UCIMS:Advances in geotechnical construction and performance monitoring

Rphel Sieenmnn,Hi-Tien Yu,Roert Bchus

aGeosyntec Consultants,1255 Roberts Boulevard,Kennesaw,GA,USA

bSpecto Technology LLC,295 Princeton-Hightstown Rd,Suite 11-356,West Windsor,NJ,USA

UCIMS:Advances in geotechnical construction and performance monitoring

Raphael Siebenmanna,*,Hai-Tien Yub,Robert Bachusa

aGeosyntec Consultants,1255 Roberts Boulevard,Kennesaw,GA,USA

bSpecto Technology LLC,295 Princeton-Hightstown Rd,Suite 11-356,West Windsor,NJ,USA

A R T I C L E I N F O

Article history:

Received 15 January 2015

Received in revised form

5 March 2015

Accepted 6 March 2015

Available online 18 March 2015

Tunneling

Geotechnical data management

Geographic information system(GIS)

Web-based user interface

The Crossrail project currently under construction in Central London has been described as“The Big Dig on Steroids”,obviously referencing the Central Artery/Tunnel project in Boston completed in 2007.To address the multiple demands for timely construction performance monitoring,Crossrail envisioned the underground construction information management system(UCIMS)to monitor construction progress and structural health along the entire route,with a network of geotechnical instruments(i.e.slope inclinometers,extensometers,piezometers,etc.)and tunnel boring machine(TBM)position information. The UCIMS is a geospatially referenced relational database that was developed using an open source geographic information system(GIS)that allowed all stakeholders near immediate feedback of construction performance.The purpose of this article is to provide a brief history of geotechnical and structural monitoring software,to describe the structure and operation of the UCIMS,and to demonstrate how the functionality afforded by this system provided the requisite feedback to the stakeholders. Examples will be given regarding how the data management and visualization concepts incorporated into the UCIMS advanced the geotechnical construction industry.

©2015 Institute of Rock and Soil Mechanics,Chinese Academy of Sciences.Production and hosting by Elsevier B.V.All rights reserved.

1.Introduction

An underground construction information management system (UCIMS)was developed to monitor construction data from the new east-west rail link across London known as the Crossrail.The Crossrail project construction works,one of Europe’s biggest construction projects,with projected costs of£15.9 billion,include underground development,comprising of shafts,tunnels,and portals that extend beneath the already congested London underground.Given the urban environment in which the tunneling and other construction activities are occurring,monitoring of the construction works and the impact on adjacent underground and aboveground structures was a key activity for the project management and engineering teams.The UCIMS monitors tens of thousands of real-time geotechnical instruments and structural sensors as well as overall construction progress.In addition to performance monitoring of a host of construction activities,the UCIMS also tracks the progress and performance of tunnel boring machines(TBMs).The UCIMS was designed to provide real-time access for all stakeholders to the construction and instrumentation data,and it required an intuitive,map-based user interface, showing progress and data locations relative to the surface features and other spatial information.

Numerous web-based geotechnical data management systems exist today to monitor real-time data,but these systems often use either photos or project drawing computer screen captures as a base map,instead of digital project map f les or live web mapping layers,such as Microstation,AutoCAD,geographic information system(GIS)f les,or Google Earth imagery data,to put monitoring data in a geospatial context.

2.Why monitor?

The traditional geotechnical engineering rationale for monitoring structural health before,during,and after construction is to provide a warning system to prevent critical failure of an asset,and to reveal unknowns and reduce uncertainty inherent in geotechnical work.With boring tunnels under some of the most expensive real estate in the world,however,the geotechnical engineering perspective is not the only view to consider.From an overall project perspective,performance monitoring is also necessary to inform stakeholders,satisfy regulators,document performance,assess damages,and possibly to reduce litigation.

From a quality management perspective,monitoring is a critical part of the quality control and improvement process. Because of the removal of over 6 million tons(Carhart,2013)of earth from London,it was known that some settlement would occur.While a number of mitigation measures,such as compensation grouting through grout shafts,have been implemented,monitoring the settlement in the vicinity of critical infrastructure is still necessary.This monitoring is needed to compare expected settlement to actual settlement and to evaluate the need for additional mitigation measures.

3.A brief history of geotechnical and structural monitoring software

As instrumentation programs have grown larger and more complex,with ever increasing amounts of data being generated, geotechnical instrumentation monitoring data management and reporting systems have evolved over time to meet changing project requirements.

The f rst generation of software can be dated back to the early 1990s(Fig.1)and in some cases even earlier.At this time,there were typically“small scale”projects with tens of sensors.DOS based,custom-built graphical representations were developed for each project.Some examples include Arley Tunnel,London Bridge Bassett convergence system(BCS)(Bassett et al.,1999),Jubilee Line Extension Red Cross Way,Heathrow Expressway,Tamar Bridge,Brooklyn Pepsi Bottling Plant,New York,and Gil-Hodge’s Bridge.

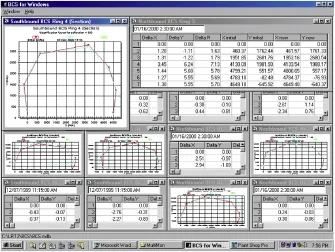

The second generation of software was prevalent through the early 2000s(Fig.2).Software tended to be used for“medium”size projects with hundreds of sensors.Microsoft Windows,Access database based,graphical interfaces were developed with user con f gurable alarms noti f cation.Example software packages from that time include MultiMon(Slope Indicator,2015a),BCSWin (Slope Indicator,2015b)and I-Site.Example projects include:the New Parliament Building,Jubilee Line Extension,Harrods,and the Channel Tunnel Railway Link.

The third generation of geotechnical and structural monitoring software is being used in the present day of“large”scale infrastructure projects,with thousands of sensors(Fig.3).Today’s software tends to be web-based,without the need to install any software on the user’s computer.These systems were developed using back-end SQL databases and provide signi f cant functionality, including alarm messages,automated PDF reports,and more.They are often purchased as software services rather than stand-alone software.

Fig.1.First generation system from the early 1990s.

Fig.2.Second generation system from the early 2000s.

Examples include:ARGUS(Yu,2011),Atlas(Slope Indicator, 2015c),ISiteCentral(Nyren et al.,2011),Geoscope,and Vista Dataview(Thorarinsson,2011).Example projects include Green Park,Blackfriars,#7 Subway Extension,2nd Avenue Subway,East Side Access,and World Trade Center Station.

4.Project requirements

In the study by Dunnicliff(1999),he provided a broad overview of the geotechnical instrumentation planning and implementation process.He outlined 21 steps to a successful program,of which Step 19 is to plan data collection,processing,presentation,interpretation,reporting,and implementation.In order to address this step in the process,Crossrail developed a detailed technical speci f cation for the successful management and reporting of the data being collected using UCIMS.

UCIMS was envisioned as a common repository for data from all stakeholders,including numerous contractors and sub-contractors. The technical speci f cation called for an instrumentation data management system,with an intuitive map-based user interface,to store and visualize site maps,geotechnical data,instrumentation records,and construction records from TBMs and spray concrete lining(SCL)systems.The amount of data to be managed included over 35,000 instruments and 79,000 sensors monitoring the earth on a minute-by-minute or second-by-second basis(Carhart,2013). Given the large number of sensors,the system needed to includesearch functions to locate and view data,navigate interactively(pan and zoom),identify and show features by selecting station number, coordinates,and names,and view in both plan and cross-section.In addition to instrumentation data,the system needed to manage and display stakeholder information such as historical building information,utilities,and other assets.

Fig.3.Third generation system from the present day.

Ultimately,UCIMS was required to function as a reporting tool for stakeholders,such as contractors,local authorities,utilities owners,and other interested parties.Each stakeholder was given access to data from their own areas to monitor performance before, during,and after construction in real-time.

5.UCIMS architecture

UCIMS was developed using itmsoil’s ARGUS monitoring software codebase,which was extended to include a GIS interface.A system diagram is provided in Fig.4.The ARGUS codebase consists of a bundle of open source software that includes Linux,Apache, MySQL,and PHP,commonly known as a LAMP stack.In this stack, Linux is the operating system,Apache is the web server,MySQL is the database management platform,and PHP is the server-side scripting language used to render the web pages.

ARGUS provided a powerful web-based graphical user interface (GUI)that allowed for the con f guration,management,and display of large amounts of instrumentation data from a variety of sources (Fig.5).However,in ARGUS,the sensor data were displayed only on static images,meaning that for each project numerous individual“plan views”needed to be con f gured to display sensors. These plan view images are typically either photographs or screen captures from CAD software packages that do not allow for the display of complex geometric objects,such as a line representing the passing of a TBM.Given the existing capabilities of the ARGUS codebase,the goal of the UCIMS development team was therefore to select and leverage compatible technologies to meet the project requirements.

The GIS interface was developed using a multi-tier client-server web GIS architecture consisting of University of Minnesota(UMN) MapServer and OpenLayers.MapServer is an open source geographic data rendering engine that makes GIS data accessible as web map service(WMS)and web feature service(WFS)layers. OpenLayers is an open source JavaScript library for displaying map data,such as WMS and WFS layers,in web browsers.UMN Map-Server was used as a“back-end”server to process the GIS data and OpenLayers was used as a“front-end”client interface to combine and display data to the user.

UMN MapServer was used to convert project data,including CAD drawings of both aboveground and underground construction works,asset information,and historical building information, into web-accessible data layers.Several other GIS servers were considered,including ArcGIS Server,GeoServer,Mapnik,and MapGuide.UMN MapServer was chosen primarily because it has a powerful and ef f cient mapping engine that f ts well with the existing ARGUS stack.It was also chosen because it has strong track record of use since the mid-1990s,has an active developer community,and supports a multitude of raster and vector data formats.

OpenLayers was used to dynamically display instrumentation data,TBM position,and other overlays on top of a variety of base map layers.OpenLayers provided the framework for allowing basic user interactions such as panning,zooming,and turning GIS data layers on and off.It also allowed for a number of advanced features, such as symbol clustering,to be implemented.OpenLayers was selected again because it f ts well within the existing ARGUS stack and was not“bundled”with other software libraries.Other Javascript application program interfaces(APIs)were evaluated, including Google Maps API and ESRI’s ArcGIS Javascript API;however,OpenLayers was ultimately chosen because of its optimal mix of features,documentation,and limited footprint in the overall application.

6.Key functionality

UCIMS was designed to solve the problems of accessibility,scale, and context.A number of innovative tools,technologies,and techniques were used to visualize geotechnical instrumentation data,TBM,and asset information simultaneously in real-time.

Fig.4.UCIMS diagram.

Fig.5.Example ARGUS plan view.

6.1.Accessibility

Desktop GIS tools have long been able to perform the necessary data management and analysis required for a project of this scale.However,given the distributed nature of the project,with both internal and external project stakeholders in multiple locations,the use of desktop software was not feasible. In addition,while powerful,desktop GIS software requires signi f cant training in order to be used effectively and ef f ciently. The users of UCIMS were not expected to have any formal GIS training.

UCIMS required an intuitive user interface,like Google Maps, which most users would need no training to use.It was therefore developed as a“thin”web-based client,with simple, streamlined features designed to be responsive for the majority of users.Using a“less is more”approach,the number of base map layers available was limited to an overall key map,a project base map,above ground layers,below ground layers,and London underground layers.Optimizing the number of map layers reduced the number of clicks needed to display relevant information and improved the overall website performance and user experience.

6.2.Scale

The issue of scale was addressed using a combination of clustering and f ltering.Given the thousands of sensors that needed to be displayed for each project site,without a combination of clustered symbol and sensor f lters,users would be easily overwhelmed by the number of sensors on the map and would be unable to identify meaningful spatial patterns.

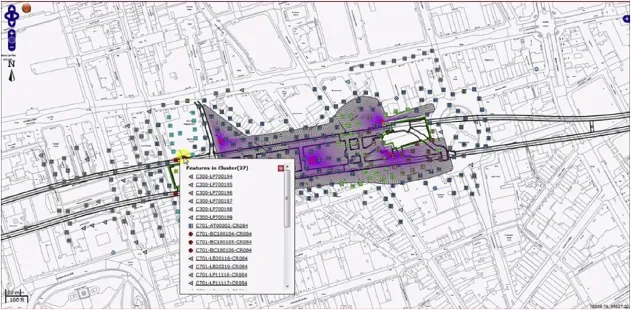

A clustering algorithm was applied to group multiple sensors, which means that when sensors are within a speci f ed distance of each other on the map,they are grouped as a single symbol(Fig.6). The color of the symbol denotes the highest alert level in the cluster.The clustered point can then be clicked to inspect the individual sensors within that group.The overall effect is an uncluttered map that ef f ciently displays all the sensors that are within the geometric envelope of the map.When the user zooms in,the cluster of points is split into smaller clusters,until the user zooms into a scale where there is enough distance to distinguish between individual sensors.

A robust set of f ltering tools were developed to allow users to visualize a subset of sensors for each project area.First and foremost,UCIMS allows for the f ltering of sensors by alarm status (high,medium,low,no data,etc.).This f lter allows users to quickly spot potential problem areas and evaluate further.Sensor information can also be f ltered by sensor type(tiltmeter,crackmeter, piezometer,inclinometer,etc.),sensor group(Area A,Area B,etc.), and by name.A spatial f lter was developed to allow users to select sensors within a certain radius of a point on the map selected by the user.Users also are able to combine,save,and load f lters for future use.

6.3.Context

During a major construction project,it is not uncommon for a contractor to be closely monitoring a local instrumentation network without being aware of nearby work,other instrumentation,or factors that may affect their local instruments.By combining instrumentation data into a central repository,UCIMS creates a comprehensive picture of existing and historical conditions.

With the addition of TBM and SCL position information,stakeholders are able to more quickly discern whether a recent alarm is due to active construction(Fig.7).UCIMS also incorporates building information and other GIS data layers,such as station numbering, and provides access to relevant information that allows stakeholders to make informed decisions based on the context of the instrumentation alert and its surroundings.

7.Conclusions

UCIMS was developed to provide an instrumentation and construction monitoring system of unprecedented functionality that is accessible through a user-friendly web-based map-driveninterface.Using an open source multi-tier client-server web GIS architecture,consisting of UMN MapServer and OpenLayers,an existing geotechnical and monitoring software package was extended to address the challenges of accessibility,scale,and context.

The UCIMS is capable of displaying the output records of thousands of sensors at a time and overlaying these sensors over base maps,including CAD drawings,geo-referenced aerial photographs, and raster maps,as well as photographs.Among many features, users are able to pan,zoom,search and f lter sensors,store views, measure areas,and click on sensors to produce time trend plots of data.These time trends,coupled with independent and automated alarm levels,provide timely feedback and protection to stakeholders.The functionality incorporated into the UCIMS not only facilitates information presentation,but,importantly,also provides timely information to operators,engineers,and managers who need to react to the output information and make time-critical decisions regarding construction activities.

Fig.6.Point clustering allows for an uncluttered display of thousands of sensors.

Fig.7.Current TBM position is displayed in red alongside current instrumentation readings.

Con f ict of interest

The authors wish to con f rm that there are no known con f icts of interest associated with this publication and there has been no signi f cant f nancial support for this work that could have in f uenced its outcome.

Bassett RH,Kimmance JP,Rasmussen C.An automated electrolevel deformation monitoring system for tunnels.Proceedings of the ICE-Geotechnical Engineering 1999;137(3):117-25.

Carhart N.The crossrail major infrastructure project-high-end risk management at work.Hazards Forum Newsletter December 2013.No 81.

Dunnicliff J.Systematic approach to planning monitoring programs using geotechnical instrumentation:an update.In:Proceedings of the 5th International Symposium on Field Measurements in Geomechanics-FMGM99, Singapore;December 1999.

Nyren R,Marr A,Jacobs D.iSiteCentral:web-based data management software. Geotechnical Instrumentation News 2011.

Slope Indicator.Atlas web-based monitoring.2015.http://www.slopeindicator.com/ atlas/index.php.

Slope Indicator.Multimon&graphx software.2015.http://www.slopeindicator. com/instruments/datalog-multimon.php.

Slope Indicator.BCSWin.2015.http://slopeindicator.com/pdf/bcswin.pdf.

Thorarinsson A.Web-based data management software.Geotechnical Instrumentation News 2011.

Yu H.ARGUS:web-based data management software.Geotechnical Instrumentation News 2011.

Mr.Raphael Siebenmannis a civil engineer with Geosyntec Consultants in Kennesaw,GA,USA.His experience encompasses site characterization program development and management,geotechnical and environmental data management and visualization,fate and transport modeling,and risk assessment.

Dr.Hai-Tien Yuhas more than 40 years of experience in the instrumentation industry with consultants,manufacturers and contractors.He has played key roles in the instrumentation and monitoring components of many major projects across the world.He is highly respected in the industry and his wealth of technical knowledge has allowed solutions to instrumentation problems to be reached,time after time.Contact information:Tel:+1 866 925 7737;E-mail address:hai-tien.yu@spectotechnology. com

Dr.Robert Bachus,P.E.,principal engineer based in Georgia with more than 30 years of experience,focuses on geotechnical engineering,geosynthetic engineering,waste by-product characterization,and waste containment.He provides design,analysis,and forensic investigation on projects related to these practice areas.

*Corresponding author.Tel.:+1 678 202 9555.

E-mail address:rsiebenmann@geosyntec.com(R.Siebenmann).

Peer review under responsibility of Institute of Rock and Soil Mechanics,Chinese Academy of Sciences.

1674-7755©2015 Institute of Rock and Soil Mechanics,Chinese Academy of Sciences.Production and hosting by Elsevier B.V.All rights reserved.

http://dx.doi.org/10.1016/j.jrmge.2015.03.002

Journal of Rock Mechanics and Geotechnical Engineering2015年2期

Journal of Rock Mechanics and Geotechnical Engineering2015年2期

- Journal of Rock Mechanics and Geotechnical Engineering的其它文章

- Laboratory study on the mechanical behaviors of an anisotropic shale rock

- A case history study on causation of the landslide in Santa Clara, California,USA

- Thermo-mechanical constitutive modeling of unsaturated clays based on the critical state concepts

- Monitoring result analyses of high slope of f ve-step ship lock in the Three Gorges Project

- Liquefaction evaluation of dam foundation soils considering overlying structure

- Improvement parameters in dynamic compaction adjacent to the slopes