin profile compared to conical profile and also dissolution of precipitates.TEM studies also confirmed the dissolution of precipitates.

Fig.14.Optical micrographs after pitting corrosion.(a)Base metal(b)WN of conical(c)WN of triangle.

3)The general corrosion resistance of the weld nugget was better than that of the parent AA2219 alloy in 3.5%NaClsolution and was attributed to the dissolution or coarsening of the strengthening precipitates in the nugget region and the consequent reduction in the galvanic coupling.

4)Tool profile has been found to affect the microstructure,mechanical properties,and corrosion resistance of friction stir welds of AA2219 Al-Cu alloy in various zones significantly.

Acknowledgements

The authors would like to thank Dr.A.Ghokale,Director,Defence Metallurgical Research Laboratory,Hyderabad,India for his continued encouragement and permission to publish this work.

[1]Thomas WM,Nicholas ED,Needham JC,Murch MG,Temple smith P,Dawas CJ.International Patent application No.PCT/GB92/02203 G.B PatApplNo.9125978.8,Dec.1991;U.SOct.1995:Patent Appl.No.5460317.

[2]Friggard O,Grong O,Bjorneklett B,Middling OT.In:Proceedings in 1stIntentional Symposium on friction stir welding.Thousand Oaks,CA,USA:TWI;June 1999.

[3]Fratini L,Buffa G,Palmeri D,Hua J,Shivpuri R.Material flow in FSW of AA7075-T6 butt joints:numerical simulations and experimental verifications.Sci Technol Weld Join 2006;11(4):412-21.

[4]Nandan R,DebRoy T,Bhadeshia HKDH.Recent advances in friction-stir welding process weldment structure and properties.Prog Mater Sci 2008;53:980-1023.

[5]Chao YJ,Qi X,Tang W.Heat transfer in friction stir welding:experimental and numerical studies.ASME J Manuf Sci 2003;125:138-45.

[6]Mishra RS,Ma ZY.Friction stir welding and processing.Mater Sci Eng 2005;50:1-78.

[7]Thomas WM,Johnson KI,Wiesner CS.Friction stir welding-recent developments in tool and process technologies.Adv Eng Mater 2003;5:485-90.

[8]Zhao Yan-hua,Lin San-bao,Wu Lin,Qu Fu-xing.The influence of pin geometry on bonding and mechanical properties in friction stir weld 2014 Al alloys.Mater Lett 2005;59(23):2948-52.

[9]Yan Junhui,Sutton MA,Reynolds AP.Process-structure-property relationships for nugget and heat affected zone regions of AA2524-T351 friction stir welds.Sci Technol Weld Join 2005;10(6):725-36.

[10]Surekha K,Murty BS,Prasad Rao K.Effect of processing parameters on the corrosion behaviour of friction stir processed AA 2219 aluminium alloy.Solid State Sci 2009;11:907.

[11]Hattingh DG,Blignault C,Van Niekerk TI,James MN.Characterization of the influences of FSW tool geometry on welding forces and weld tensile strength using an instrumented tool.J Mater Process Technol 2008;203(1-3):46-57.

[12]RamanjaneyuluK,MadhusudhanReddyG,VenugopalRaoA,Markandeya R.Structure-property correlation of AA2014 friction stir welds-role of tool pin profile.J Mater Eng Perform 2013;22:2224-40.

[13]Nicholas ED,Thomas WM.A review of friction processes for aerospace applications.Int J Mater Prod Technol 1998;13(1-2):45-55.

[14]Threadgill PL,Leonard AJ,Shercliff HR,Withers PJ.Friction stir welding of aluminium alloys.Int Mater Rev 2009;54(2):49-93.

[15]Paglia CS,Buchheit RG.A look in the corrosion of aluminium alloy friction stir welds.Scr Mater 2008;58:383-7.

[16]Srinivasa Rao K,Prasad Rao K.Pitting corrosion of heat-treatable aluminium alloys and welds:a review.Trans Indian Inst Metals 2004;576.5s93-610.

30 September 2014;revised 19 October 2014;accepted 20 October 2014

Available online 13 February 2015

.

E-mailaddresses:venkat.auce@gmail.com(C.VENKATARAO),gmreddy_dmrl@yahoo.com(G.MADHUSUDHAN REDDY),arunaraok@ yahoo.com(K.SRINIVASA RAO).

Peer review under responsibility of China Ordnance Society.

http://dx.doi.org/10.1016/j.dt.2014.10.003

2214-9147/Copyright©2015,China Ordnance Society.Production and hosting by Elsevier B.V.All rights reserved.

Copyright©2015,China Ordnance Society.Production and hosting by Elsevier B.V.All rights reserved.

- Defence Technology的其它文章

- Effect of tool pin profile on microstructure and tensile properties of friction stir welded dissimilar AA 6061-AA 5086 aluminium alloy joints

- Microstructure and pitting corrosion of armor grade AA7075 aluminum alloy friction stir weld nugget zone-Effect of post weld heat treatment and addition of boron carbide

- Multiobjective optimization of friction welding of UNS S32205 duplex stainless steel

- Variation of chemical composition of high strength low alloy steels with different groove sizes in multi-pass conventional and pulsed current gas metal arc weld depositions

- Friction stir surfacing of cast A356 aluminium-silicon alloy with boron carbide and molybdenum disulphide powders

- Theoretical study of BTF/TNA cocrystal:Effects of hydrostatic pressure and temperature