生物降解地膜对玉米的生物学效应及其降解特性

胡宏亮, 韩之刚, 张国平

(浙江大学农业与生物技术学院,杭州 310058)

生物降解地膜对玉米的生物学效应及其降解特性

胡宏亮, 韩之刚, 张国平*

(浙江大学农业与生物技术学院,杭州 310058)

通过大田试验,从土壤保温性、作物生长发育与产量、田间降解等方面对5种可降解地膜进行分析比较。结果显示:可降解地膜覆盖能显著提高土壤不同深度的温度,其中M2和M52种地膜的整体保温效果最为突出,达到了接近普通地膜的水平;地膜覆盖可显著加快玉米生育进程和增加玉米产量,且部分可降解地膜的促进效果优于普通地膜。在地膜降解方面,5种可降解地膜破裂启动期较为一致,发生于覆膜后约20 d,可基本满足玉米苗期对温度、水分的需要;覆膜90~100 d后可降解地膜从土壤表面基本消失。以上结果显示,供试的5种可降解地膜不仅具有显著的生物学效应和经济学效果,其降解特性也基本符合玉米生长对环境条件的要求,完全可以替代传统地膜。

地膜; 降解; 玉米; 生物学效应; 产量

Summary Over the past few decades, the use of traditional mulch film made of poly-ethylene enhanced agriculture production worldwide, and meanwhile raised a range of agricultural and ecological concern associated with degradation of soil fertility due to residue accumulation. It has become an increasingly challenging issue for agricultural sustainability. As a consequence, biodegradable films are proposed as an effective solution to alleviate this issue. Among them, poly (butyleneadipate-co-terephthalate) (PBAT), a biodegradable aliphatic-aromatic polyester, possesses similar mechanical properties to polyethylene and therefore is generally considered an ideal substitute for conventional films. This study aimed at making a comprehensive evaluation of several recently developed biodegradable films by comparing their biological effects and field degradation properties.

Five biodegradable films with a main component of PBAT were applied to cover the beds of maize in an experimental field, and then the soil temperature, plant growth indices and yield components of maize were investigated. Meanwhile, the field degradation of both biodegradable and conventional films was assessed by a standard of degradation degree.

The results showed that the biodegradable films, compared to bare plot, markedly raised soil temperatures at three observation depths (5 cm, 10 cm and 15 cm) and this heat capturing effect was as pronounced as the conventional polyethylene film. The temperature boosting effect varied with soil depth and time,i.e., the biggest diurnal fluctuation of temperature occurred at the depth of 5 cm in each treatment, while the least was at the depth of 15 cm. The growth of maize was significantly stimulated in all mulched plots, with the occurrence of seedling emergence and silking stage being 3-5 days and 10-13 days earlier than bare plots, respectively. A minor advantage of biodegradable film over conventional film was also observed. The highest chlorophyll content (indicated by SPAD) was found in the bare plot, followed by M2, and M1was the lowest, yet there were no significant differences among mulching treatments. By contrast, leaf area indices (LAI) of the biodegradable films were significantly higher than non-mulched plot, with the highest in M2. At the jointing stage, the plant height under all mulched plots were greater than that under the bare plot. While at the maturity stage, plants in the bare plot had the highest height, and there were no significant differences among the five biodegradable films. The largest accumulation of nitrogen, phosphate and potassium in plants occurred in the bare plot, being significantly higher than in the mulched plots. The fresh yield, kernels per ear and 100-kernel mass were significantly larger in all mulched plots than in the bare plot. The yield per plot of the biodegradable films was higher than that of the conventional film, yet no difference existed between the biodegradable films and the conventional film in terms of kernels per ear and 100-kernel mass. Field observation revealed that the biodegradable films started losing integrity at approximately 20 days after application in the field. The earliest clear disappearance of film started at 90 days after application for M2. While the relatively slow degradation was found in M1and M5, which were torn into separate subunits with roughly 10 cm cracks after 100 days of field exposure, reaching the 4th period of degradation.

In sum, all the biodegradable films are capable of enhancing maize growth by improving soil temperature and even contribute a larger economic yield than the conventional film; moreover, the biodegradable films maintain stability for approximately 20 days after application in the field and disappear after 90-100 days, demonstrating the applicable effectiveness for mulching as a substitute of the conventional film.

地膜覆盖是一项应用广泛而又十分重要的农业生产辅助措施。塑料地膜通过改变土壤能量平衡从而改善作物生长小气候[1-2]。这一田间小气候的改变可引起土壤温度变化,并影响作物生长与产量[3-6]。塑料地膜除了具有增温保墒、抑制杂草、减少病虫害和提高水分利用率等作用外,更因为其操作简易性、化学稳定性、持久性、灵活性和无毒性,在过去的数十年间全球用量快速增加[7]。我国从1979年开始从日本引进地膜栽培技术,发展迅速,已经成为一项常用的农业增产措施。据统计,我国农作物地膜覆盖面积1981年为15万hm2,而至2005年已达1 350万hm2[8]。覆盖作物从最初的经济蔬菜扩大到包括玉米、水稻、小麦在内的大宗粮食作物。我国现有的1.217亿hm2土地中,使用塑料地膜覆盖栽培的面积超过0.17亿hm2,年增产粮食和经济作物收益达500亿元。2011年,我国农用塑料薄膜使用量为229.5万t,其中地膜使用量124.5万t,地膜覆盖面积1 979万hm2[9],是世界上塑料地膜使用最多的国家。

然而,大部分塑料地膜在使用后直接残留在土壤中或被随意燃烧,释放出有害物质,对环境造成负面影响。目前,生产塑料地膜的材料主要从石油中获得,地膜成分通常为聚乙烯(polyethylene, PE),使用后造成了极大的处理困难[10]。聚乙烯在自然条件下极难降解,降解周期一般为200年。同时,我国多年来大量使用8 μm或6 μm的PE膜,因厚度薄而在田间极易破碎,不仅造成地膜二次利用率低,也因难以回收而使残膜在土壤中不断积累。土壤中的大量残膜导致了土壤物理结构层次的改变,使土壤水分和养分向下运输受到阻碍,土壤孔隙度、通透性降低,造成耕地质量下降[11-13]。据统计,截至2003年全世界每年的农用及相关领域的塑料使用量达248万t[14]。田间残膜的大量积累已成为农村白色污染的主要来源之一。严昌荣等[15]对我国5个典型省长期覆膜农区的调查结果显示,农田地膜残留量从71.9 kg/hm2(湖北)到259.1 kg/hm2(新疆)不等。显然,有效处理大量塑料地膜已成为当今世界的一项重大课题和挑战。

虽然回收利用是一种可能的方法,但是从田间拾取残膜十分费时(16 h/hm2),即使采用机械回收,也需要人工劳作[16];并且在很多蔬菜栽培中,地膜受泥污和残渣污染严重,难以直接从田间回收[17]。解决这一问题的有效途径之一就是改变材料基质,研制生物降解塑料地膜。如果地膜能在覆盖一段时间后自行降解且无有害物质残留,将从根源上解决目前普遍的“白色污染”问题。生物降解材料在其使用末期能整合到土壤中,被微生物转化为二氧化碳或甲烷、水分和生物质[18-21]。根据美国材料与试验协会标准(American Society for Testing and Materials, ASTM)的定义,生物降解塑料是指因受自然界微生物(细菌、真菌)和藻类等的活动影响而发生降解的可降解塑料[22-24]。聚酯由于含有一个可水解酯键,是一类重要的生物降解塑料,且其材料特性与传统塑料相似[25-26]。可生物降解聚酯地膜因能在自然界条件下完全降解为二氧化碳和水,近年来受到高度关注。目前已研制出多种商业用途的生物降解聚酯材料,品种包括聚乳酸、脂肪-芳香族共聚酯、聚羟基烷酸酯等。聚己二酸对苯二甲酸丁二酯[poly (butyleneadipate-co-terephthalate), PBAT]是一种脂肪芳香族聚酯,不仅具有生物降解性能,还具有与聚乙烯相似的机械性能[27]。而其他聚酯,如聚乳酸(poly lactic acid, PLA)和聚羟基丁酸酯(polyhydroxybutyrate, PHB),难以实现以低成本达到覆膜所需的机械性能[28]。本研究选用新研制的几种以PBAT为主要成分、不同配方的可控生物降解地膜(即可以通过配方改良调控降解速率的生物降解地膜),对其在田间覆盖期间的保温、增产效果和田间降解情况进行观测分析,综合评价不同生物降解地膜的生物学效应和降解特性,从而为该类新型可控生物降解地膜的研制及应用提供理论依据与技术支撑。

1 材料与方法

1.1 预备试验

试验在杭州市浙江大学紫金港校区实验农场进行。材料选用杭州鑫富药业股份有限公司研制的5种降解地膜,主要成分为PBAT,另加少量生物降解材料及助剂;以普通膜为对照,市售,主要成分为聚乙烯;另设不覆膜(露地)处理。所用作物为蚕豆,2012年11月20日播种。根据地膜的土壤保温性、田间机械稳定性以及蚕豆的生长发育表现,确定综合效果最佳的类型,并将结果返回公司,进一步优化地膜配方,形成5种改良地膜,分别编号为M1~M5。

1.2 验证试验

本试验旨在进一步测试所研发的5种改良地膜的生物学效应及其大田降解特性。试验设7个处理,包括不覆膜(M0)、分别覆盖5种可降解地膜(M1~M5)和覆盖普通聚乙烯膜(M6)。供试作物为玉米,品种为浙大甜玉米7号。于2013年3月28日直播并覆膜,畦宽0.9 m,穴播,每穴2粒种子,于三叶期定苗为每穴1苗,行距40 cm,株距30 cm。各处理重复3次,小区面积12 m2。

生育期间观察各处理玉米生育进程;播种后每隔10 d测定土表下5 cm、10 cm和15 cm 3个深度的温度。拔节期测定株高、叶面积指数和功能叶叶绿素含量。成熟后测定株高、地上部干质量、每穗粒数、百粒质量及小区产量,并分析茎秆和叶片的氮、磷、钾含量。氮含量采用凯氏定氮法,在FOSS Tecator Digestor Auto消煮仪上360 ℃消煮后用定氮仪(Kjeltec 8400)测定;磷、钾含量采用ICP测定,用微波(Multiwave 3000,Anton Paar)消煮后在ICP仪(Optima 8000)上测定。所有数据均采用Microsoft Excel 2013和SAS 9.1.3软件进行统计分析。

同时,试验期间每隔10 d对地膜降解情况进行田间调查和统计。以0~5级评估地膜降解程度:0级,地膜外观形态完整,未出现裂纹;1级,开始出现10 cm以下裂纹;2级,出现约20 cm较大裂纹;3级,出现约50 cm大块裂纹;4级,地膜分裂成多块较大的独立部分,并且内部出现10 cm裂纹;5级,土壤表面地膜基本消失,仅少量残留。

2 结果与分析

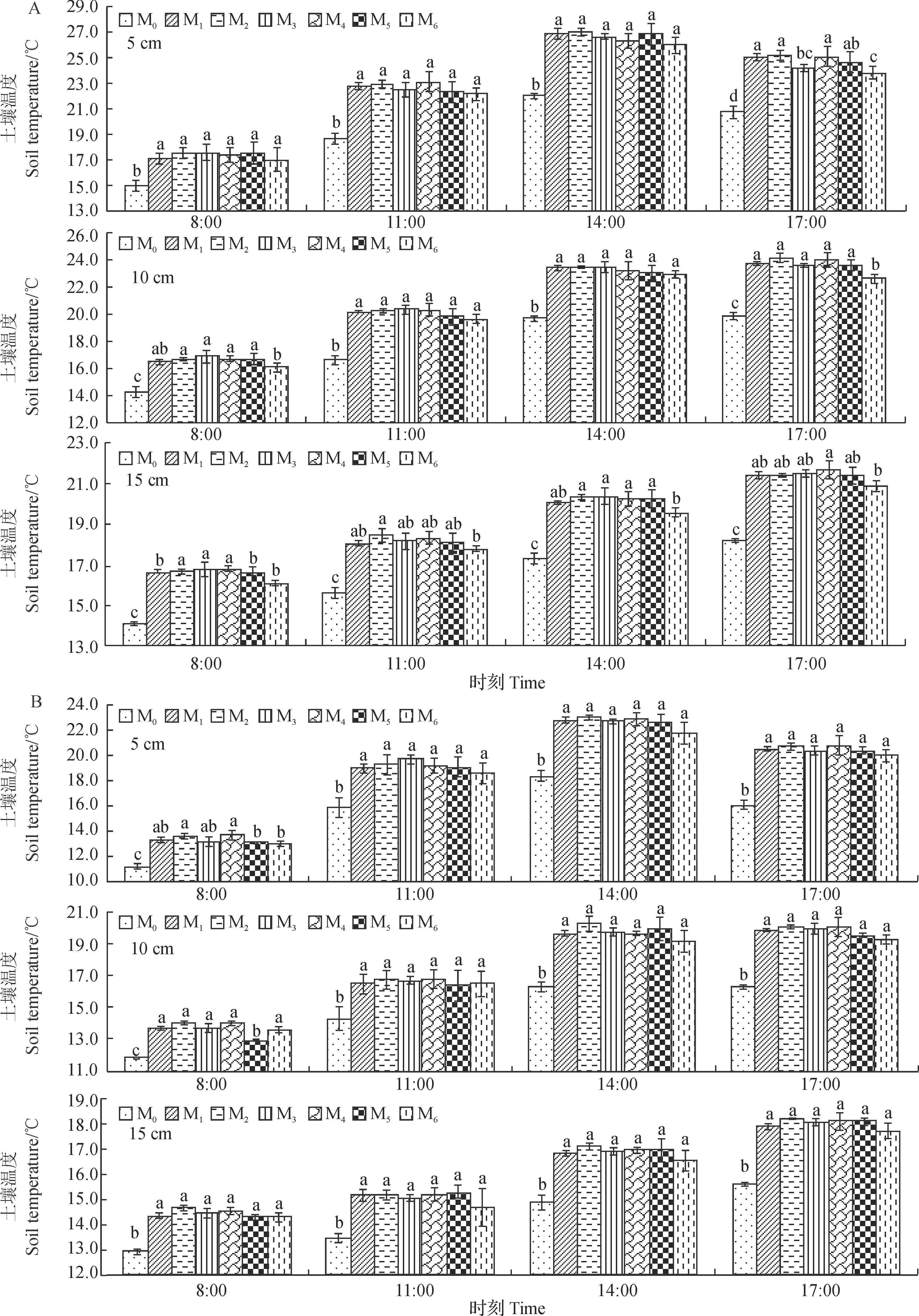

2.1 不同覆膜处理对土壤温度的影响

2013年4月11日和4月21日不同覆膜处理的土壤温度变化见图1。从中可以看出:可降解地膜和普通地膜均可显著提高不同深度土壤的温度,且整体上不同降解地膜和普通膜之间差异不大,5种可降解地膜之间无显著差异。地膜的增温作用因土壤深度和测量时间而异。在浅土层(5 cm)下,土壤温度日变化最大,以4月11日为例,露地处理在观察期间在15 ℃至22 ℃之间变动,而地膜处理在17 ℃至27 ℃之间;而在15 cm深土壤下,露地处理在14 ℃至18 ℃之间变动,地膜处理则在16.5 ℃至21.5 ℃之间。另外,10 cm和15 cm深土壤的日最高温度出现在17:00时,而5 cm深土壤的日最高温出现较早。4月21日的观察结果显示,可降解地膜和普通地膜均显著提高了3个不同土壤深度的温度,且与露地处理的温度差异随日照时间而增大;同时,与4月11日相比,可降解地膜与普通地膜在3个土壤层的温度差异减小,说明可降解地膜由于发生了一定的田间破损或降解而失去了完整性,保温性能已呈下降趋势。

A:2013年4月11日;B:2013年4月21日。M0:不覆膜;(M1~M5):覆盖5种不同配方的可降解地膜;M6:覆盖普通聚乙烯地膜。柱状图上的不同小写字母表示在该时刻和该土壤深度下不同地膜处理之间在P<0.05水平差异有统计学意义。A: April 11, 2013; B: April 21, 2013. M0: Bare plot without film mulching; (M1-M5): Plots mulched with five biodegradable films of different compositions; M6: Plot mulched with conventional polyethylene film. Different lowercase letters above the columns represent statistically significant differences among the different mulch film treatments at the same soil depth during the same time (P<0.05).

2.2 不同覆膜处理对玉米生育进程的影响

在露地栽培条件下,玉米的全生育期为97.3 d,可降解地膜和普通地膜均显著缩短了玉米达到各生育时期需要的时间,为85.0~87.3 d(表1)。地膜覆盖加速玉米生长发育的效果在苗期就开始体现,地膜覆盖玉米12~14.3 d即出苗,而露地玉米需要17.3 d,提前了3~5 d;到拔节期、抽雄期和吐丝期,露地和覆膜处理之间的差异进一步拉大,至吐丝期,地膜覆盖比露地处理早10~13 d。显然,地膜覆盖处理加快玉米生育进程对于鲜食玉米提早上市、增加收益具有积极意义。

可降解地膜与普通地膜相比具有一定的微弱优势。苗期至吐丝期及成熟期,均以5种可降解地膜处理的较早,其中以M2和M5的作用最为明显,玉米成熟比普通地膜(M6)早2 d以上。

表1 不同覆膜处理对玉米主要生育期出现时间的影响

Table 1 Effect of different mulch film treatments on growth stages of maize d

生育期GrowthstageM0M1M2M3M4M5M6出苗Seedlingemergence17.3a(0)12.3c(5.0)12.3c(5.0)12.0c(5.3)12.6c(4.7)13.3bc(4.0)14.3b(3.0)拔节Jointing31.0a(0)25.3d(5.7)25.7d(5.3)25.0d(6.0)26.0cd(5.0)26.7c(5.3)27.0b(4.0)抽雄Tasseling70.3a(0)62.8b(7.7)62.3b(8.0)62.0b(8.3)63.7b(6.7)62.0b(8.3)63.0b(7.3)吐丝Silking81.7a(0)70.0b(11.7)69.3b(12.3)70.7b(11.0)70.3b(11.3)68.7b(13.0)71.3b(10.3)成熟Maturity97.3a(0)86.0cd(11.3)85.3d(12.0)86.6bc(10.7)86.0cd(11.3)85.0d(12.3)87.3b(10.0)

M0:不覆膜;(M1~M5):覆盖5种不同配方的可降解地膜;M6:覆盖普通聚乙烯地膜。括号内的数字表示该处理比露地处理提前的天数;同行数据后的不同小写字母表示在P<0.05水平差异有统计学意义。

M0: Bare plot without film mulching; (M1-M5): Plots mulched with five biodegradable films of different compositions; M6: Plot mulched with conventional polyethylene film. Numbers in brackets represent days earlier than the treatment of bare plot. Values within a row followed by different lowercase letters represent statistically significant difference at the 0.05 probability level.

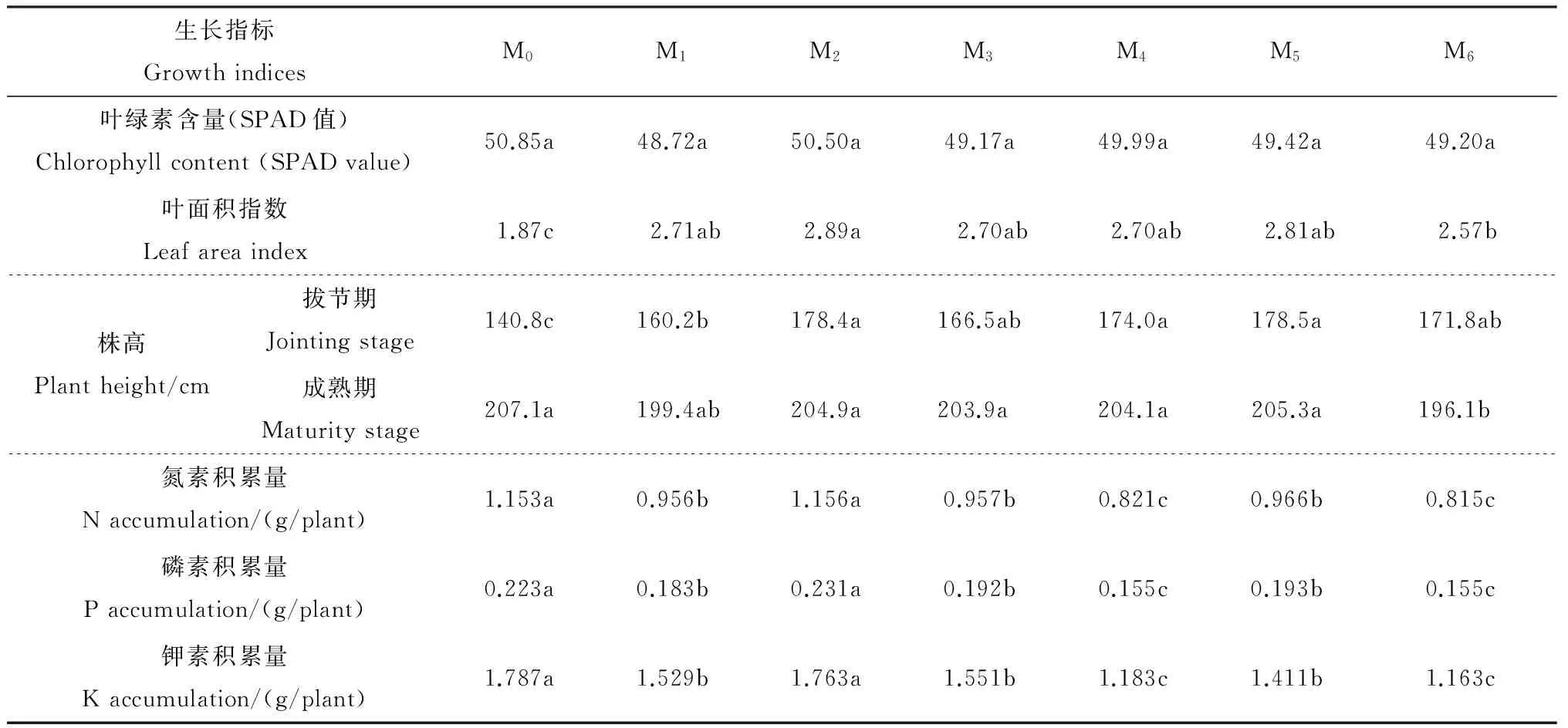

2.3 不同覆膜处理对玉米生长与养分吸收的影响

拔节期叶片叶绿素含量以露地处理的最高,M2次之,M1最低,各处理间在统计学上差异不显著(表2)。拔节期的玉米叶面积指数以可降解地膜最高且显著高于普通地膜,露地处理最小,仅1.87。拔节期株高以露地处理的最低,仅140.8 cm,显著低于可降解地膜处理(160.2~178.5 cm)和普通地膜(171.8 cm);可降解地膜以M1最低,M2、M4和M5表现相近。在成熟期,露地处理株高为207.1 cm,明显高于可降解地膜(199.4~205.3 cm)和普通膜(196.1 cm)。可见,在拔节期前露地玉米因地温较低,生长相对缓慢;拔节后,由于温度上升,露地玉米发育加快,同时地膜保温优势对玉米生长的影响已较小。以上结果与赵爱琴等[29]的报道不同,其原因可能是本试验中5月以后气温较高,地膜的保温作用相对较小。在氮、磷、钾积累方面以不覆膜的积累量最高,显著高于部分地膜覆盖处理。在覆膜处理中,氮、磷、钾积累量均以M2最高,M6最低。露地处理的养分积累量最高,其原因可能是取样时M0处理的玉米植株生育期相对滞后,茎、叶等营养器官仍保留有较多的养分;而覆膜处理植株均已完熟,茎、叶中的养分已较多转移至籽粒或被淋失。

表2 不同覆膜处理对玉米生长和养分吸收的影响

Table 2 Effects of different mulch film treatments on maize growth and nutrient uptake

生长指标GrowthindicesM0M1M2M3M4M5M6叶绿素含量(SPAD值)Chlorophyllcontent(SPADvalue)50.85a48.72a50.50a49.17a49.99a49.42a49.20a叶面积指数Leafareaindex1.87c2.71ab2.89a2.70ab2.70ab2.81ab2.57b株高Plantheight/cm拔节期Jointingstage140.8c160.2b178.4a166.5ab174.0a178.5a171.8ab成熟期Maturitystage207.1a199.4ab204.9a203.9a204.1a205.3a196.1b氮素积累量Naccumulation/(g/plant)1.153a0.956b1.156a0.957b0.821c0.966b0.815c磷素积累量Paccumulation/(g/plant)0.223a0.183b0.231a0.192b0.155c0.193b0.155c钾素积累量Kaccumulation/(g/plant)1.787a1.529b1.763a1.551b1.183c1.411b1.163c

M0:不覆膜;(M1~M5):覆盖5种不同配方的可降解地膜;M6:覆盖普通聚乙烯地膜。同行数据后的不同小写字母表示在P<0.05水平差异有统计学意义。

M0: Bare plot without film mulching; (M1-M5): Plots mulched with five biodegradable films of different compositions; M6: Plot mulched with conventional polyethylene film. Values within a row followed by different lowercase letters represent statistically significant difference at the 0.05 probability level.

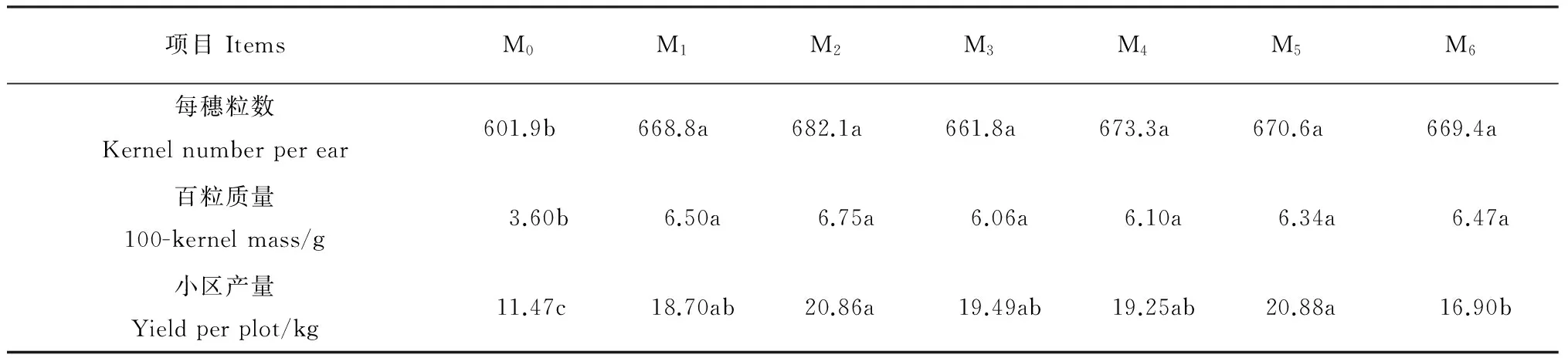

2.4 不同覆膜处理对玉米产量及构成因子的影响

5种可降解地膜和普通地膜覆盖处理的小区鲜玉米产量均显著高于露地处理,其中以可降解地膜M2和M5的产量最高,且显著高于普通地膜;5种可降解地膜处理在统计学上无显著差异(表3)。每穗粒数和百粒质量均为覆膜处理高于露地处理,但5种降解地膜处理之间以及它们与普通地膜之间在统计学上无显著差异。显然,M2和M5的小区产量高于普通地膜是由于几个产量构成因子综合改善的结果,抑或由于每株穗(棒)数较多所致。

表3 在不同覆膜处理下玉米每穗粒数、百粒质量与小区产量

M0:不覆膜;(M1~M5):覆盖5种不同配方的可降解地膜;M6:覆盖普通聚乙烯地膜。同行数据后的不同小写字母表示在P<0.05水平差异有统计学意义。

M0: Bare plot without film mulching; (M1-M5): Plots mulched with five biodegradable films of different compositions; M6: Plot mulched with conventional polyethylene film. Values within a row followed by different lowercase letters represent statistically significant difference at the 0.05 probability level.

2.5 地膜降解速率

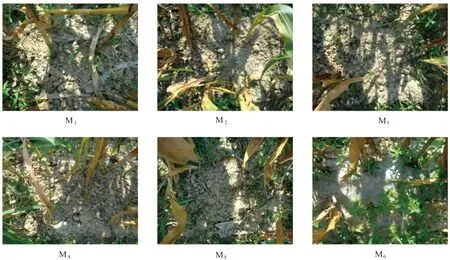

可降解地膜的降解程度随覆盖时间增加而逐渐加深,而普通地膜的变化较小,只出现少量细小的裂纹,属于正常破损(图2)。

不同可降解地膜的降解启动期基本相同,但降解速率存在着一定的差异。覆盖后约20 d,地膜形态完整性开始变差,出现细小的裂缝;不同地膜的启动期长度各异,M1和M3启动期最长,1级程度降解持续约30 d,其他可降解地膜则约为20 d。此后,可降解地膜M2、M3和M4降解速率较快,覆盖后90 d,M2基本从土壤表面消失;M3和M4在覆盖后100 d基本消失;M1和M5降解相对较慢,但在生育期末降解也达到4级(表4)。

M0:不覆膜;(M1~M5):覆盖5种不同配方的可降解地膜;M6:覆盖普通聚乙烯地膜。M0: Bare plot without film mulching; (M1-M5): Plots mulched with five biodegradable films of different compositions; M6: Plot mulched with conventional polyethylene film.

表4 不同地膜的田间降解程度

M0:不覆膜;(M1~M5):覆盖5种不同配方的可降解地膜;M6:覆盖普通聚乙烯地膜。(0~5)表示地膜降解程度指标。0级:地膜外观形态完整,未出现裂纹;1级:开始出现10 cm以下裂纹;2级:出现约20 cm较大裂纹;3级:出现约50 cm大块裂纹;4级:地膜分裂成多块较大的独立部分,并且内部出现10 cm裂纹;5级:土壤表面地膜基本消失,仅少量残留。

M0: Bare plot without film mulching; (M1-M5): Plots mulched with five biodegradable films of different compositions; M6: Plot mulched with conventional polyethylene film. Numbers 0-5 indicate different degradation degrees of mulch films. 0: Films remaining intact; 1: Films losing integrity and developing minor cracks within 10 cm in length; 2: Larger cracks with length of approximately 20 cm; 3: Cracks developing into bigger ones sized 50 cm in length; 4: Films torn into separate subunits with roughly 10 cm cracks in each; 5: Disappearance of films with tiny fragments allowed.

3 讨论

随着传统聚乙烯地膜使用量的不断增加,其负面影响也不断显现。由于自然界尚不存在对聚乙烯快速降解的微生物,普通地膜需要长达200年以上的周期才能完全消失。作为对传统非降解地膜的一种环保型替代产品,生物降解地膜需要满足几个基本条件:1)具有接近或同等的生物学效应。增温保墒、改善田间小气候,达到促进作物生长,贡献与传统地膜相近的经济产出;2)具有适宜于覆盖作物的降解特性。在作物苗期或低温时期保持稳定、完整的田间形态,以保证适宜的土壤温度和湿度;在作物生长后期或收获之后,及时启动降解,并在后茬种植之前基本分解为细小的碎片,避免对下季作物根系水分和矿物质元素吸收造成影响;3)具有足够的力学性能和拉伸强度,达到田间铺盖的强度要求,能抑制杂草生长。传统厚度较大的聚乙烯地膜由于机械性能较好,且在自然界中不易分解,因此可以较好地满足这一要求,但可降解地膜使用了新型材料(主要为PBAT),其田间实际抗杂草情况尚有待验证。这也是评价可降解地膜实际应用价值的重要标准。

本试验选用的5种可降解地膜在提高土壤温度、加快和促进玉米生长发育方面具有显著的效果,且得到了比普通地膜更高的玉米鲜穗产量,表明可降解地膜具备更强的生物学效应。在地膜田间降解方面,5种可降解地膜均在覆膜后20 d开始出现裂缝,在覆膜60~80 d后开始达到3级降解程度,在该时期地膜的完整性受到较大的影响,可以推测对土壤的增温作用开始减弱,同时杂草生长开始加快。结合玉米生育进程,可降解地膜的启动降解期稍早,尚不能有效抑制前期杂草生长,地膜在自身受到损坏的同时,其受杂草生长导致的机械力影响而破裂更加明显。到覆膜后100 d,可降解地膜基本从田间表面消失,在生物学效应上基本不影响作物后期的生长。

但与普通地膜相比,可降解地膜也有明显的不足之处。首先是材料成本上,目前可降解地膜使用成本是市售聚乙烯地膜的近3倍,因此难以在生产上大面积推广。降低可降解地膜的价格将是该产品推广应用的主要措施。可以相信,随着生产工艺的改进、规模生产的推进以及政府对新产品支持力度的加大,会逐渐降低可降解地膜的生产成本,从而被广大农民所接受。除了以高分子为材料的可降解膜,目前以苎麻纤维为主要成分的环保型麻地膜是一种成本低、发展前景好的可降解地膜。我国由于麻类原料生产和人力资源方面的优势,麻地膜产品成本较低[30]。中国麻类研究所以苎麻落麻、黄麻等为主要材料研制出了可降解麻地膜[30],并在白菜、早稻育秧、辣椒等试验或示范中取得了优异效果[31-33]。麻地膜还具有独特的土肥优势,降解后的麻类纤维无污染,并能改善土壤物理形状;麻地膜降解物还能提高土壤有机质含量和微生物数量,提高土壤肥力[31]。有报道指出,可降解材料的降解特性通常与其化学组分[34-35]、工艺参数、贮藏与使用环境[36-37]有关。在地膜开发与生产过程中,还需要根据地理区域、种植栽培方式和季节性添加特殊的降解助剂,以调整地膜的物理特性[38]。目前已有类似的研究证明可以通过良好的配方控制,使可降解地膜达到与高密度聚乙烯相近甚至更好的机械性能[39]。乔海军等[40]选用以淀粉、聚己内酯和石蜡等为主要成分的生物降解地膜,在甘肃省进行玉米覆膜试验,发现可降解地膜在播种后30 d部分破损,出现少量破孔,在覆膜170 d后大量破碎为小块地膜,部分变得很薄很脆。Kijchavengkul等[41]研究表明,降解地膜的生物学效果及降解速率与自然光强弱有关。因此,在实际使用时,需要考虑当地或栽培季节的自然因素而选择适宜的降解地膜种类。

[1] Liakatas A, Clark J A, Monteith J L. Measurements of the heat balance under plastic mulches. Part I. Radiation balance and soil heat flux.AgricultureandForestMeteorology, 1986,36:227-239.

[2] Tarara J M. Microclimate modification with plastic mulch.HortScience, 2000,35(2):169-280.

[3] Cooper A J. Root temperature and plant growth. Research review No. 4. Commonwealth Bureau of Horticulture and Plantation Crops, East Malling, Maidstone, Kent, 1973:73.

[4] Díaz-Pérez J C, Batal K D. Colored plastic film mulches affect tomato growth and yield via changes in root-zone temperature.JournaloftheAmericanSocietyforHorticulturalScience, 2002,127:127-135.

[5] Ibarra-Jimenez L, Quezada-Martin R, Cedeno-Rubalcava B,etal. Watermelon response to plastic mulch and row covers.EuropeanJournalofHorticulturalScience, 2006,71:262-266.

[6] Lamont W J. Plastics: Modifying the microclimate for the production of vegetable crops.HortTechnology, 2005,15(3):477-481.

[7] Clarke A D. Some plastic industry developments, their impact on plastic film for agricultural application.Plasticulture, 1987,74:15-26.

[8] 何文清,严昌荣,赵彩霞,等.我国地膜应用污染现状及其防治途径研究.农业环境科学学报,2009,28(3):533-538.

He W Q, Yan C R, Zhao C X,etal. Study on the pollution by plastic mulch film and its countermeasures in China.JournalofAgro-EnvironmentScience, 2009,28(3):533-538. (in Chinese with English abstract)

[9] 中华人民共和国农业部.中国农业统计资料.北京:中国农业出版社,2011:5.

Ministry of Agriculture of the People’s Republic of China.ChinaAgricultureStatisticalReport. Beijing: China Agriculture Press, 2011:5. (in Chinese)

[10] Halley P, Rutgers R, Coombs S,etal. Developing biodegradable mulch films from starch-based polymers.Starch, 2001,53:362-367.

[11] 梁美英,卜玉山,李伟,等.不同地膜与覆盖方式土壤水温与作物增产效应.山西农业大学学报:自然科学版,2010,30(5):426-431.

Liang M Y, Pu Y S, Li W,etal. Effects of different plastic films and mulching patterns on the soil temperature, moisture, and corn yield.JournalofShanxiAgriculturalUniversity:NaturalScienceEdition, 2010,30(5):426-431. (in Chinese with English abstract)

[12] 梁美英,卜玉山,李伟,等.不同覆盖材料土壤水温效应与作物增产效应分析.中国农学通报,2011,27(9):328-355.

Liang M Y, Pu Y S, Li W,etal. Effects of different mulching materials on soil moisture and temperature and crop yield.ChineseAgriculturalScienceBulletin, 2011,27(9):328-355. (in Chinese with English abstract)

[13] 梁流涛,王岩松,刘桂英.农村发展中的环境问题及其形成机制研究:以山东省王景河村为例.地域研究与开发,2011,30(6):89-93.

Liang L T, Wang Y S, Liu G Y. Study on rural environmental problems and its formation mechanism in the rural development: A case of Wangjinghe village in Shandong Province.ArealResearchandDevelopment, 2011,30(6):89-93. (in Chinese with English abstract)

[14] Hussain I, Hamid H. Plastics in agriculture//Andrady A L.PlasticsandtheEnvironment. Hoboken, USA: Wiley, 2003:185-209.

[15] 严昌荣,刘恩科,舒帆,等.我国地膜覆盖和残留污染特点与防控技术.农业资源与环境学报,2014,31(2):95-102.

Yan C R, Liu E K, Shu F,etal. Review of agricultural plastic mulching and its residual pollution and prevention measures in China.JournalofAgriculturalResourcesandEnvironment, 2014,31(2):95-102. (in Chinese with English abstract)

[16] McCraw D, Motes J E.UseofPlasticMulchandRowCoversinVegetableProduction. OSU Extension Facts-Cooperative Extension Service, Oklahoma State University, USA, 1991.

[17] Hemphill D D. Agricultural plastics as solid waste: What are the options for disposal?HortTechnology, 1993,3:70-73.

[18] Immirzi B, Malinconico M, Romano G,etal. Biodegradable films of natural polysaccharides blends.JournalofMaterialsScienceLetters, 2003,22(20):1389-1392.

[19] Russo R, Giuliani A, Immirzi B,etal. Alginate/polyvinylalcohol blends for agricultural applications: Structure-properties correlation, mechanical properties and greenhouse effect evaluation.MacromolecularSymposia:CurrentTopicsinPolymerScienceandTechnology, 2004,218:241-250.

[20] Russo R, Malinconico M, Petti L,etal. Physical behaviour of biodegradable alginate-poly (vinyl alcohol) blend film.JournalofPolymerSciencePartB:PolymerPhysics, 2005,43:1205-1213.

[21] Kapanen A, Schettini E, Vox G,etal. Performance and environmental impact of biodegradable films in agriculture: A field study on protected cultivation.JournalofPolymersandtheEnvironment, 2008,16(2):109-122.

[22] ASTM D6400-99. Standard specification for compostable plastics.AnnualBookofStandards. ASTM, Philadelphia, USA, 1976.

[23] Hammer W J. Plastics in the environment: The gathering storm//Gebelein C G.BiotechnologicalPolymers:Medical,PharmaceuticalandIndustrialApplications. Pennsylvania, USA: Technomic Publishing Company, 1993:175-190.

[24] Swift G. Requirements to define biodegradable polymers// Gebelein C G.BiotechnologicalPolymers:Medical,PharmaceuticalandIndustrialApplications. Pennsylvannia, USA: Technomic Publishing Company, 1993:191-196.

[25] Hocking P J, Marchessault R H. Biopolyesters//Griffin G J L.ChemistryandTechnologyofBiodegradablePolymers. New York, USA: Blackie Academic, 1994:48-96.

[26] Steinbüchel A, Füchtenbusch B. Bacterial and other biological systems for polyester production.TrendsinBiotechnology, 1998,16:419-427.

[27] Kijchavengkul T, Auras R, Rubino M,etal. Atmospheric and soil degradation of aliphatic aromatic polyester films.PolymerDegradationandStability, 2010,95:99-107.

[28] Kasirajan S, Ngouajio M. Polyethylene and biodegradable mulches for agricultural applications: A review.AgronomyforSustainableDevelopment, 2012,32(2):501-529.

[29] 赵爱琴,李子忠,龚元石.生物降解地膜对玉米生长的影响及其田间降解状况.中国农业大学学报,2005,10(2):74-78.

Zhao A Q, Li Z Z, Gong Y S. Effects of biodegradable mulch film on corn growth and its degradation in field.JournalofChinaAgriculturalUniversity, 2005,10(2):74-78. (in Chinese with English abstract)

[30] 王朝云,吕江南,易永健,等.环保型麻地膜的研究进展与展望.中国麻业科学,2007,29(增刊2):380-384.

Wang C Y, Lü J N, Yi Y J,etal. Progress and prospect of the research of environmental friendly bast fiber mulch film.PlantFiberSciencesinChina, 2007,29(Suppl. 2):380-384. (in Chinese with English abstract)

[31] 尚瑞广,王朝云,易永健,等.麻地膜覆盖保温特性及对白菜生长和产量的影响.中国农学通报,2012,28(16):255-260.

Shang R G, Wang C Y, Yi Y J,etal. Effects of bast fiber mulching film on heat preservation and growth and yield of Chinese cabbage.ChineseAgriculturalScienceBulletin, 2012,28(16):255-260. (in Chinese with English abstract)

[32] 熊常财,李景柱,汪红武,等.早稻可降解麻地膜育秧机插技术试验与示范.湖北农业科学,2013,52(13):2994-2996.

Xiong C C, Li J Z, Wang H W,etal. Test and demonstration of degradable bast fiber mulching film breeding and machine transplanting technology of early rice seedling.HubeiAgriculturalSciences, 2013,52(13):2994-2996. (in Chinese with English abstract)

[33] 舒英杰,周玉丽,张子学,等.麻地膜与肥料互作对辣椒生长、土壤养分及土壤酶活性的影响.中国生态农业学报,2012,20(2):175-180.

Shu Y J, Zhou Y L, Zhang Z X,etal. Effect of bast-fiber film mulching and fertilization interactions on soil nutrient, soil enzyme activity and pepper growth.ChineseJournalofEco-Agriculture, 2012,20(2):175-180. (in Chinese with English abstract)

[34] Willett J L. Mechanical properties of LDPE/granular starch composites.JournalofAppliedPolymerScience, 1994,54:1685-1695.

[35] Cho J W, Woo K S, Chun B C,etal. Ultraviolet reflective and mechanical properties of polyethylene mulching films.EuropeanPolymerJournal, 2001,37:1227-1232.

[36] Jasberg B, Swanson C, Nelsen T,etal. Mixing polyethylene-poly (ethylene-co-acrylic acid) copolymer starch formulations for blown films.JournalofPolymerMaterials, 1992,9:153-162.

[37] Lawton J W. Effect of starch type on the properties of starch containing films.CarbohydratePolymers, 1996,29:203-208.

[38] Briassoulis D. Mechanical behaviour of biodegradable agricultural films under real field conditions.PolymerDegradationandStability, 2006,91:1256-1272.

[39] Tocchetto R S, Benson R S, Dever M. Outdoor weathering evaluation of carbon-black-filled, biodegradable copolyester as substitute for traditionally used, carbon-black-filled, nonbiodegradable, high-density polyethylene mulch films.JournalofPolymersandtheEnvironment, 2001,9(2):57-62.

[40] 乔海军,黄高宝,冯福学,等.生物全降解地膜的降解过程及其对玉米生长的影响.甘肃农业大学学报,2008,43(5):71-75.

Qiao H J, Huang G B, Feng F X,etal. Degradation and its effect on corn growth of biodegradable mulch film.JournalofGansuAgriculturalUniversity, 2008,43(5):71-75. (in Chinese with English abstract)

[41] Kijchavengkul T, Auras R, Rubino M,etal. Assessment of aliphatic-aromatic copolyester biodegradable mulch films. Part I: Field study.Chemosphere, 2008,71:942-953.

Biological effect of biodegradable mulch films on maize and their degradation properties. Journal of Zhejiang University (Agric. & Life Sci.), 2015,41(2):179-188

Hu Hongliang, Han Zhigang, Zhang Guoping*

(CollegeofAgricultureandBiotechnology,ZhejiangUniversity,Hangzhou310058,China)

mulch film; degradation; maize; biological effect; yield

国家科技支撑计划项目(2012BAD11B03).

联系方式:胡宏亮,E-mail:hlhu@zju.edu.cn

2014-09-19;接受日期(Accepted):2014-11-24;网络出版日期(Published online):2015-03-20

S 31; X 705

A

*通信作者(Corresponding author):张国平,Tel:+86-571-88982115;E-mail:zhanggp@zju.edu.cn

URL:http://www.cnki.net/kcms/detail/33.1247.S.20150320.2106.011.html