Improvements of marine clay slurries using chemical-physical combined method(CPCM)

Dongqing Wu,Wenyu Xu,Romy Tjuar

Chemilink R&D Centre,20 Kranji Road,Singapore 739462,Singapore

Improvements of marine clay slurries using chemical-physical combined method(CPCM)

Dongqing Wu*,Wenyu Xu,Romy Tjuar

Chemilink R&D Centre,20 Kranji Road,Singapore 739462,Singapore

A R T I C L E I N F O

Article history:

Received 22 December 2014

Received in revised form

2 February 2015

Accepted 5 February 2015

Available online 20 February 2015

Chemical-physical combined method

(CPCM)

Soil improvement

Marine clay(MC)slurry

Land reclamation

Chemical stabilization

Vacuum preloading(VP)

Geo-bags

Surcharge

In this paper,the effectiveness,applicability and validity of chemical-physical combined methods (CPCMs)for treatment of marine clay(MC)slurries were evaluated.The method CPCM1 combines chemical stabilization and vacuum preloading(VP),while CPCM2 is similar to CPCM1 but includes both the application of surcharge and use of geo-bags to provide con f nement during surcharge preloading. The key advantage of CPCM2 using geo-bags is that the surcharge can be immediately applied on the chemically stabilized slurries.Two types of geo-bags were investigated under simulated land f lling and dyke conditions,respectively.The test results show that the shear strength(cu)of treated slurry by CPCM2 is generally much higher than that by CPCM1.Besides,the use of CPCM2 can signi f cantly reduce the treatment time due to the short drainage paths created by geo-bags.Overall,CPCM2 allows faster consolidation and higher preloading that help to achieve higher mechanical properties of the stabilized slurry.There are consistent relationships betweencUand water content of slurries treated by CPCM2. Several important observations were also made based on comparisons of experimental data.

©2015 Institute of Rock and Soil Mechanics,Chinese Academy of Sciences.Production and hosting by Elsevier B.V.All rights reserved.

1.Introduction

Large-scale land reclamation projects have been undertaken since the last few decades in different countries and/or regions across the world.Limited suitable costal land combined with high increase of economy and population has been the main reason accounting for this fast development.However,there are some constraints concerning the increasing demand of land reclamation practice.Aside from the availability of the land f ll materials which normally use sands or hill-cut materials,another drawback is the deeper and deeper water depth to be reclaimed.In the past,land reclamation works used to be carried out from depths of 5-10 m. However,in the current land reclamation practice,works have to venture deeper water of more than 15-20 m and thus will incur much higher costs.

Most projects in China used the method of vacuum preloading (VP)to improve dredged or very soft clays in coastal cities for land reclamation purpose.One concern raised from this practice is the limited achievable ultimate bearing capacity,which is commonly 60-80 kN/m2.The consequence of this limited bearing capacity means that it often requires further ground improvement,especially for areas designated for heavy duty activities.

Another method to improve very soft clay materials is through chemical treatment or stabilization(Zhang et al.,2008).Using appropriate chemical additives,soil physical properties can be improved so as to meet engineering requirements,though this type of chemical way is not used as common as VP or surcharge method. One successful record of chemical treatment application was reported for the construction of an international airport in Japan(Sato and Kato,2002).Although there were evidences that chemical treatment method was successful for treating dredged clay materials with low water contents,it has been widely acknowledged that chemical treatment is not effective to improve the dredged clay slurries or marine clay(MC)with higher initial water contents (>(3-4)LL,LLis the liquid limit),even higher chemical dosage is used.

The chemical-physical combined method(CPCM)is a brandnew academic and practical model incorporated with innovative methodology proposed by Chemilink years ago(Wu et al.,2013a,b). The CPCM has provided a new development direction for the higher effective and ef f cient improvement of very soft soils for infrastructural construction,especially for land reclamation using MC slurries.The concept of CPCM is proposed through the external preloading to trigger the discharge of water from chemically stabilized soft to very soft soils such as MC slurries or mixtures,and consequently condense the consolidating structure like thecompaction in the conventional chemical-soil stabilization (Suhaimi and Wu,2003).The mixture of MC slurry and chemical additives will be compressed by squeezing water out so that the mixture structure becomes denser with lower water content. Consequently,the chemical reactions will be more effective as mixture particles are moving closer to each other;thus strengths can be greatly increased within relative shorter time.Chemilink SS-330 series were used in the CPCM to improve the properties of MC slurry.The predominant function is enhancing the chemical reactions mainly including cementation;whilst speeding up sedimentation is a secondary function in which the chemical additive can make the particles of MC f occulate together to become the clay lumps.Several SS-331 sub-series,which were used in the experiments,are the similar products but with different minor chemical additives in order to achieve better geotechnical performances with the used MCs.

Series of in-house tests have been conducted to evaluate the technical effectiveness and performance of CPCM to achieve higher strengths of clay slurry materials.The chemically stabilized MC slurries preloaded by vacuum(called CPCM1)have presented much higher mechanical performances(Wu et al.,2013b),while a series of in-house tests on different MCs has proven that CPCM can similarly achieve several times higher shear strength within much shorter time when compared with those of pure MC slurries only physically consolidated by VP(Wu et al.,2013a).More physical approaches and combinations can be further explored and developed for purposes of better performances,higher ef f ciency and wider applicable scope of CPCM.Aside from VP,the surcharge is the most conventional and commonly used preloading means to provide a physically static force to remove water from chemically stabilized soils.However,the surcharge is unable to be immediately applied on the stabilized slurry due to its instability.In presence of geo-bags,the surcharge can be immediately applied on the chemically stabilized slurry contained in geo-bags(called CPCM2) without instability issue concerned.Two types of geo-bags in both shapes of cylinder and long-beam were investigated under CPCM2 to simulate land f ll and dyke,respectively.

Although encouraging results were obtained by using both approaches of CPCM1 and CPCM2 as presented in this paper,further study needs to be conducted especially to obtain better understandings on some practical empirical relationships,more appropriate physical approaches,and combinations for CPCM system that is still new.Nevertheless,the current f ndings and future developments of CPCM could provide more innovative solutions to the challenge of effective improvement of clay slurry,especially for land reclamation purpose.

2.CPCM1 incorporated with vacuum preloading

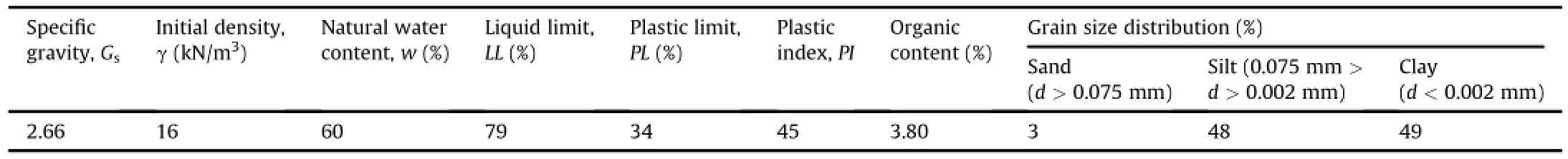

A typical Singapore MC from excavation was selected for CPCM and its basic properties are given in Table 1,wheredis the diameter.

The MC used in the study sampled from the lower layer of Singapore MC(Arulrajah and Bo,2008)with the chemical composition is typically composed of kaolinite and illite (Kamruzzaman,2003).Large numbers of in-house tests using the three-dimensional(3D)consolidation cells(inner diameter of 17 cm and height of 100 cm)were conducted to verify the effectiveness of CPCM1,which combines chemical treatment and VP with drains to improve MC with higher initial water content.

Samples of the Singapore MC with initial water content ranging from2LLto 5LLwere f rstly mixed with various versions of chemical additives(Chemilink SS-330 sub-series products).Subsequently,VP (normally f xed pressure at 95 kPa)was applied to the samples. Fig.1 shows the experiment setup of the VP application for CPCM1.

Fig.1.Experimental setup of vacuum preloading application.(a)Sketch illustration of vacuum preloading experiment,(b)Vacuum preloading experiments using large 3D consolidation cell.

Table 1Basic properties of typical Singapore marine clay(MC).

Signi f cant vertical displacements were recorded during the VP application for all samples,ranging from 50%to 80%of their initial heights,due to the water being sucked out of the samples.The shear strengths were determined using fall-cone tests on thesamples,and the corresponding water content determination was conducted as per-conventionally by using oven.Fig.2 shows the values of shear strengths and f nal water contents selected from the better performing results of MC-additives mixtures,in terms of the measured shear strength under CPCM1 system.

The results and comparisons shown in Fig.2 prove the effectiveness of this CPCM1 incorporated with VP and addition of SS-330 sub-series products as chemical additives.As reference,the shear strength of both the pure MCs with initial water contents from 2LLto 5LLand the MC mixed with cement are also presented in the same f gure.It seems that the addition of 4%cement did not help much to improve the shear strength of the mixture due to the higher water content(4LL)of MC samples.In contrast,SS-330 additives at similar dosage generally performed well to increase the shear strengths up to 2-3 times that of the pure MC;whilst the similar conclusion has been also derived using China Zhujiang MC (Wu et al.,2013a).Meanwhile,the f nal water content values were mostly higher than those of the pure MC samples.The initial water content did not seem to have clear effect on the f nal water content, while the higher additive dosage resulted in an increase in f nal water content.In fact,the chemically treated soil has lost its original properties and becomes another type of soil,called“transformed soil”and some details were discussed by Wu et al.(2013b). The micro-structure and its development of the transformed MC have been also investigated by Bao et al.(2015).

It is interesting to note that the addition of incinerated bottom ash(IBA)in one sample resulted in a further increase in shear strength.The reasons are mainly due to the bigger physical particles of IBA compared with particles of MC and the chemical reactions that probably include the pozzolanic reaction among IBA, MC and chemical additive mixture(called MC-IBA matrix).The environmental impact due to the heavy metal leaching from this MC-IBA matrix will be discussed in separate papers.

3.CPCM2 incorporated with surcharge and geo-bags

Compared with VP,physical surcharge is the most traditional and typical preloading method.Since there is an instability issue if applying surcharge loading immediately on the very soft slurry,the geo-bags(made of non-woven geo-textile)have been introduced as the containers of slurries to be improved.The surcharge loadings in the form of physical dead weights were immediately placed on top of the chemically treated MC slurries contained by geo-bags in order to squeeze the water out rapidly so as to compress slurries’particles closer together in a relatively short period of time.

Two types of geo-bags were used:column-shape(or cylindrical shape)and beam-shape(also known as geo-tube).The idea of f lling the MC-mixture into two different shapes of geo-bags is to simulate different functions in land reclamation such as the f lling material in a larger water depth,and the dyke or embankment.In this paper,the column-shape geo-bags used in the experiments had a diameter of 10 cm and height of 30 cm;the beam-shape geobags had diameter of 10 cm and length of 100 cm.

Fig.3 demonstrates the experimental setup during the surcharge loading application of chemically treated MC f lled in the column-shape geo-bag with the surcharge loading on top of it. Fig.4 shows a physical sample of the chemically treated MC f lled in geo-tube,which was taken from the deep loading tank right after CPCM2 process as well as a small soil sample after removing the geo-tube material.

The typical Singapore MCs with the initial water content of 158% (2LL)and 6%(based on the dry weight of MC)of chemical additive SS-331H were used in all CPCM2 tests in this study.

It should be noted that all tested samples were immersed in sea water during the whole CPCM2 process(one month loading application period)to simulate the real application situation.Subsequently,after the samples have f nished the pre-determined one month loading application period,geo-bags were cut open and then fall-cone tests were conducted on the MC-matrix to obtain the shear strength values in conjunction with the water content values. The given one month time was expected to be suf f cient to allow the completion of physical consolidation for tested samples.

Fig.2.Selected testing results under CPCM1.Note:Chemilink SS-330 series includes SS-331C,E,and H.

Fig.3.Surcharge loading application on top of column-shape geo-bag f lled with chemically treated MC.

Fig.4.Beam-shape sample after 1-m CPCM2 process.

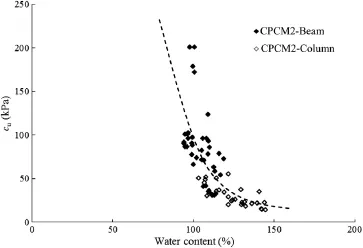

Fig.5 shows the average of achieved strengths from both column-and beam-shape samples(called CPCM2-Column andCPCM2-Beam,respectively),alongside with the result obtained from an identical sample under CPCM1 as a reference.Meanwhile, Fig.6 presents the obtained shear strength versus corresponding water content values.

Within surcharge ranges of 0-20 kPa,it can be seen that the samples under CPCM2-Beam achieved higher strength compared with samples under CPCM2-Column.Furthermore,higher surcharge load resulted in higher shear strength within the same period of time as expected.On the other hand,the samples under CPCM1 achieved lower strength under signi f cantly higher loading magnitude.

Since the tested MCs under CPCM2 were prepared under the same initial water content(2LL),the same chemical additive(SS-331H)and the same dosage(6%),and also under relatively similar preloading conditions such as loading values and drainage paths, the characteristics of these resulted transformed MCs are similar.

A clear trend-line envelop related to the shear strength values vs.water contents of these similar transformed MCs can also be found in Fig.6.Lower water content values were obtained from the samples with higher strengths,and vice versa.However,the relationship between shear strength and water content seems to be more sensitive toward the lower end of water content values, resulting in a large difference of strengths’increment with minor decrease in the water content values.In other words,to reduce water content slightly by increasing preloading may result in a very signi f cant increment of the shear strength.

Based on the f ndings from the studies of purely chemically stabilized MC slurry(Figs.7 and 8),it can be reasonably predicted that the shear strength shown in Fig.5 will further be increased by chemical reactions with elapsed time after the completion of consolidation,regardless of whether the surcharge being removed or not.It should also be noted that the samples under the same conditions as those of CPCM2 tests can achieve an average strength of 20 kPa within the same one month time due to chemical reactions only(Fig.7).

Therefore,the much higher shear strengths achieved under CPCM2,when compared with that of the chemically stabilized MC without preloading,have once again proven the validity and effectiveness of CPCM method,as what CPCM1 did.

Generally speaking,the samples without preloading got very limited consolidation effect and thus the achieved strengths should be mostly gained from chemical reactions.If the slurry has a higher initial water content(>(2-3)LL),the achievable shear strength could be extremely lower(Wu et al.,2013b).

Fig.5.Shear strength vs.surcharge under CPCM2.

Fig.6.Shear strength vs.water content under CPCM2.

Fig.7.Shear strength development of chemically stabilized MC slurries without preloading.

4.Comparison and discussion on CPCM

4.1.Effectiveness of CPCM

Generally,the shear strength of a speci f c soil achieved upon the completion of the physical consolidation under a f xed loading is, more or less,limited(see Fig.2).However,with introduction of appropriate chemical additives,such strength can be signi f cantly increased under CPCM1 and unlike pure soil case,the strength will continuously increase due to chemical reactions even after the completion of consolidation.

Similarly,at the pre-given initial conditions such as water content,chemical additive and its dosage and within a f xed time period,the shear strength could be limited(Fig.5)or even extremely lower if the initial water content is higher than(3-4)LL(Wu et al.,2013b).However,with the introduction of physical loadings,the shear strength can be increased in such as 5-6 times higher than that without preloading at the same time period,while the shear strength will continuously increase because of chemical reactions among this newly transformed soil.This is why the CPCM method has provided a new development direction in soil improvement.

Fig.8.Pure chemically stabilized MC samples under sea water.

4.2.Drainage path

Fast consolidation is de f nitely crucial for CPCM method in order to reduce the water as fast as possible and simultaneously make particles closer to each other.While this condition consequently strengthens the effectiveness of chemical reactions among the soils to be improved in order to achieve much higher strengths within a shorter time,reducing the drainage path is an effective way to speed up the consolidation.

In practice,VP application is combined with prefabricated vertical drains(PVD)to remove the water out.The PVD spacing is normally ranging from 0.8 m to 1.2 m.A half of this spacing can also be interpreted as the drainage path or length.The longer drainage path prolongs the time for the consolidation to be completed and therefore reduce the effectiveness of chemical reactions.CPCM2,on the other hand,uses the advantage of geo-bags to function as the container of chemically treated MC initially in slurry form and loaded with physical surcharge to force the water out from the slurry.Since the water can be drained through all sides of geo-bags which also function as the f lter depending on the shape and size of geo-bags,the drainage length can be adjusted to be shorter.This shorter drainage length will enable water to be squeezed out very quickly and clay particles drawn closer together,which will make the chemical additive to create more effective bonds between those particles so as to achieve higher strengths.

The f nal drainage length of CPCM2-Beam samples is basically 15-25 mm;whilst that length for CPCM2-Column is 50-60 mm, which is 2-3 times that of CPCM-Beam.Comparison between the two lines of shear strength(cu)vs.surcharge(preloading)as shown in Fig.5 indicates that the higher shear strength was achieved with the shorter drainage path at the same preloading and time conditions.

The shear strength and the corresponding water content of the samples CPCM2-Beam were carefully determined after one month time along its vertical depth at central and two-end sections,where the vertical direction to both top and bottom surfaces is the main drainage path.The measured shear strengths and water contents along the depth at all sections are almost the same,suggesting the completion of consolidation.But the measured data at the both end sections are slightly better than those at central sections.It could be induced by the samples at both ends with a horizontal drainage path in addition to the vertical drainage paths.

4.3.Preloading magnitude

Similarly,eachcu-preloading line shown in Fig.5 also con f rms that under the same conditions,the higher preloading can produce higher shear strength during consolidation process,which comfortably tallies with the concept of conventional consolidation theory.This is because the higher preloading can make clay particles closer so as to strengthen chemical reactions inside soil to be improved.

The drainage path looks more sensitive than the magnitude as shown in Fig.5.For example,at the same surcharge of 10 kPa,the shear strength achieved in CPCM2-Beam is about 2 times that of CPCM2-Column,while the drainage length of CPCM-Beam is just a half of or lesser than that of CPCM-Column.

4.4.Strength development during and after CPCM

Especially,when the initial water content is relatively lower than 2LL,the strength of the purely chemically stabilized soil can still increase signi f cantly to meet some basic engineering requirements(Fig.7).However,with CPCM application at a proper preloading,the water content of the slurry can be easily reduced much below 2LLf rst and then the strength will continuously develop with elapsed time due to the chemical reactions,regardless of preloading.

In order to simulate the whole strength development process, three typical clay slurries or mixtures stabilized by the chemical additive are selected in combination with both processes of CPCM and then pure chemical reactions without physical loading as shown in Fig.9.From this f gure,it can be seen that the initial strength increasing trend under CPCM is very fast and then becomes relatively slower without preloading.Finally,the strength after a period(say several months)will remain stable or increase at an extremely slow rate as time increases.Such strength development is very similar to that of conventional soil stabilization or concrete.This strength development prediction provides a promising concept to predict the desirable strength using CPCM at required time during and after physical preloading.Furthermore, with such consideration of whole strength development process, the reclaimed land under CPCM can be designed for heavy-duty foundations for port and industrial purposes.

Fig.9.Strength development during and after CPCM.

4.5.Overall bearing capacity of CPCM2 with geo-bags

In fact,unlike the CPCM1 case,the bearing capacity of CPCM2 cannot be directly estimated merely based on the shear strength of the inside clay.The properties of the geo-bag as the container will also play an important role in the estimation of the overall bearing capacity of the CPCM2 system.

Although it is believed that the higher shear strength of the stabilized clay inside the geo-bag represents the higher bearing capacity of the system,the capacity calculated only based on the soil strengths will de f nitely underestimate the capacity of the whole system.

Due to the nature of the CPCM system group discussed in this study,CPCM1 could be used comfortably to improve the MC slurry for large area of land reclamation,while CPCM2 may be more suitable for areas with special requirements and/or purposes,such as CPCM-Beam used for constructing dykes and CPCM-Column used for construction at corners or at larger depths.

5.Conclusions

(1)The CPCM has been again proven by different preloading means to be valid,effective and ef f cient.CPCM provides a development direction incorporated with innovative methodology for improvement of very soft soils for infrastructural construction,especially for land reclamation using MC slurries.

(2)The most conventional surcharge preloading incorporated with geo-bags has been investigated to explore the mechanism and workability of CPCM,in addition to the currently popularVP commonly incorporated with PVD.Based on the experimental data with surcharge preloading,the achieved shear strength can be 4-5 times higher than that of the purely chemically stabilized slurry within one month time.

(3)The studies of CPCM show that the faster consolidation can result in more effective chemical reactions and thus produce higher strength within a short period of time.Therefore,how to speed up the consolidation process at beginning of the whole soil improvement process is the key factor for CPCM applications to maximize the achievable strength.Reducing the drainage path or increasing the preloading magnitude can be done to serve the purpose.

(4)Although a signi f cant increase of shear strength is gained due to the both physical consolidation and chemical reactions during the preloading application,the increase of shear strength is also gained from the chemical reactions that will continue even after the removal of preloading.Thus both strength increments during and after CPCM application have to be considered in the design of the desirable strength of the reclaimed land using CPCM at an appropriate time.

(5)Future studies and experiments,especially f eld applications with various fulldimensions/scales need to be conductedto geta better understanding on CPCMmethods,while some criticaland useful empirical relationships could be set up for guiding more engineering practice.Furthermore,other possible physical means such as dynamic compaction and the combinations with both surcharge and VP should be explored and adopted in future.

Con f ict of interest

The authors wish to con f rm that there are no known con f icts of interest associated with this publication and there has been no signi f cant f nancial support for this work that could have in f uenced its outcome.

Acknowledgement

The paper is based on experimental results from the R&D project,titled“Creating a Marine Clay Matrix with Incineration Bottom Ash(IBA)for Land Reclamation”(Wu et al.,2014),under the Innovation for Environmental Sustainability(IES)Fund from National Environment Agency(NEA)of Singapore(ETO/CF/3/1). Authors would like to thank NEA for allowing them releasing the data.

Arulrajah A,Bo MW.Characteristics of Singapore marine clay at Changi.Journal of Geotechnical and Geological Engineering 2008;26(4):431-41.

Bao SF,Dong ZL,Mo HH,Wu DQ.Laboratory tests on new reinforcement technology of newly hydraulic reclamation mud with high clay content.Rock and Soil Mechanics 2015;36(1):61-7(in Chinese).

Kamruzzaman AHM.Physico-chemical and basic engineering behavior of treated clay.PhD Thesis.Singapore:National University of Singapore;2003.

Sato T,Kato H.Application of the pneumatic f ow mixing method to land development for Central Japan International Airport.In:Underwater Technology, 2002.Proceedings of the 2002 International Symposium.New York,USA:IEEE; 2002.p.93-8.

Suhaimi HG,Wu DQ.Review of chemical stabilization technologies and applications for public roads in Brunei Darussalam.The Journal of Road Engineering Association of Asia&Australia 2003;10(1):42-53.

Wu DQ,Dong ZL,Xu WY.Application of the chemical-physical combined method in land reclamation using marine clays from seabed.Chinese Journal of Rock Mechanics and Engineering 2013a;32(9):1379-784(in Chinese).

Wu DQ,Xu WY,Zhu DP.The chemical-physical combined method for improving clay slurry in land reclamation.In:IACGE 2013.Reston,VA,USA:The American Society of Civil Engineers;2013b.p.308-15.

Wu DQ,Xu WY,Guo L,Tjuar R,Quek A.IES f nal report on creating a marine clay matrix with incineration ash(IBA)for land reclamation.Singapore:Chemilink R&D Center;2014.p.107.

Zhang CL,Wang SC,Zhu W,Liu QS,Ohki T.In f uence of initial water content on cement solidi f cation effect of dredged material.Rock and Soil Mechanics 2008;29(Suppl.):567-70(in Chinese).

Dr.Dongqing Wuborn in 1959 in China,graduated from The East China University of Water Resources with B.Eng.in January,1982 and then Hohai University with M.Eng.He completed his PhD dissertation in geotechnicalengineering at Nanyang Technological University(NTU)in Singapore in 1994.Dr.Wu is the Founder and Chief Scientist of Chemilink®Technologies&Products and currently the CEO of Chemilink Technologies Group,Presidentof Chemilink R&D Centre and Executive Chairman of Chemilink NewSoil Engineering Pte Ltd.Dr.Wu was a project engineer and then a lecturer in China during 1980s,where,he received the Excellent Development Award in Science&Technology from China central government and the Excellent Paper Award from Chinese Academy of Sciences.He started his new professional career based on Singapore in 1994 and received several governmentgranted R&D projects for past 10 years.His technical portfolios include civil engineering,material science and environment engineering,and his outputs in R&D, technical and engineering aspects may be found in some 100 publications.He obtained rich industrial experiences from conducting or involving in hundreds of civil and building projects locally and internationally.His technical and engineering performances are widely reported by newspapers,magazines and TVs including“Discovery Channel”in its“Man Made Marvels”program(2008)for his unique innovation applied in Singapore Changi Airport runways.Along the way towards a zero solid waste society,he is a pioneer to promote“Singapore NewSoil”brand for infrastructure construction,where the NewSoil is transformed from various solid wastes.He is also a pioneer researcher to use“Marine Clay-Incineration Bottom Ash Matrix”for land reclamation,while he is the f rst to create the Chemical-Physical Combined Method to effectively conduct land reclamation using waste materials.

*Corresponding author.Tel.:+65 96328896.

E-mail address:wu@chemilink.com(D.Wu).

Peer review under responsibility of Institute of Rock and Soil Mechanics,Chinese Academy of Sciences.

1674-7755©2015 Institute of Rock and Soil Mechanics,Chinese Academy of Sciences.Production and hosting by Elsevier B.V.All rights reserved.

http://dx.doi.org/10.1016/j.jrmge.2015.02.001

Journal of Rock Mechanics and Geotechnical Engineering2015年2期

Journal of Rock Mechanics and Geotechnical Engineering2015年2期

- Journal of Rock Mechanics and Geotechnical Engineering的其它文章

- UCIMS:Advances in geotechnical construction and performance monitoring

- A case history study on causation of the landslide in Santa Clara, California,USA

- Thermo-mechanical constitutive modeling of unsaturated clays based on the critical state concepts

- Monitoring result analyses of high slope of f ve-step ship lock in the Three Gorges Project

- Liquefaction evaluation of dam foundation soils considering overlying structure

- Improvement parameters in dynamic compaction adjacent to the slopes