Monitoring result analyses of high slope of f ve-step ship lock in the Three Gorges Project

Qixiang Fan,Hongbing Zhu,Jun Geng

China Three Gorges Corporation,Beijing,100038,China

Monitoring result analyses of high slope of f ve-step ship lock in the Three Gorges Project

Qixiang Fan,Hongbing Zhu*,Jun Geng

China Three Gorges Corporation,Beijing,100038,China

A R T I C L E I N F O

Article history:

Received 19 January 2015

Received in revised form

2 February 2015

Accepted 3 February 2015

Available online 16 March 2015

Three Gorges Project(TGP)

Five-step ship lock

Slope

Monitoring analysis

The construction of the double-lane f ve-step ship lock of the Three Gorges Project(TGP)was commenced in 1994,the excavation of the ship lock was completed by the end of 1999,and the ship lock was put in operation in June 2003.The side slopes of the ship lock are characterized by great height (170 m),steepness(70 m in height of upright slope),and great length(over 7000 m in total length).In association with the ship lock,the surrounding rocks in slope have a high potential to deform,with which the magnitude of deformation is restricted.Monitoring results show that the deformation of the f ve-step ship lock high slopes of the TGP primarily occurred in excavation period,and deformation tended to be stable and convergent during operation period,suggesting the allowable ranges of deformation.At present,the slopes and lock chambers are stable,and the ship lock works well under normal operation condition,enabling the social and economic bene f ts of the TGP.

©2015 Institute of Rock and Soil Mechanics,Chinese Academy of Sciences.Production and hosting by Elsevier B.V.All rights reserved.

1.Introduction

As one of the three most important structures of the Three Gorges Project(TGP),the ship lock is constructed by deep cutting and excavation in granite at the north of Tanziling on the left bank. The ship lock of the TGP consists of upstream and downstream approach channels,main lock chamber section,water conveyance system,and mountain drainage system.The total length of the ship lock is 6442 m,and the main section of the ship lock(chamber section)is 1621 m long.The high slopes are critical issues concerning the safe operation of the TGP.The maximum height of these slopes is 170 m,and the slopes higher than 120 m account for 460 m in length.Central rock piers with width of 54-57 m are placed in the double-lane lock chambers.Therefore,a bilateral doublegrooved slope is formed in the section of the main structure (Zhang,2001).The high slopes of the permanent ship lock are formed by deep cutting in the mountain side characterized by great height,complex topography,wide-spread range,complete stress relief,exhibiting marked unloading and heterogeneity characteristics.Thus the deformation and slope stability issues raise concerns for these slopes.As for the slopes of the permanent ship lock, the global and local stability problems of these slopes must be well addressed and the slopes deformation of these should be strictly controlled in order to satisfy normal operation of the miter gate of the ship lock(Fan,2004;Fan et al.,2011).The typical section and photo of the lock chamber of the double-lane f ve-step ship lock is shown in Figs.1 and 2,respectively.

The f ve-step ship lock high slope ofthe TGP is a challenging issue not only in engineering geological investigation,mechanical properties and stability analysis of rock mass,and safety monitoring,but also in theories and methods for design of high slope,as well as construction safety.For such a large-scale project,no knowledge or practicalexperience is available.To solve the key issues encountered during construction,the following measures are taken:

(1)Reasonable construction procedures are proposed to harmonize the relations between surface deformation and underground engineering in association with deep excavation and anchoring support.

(2)The one-step complete excavation method of upright slope meets the technical requirements of the excavation.

(3)Using the integrated control blasting technology,the impact of groove excavation blasting is kept in the allowable range of design,satisfying the requirements of engineering rock quality and construction progress.

(4)The fore shaft support technology is utilized to control the deformation and collapse of rocks at the top of upright slopes for the purpose of slope stability and construction safety during construction period(and excavation period).

(5)The major indexes for estimating the stability of side wall rocks are determined to deal with the relation between the curing time of concrete lining and controlled blasting.

Fig.1.Typical pro f le of the high slope of the double-lane f ve-step ship lock of the TGP.

These procedures are carefully proposed based on long-term scienti f c research.During design and construction stages of the TGP,the construction procedures and methods were adjusted and optimized continuously by f eld experimental investigation,accumulated experience during construction practices,and the integrated application of multi-discipline methods including engineering geological survey,rock mechanics test,numerical simulation,controlled blasting of engineering excavation,anchoring, and back analysis of the monitoring data.The design and construction techniques are considered to be ground-breaking in termsof large slope excavation gradient,novel geological survey method and technology,evaluation theory and method for rock mechanics property and seepage characteristics.The safety monitoring and feedback method,in terms of the dynamic design concept and method of super-high slope associated with other methods,is applicable to deep excavation of high rock slope.By the end of 1999, a high and steep slope with complex structure was completed after excavation,and the rock stability of the high slope was effectively controlled after anchoring measures used,indicating that the ship lock excavation of the TGP was successful.

Fig.2.Photo of the high slope of the double-lane f ve-step ship lock of the TGP.

In this paper,the deformations of the high slope of the TGP ship lock recorded during construction and operation periods were analyzed.It is shown that the deformation of the slope occurred mainly in construction period,and was kept stable in operation period.The deformations of side wall and the stresses of highstrength rock bolts are well controlled.

2.Analysis of monitored deformation of high slope of the TGP ship lock

Construction of the TGP ship lock began in April 1994.The excavation of lock chamber was basically completed in April 1999. By the end of December 2014,the slope of the ship lock remained stable for more than 14 years.In order to evaluate the high slope stability and the operation safety of the ship lock,nearly 1000 monitoring devices were laid out in various locations of the slope. To date,90%of the monitoring devices work well.

2.1.Monitoring results of the TGP ship lock slope

Since the completion of ship lock excavation in April 1999,the boundary conditions that in f uence the slope deformation magnitude have been basically identi f ed.Based on the measured results, the displacement after April 1999 kept nearly constant,with minor f uctuations.The variations of these measured values are mainly triggered by errors recorded in data observation,showing no obvious relations with temperature.

2.1.1.Top of central piers

The deformation of the central piers of the ship lock consists of the rebound deformation due to unloading during stress relief and the deformation induced by deadweight during the construction of the upright slopes.During excavation,stress relief happened in three directions of the central piers,namely,left and right sides, and the top.While at the lock head,stresses are released not only in the three directions but also in the free face downstream.Meanwhile,the geological condition and initial in-situ stress state vary at different parts of central piers.All of these factors contribute to the complicated deforming behaviors of the central piers.Typical deformation curves of central piers are shown in Fig.3.

It can be seen form Fig.3 that there are signi f cant differences in magnitude and direction of displacement along the direction of lock chamber at different parts of the central piers.Most of the monitoring points at the south of the central piers deform towards south and the ones at the north towards north.Between the second and third lock heads,the direction of displacement at some parts of the central piers is the same.In December 2014,the measured displacements of the central piers towards the lock chamber were-19.49 to 33.59 mm and-5.89 to 23.76 mm at the north and south,respectively.

In December 2014,the displacements of the central pier top measured downstream were-1.87 to 26.57 mm and-4.98 to 22.67 mm at the north and south,respectively.The measuring point TP119GP01,situated on the 160 m platform at the horizontal slope top of the third lock head,showed a maximum downstream displacement,which was primarily induced by unloading of the upright slope.

The vertical displacement on the top of the central pier was mainly presented in form of settlement recorded in December 2014,with the measured values of-5.80 mm(rebound)to 15.27 mm(settlement).

In order to analyze the convergence of surface deformation on the top of the central pier and to reduce the impact of observation errors,average annual values of the displacement towards the lock chamber were selected for comparison purpose(see Table 1).It can be observed from Table 1 that the annual average and the longterm average annual displacements(from 2000 to 2014)of the central pier top towards the lock chamber varied between ±1.5 mm,indicating that the central pier stays stable and the deformation of the central pier quickly converges after excavation.

2.1.2.South and north high slopes

The south and north slopes mainly deform towards the chamber (the direction of free face),with the horizontal displacement towards the lock chamber much greater than the horizontal and vertical displacements along the direction of water f ow.The typical deformation curves of the south slope are shown in Fig.4.

The horizontal displacements of the north and south slopes towards the lock chamber slightly decrease with reduced elevation. By April 1999 when excavation was completed,the displacements of the north and south slopes towards the lock chamber were 9-39 mm and 4-53 mm,respectively;and the displacements of the slopes top towards the lock chamber were 11-27 mm and 4-35 mm,respectively.After that the displacements of the slopes increased slightly.By December 2014,the maximum displacements of the south and north slopes towards the lock chamber were74.27 mm and 58.82 mm,respectively.For the south slope,the maximum displacement was recorded at the measuring point TP41GP02 at elevation 185 m of the stake 15+930.The maximum displacements of north and south upright slopes top were 35.09 mm and 47.22 mm,respectively.

Fig.3.Displacement of the measuring point TPBM68GP01 at elevation 160 m at the north of central pier top.

The downstream displacements of the north and south slopes were small.The measured displacements in December 2014 were-2.53 to 33.96 mm,with the maximum value observed at the measuring point TP42GP02 at elevation 200 m bench on the south slope.This measuring point was situated at the corner of the broadened section of the vertical shaft,and its displacement was mainly triggered by unloaded downstream free face.

The vertical displacement of north and south slopes was mainly in the form of settlement that was within 17 mm.The settlement roughly occurred during excavation.After completion of excavation,the displacement varied within a slight magnitude,and its increment was reduced with elapsed time and f nally tended to converge.

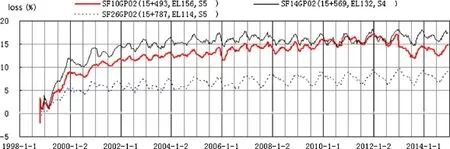

The trend of displacement measured at each measuring point was different due to the differences in completion sequence of slopes,rock geological conditions and excavation state,as well as the effect of anchoring methods.By the end of December 2014,the displacement values of north and south slopes ranged between 0.57 mm and-20.86 mm,averaging 9.65 mm.The displacement increment in December of each year(from 1999 to 2014)decreased year after year,indicating that the deformation was convergent,as shown in Figs.5 and 6.Regression analysis was conducted for the displacement and the f tting curves can be expressed as follows:

Table 1Annual average values of the horizontal displacement at the central pier top towards the lock chamber.

wheretis the time(from April 1999);a,b,Kandmare the f tting parameters.For each measuring point,these four f tting parameters are different.

According to the monitoring results,the deformation of slope was mainly induced by excavation.Most of the deformation was observed during excavation,and increased with increasing excavation depth.The deformation rate measured after excavation decreased.At present,the deformation of slopes has converted to a stable value,and the slopes are stable in a global sense.It is indicated that reservoir impoundment and navigation through the ship lock have no obvious effect on the deformation of north and south high slopes.

The measured surface deformation was primarily in the direction towards the lock chamber.The convergence of the surface deformation rates of the north and south upright slopes were the fastest.Most of measuring points on the north and south slopes exhibited a fast convergence velocity of deformation,except for a few measuring points on the top.In view of rock lithology,the deformation rate of the measuring points in fresh and weakly weathered rocks converged faster,except for several measuring points characterized with a slow convergence velocity in the strongly weathered rocks on the top of north and south slopes.The relative deformations of the blocks measured in unloading zones of the upright slope have remained constant since completion of slope excavation and supporting in 1999,which indicates that the upright slope is stable.

2.2.Deformations of lock head and side wall

Normal and inverted plumb lines were deployed at each lock head to monitor the horizontal displacement of the lock head;and tension wire alignment was laid out in the pipeline gallery on the top of lift walls on the north and south slopes of all lock chambers to monitor the horizontal displacement of lift walls.Speci f cally,the vertical lines of the 1st and 5th lock heads were set in the 3rd block of the lock heads;and the vertical lines of the 2nd,3rd,4th,and 6th lock heads were set in the 2nd block of these lock heads.Theanchorage point of foundation plumb line holes of each lock head is roughly 42-63 m below the f oor elevation of the foundation gallery.

Fig.4.Displacement of the measuring point TPBM94GP02 at elevation 168 m bench of the south slope.

2.2.1.Lock head and gate pier

The normal and inverted plumb lines at each lock head subsequently began to work between September 2001 and August 2002. By the end of December 2014,the measured deformation at lock heads is shown in Table 2,and the typical curves are shown in Fig.7.

Table 2 and Fig.7 show that the displacement at the bottom of the lock head is smaller,with the value of-1.5 to 1.5 mm.The displacement at lock head top is-0.83 to 7.27 mm towards the lock chamber,and-3.93 to 7.71 mm towards the downstream direction. The deformation of the lock head does not affect the opening of the miter gate of the ship lock.In contrast,the measured deformations of the 5th and 6th lock heads are slightly greater and change periodically with temperature.This is mainly associated with the characteristic of mixed structure of abutment piers.The annual variation of displacement towards the lock chamber,induced by change of temperature,is approximately within 2 mm.Reservoir impoundment and lock f lling and discharge have a slight effect on the displacement of lock head top.

Fig.5.Trend value of displacement at elevation 139 m on the top of north upright slope at the stake 15+787.

Fig.6.Trend value of displacement at elevation 155 m on the top of south upright slope at the stake 15+770.

2.2.2.Lock chamber side wall

Table 3 shows the measured horizontal displacement,towards the lock chamber,of pipeline gallery in the south and north slopes by December 2014.It is shown that the values of the horizontal displacement change between-1.46 mm and 7.45 mm.The displacements of the 4th and 5th lock chambers are relatively large due to the gravity structure of the upper chambers.The displacement does not increase with elapsed time.

General speaking,the changes in the horizontal displacement of foundation at the lock head,and the displacement of lock head top towards the lock chamber,upstream and downstream are minor. The vertical displacement of foundation of the north and south lines varies within±1 mm before and after impoundment each year.It is shown that a minor effect of impoundment on foundation deformation is observed.

3.Monitoring of anchorage force of the TGP ship lock slope

In order to enhance the stability of high slopes of the TGP ship lock,improve the stress state of slope rock,and prevent unloading excavation and development of cracks,a total of 230 sets of 1000-kN end anchor cables,666 of 3000-kN end anchor cables,and 1271of 3000-kN two-ended anchor cables were utilized to reinforce the slopes.In addition,a great number of blocks that have the potential of instability were encountered during excavation of the stage II at the upright slope of the ship lock.To enhance the stability of these blocks,1309 sets of 3000-kN end anchor cables and 528 of 3000-kN two-ended anchor cables were arranged(Fig.8).

Table 2Range of measured displacement values on the top of each lock head(unit:mm).

Fig.7.Correlation curves of horizontal displacement on the top of lock head I.

Table 3Measured horizontal displacement of pipeline gallery on north and south slopes (towards the lock chamber).

3.1.Prestress of anchor cables

One hundred and f fteen anchor cable dynamometers were deployed to observe the long-term prestress state of anchor cables,of which two are bonded anchor cables,and others are unbonded cables.The statistics of prestress loss ratio after anchor cable lock-in is shown in Table 4,and typical process curves are shown in Fig.9.

As can be seen from Table 4 and Fig.9,the measured prestress loss after anchor cable lock-in is-0.6%to 6.4%,averaging 2.8%.It was roughly 12.61%in average in December 2014.The change in anchor cable prestress loss is in agreement with the general rules of stress loss obtained in other cases.After one year of installation of the anchor cables,the average prestress loss after cable lock-in was 8%, most of the anchor cables being within 5%.Two years later,the prestress change was slight and almost kept constant,and an annual change of prestress due to the minor effect of temperature can be observed.

Fig.8.Photo of anchor cables laid out at the high slope of double-lane f ve-step ship lock.

There was a slight difference between the magnitude of prestress loss of the anchor cable on the blocks and non-block parts,and the prestress loss matched with its change rule.Takingthe block f1239 for example,its average prestress loss rate was about 7.2%after lock-in for one year,while the average prestress loss rate measured by other dynamometers at the south slope was around 7.6%one year after lock-in.Reservoir impoundment and ship lock navigation have no obvious impact on the anchorage force of the anchor cables,and no dramatic change has been observed in anchor cable prestress.This confrms that all slopes are stable.

Table 4Measured prestress loss ratio of anchor cable by dynamometers.

Fig.9.Process curves of prestress loss after lock-in of 3000-kN anchor cable at the south slope.

3.2.Stress of high-strength anchor bolt

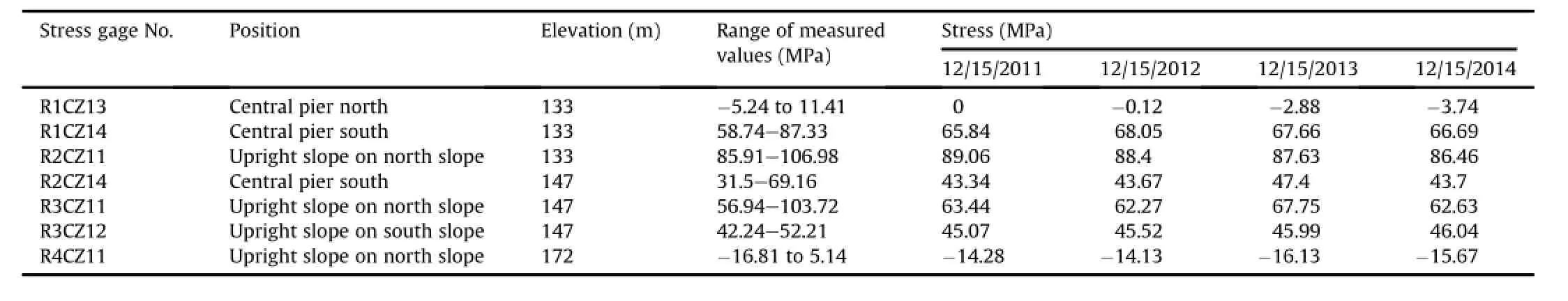

The main part of the TGP ship lock is located within the deeply cut rock tank at the left side of Tanziling.The walls of the ship lock are of thin reinforced concrete lining structure combined with mixed(gravity+lining)structures.The lining structure bears loads associated with bed rocks behind the walls so as to meet the requirements of structural stability in terms of strength.At the same time,string stress gages were amounted on the free segment of the anchor bolt at interface of lining and bed rock to observe the stress of high-strength anchor bolt.

The measured stresses of high-strength anchor bolt at the lock head I are shown in Table 5,and time-history curves of anchor bolt stressareshowninFig.10.AscanbeseenfromTable5andFig.10,the stress measured by 48 stress gages was within 315 MPa in December 2014.The maximum tensile stress recorded by the stress gages was within150MPa,except threestressgages,i.e.R4CZ21(EL.165.8mon the north slope of the 2nd lock chamber),R8CZ31(EL.152.03 m on thenorth slopeof the3rdlockchamber),andR1CZS53(EL.56.5mon the south slope of the 5th lock chamber),which had a maximum tensile stress of more than 200 MPa.In presence of the navigation of the ship lock in 2003,flling and discharge of lock chamber had a slight impact on variation of anchor bolt stress.On the whole,the measured stresses of anchorboltare generallysmalland farlessthan the design values of anchor bolts,which indicates that the lining structure of the ship lock is stable.

Table 5Stress of high-strength anchor bolt on 15+060 section of lock head I.

Fig.10.Stress of high-strength anchor bolt on the north slope of lock head I(R2-4CZ11).

4.Conclusions

Up to December 2014,the TGP ship lock had beenputin operation for over 10 years and experienced a 5-year reservoir impoundment testing.The monitoring results show that the slopes of the ship lock are stable,and the deformation of lock head and lift wall and the stress of high-strength anchor bolts are all within the allowable range.Reservoir impoundment has no signi f cant effect on the deformation of the ship lock,and the variations in deformation and stress at various key positions after monitoring are normal.The high slopes and ship lock are basically in a stable state and the upstream and downstream channels and linkage sections enjoy good shipping capability,suggesting the ef f cient operation of the TGP ship lock.

Con f ict of interest

The authors wish to con f rm that there are no known con f icts of interest associated with this publication and there has been no signi f cant f nancial support for this work that could have in f uenced its outcome.

Dai Huichao.Research on rock mechanics problems of division pier of the Three Gorges permanent shiplock.Chinese Journal of Rock Mechanics and Engineering 2001;20(5):680-4(in Chinese).

Fan Qixiang.Key technical issues of TGP permanent shiplock.Engineering Science 2004;6(1):48-52(in Chinese).

Fan Qixiang,Zhu Hongbing,Chen Xuchun.Key rock mechanics issues related to the Three Gorges Project in China.Journal of Rock Mechanics and Geotechnical Engineering 2011;3(4):329-42.

Zhang Chaoran.Practice and experimental veri f cation of TGP’s permanent shiplock slope.Engineering Science 2001;3(5):22-7(in Chinese).

Dr.Qixiang Fangraduated from Gezhouba Institute of Hydro Electric Engineering with a B.S.in 1984,and obtained M.S.and Ph.D.from Tsinghua University in 1999 and 2010,respectively.He held several positions in the China Three Gorges(CTG)Project Preparatory Of f ce, including associate engineer in the Division of Technology in the Department of Construction Technology,project supervising engineer and leader of the supervision team of the Liyuan Project and later the Deputy Director of the Construction Division of the Liyuan Company.He served in CTG’s Construction Department as Deputy Director of the Division of General Management and later as the Director of the department,Director of the Division of Temporary Ship Lock Project and later the Director of the Division of Temporary Ship Lock and Ship Lift under the Left Bank Construction Department of the Three Gorges Project,the Deputy Director and later the Director of the Navigation Construction Department and Deputy Director of Management Department of Beijing National Aquatics Center(known as the Water Cube).He now is Executive Vice President of the CTG and is in charge of the construction of CTG’s Jinsha River hydropower projects.Dr.Fan is well experienced in management of large-scale complex hydropower projects,design,installation and testing of complex centralized control system,stability of high slopes,construction and installation of large-scale metal structures and structural concrete,etc.He has published over 80 papers.He has participated in the construction of several large-scale hydropower projects successively and made outstanding contribution to the construction and management of the TGP.

*Corresponding author.Tel.:+86 10 57081690.

E-mail address:zhu_hongbing@ctgpc.com.cn(H.Zhu).

Peer review under responsibility of Institute of Rock and Soil Mechanics, Chinese Academy of Sciences.

1674-7755©2015 Institute of Rock and Soil Mechanics,Chinese Academy of Sciences.Production and hosting by Elsevier B.V.All rights reserved.

http://dx.doi.org/10.1016/j.jrmge.2015.02.007

Journal of Rock Mechanics and Geotechnical Engineering2015年2期

Journal of Rock Mechanics and Geotechnical Engineering2015年2期

- Journal of Rock Mechanics and Geotechnical Engineering的其它文章

- Laboratory study on the mechanical behaviors of an anisotropic shale rock

- A case history study on causation of the landslide in Santa Clara, California,USA

- Thermo-mechanical constitutive modeling of unsaturated clays based on the critical state concepts

- UCIMS:Advances in geotechnical construction and performance monitoring

- Liquefaction evaluation of dam foundation soils considering overlying structure

- Improvement parameters in dynamic compaction adjacent to the slopes