Numerical analysis of keyhole establishment time in keyhole p lasma arc welding*

Sun Junhua and Hu Qingxian孙俊华,胡庆贤**

Numerical analysis of keyhole establishment time in keyhole p lasma arc welding*

Sun Junhua and Hu Qingxian

孙俊华,胡庆贤**

Numerical analysis of keyhole shape and keyhole establishment time is of great significance for selection and optimization of the process parameters in keyhole plasma arc welding.In this paper,a three-dimensional transientmodel is developed to analyze the evolutions of keyhole shape and keyhole establishment time in continuous current plasma arc welding process.Firstly,a combined volumetric heat sourcemodel isused to simulate the transient variation of temperature field.And then the surface deformation equation isadopted to calculate dynamic featuresof the keyhole shape and keyhole establishment time inside weld pool,in which the force action on weld pool surface is considered.Experiment is conducted to validate the numerical simulation results.The predicted keyhole sizeand keyholeestablishment timeare in agreementwith theexperimental measurement.And the calculated fusion zone geometry is consistentwith themeasured one.

numerical analysis,plasma arc welding,keyhole establishment time,transient variation

0 Introduction

Plasma arc welding(PAW)is an arc welding process developed on the basis of gas tungsten arc welding.Since it uses special torch with a constraining orifice to form a highly constrained plasma jet,thishighly constrained plasma jet can displace the molten metal in the weld pool so that a keyhole through the thickness of workpiece can be established.The PAW process in keyholemode can penetrate thicker pieces with a single pass.Compared with laser beam welding and electron beam welding,the keyhole PAW is low in cost and easy to operate.Therefore,the keyhole PAW as a higher efficient welding process has a wide application prospect in modern industrial production[1-4].

It is well known that the keyhole in PAW is sensitive to any changes of the welding parameters,which makes it have narrower ranges of appropriate welding parameters for good weld quality.These factors limit its wide application in manufacturing,especially forweldingmedium thickness plates[5].To expand the ranges of appropriate welding parameters for good weld quality in PAW,it is necessary to understand the underlying physicalmechanisms of keyhole dynamics.Therefore,it is of great significance to establish a mathematicalmodel for analyzing keyhole behaviors.

In this paper,a transientheat transfermodel is established to calculate the temperature field in the keyhole PAW process,and the dynamic evolution of 3D keyhole shape and size is numerically simulated according to the force balance conditions on the keyholewall.The transient temperature field,keyhole shape and keyhole establishment time are calculated so that the keyhole PAW process is quantitatively analyzed.

1 Model of keyhole behaviors

A transient heat transfer model is established to investigate the thermal conduction phenomenon in keyhole PAW.How to establish an adaptive heat sourcemodel to describe the distribution of plasma heat density along theplate thickness direction is a key issue.Considering the strong digging action of the plasma arc and the“reversed bugle-like”configuration of weld geometry at transverse cross-section,a combined volumetric heat source model “double-ellipsoid+cylinder”is used.Along the workpiece thickness direction,a double-ellipsoid heat source is used at the upper part of workpiece,while the cylinder heat source is used at the lower part of workpiece.The power fractions of double-ellipsoid and cylinder heat sources change with time,and the proportion of conical heat source increases gradually to a constant value.Based on such a combined volumetric heat source mode,the temperature field can be calculated in keyhole PAW[6-7].

Based on the calculated temperature field,the weld pool can be determined.In PAW process,the weld pool evolves from partial penetration to full penetration after the arc ignition.In order to describe the key-holing process in keyhole PAW,the forces action on weld pool surface need to be quantitatively analyzed.In keyhole PAW process,both plasma arc pressure and gravitational force promote the keyhole formation,but surface tension hinders the keyhole formation.Under the actionsof these forces,the weld pool surface deforms and the keyhole forms.The keyhole undergoes the dynamic transformation from blind to open with the evolutions ofweld pool.According to the characteristics of force action and surface deformation of weld pool in keyhole PAW,the keyhole model is established with considering the dynamic balance conditions related to keyhole opening and closing.And the surface deformation equation has to meet a constraint that the volume of weld pool is constant[8-11].

2 Results and discussion

The workpiece material is AISI304 stainless steel plate with dimensions 200 mm in length,60 mm in width and 8 mm in thickness.The welding conditions were as follows:welding current 170 A,arc voltage 24 V and welding speed 120mm/min.The shielding gas and the plasma gaswere argon,and the flow rateswere 20 L/min and 3 L/min,respectively.

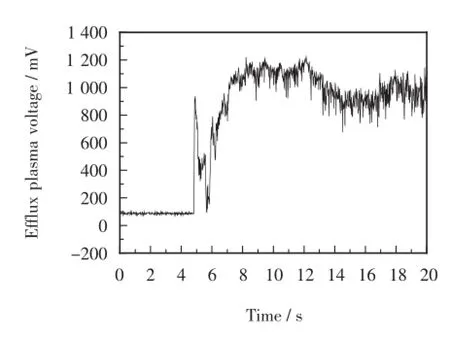

According to the corresponding process conditions in this study,the PAW tests were made.The efflux plasma voltage(related to establishment of open keyhole)was detected by a date acquisition system,as shown in Fig.1. And the keyhole image was captured by the CCD camera from the backside of workpiece,as shown in Fig.2a.Theboundary of keyhole was extracted separately by using Matlab.And the keyhole length and width can be obtained after image processing and calibration[12].Based on the keyhole images in the study case,the keyhole length and width are 1.2mm and 1.58mm,respectively.Fig.2b shows the keyhole's dimension definition.

Fig.1 M easured signal of the efflux p lasma voltage in keyhole PAW

Fig.2 Captured keyhole image and definition of keyhole dim ension in PAW

Based on the efflux plasma voltage signal detected during the experiment,it is found that the keyhole is established at 5 s after the arc ignition,and a quasi-steady state is reached after 8 s.The transient variation feature of temperature field and keyhole shape isnumerically simulated after arc ignition.

Fig.3 shows the calculated temperature field on transverse cross-section at different time.Observing the evolution of temperature field in Fig.3,the following thermal features of the keyhole PAW process are found.As shown in Fig.3a,after initial deposition of impinging plasma arc on the surface,the metal is heated and melted.As time goes on,the weld pool is formed and its volume expands gradually,as show in Fig.3b-Fig.3d.And theweld pool gets full penetration at t4.Subsequently,the weld pool continues to expand with time,and turns to be stable at t7.Since then,the weld pool sizes almost do not change,as shown in Fig.3e-Fig.3h.

Fig.4 Evolution of 3-D keyhole versus time in keyhole PAW

Fig.4 shows the evolution of the 3-D keyhole shape with time in keyhole PAW.It can be seen that the keyhole undergoes transient variation of“establishing-expandingstabilizing”process.At the initial stage of welding,themolten pool is formed with the heat input to the workpiece surface.Under the effects of gravitational force,plasma arc pressure and surface tension on the weld pool surface,the free surface deformation occurs,and a depression appears.With the action of plasma arc,the depression becomes larger and transforms to a keyhole.At first,blind keyhole emerges,as shown Fig.4a-Fig.4d.At instant t5,the blind keyhole transforms into the open keyhole penetrating through the workpiece,and a complete keyhole is established,as shown in Fig.4e.And then,the keyhole expands continually with the expansion of weld pool size.Finally,the keyhole size tends to a stable value at t7,as show in Fig.4 f-Fig.4h.

Fig.5 shows the transverse cross-section(y-z)and longitudinal cross-section(x-z)of the keyhole at different time.At first,the keyhole undergoes its initial forming process,and is in the blind keyhole state,as illustrated in Fig.5a-Fig.5b.With the time going on,the keyhole undergoes establishing-expanding-stabilizing process,which is shown in Fig.5c-Fig.5d.It can be seen that the keyholes nearly coincide between t7moment and t8moment. Therefore,the PAW process reaches a quasi-steady state after 8 s.The width and length of the keyhole in quasisteady state are 1.6 mm and 1.2mm,respectively.The calculated keyholewidth and length are generally in agreementwith themeasured one.

Fig.5 Transient variation of the transverse(a,c)and longitudinal(b,d)cross-section of keyhole shape (t1=1 s;t2=2 s;t3=3 s;t4=4 s;t5=5.139 s;t6=5.5 s;t7=8 s;t8=10 s)

After welding,the test piece was processed,and the metallograph of weld at cross section was obtained.Fig.6 compares the calculated and experimentallymeasured weld fusion lines of keyhole PAW.Both are in agreementwith each other.

Fig.6 Comparison between the calculated and m easured fusion zone

3 Conclusions

(1)Based on the characteristics of force-action at keyhole wall,a three-dimension keyhole model is established to determine the evolution of keyhole shape with time.The keyhole undergoes variation of“establishing-expanding-stabilizing”process.

(2)The calculated results show that at instant5.139 s,the blind keyhole transforms into the open keyhole penetrating through the workpiece,and a complete keyhole is established.Itmatcheswellwith themeasured keyhole establishment time 5.0 s.

(3)The predicted weld pool geometry,and keyhole dimension are generally in agreement with the experimentalmeasured ones for the study case.

References

[1] Metcalfe J C,Quigley M B C.Heat transfer in plasma-arc welding.Welding Journal,1975,54(3):99s-103s.

[2] Lancaster J F.The physics of welding.Oxford:Perganon Press,1984:268-280.

[3] Fortain JM.Plasma welding evolution and challenges.IIW Doc.XII-1948-08,2008:1-11.

[4] Martikainen JK,Moisio T J I.Investigation of the effect of welding parameters on weld quality of plasma arc keyhole welding of structural steels.Welding Journal,1993,72(7):329s-340s.

[5] Dong C L,Wu L,Shao Y C.The history and state-of-the-art of keyholemode plasma arc welding.China Mechanical Engineering,2000,11(5):577-580.(in Chinese)

[6] Wu CS.Welding thermal processesandweld poolbehaviors. New York:CRC Press/Taylor and Francis Group,2011.

[7] Hu Q X,Wu C S,Zhang Y M.Finite element analysis of keyhole plasma arc welding based on an adaptive heat source mode.ChinaWelding,2007,16(2):55-58.

[8] Wu C S,Chen J,Zhang Y M.Numerical analysis of both front-and back-side deformation of fully-penetrated GTAW weld pool surfaces.Computational Materials Science,2007,39(3):635-642.

[9] Huo Y S,Wu C S.Determining the keyhole geometry based on double-elliptic distribution of plasma arc pressure.China Welding,2009,18(3):12-15.

[10] Dai D S,Song Y L,Zhang H,et al.Study on arc force in plasma arc welding.Transactions of the China Welding Institution,2002,23(2):51-54.

[11] Sahoo P,Debroy T,Mcnallan M J.Surface tension of binary metal-surface active solute systems under conditions relevant to welding metallurgy.Metallurgical Transactions B,1988,19(3):483-491.

[12] Zhang G K,Wu C S,Liu ZM.Experimental observation of both keyhole and its surrounding thermal field in plasma arc welding.International Journal of Heat and Mass Transfer,2014,70(3):439-448.

*This research is supported by the Doctoral Research Fund Project of Shandong Jianzhu University(No.XNBS1259),the Open Research Fund of Provincial Key Lab of Advanced Welding Technology,Jiangsu University of Science and Technology(No.JSAWT-13-02).

**Sun Junhua,School of Materials Science and Engineering,Shandong Jianzhu University,Jinan,250101. Hu Qingxian,Provincial Key Lab of Advanced Welding Technology,Jiangsu University of Science and Technology,Zhenjiang,212003. Sun Junhua,Corresponding author,E-mail:sunjunhua1979@126.com

- China Welding的其它文章

- A Fe-Ni-Cr system filler metal for brazing of stainless steel*

- Numerical analysis of thermal process in continuous drive radial friction welding*

- Effect of refilling time on Microstructure and Mechanical properties of friction spot welded LY12 alum inum alloy*

- Simulation of phased array S-scan acoustic field in FSW joint of alum inum alloy extrudate w ith com p lex shape*

- Mechanical and corrosion properties of 445J2 ultra pure ferritic stainless steel joint*

- Simulation on the deformation controlling of T-joint LBW w ith auxiliary heat source for high strength alum inum alloy*