Effects of Calcium Oxide on Physicochemical Properties of Spray-dried Bayberry Powder

Xianju SONG

School of Life Science,Taizhou University,Taizhou 318000,China

Effects of Calcium Oxide on Physicochemical Properties of Spray-dried Bayberry Powder

Xianju SONG*

School of Life Science,Taizhou University,Taizhou 318000,China

[Objective]Effects of different contents of calcium oxide on physicochemical properties of spray-dried bayberry powder were studied.[Method]Bayberry powder produced from bayberry juice adding 0,2 and 4 g/L calcium oxide using the spray drying technique has been selected.The physicochemical properties of the spray-dried bayberrypowderwere investigated bydetermining moisture content, colour,apparent density,wettability,angle of repose and moisture absorption rate of bayberry powder.[Result]The results showed that the content of calcium oxide had a significant effect on the moisture content and colour of bayberry powder.Effects of different contents of calcium oxide on the apparent density of spray-dried bayberry powder were not obvious.Adding calcium oxide had a significant effect on the wettability,angle of repose and moisture absorption rate of spray-dried bayberry powder,nevertheless,there was not obvious difference on these properties between adding 2 and 4 g/L calcium oxide.[Conclusion]The results confirmed that the content of calcium oxide had a significant effect on the properties of spray-dried bayberry powder.

Calcium oxide;Spray-drying;Bayberry powder;Physicochemical properties

B ayberryjuice contains high sugarwhich is mainly low molecular sugar,so it easily leads to adheringphenomenonin the spray drying process,the obtained spray-dried bayberry powder easily tends to moisture absorption and bond.To solve the cohesiveness of sugar materials in the spray drying process,some methods like raising the glass-transition temperature (GTT)[1],modifying low molecular sugar[2]and specific spray drying techniques[3]were adopted.

In this study,chemical modification method was adopted to integrate low molecular sugar with calcium ion, and improve the anti-wettability and fluidity of spray-dried bayberry powder,thereby learning about the effect law ofcalcium oxide contenton physicochemical properties of spraydried bayberry powder.

Materials and Methods

Materials

Raw materials and reagents

Dongkuibayberry,purchased from Linhai market;bayberry powder,produced from fresh bayberry juice by juicing,mixing and spray drying;calcium oxide,made in Shanghai Reagent Factory.

Key instrumentsSP-1500 lab spray dryer,Shanghai Sunyi Tech.Co.,Ltd.; HP-200 precise colorimeter,Shanghai Chinaspec Optoelectronics Technology Co.,Ltd.;FA1104 electronic balance,Shanghai Precision&Scientific InstrumentCo.,Ltd.;DS-1waring blender,Shanghai Specimen Model Factory;electric blast drying oven, ShanghaiYiheng Scientific Instruments Co.,Ltd.;biochemical incubator,Shanghai Yuejin Medical Optical Instruments Factory.

Methods

The preparation of bayberry powder

The technological parameters of spray drying were as follows:the content of soluble solid state material of bayberry juice was 14%,hot air temperature was 160℃,the flow of hot air was 15 ml/s,and filling flow was 8 ml/s.Under these conditions,spraydried bayberry powder was prepared.

The determination of moisture contentThe determination of moisture content of bayberry powder was based on the method of Huang Weikun[4]. About 3 g bayberry powder was got, then it was baked in the drying oven with (102±3)℃until constant weight. The experiment was repeated again, finally the average value of the two was taken.

The determination of colourHP-200 precise colorimeter was adopted to measure L value and a value of bayberry powder,in which L value represented whiteness,and a value represented red and green degree of the samples,the greater the value,the redder the samples[5].The measurement was repeated six times and the average value was got.

The determination of apparent density20 g bayberry powder was fallen into 100 ml measuring cylinder from the funnel,the weight and the volume of the powder were measured.The process was repeated three times,finally the apparent density(g/cm3)was calculated[6-7].

The determination of wettability

100 ml deionized water was added into 250 ml beaker,then the beaker was put into thermostatic waterbath with 25℃,after that,10 g bayberry powder was added,then the time of all bayberry powder dispersing into the water was recorded.

The determination of angle of repose200 g bayberry powder was poured on the surface plate by the fixed funnel,the angle of repose of the obtained cone-shaped body was measured[8].The angle of repose(ψ)of the samples was represented by angle and calculated according to the formula(1):

In the formula,h was vertebral shape height of powder(mm),the result was the arithmetic mean value of the five measurements.

The determination of moisture absorption rate[9]The dried weighing bottle was weighed,and the weight was recored as M1;the spray-dried bayberry powder was added into the weighing bottle,then weighing,the weight was recored as M2;after that, the bottle was put into a dryer with Na-Cl saturated salt solution.The dryer was put into constant temperature incubation with 25℃for 24 h,then the weighing bottle with bayberry powder was taken out and weighed,the weight was recored as M3.Finally,the moisture absorption rate was calculated according to the formula(2):

Results and Analyses

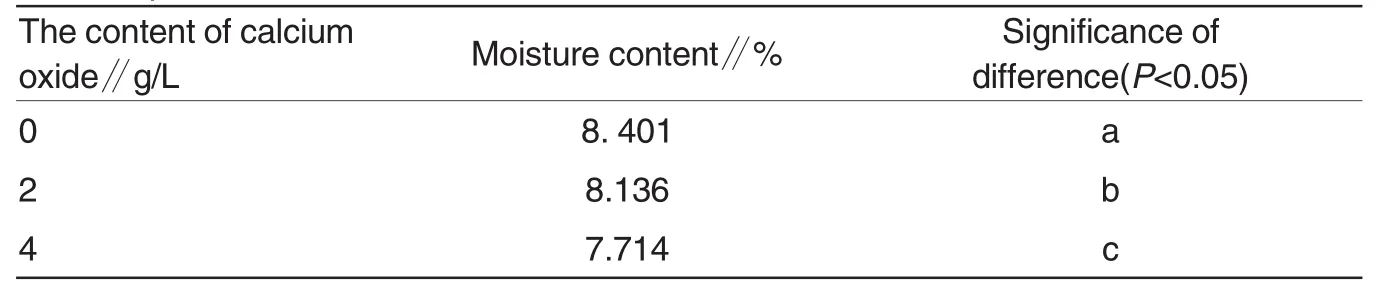

Effects of different contents of calcium oxide on the moisture content of bayberry powder

Effects of different contents of calcium oxide on the moisture content of bayberry powder were in Table 1. As shown in Table 1,with the increase of calcium oxide content,the moisture contentofbayberry powderdecreased,moreover,effects of different contentsofcalcium oxide on the moisture content of bayberry powder were significant,there were significant differences on the moisture content among three kinds of bayberry powder obtained by spray drying.

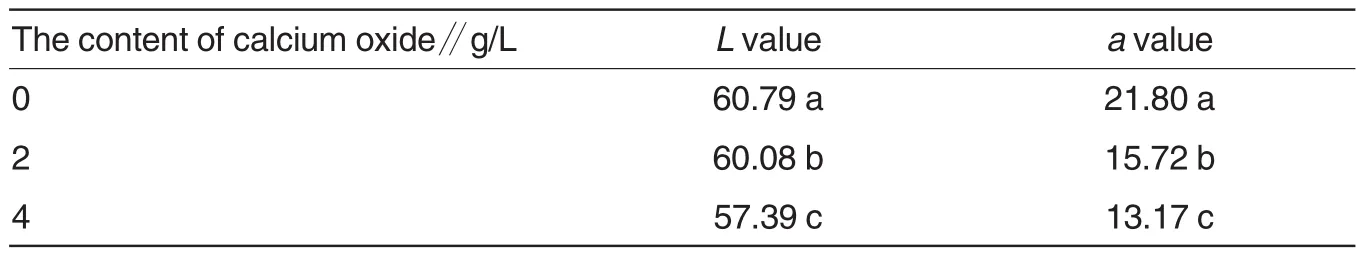

Effects of different contents of calcium oxide on the colour of bayberry powder

It can be seen from Table 2 that L value and a value of bayberry powder obtained from bayberry juice with three contents of calcium oxide using spray drying method decreased with the increase of calcium oxide content, showing that the colour of bayberry powder darkened with the increase of calcium oxide content,namely it changed from bright red to dark red, the red became shallower.Thus,calcium oxide content had obvious effect on L value and a value of bayberry powder,there were significant differences on L value and a value among three kinds of bayberry powder obtained by spray drying.

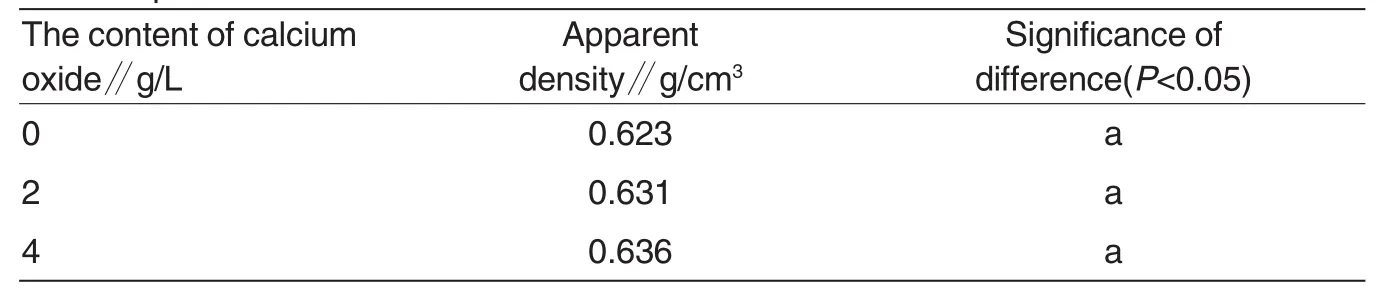

Effects of different contents of calcium oxide on the apparent density of bayberry powder

Effects of different contents of calcium oxide on the apparent density of bayberry powder were in Table 3. The apparent densities of bayberry powder obtained from bayberry juice adding 0,2 and 4 g/L calcium oxide using the spray drying technique were 0.623,0.631 and 0.636 g/cm3,respectively.The analysis results showed that there were not significant differences on the apparent densities among three kinds of bayberry powder,calcium oxide content had not obvious effect on the apparent density of bayberry powder.

Table 1 Effects of different contents of calcium oxide on the moisture content of bayberry powder

Table 2 Effects of different contents of calcium oxide on the colour of bayberry powder

Table 3 Effects of different contents of calcium oxide on the apparent density of bayberry powder

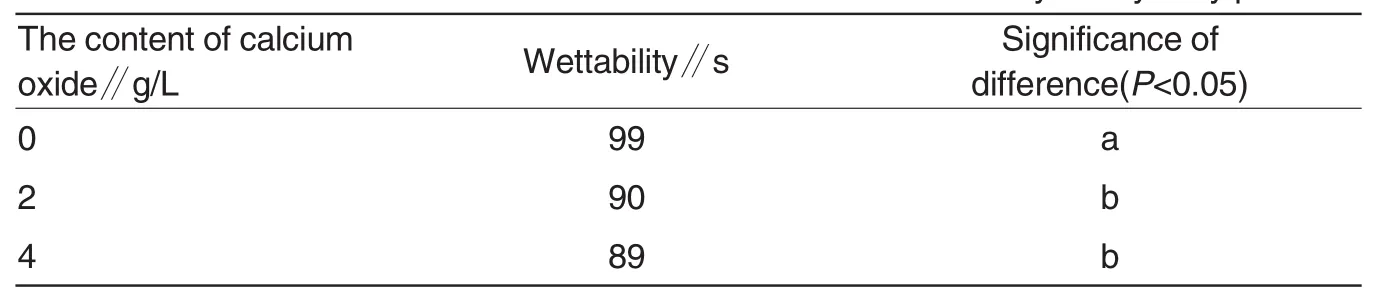

Effects of different contents of calcium oxide on the wettability of bayberry powder

Effects of different contents of calcium oxide on the wettability of bayberry powder were in Table 4.With the increase of calcium oxide content, the time of all bayberry powder dispersing into the water decreased;the dispersing seconds of all bayberry powder obtained from bayberry juice adding 0,2 and 4 g/L calcium oxide using the spray drying technique were 99,90 and 89 s,respectively.Thus as seen in Table 4,adding 2 g/L calcium oxide can significantly improve the wettability of bayberry powder,and the difference on the wettability of bayberry powderobtained from bayberry juice between adding 2 and 4 g/L calcium oxide was not obvious.

Effects of different contents of calcium oxide on the angle of repose of bayberry powder

Effects of different contents of calcium oxide on the angle of repose of bayberry powder were in Table 5. With the increase of calcium oxide content,the angle of repose of bayberry powder decreased;the angles of repose of bayberry powder obtained from bayberry juice adding 0,2 and 4 g/L calcium oxide using the spray drying technique were 25.0°,22.3°and 21.5°,respectively.As shown in Table 5,adding 2 g/L calcium oxide can significantly decrease the angle of repose,indicating that the mobility of bayberry powder was enhanced,and there was not significant difference on the angle of repose of bayberry powder obtained from bayberry juice between adding 2 and 4 g/L calcium oxide,thus the mobility of the two kinds of bayberry powder had not significant difference.

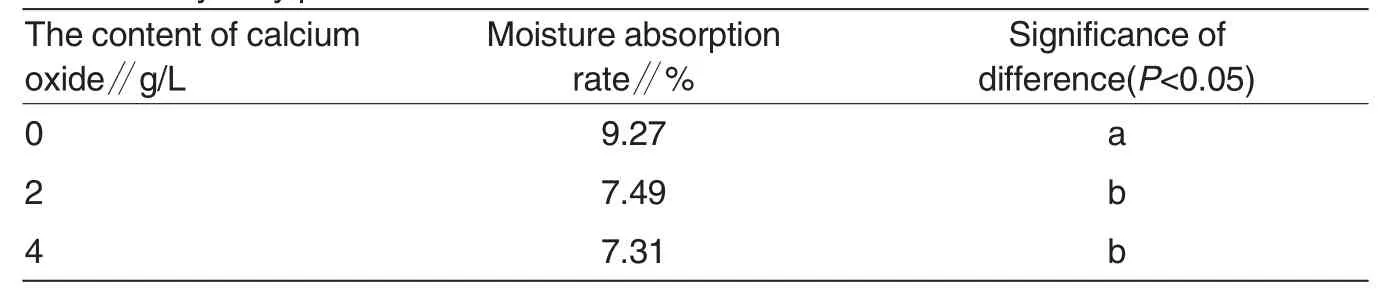

Effects of different contents of calcium oxide on the moisture absorption rate of bayberry powder

Effects of different contents of calcium oxide on the moisture absorption rate of bayberry powder were in Table 6.As shown in Table 6,with the increase of calcium oxide content,the moisture absorption rate of bayberry powder decreased;the moisture absorption rates of bayberry powder obtained from bayberry juice adding 0,2 and 4 g/L calcium oxide using the spray drying technique were 9.27%, 7.49%and 7.31%,respectively.From Table 6,it still can be seen that adding 2 g/L calcium oxide can significantly decrease the moisture absorption rate of bayberry powder,and there was not significant difference on the moisture absorption rate of bayberry powder obtained from bayberry juice between adding 2 and 4 g/L calcium oxide.

Table 4 Effects of different contents of calcium oxide on the wettability of bayberry powder

Table 5 Effects of different contents of calcium oxide on the angle of repose of bayberry powder

Table 6 Effects of different contents of calcium oxide on the moisture absorption rate of bayberry powder

Conclusions

Calcium oxide content had a significant effect on the moisture content and colour of bayberry powder;with the increase of calcium oxide content, the moisture content of bayberry powder decreased,and the colour of bayberry powder changed from bright red to dark red.The content of calcium oxide had not obvious effect on the apparent density of bayberry powder. With the increase of calcium oxide content,the wettability of bayberry powder improved,adding 2 g/L calcium oxide can significantly improve the wettability of bayberry powder,and the difference on the wettability of bayberry powderobtained from bayberry juice between adding 2 and 4 g/L calcium oxide was not obvious.With the increase of calcium oxide content,the angle of repose of bayberry powder decreased,adding 2 g/L calcium oxide can significantly decrease the angle of repose,and there was not significant difference on the angle of repose of bayberry powder obtained from bayberry juice between adding 2 and 4 g/L calcium oxide.With the increase of calcium oxide content,the moisture absorption rate of bayberry powder decreased,adding 2 g/L calcium oxide can significantly decrease the moisture absorption rate of bayberry powder, and there was not significant difference on the moisture absorption rate of bayberry powder obtained from bayberry juice between adding 2 and 4 g/L calcium oxide.

[1]SLADE L,LEVINE H,IEVOLELLA J,et al.The glassy state phenomenon in applications for the food industry[J].Journal of the Science of Food and Agriculture,1993,63(2):133-176.

[2]HAN L(韩磊),TANG YX(唐金鑫),WU YF(吴亚飞),et al.Spray drying of substances containing sugars(含糖类物料的喷雾干燥)[J].Chemistry&Industry of Forest Products(林产化学与工业), 2006,26(2):117-121.

[3]WANG ZL(王宗濂),HAN L(韩磊), TANG JX(唐金鑫).Design principle of spray-drying air disperser(喷雾干燥热风分布器设计原则)[J].Drying Technology&Equipment(干燥技术与设备), 2003(1):40-42.

[4]HUANG WK(黄伟坤).Food inspection and analysis(食品检验与分析)[M].Bei-jing:China Light Industry Press(北京:轻工业出版社),1989.

[5]YE XQ (叶兴乾).The principle of colorimeter and its application in food color measuring(色差计原理及其在食品测色上的应用)[J].Guangzhou Food Science and Technology(广州食品科技), 1988(1):19-22.

[6]CHEN QX(陈清香),HUANG W(黄苇), WEN SN(温升南),et al.Spray drying processing technology of papaya powder(番木瓜粉喷雾干燥工艺研究)[J]. Modern Food Science&Technology (现代食品科技),2009,25(1):68-72.

[7]SONG HX(宋宏新),LI H(李宏),LIU XY (刘晓阳).Technics study on tomato powder preparation by spray drying or vacuum freeze drying(番茄喷雾干燥及真空冷冻干燥制粉工艺研究)[J].Food Science(食品科学),2007,28(5):101-103.

[8]WONG CY.Use of angle of repose and bulk densities for powder characterization and the prediction of minimum fuidization and minimum bubbling velocities[J].Chemical Engineering Science, 2002,57(14):2635-2640.

[9]GONG ML(公茂利),CHEN MG(陈明功), LIN XL(林秀玲).Research on relationship between activation methods and moisture absorption ability of attapulgite (凹凸棒土活化方法与吸湿性关系的研究)[J].Journal of Anhui University of Science and Technology:Natural Science(安徽理工大学学报(自然科学版)), 2008,28(1):74-77.

Responsible editor:Nanling WANG

Responsible proofreader:Xiaoyan WU

氧化钙对喷雾干燥杨梅粉理化性质的影响

宋贤聚*

(台州学院生命科学学院,浙江台州318000)

[目的]研究不同氧化钙含量对喷雾干燥杨梅粉理化性质的影响。[方法]将添加氧化钙含量为0、2、4 g/L的杨梅汁喷雾干燥得到杨梅粉,通过测定杨梅粉的水分含量、色泽、表观密度、湿润性、休止角和吸湿性研究三种杨梅粉的理化性质。[结果]氧化钙的添加量显著地影响杨梅粉的水分含量和色泽;氧化钙含量对杨梅粉表观密度的影响不显著;添加氧化钙可以显著影响杨梅粉的湿润性、休止角和吸湿性,而添加2和4 g/L氧化钙的杨梅汁所制得的杨梅粉之间没有显著差异。[结论]添加氧化钙影响喷雾干燥杨梅粉的产品品质。

氧化钙;喷雾干燥;杨梅粉;理化性质

浙江省自然科学基金资助项目(Y3110376)。

宋贤聚(1973-),男,浙江兰溪人,讲师,从事农产品加工方面的研究,E-mail:Songxj_jj@163.com。*通讯作者。

2015-04-20

修回日期 2015-07-16

Supported by the Project of Natural Science Fund of Zhejiang Province(Y3110376).

*Corresponding author.E-mail:Songxj_jj@163.com

Received:April 20,2015 Accepted:July 16,2015

Agricultural Science & Technology2015年8期

Agricultural Science & Technology2015年8期

- Agricultural Science & Technology的其它文章

- Variations of Frost-free Period and Its Impact on Grain Yields in Henan Province during 1961-2013

- Fuzzy Analysis Method for Orthogonal Test on Seed Propagation of Eurya chinensis

- Establishment of a Method for Determination of Anemoside B4 Content in Pulsatilla Water Extract

- Anther Dehiscence Disturbed by High Temperature and Water Stress Presented in OsDIR Gene Expression in Rice(Oryza sativa L.)

- Influences of Surface Drip Irrigation on the Growth,Yield and Quality of Several New Species of Guitang Sugarcane

- Interspecific Cross Compatibility of Rhododendron in Changbai Mountain