Radial fretting character research ofthe shaft-hub of compress impellerbased on virtual orthogonal experiment

Jun-sheng ZHAO

,Xue-long LU 1,X in-zhong HUANG2

(1 School of Mechanical and Power Engineering,North University of China,Taiyuan 030051,China)

(2 Final Assembly and Debugging Department of the2nd Academy,CASIC,Beijing 100854,China)

Radial fretting character research ofthe shaft-hub of compress impellerbased on virtual orthogonal experiment

Jun-sheng ZHAO1*

,Xue-long LU1,X in-zhong HUANG2

(1School of Mechanical and Power Engineering,North University of China,Taiyuan 030051,China)

(2Final Assembly and Debugging Department of the2nd Academy,CASIC,Beijing 100854,China)

A three-dimensionalmodel of as haft-hub of compressor impeller was set up by Pro/E.Based on the ANSYS,the finite elementmodel was established,using the analysis method of combining submodle and paramesh.The shaft-hub of compressor impeller was simulated by virtual orthogonal design optimization method.Based on the fact that there existed radial fretting in the shaft-hub interference fit joint,researching the influence significance order and law of interference,friction coefficient and rotating speed to the maximum unit frictional work,the average friction work and the optimized parameter were obtained.

Compressor impeller,Radial fretting,Finite element method(FEM),Virtual orthogonal experiment;

*Corresponding author:Jun-sheng ZHAO,Associate professor.

E-mail:zjs@nuc.edu.com

1 In troduction

Fretting can be commonly found in mechanical vibration,fatigue load,hot and cold cycle and workingconditionwith the components in tight.Fretting componentsmaterial damage and accelerate the crack initiation and propagation.Ithas become one of themain causes in failure of some of the key parts and components and even is called industrial cancel.Turbocharger compressor impeller damage ismainly caused by the crack propagation,and the study found that the formation of the crack is due to fretting wear.Compressor impeller is the important part of the turbocharger,and it generally presses on the impeller shaft by the interference fit directly and makes transmission torque in the way of this connection.Compressor impeller works at a high speed.The current widespread of the turbocharger speed range is 60000-120000 r/min,the max comes up to 260000 r/min.Frictional work is the product of the friction stress and sliding distance.It is an important parameter tomeasure the degree of friction and wear.Researching the influence ofmagnitude of interference,rotate speed and friction coefficient to contact pressure,friction stress,the ways of their changes can be found out,which can reduce the degree of compressor impeller s shaft-hub friction and wear effectively and provide theoretical basis for the compressor impeller assembly process,thus improving the working reliability of the compressor impeller.

2 Numerical simulation

2.1 Experimental subject

Take a certain type of vehicle turbocharger compressor impeller as an example to calculate.This compressor impeller is consist of the rotary steering parts in the inlet of the impeller and impeller with radial vane part behind the former.12 blades are distributed uniformly in circumferential direction in this type of im-peller.Thematerials of impeller is castaluminum and axle is 45 steel,as shown in Table 1.

Tab le 1 The m ain param eters o f im peller

2.2 Establishment ofmodel

While the compressor impeller shaft-hub is cyclic symmetric,we can analyze one cycle by using the method of the substructure analysis.Impeller and axis can be divided into six substructures along the circumferential direction.In otherwords,the 60 degrees is a symmetric cycle.A three-dimensionalmodel of a substructure was set up by Pro/E.Then,themodels are put into the software ANSYS and are analyzed by using the analysis method of combining submodle and paramesh.A large number of calculations was made according to different amount of interference,rotating speed and friction coefficient.Substructure of the 3D model is shown in Fig.1,meshed substructure is shown in Fig.2.

Fig.1 Substructure o f the 3D m odel

Fig.2 Meshed substructure

This paper adopts Solid185 element to mesh.Taking computational efficiency and computational accuracy into consideration,choosing the length of the element is 0.8 mm.44 grid 6 grid are divided along the axial and the circumferential direction on the outer surface of the axis and the inner surface of the compressor impeller axis hole.Without establishingmultiple different interference model of,interference finite elementmodel can be got by offsetting radius of axis using paramesh.It can greatly save processing time.

3 Param eter selection

3.1 The amount of the interference

As the compressor impeller is shaft-hub interference fit joint assembly,impeller generally is pressed on the axiswith a certain amount of interference and transmit torque by the contact friction.When the friction stress between the friction surface is less than the product of the contact pressure and the friction coefficient,the area between the axis and the hub are in stick zone.When the friction stress between the friction surface is more than the product of the contact pressure and the friction coefficient,relative slip will happen between axis and hub and the area between the spindle and the hub are in slip zone.The change of Centrifugal force will cause the radial fretting in impeller shaft-hub,the influence of different amount of interference to contact pressure is very significant.If the amount of the interference is too small,impeller shaft-hub will easily come loose and result in the supercharger working accident;If the amount of the interference is too big,the impeller stress will be excessive high,which can make the impeller inner hole cracked when it is assembled and affect the life of the turbocharger.In order to find the law of the amount of interference and radial fretting character of the shaft-hub of compress impeller,this paper selects the amount of interference values are 0.006 mm and 0.006 mm,0.008 mm and 0.009 mm.

3.2 The coefficient of friction

Friction is the important factors that affect the contact surface tangential stress,and it can accelerate the micro crack generation and propagation in contact surface,which eventually causes a decline in structural fatigue life.Under the condition that the contact load is given,friction force t is proportional to the size of friction coefficient.Not only the coefficient of friction affects the friction stress in the contact surfaces and sliding distance,but also affects the friction work and the division of fretting regime.In order to find the law of the coefficient of friction and radial fretting character of the shaft-hub of compress impeller,this paper selects the coefficient of friction values are 0.10,0.15,0.20 and 0.25.

3.3 Rotating speed

Rotating speed is the outside load,which is applied in the assembly of compressor impeller shaft-hub.Given a certain amount of interference in the process of compressor impeller rotating,the changes of the amount of the impeller centrifugal force will change along a radial direction as the rotating speed is not stable.Changes of the centrifugal force will cause the change of the distance on the sliding surfaces,which lead to fretting in contact area.In a word,for the actual leaf wheel hub assembly,rotating speed change will directly lead to the fretting of impeller.In order to find the law of the rotating speed and radial fretting character of the shaft-hub of compress impeller,this paper selects the rotating speed values are 90 000 r/min,100 000 r/min,110 000 r/min and 120 000 r/min.

Tab le 2 Orthogonal design

3.4 Other parameters

This paper only researches the radial fretting character of the shaft-hub of compress impeller.Tangential fretting caused by torque has not been considered.Therefore tangential fretting character of impeller shaft and the shaft shoulder,which caused by the centrifugal is not involved.The influence of other parameters to radial fretting character of the shaft-hub of compress impeller also need to be considered such as torsional fretting characteristics caused by torque effect,the change of turbocharger impeller rotating speed,loading frequency,etc.

4 The Determ ination of the Schem e and the Selection of the Ob jective Function

4.1 The determination of scheme

The research objectof this paper includes three factors:the amount of interference,the coefficient of friction and the rotating speed.Each factor selects four levels,And choose L16(45)orthogonal table,the orthogonal design,as shown in Table 2.

4.2 Selection of the objective function

Fretting will notonly cause friction and wear of contact surface,bur also can accelerate the crack initiation and propagation,which results in reducing the fatigue life of components.Frictional work is the product of friction stress and sliding distance.It is an important parameter tomeasure the degree of the friction and wear.The change of the friction work can lead to fretting wear and crack initiate in fretting regime.The compressor impeller structure shows thatmass distribution in radial direction close to the small side is relatively small and close to the back side is relatively large.Contact pressure distribution is according to certain rules along the axial direction.The larger quality gets bigger centrifugal force at the same speed,which can reduce the squeezing affecting between compressor impeller and the rotor shaft,thus reducing the contact pressure in contact surface.This paper selects theminimum of themaximum unit frictionalwork and the minimum of the average friction work as the objective function of analysis and optimization.

5 The resu lts and discussion

5.1 Significant analysis of the factors

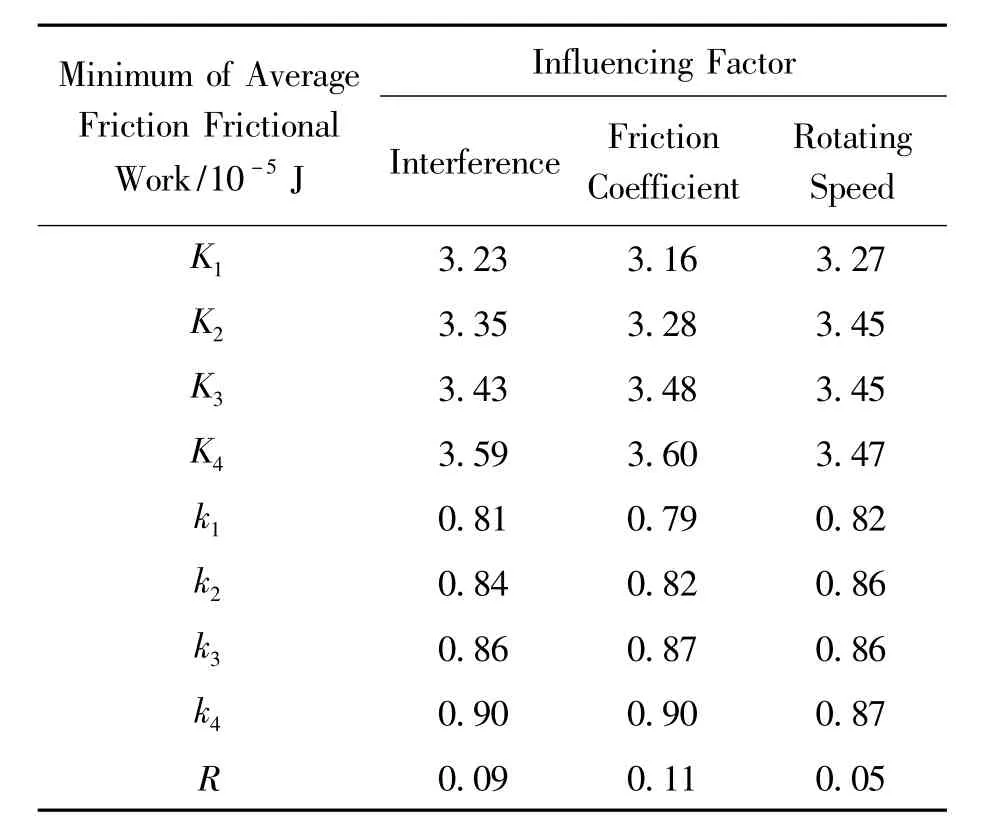

By analyzing the simulation results of the available data Table 2,we can get the range analysis of unit frictionalwork and average friction work,as shown in Table 3 and Table 4.

Range analysis of Table 3 shows:RFrictionCofficient>Rinterference> RRotatingspeed,the important degree of three factors to theminimum of themaximum unit frictional work is that friction coefficient is themaximum,the amount of interference is second,rotating speed is the minimum.

Range analysis of Table 4 shows:RFrictionCofficient>Rinterference> RRotatingspeed,the important degree of three factors to theminimum of theminimum of the average friction work is that friction coefficient is the maximum,the amount of interference is second,rotating speed is theminimum.

5.2 The influence law of the parameterson the objective function

From Fig.3,we know that as the increase of the amount of interference,the rotational speed and the friction coefficient,the maximum unit frictional work also presents the increasing trend,only varying in degrees of increase.

From Fig.4,we know that as the increase of the amount of interference,rotational speed and friction coefficient,the average frictional work also presents the increasing trend,only varying in degrees of increase.

Tab le 3 Range analysis o f unit frictionalw ork

Tab le 4 Range analysis o f average frictionalw ork

Fig.3 In fluence o f param eters on m axim um unit friction

Fig.4 In fluence o f param eters on average frictional w o rk

5.3 Optimization of the parameter

As this paper studies has 2 objective functions,the comprehensive balancemethod should be used in the optimization of technological parameters.In other words,analyzing each index separately,finding out the optimal level of each index and then balancing the optimal conditions for the various index to find out each index are the best possible conditions comprehensively.

From Table 3 and Table 4,we can get the best combination of four factors to a single objective function:

1)The maximum unit frictional work:interference 1,friction coefficient1 and rotating speed 1.

2)The average friction work:interference 1,friction coefficient1 and rotating speed 1.

The best combination of the amount of interference above-mentioned all are level 1.So the optimal interference is level1.The best combination of the friction coefficient above-mentioned all are level 1.So the optimal friction coefficient is level1.The best combination of the rotating speed above-mentioned all are level 1.So the optimal rotating speed is level 1.

Based on the analysis listed above the best combination of the three parameters are interference 1,friction coefficient1,and rotating speed 1.That is to say the friction coefficient is 0.006 mm,the friction coefficient0.1 and the rotating speed is 90 000 r/min.

This portfolio is the first experimental combination.itsmax unit frictionalwork is 2.36 ×10-5J.It is less than other combination of experiments and the average friction work also is the minimum.Thus,the optimized technological parameters combination is credible.Not only reduce the squeezing effect between the compressor impeller and the rotating axis,but also reduce the contact pressure in the contact surface and reduce the friction and wear effectively.

6 Summ ary

1)The friction coefficient of the compressor impeller shaft-hub interference fit joint assembly is the important factors affected the degree friction and wear.The important degree of three factors to themaximum unit frictional work and the average friction work is that friction coefficient is themaximum,the amount of interference is second,rotating speed is theminimum.

2)The virtual orthogonal experiment results show that as the increase of the amount of interference,rotational speed and friction coefficient,the maximum unit frictional work and the average frictionalwork also presents the increasing trend,only varying in degrees of increase.

3)The best combination parameters of the compressor impeller shaft-hub interference assembly is the friction coefficient is 0.006 mm,the friction coefficient0.1 and the rotating speed is 90 000 r/min.

Acknow ledgem ents

This paper is supported by the Natural Science Foundation of Shanxi Province(2012011023-2),and High and New Technology industrialization Project of Shanxi Province Colleges and Universities(20120021).

[1]Zhou ZR.Leo Vincent.FrettingWear[M].Beijing:Beijing Science Press,2002.

[2]ZHAO Jun-sheng,HUANGXin-zhong.Vibration Characteristic Simulation and Finite Element Analysis of Compressor Impeller Based on ANSYS[J].Machine Design and Manufacture,2012,4(4):24-26.

[3]HUANG Xin-zhong.Contact Numerical Analysis and Fretting Character Research on Shaft-Hub of Compressor Impeller[D].Taiyuan:North University of China,2012.

[4]Wei Zhi-ming,Tan Jian-song.The Research of Fretting Wear Influence on the Reliability of the Engine Block[J].Vehicle engine,2006,4(2):56-58.

[5]ZHANG Hong-wu,LIAO Ai-hua,WU Chang-hua.Study on Elastoplastic Frictional Contact Problem in Interference Fits of Comperssors[J].Engineering Mechanics,2007,24(1):186-192,177.

[6]YANG Li-li,XIE Chun-ping,SU Xu-zhong.The Optimization Design of the Key Factors in Plug Tightly Winding Spun Yarn[J].Progress in Textile Science,2007(1):27-28,50.

基于虚拟正交试验的压气机叶轮轴-毂径向微动特性研究

赵俊生1*,鹿雪龙1,黄新忠2

1.中北大学机械与动力工程学院,太原 030051

2.中国航天科工集团第二研究院总装调部,北京 100854

采用Pro/E建立压气机叶轮轴-毂三维模型,利用ANSYS软件采用子结构结合网格随移技术的分析方法,建立其有限元模型;采用虚拟正交试验方法对压气机叶轮轴-毂进行仿真,得出过盈量、摩擦系数、转速对最大单位摩擦功和平均摩擦功影响显著性次序及影响规律,从而得到最优组合。

压气机叶轮轴-毂;径向微动;有限元法;虚拟正交试验

10.3969/j.issn.1001-3881.2015.06.010 Document code:A

TD63+7

2 September 2014;revised 22 October 2014;accepted 10 November 2014

- 机床与液压的其它文章

- Time constant of a hydraulic servo valve withdynamic pressure feedback

- Research on fault diagnosis and fault toleranttechnology of IGBT in active power filters

- A new test generation algorithm fornon- robust path delay faults

- Study on high precision cymometer ofmechanical vibration

- Custom implant design for patients withmandible defects based on rapid prototyping

- Design of car reverse anti- collision warningsystem based on AT89S52