超声萃取-气流式液相微萃取-气相色谱质谱在线联用快速检测蔬菜中有机磷农药残留

南京熙 毕程程 金京一 吴 学

(1.延边大学理学院化学系,吉林 延吉 133002;2.延边出入境检验检疫局,吉林 延吉 133000)

In the stages of cultivation,harvest and storage,pesticides are widely used to protect crops from pests and bacteria and provide quality assurance(Wang,Willis,Daniel,2012).The extensive use of pesticides has resulted in numerous negative effects on food security,the ecological environment and human health(Kaushik,Satya,Naik,2009).Food safety is receiving increasing attention all over the world.Many international organizations and countries(such as the WHO,the United Nations Food and Agriculture Organization,the Eu-ropean Union and the United States of America,among others)have limited the residues of pesticides in international trade(Shinger,Elbashir,Ahmed,Aboul-Enein,2012).

Vegetables are an important source of food but are also a potential source of pesticides(Latif,Sherazin,Bhanger,2011).Pesticide residues in vegetables have been listed as the priority project of food risk monitoring (Lee,Law,Wong,1996).Organophosphorus pesticides (OPPs)are widely used in the world.At present,the varieties and dosages of OPPs have outnumbered other types of pesticides in China.The monitoring of OPPs can ensure the safe supply of food.The analysis methods of OPPs in vegetables in previous reports were time-consuming and difficult.In particular,the sample extraction required tedious clean-up procedures and reconcentration for the final instrument analysis due to matrix interference(Lee,Law,Wong,1996),which hinders the analysis of OPPs.Therefore,a fast and easy analysis method of OPPs has already been urgently sought.

Ultrasonic extraction was widely used in the extraction of trace organic compounds in various plant samples.Compared with Soxhlet extraction(Wang,Jin,Ma,Lu,Lin,2011)and liquid-liquid extraction(Hajlová,Holadová,Kocourek,Poustka,Godula,Cuhra,Kempny,1998;Mekebri,Grane,Blondina,Oros,Rocca,2008),ultrasonic extraction is less solvent-and time-consuming.Compared with the accelerated solvent extraction (Nerín,Battle,Cacho,1998)and supercritical fluid extraction (Valverde-García,Fernandez-Alba,Contreras,Agüera,1996),ultrasonic extraction has a lower instrument cost,is more universally applicable and is simpler.This paper adopted ultrasonic extraction to extract the OPPs in vegetable samples.Matrix interference in the sample remains a significant difficulty for the analysis methods.The extracted sample is often treated by purification and reconcentration methods,such as column chromatography(Vázquez,Mughari,Galera,2008;Hoeck,David,Sandra,2007),solid phase extraction(Díaz,Vàzquez,Ventura,Galceran,2004;Columé,Cárdenas,Gallego,2001;Albero,Sánchez-Brunete,Tadeo,2003)and the gel permeation chromatography technique(Ouyang,Zhao,Janusz,2005;Li,Lee,2009;Alcudia-León,Lucena,Cárdenas,Valcárcel,2009).The above purification techniques are used with large quantities of materials,significant time and a high cost.The most important thing is that the purified sample is not appropriate for on-line instrument analysis and is usually injected into an analytical instrument after concentration.Gas flow liquid phase microextraction(also known as gas purge-microsyringe extraction,GP—MSE),which is an open extraction system with a gas purge,is a novel headspace liquid phase microextraction technology(Li,Lee,2002;Piao,Bi,Yang,Wang,Wang,Li,2011).In GP—MSE,the volatile and semivolatile organic compounds are brought into a microsyringe that contains extracting solvent at a microliter grade.After the extraction,the samples can be directly analyzed by the GC—MS(Yang,Piao,Qiu,Wang,Ren,Li,2011).The GP—MSE possesses the following advantages:the process is usually completed within a few minutes;the system can quickly distinguish between volatile and semivolatile organic compounds and the matrix;the system can play the role of enrichment,purification and reconcentration;and samples can be directly brought into the terminal detector.The application of GP—MSE in sample pretreatment requires further development as a novel microextraction technique.In the study,GP—MSE was applied for a re-extraction of a sample extracted by ultrasonic extraction.

This paper established an analysis system of ultrasonic extraction and gas flow liquid phase microextraction coupled with on-line gas chromatography – mass spectrometry(GC—MS)for the determination of 28types of organic phosphorus pesticide residues in vegetables.The detailed contents are as follows:the extraction conditions of ultrasonic extraction and gas flow liquid phase microextraction;the selection of qualitative and quantitative ions with GC—MS;and the comparison between gas flow liquid phase microextraction and solid phase extraction.The analysis system was also used for the analysis of real vegetable samples.The proposed method would provide a rapid determination for organic phosphorus pesticide residues in vegetable samples,especially for the mass vegetable samples with short analysis times,thereby saving manpower and material resources.

1 Experimental section

1.1 Chemicals and Materials

Pesticide-residue-grade acetone, acetonitrile, dichloromethane,ethyl acetate and n-hexane were obtained from Fisher(America).Analytical-grade anhydrous sodium sulfate was purchased from Shanghai Ling Feng Chemical Reagent Co.Ltd.(Shanghai,China).Twenty-eight types of pesticides standards(dichlorvos,methamidophos,ethoprophos,phorate,methacrifos,thiometon,terbufos,diazinon,fonofos,disulfoton,chlorpyrifos,chlorpyrifos-methyl,dimethoate,tolcolfos-methyl, pirimiphos-methyl, parathionmethyl,malathion,fenthion,fenitrothion,dimethylvinfos,parathion,quinalphos,chlorfenvinphos,isocarbophos,ph-enthoate,edifenphos triazophos and EPN)were purchased from the Agro-environmental Protection Institute,Ministry of Agriculture(China).The purity of the standards was 9 9.8%,and the concentrations of all standards were 1 00μg/mL.A mixed stock standard solution (2.0mg/L)was prepared with 28types of pesticides standards in h exane∶acetone(4∶1,V/V).Standard working solutions of different concentrations were prepared by diluting the stock solutions with hexane∶acetone(4∶1,V/V).The standard solutions were stored in the dark at 0~4℃until used.

1.2 Sample Preparation

The Chinese cabbage and celery was purchased from a local market of Yanji City (China).These samples were crushed by a high-speed rotary cutting mill (GM-200,Retsch,Germany).The standard working solutions were spiked into the samples at levels of 0.01mg/kg for OPPs.

1.3 Ultrasonic Extraction

The procedure of ultrasonic extraction was as follows:the sample was homogenized by a high-speed homogenizer(T25,IKA,Germany),and 10g of the homogeneous sample was then inserted into a 100mL conical flask.Ethyl acetate was then added into the conical flask.After ultrasonic extraction(AS10200AT,Tianjin ossett company,China)for 5min,the sample was filtered into another conical flask.Six grams of sodium chloride was added into the conical flask,shaken violently for 1min,and left to stand at room temperature.When the organic phase and the aqueous phase were stratified,the upper solution was pipetted and was then dried by anhydrous sodium sulfate.The solution was concentrated in a 40℃water bath to nearly dry by a Termovap sample concentrator (R-210v,Buchi,Switzerland).Finally,the volume was set to 0.1mL with ethyl acetate and waited for further processing.

1.4 GP—MSE

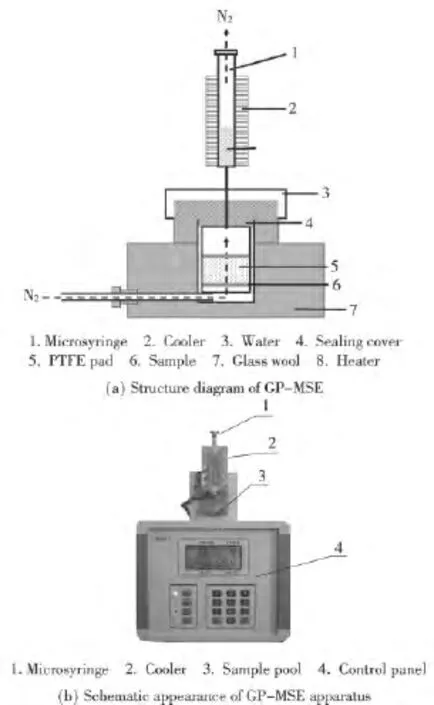

GP—MSE was used to purify and enrich the extract by ultrasonic extraction in the 1.3section.The specific operation was conducted using the GP—MSE apparatus named ME-101Multifunctional Microextraction Apparatus (ME-101,Key Laboratory of Natural of Changbai Mountain &functional Molecules,Ministry of Education,China)in Figure 1(Piao,Bi,Yang,Wang,Wang,Li,2011).As in previous reports,the extraction process can be briefly described as follows(Yang,Piao,Qiu,Wang,Ren,Li,2011):10μL of the extract obtained by ultrasonic extraction was inserted into the sample pool and covered with a polytetrafluoroethylene(PTFE)pad,and inserted into a 100μL microsyringe(710RN,Hamilton,Australia);10μL n-hexane was also inserted into the microsyringe as an extraction solvent.The extraction parameters were set as follows:the gas flow rate was 2mL/min,the extraction temperature was-2℃,the sample temperature was 250℃,and the extraction time was 3min.The apparatus then ran the program and started the re-extraction.After the extraction was completed,the secondary extract(1μL)was injected into a gas chromatography/mass spectrometry system for analysis.

图1 多功能微萃取仪装置图Figure 1 Apparatus of gas purge-microsyringe extraction(GP—MSE)

1.5 Solid Phase Extraction

Solid phase extraction was used for comparison with GP—MSE;the extraction procedure was as follows:a 5 00mg ENVI-Carb(Sigma-Aldrich,America)/PSA (Agilent Technologies,America)composited column was eluted with 8mL of ethyl acetate/hexane(1∶1,V/V);the extract obtained by ultrasonic extraction in the 1.3section was then transferred to the column.After the solution flowed through the column,the column was eluted with ethyl acetate/hexane(1∶1,V/V)and collected the elution.The elution was concentrated using a Termovap Sample Concentrator in a 40℃water bath to nearly dry;the volume was then set to 1mL with ethyl acetate for GC—MS analysis.

1.6 GC—MS Analysis

Analysis of organic phosphorus pesticides(OPPs)was performed on a CLARUS 600Gas Chromatography—Mass Spectrometry (GC—MS) (CLARUS 600,PerkinElmer(PE),America)with an electron impact ion source (EI source)by injecting 1μL of each extract.The analytes were separated on a DB1701ms fused-silica capillary column (3 0m ×0.25mm;thickness 0.25μm)(J & W by Agilent Technologies)and detected on a PE Clarus600quadrupole mass spectrometer system.The GC oven program started at an initial temperature of 70℃and was held for 2min,then increase by 20℃/min to 150℃,by 5℃/min to 190℃and kept 2min,by 10℃/min to 280℃,and held for 8min.Other operating conditions were as follows:the injection temperature was 250℃in splitless mode;the column flow was 1.0mL/min;and helium (99.999%pure)was used as a carrier gas.The GC—MS interface temperature was 2 80℃.The directly coupled mass spectrometer analyzed the substances after electron impact ionization at 70eV in selected ion monitoring(SIM)mode.The selected ions of quantification and identification for the targets are given in Table 1.

2 Results and discussion

2.1 Optimization of Ultrasonic Extraction Conditions

The ultrasonic extraction was selected as the extraction method in the research by the comparison of different extraction methods.Compared to conventional extractions,the high-speed ultrasonic extraction method required less time and less solvent and comparatively advantageous extraction efficiency.These results were consistent with that found in previous literature(Hajlová,Holadová,Kocourek,Poustka,Godula,Cuhra,Kempny,1998).The effects of extraction solvents in ultrasonic extraction were investigated with a spiked celery sample(0.010mg/kg pesticide).The extraction solvent was selected by considering the extraction efficiency,matrix interference,stability and other factors.The results showed that the ethyl acetate with low toxicity was the most suitable for the research.

2.2 Optimization of GP—MSE Conditions

The GP—MSE was used for the re-extraction in the research to realize the purification and enrichment of the target compounds.Matrix effects in vegetable samples (such as chlorophyll)were the biggest problem for a reliable quantitative analysis of pesticide residues(Lee,Law,Wong,1996).The experiment optimized the key factors in GP—MSE influencing the extraction efficiency,which included the gas flow rate,the temperature of the sample phase,the extraction time and the extraction solvent,to reduce the sample matrix interference and achieve satisfactory extraction efficiency.A spiked blank sample(0.010mg/kg)was used for the optimization of the GP—MSE conditions.

表1 28种农药的保留时间及质谱分析定性、定量离子参数Table 1 Ions selected for quantification and identification of compounds

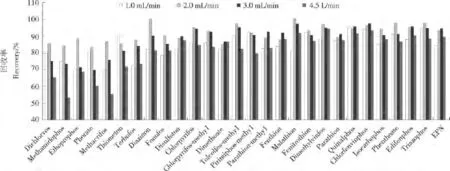

2.2.1 Gas Flow Rate In the GP—MSE system,the volatile and semivolatile compounds were driven to the extraction phase by gas flow,so the gas flow was the basic factor affecting the extraction efficiency(Yang,Piao,Qiu,Wang,Ren,Li,2011).To understand the effect of the gas flow rate on the extraction,the gas flow rate was set at 1.0,2.0,3.0and 4.5mL/min(1.0and 4.5mL/min are the minimum and maximum velocities of the instrument,respectively).The recoveries of 28types of organic phosphorus pesticide residues in spiked Chinese cabbage samples were studied,and the results were shown in Figure 2.Figure 2showed that the recoveries of the targets showed no obvious dependence on the gas flow rate.The targets could be completely extracted by the extraction phase over the entire gas flow range.To effectively control the volume of the extraction phase,the gas flow was set to 2.0mL/min.

图2 气流速率对萃取效率的影响Figure 2 Effect of gas flow rate on the extraction efficiency

图3 样品相温度对萃取效率的影响Figure 3 Effect of sample temperatures on extraction efficiency

2.2.2 Sample Temperature Pesticide compounds mostly belong to the volatile and semivolatile compounds.When the samples were given a certain temperature,the targets could reach the extraction phase quickly.The temperatures of the samples were set at 150,200,250and 280℃.The recoveries of the targets were shown in Figure 3.The result showed that the recoveries of the targets with low boiling points were high and had good stability at a lower temperature,but the recoveries of the targets with high boiling points were relative low.When the temperature was increased to 250℃,the recoveries of the targets with low and high boiling points could all meet the requirements.Therefore,the temperature was set at 250℃in later experiments.

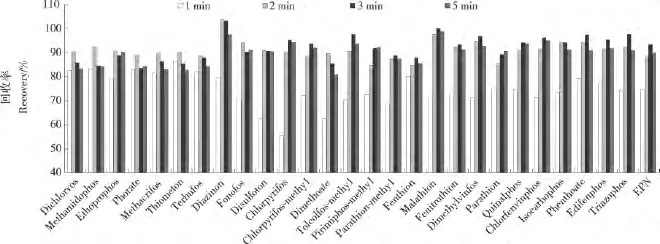

2.2.3 Extraction Time In most previous studies,the extraction time of microextraction was controlled at 15~20min(Wang,Kwok,He,Lee,1998;Wu,Xia,Chen,Hu,2008).However,a shorter extraction time was required in the GP—MSE technique.As shown in Fig.4,the extraction was finished within 3min,and the recoveries of the target compounds were higher than 85%;the recoveries did not va-ry with increasing extraction time after 2min.This result indicates that after trapping by the organic solvent,chemicals were not evaporated from the GP—MSE system.Therefore,the extraction time can be chosen to match the properties of target chemicals or experimental objectives.An extraction time of 3min was used in the following experiments,taking account of both the simplicity of operation and the reproducibility.

图4 萃取时间对萃取效率的影响Figure 4 Effect of extraction time on the extraction efficiency

2.2.4 Extracting Solvent The“like-dissolve-like”rule is a well-established principle in extraction techniques that can also be applied in GP—MSE.Five organic solvents(dichloromethane,acetonitrile,hexane,acetone,ethyl acetate)were selected,and the results were compared.The pesticides selected have high solubilities in those organic solvents,so similar recoveries were obtained for all cases.Based on the toxicity and suitability in the GC—MS analysis,the hexane was selected as an extraction solvent in the following experiments.

2.3 Selection of Monitoring Ions

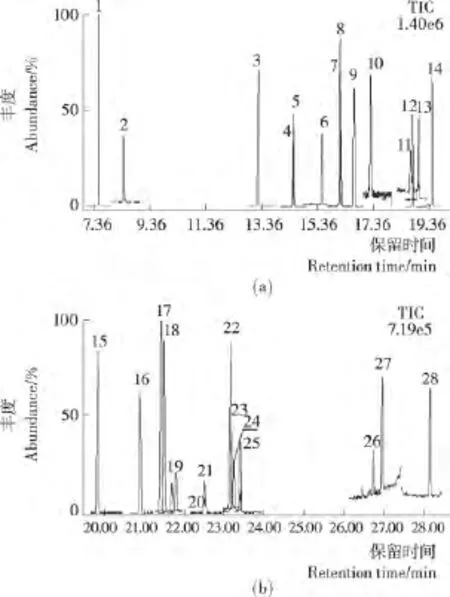

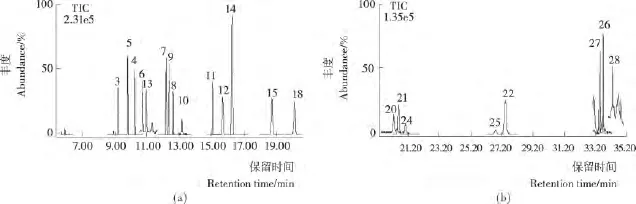

Twenty-eight types of pesticide mixed standard solutions were prepared for the selection of monitoring ions.In the mixed standard solutions,the concentrations of pesticides were 0.01mg/kg.A full scan was run at the instrument conditions of GC—MS.The principles of choosing the monitoring ions were as follows:larger mass-charge ratio,larger abundance and the least interference at the retention time of the analyte according to the mass spectrum and background interference.The results were shown in Table 1.Figure 5 gave the chromatograms of 28pesticides in the selected ion mode.

图5 28种有机磷农药的基质匹配标准溶液选择离子监测色谱图Figure 5 Chromatograms of quantification ions of organophosphorus pesticides(OPPs)in mixed OPPs standard(0.01mg/kg)analyzed by GC—MS with the selected ion mode

2.4 Evaluation of Method Performance

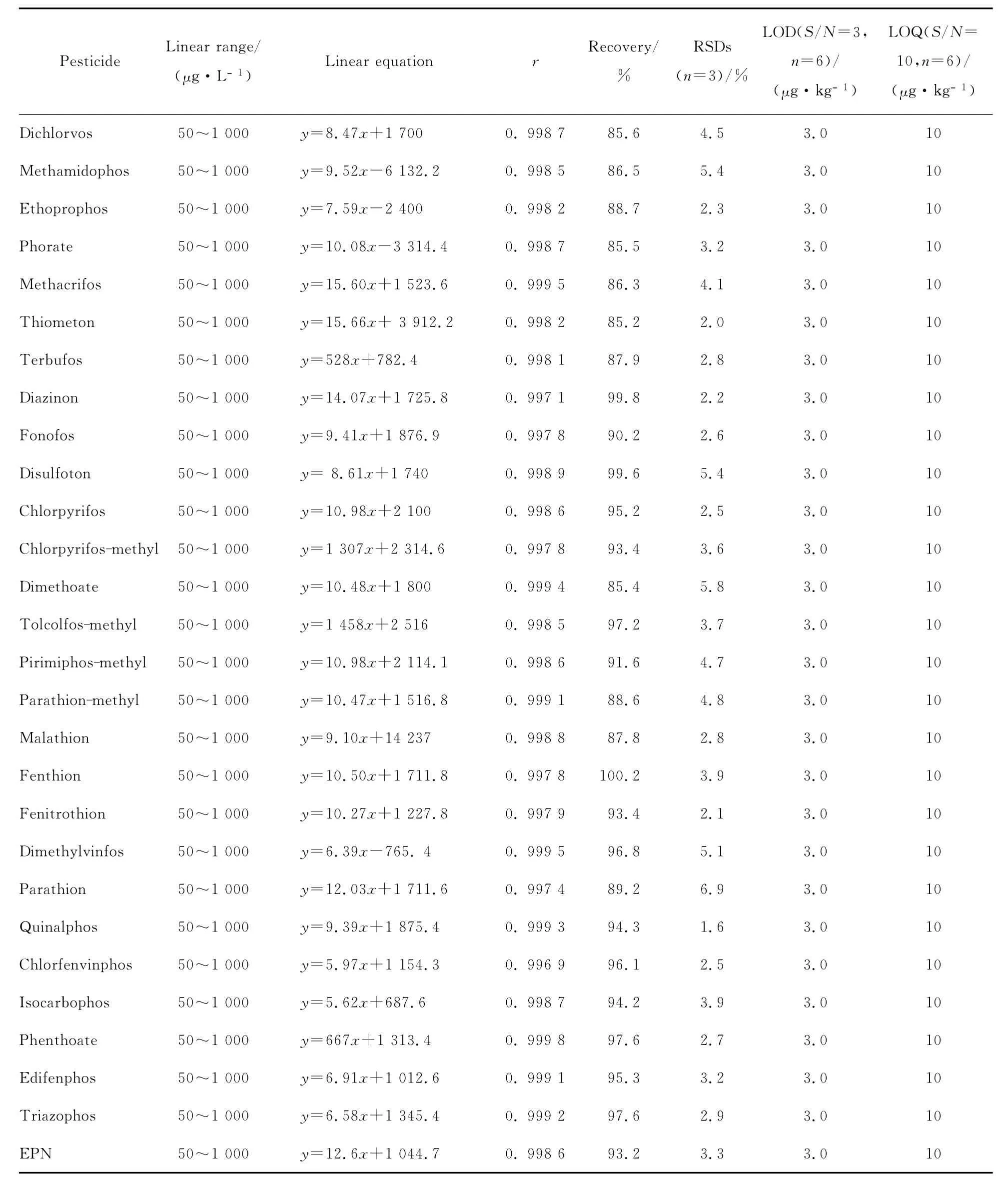

The minimum detection limit(LOD)and quantification limit(LOQ)of the method was calculated as three times and ten times the noise response of the blank sample(S/N=3),respectively.These values were 3μg/kg and 10μg/kg,respectively,for the 28OPPs(Table 2).Twenty-eight types of pesticide in spiked blank samples showed a good linear relationship in the range of 50~1 000μg/kg,and the correlation coefficients(R2)were greater than 0.99(Table 2).The recoveries of the OPPs ranged from 85.5%to 100.2%with RSD values of 1.6%~6.9%.

表2 28种农药的线性方程、线性范围、相关系数、检出限和定量限Table 2 Quality Parameters of UAE—GPMSE—GC—MS analysis system for anaysis of OPPs in vegetable samples

2.5 Analysis of Real Samples

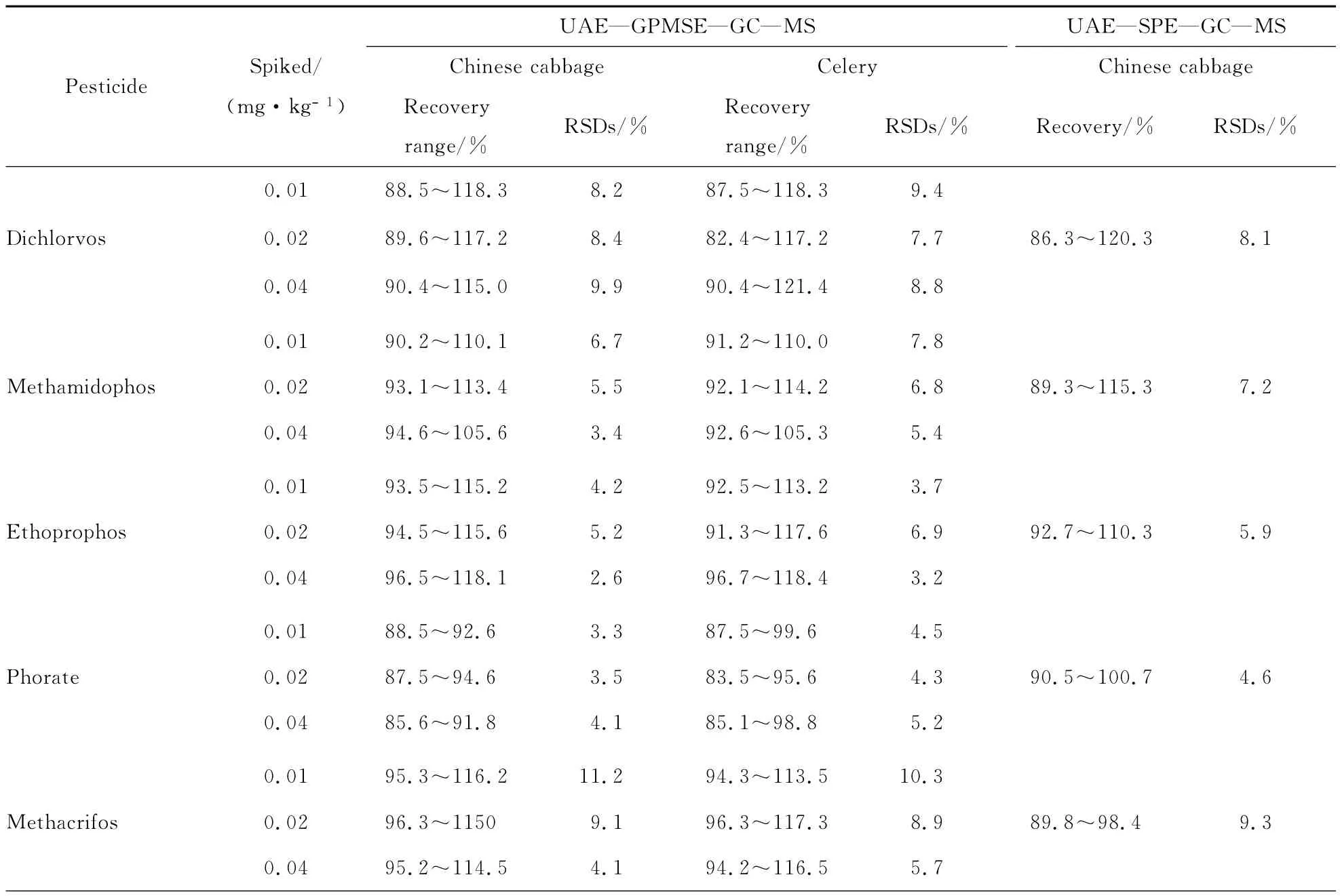

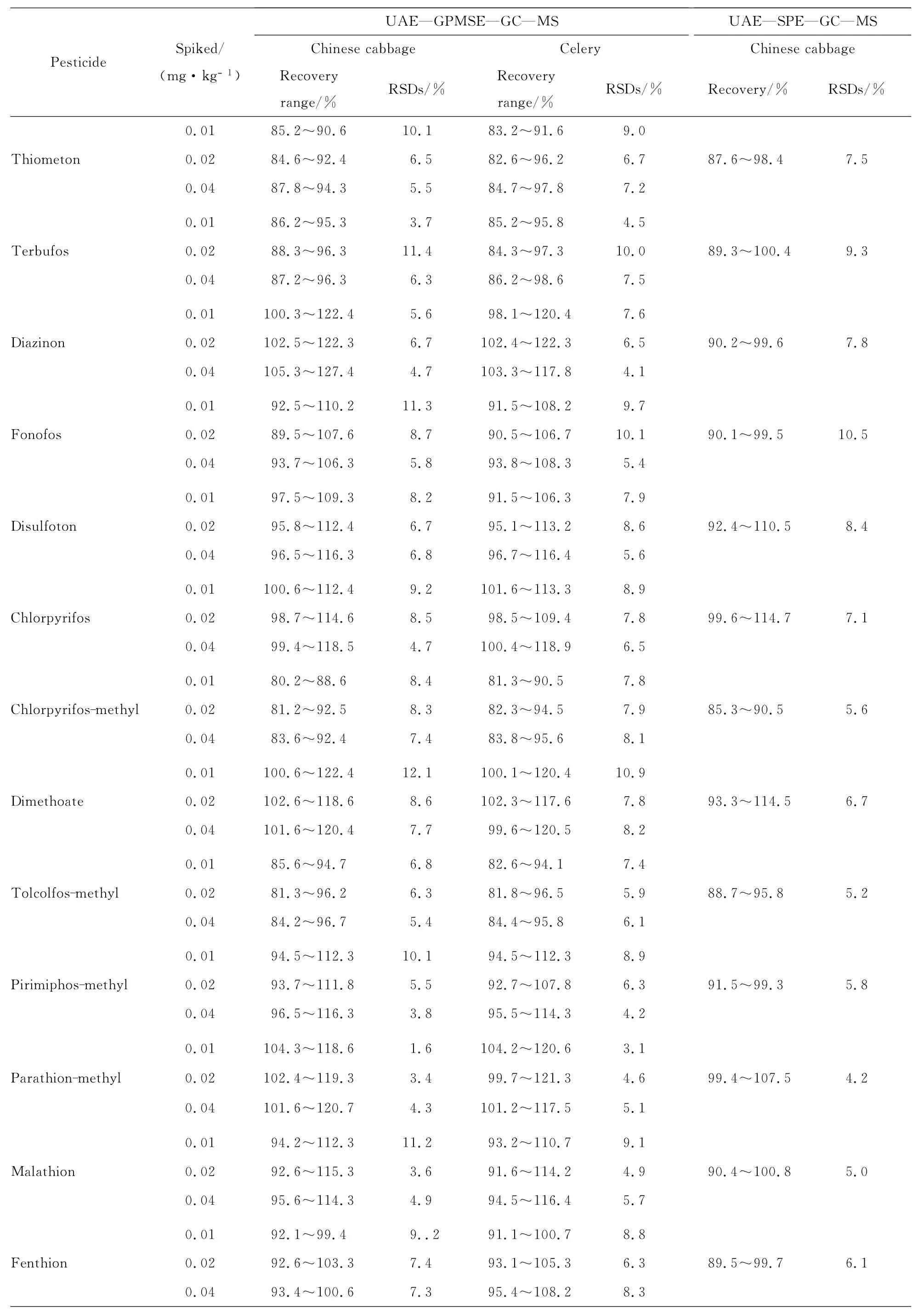

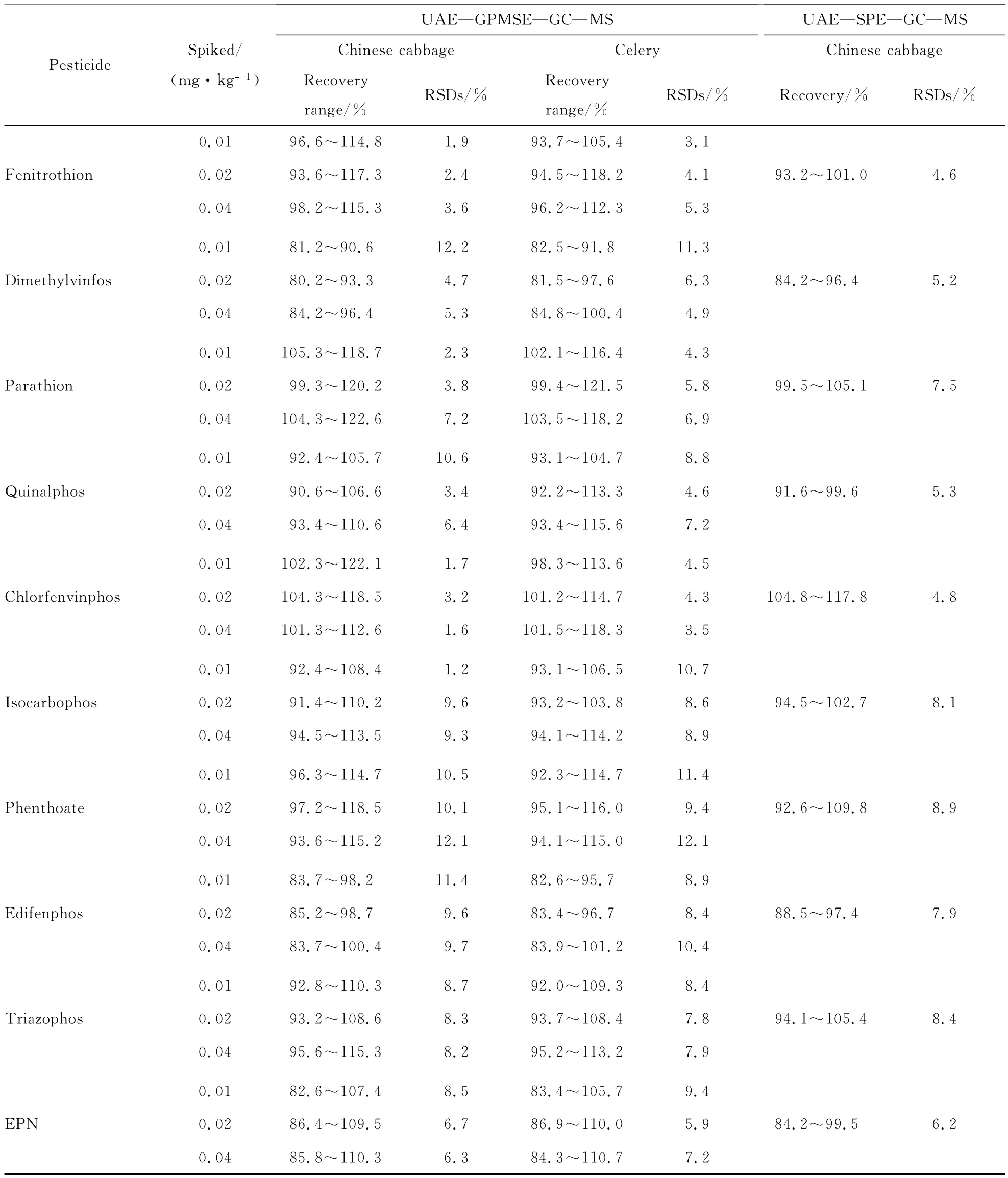

Five types of vegetable samples were selected randomly from the local market and were analyzed by the method in this study.The results showed that chlorpyrifos was detected from the radish sample at a content level of 0.045mg/kg,and dimethoate was detected in celery and Chinese cabbage samples at content levels of 0.037mg/kg and 0.018mg/kg,respectively.The target ingredients were not detected in all samples.Three levels of spiked samples(0.010,0.020,0.040mg/kg)were used for the quality control of the method.The recoveries were 80.2%~1 22.6%,and the RSD were 1.6%~12.1% (see Table 3).The results showed that the method had high recoveries and sensitivity and could meet the requirements of the determination of pesticide residues.The chromatography of real samples and spiked real samples were given in Figure 6.

图6 白菜加标溶液选择离子监测色谱图Figure 6 Chromatograms of quantification ions of organophosphorus pesticides(OPPs)in spiked Chinese cabbage sample(0.01mg/kg)analyzed by GC-MS with the selected ion mode

表3 白菜和芹菜样品中28种有机磷农药的加标回收率及相对标准偏差Table 3 Recoveries and relative standard derives(RSDs)of OPPs at spiked real samples by UAE—GPMSE—GC—MS(in this study)and UAE—SPE—GC—MS(n=3)

续表3

续表3

Solid-phase extraction was also used for analysis of the spiked real samples.Compared with this method,the method in this study achieved comparable results(Table 3)but had a shorter analysis time,less solvent consumption and the advantage of direct injection into GC—MS.

3 Conclusions

This study developed a rapid analysis system for detecting organophosphorus pesticides residues in vegetables and edible fungi using ultrasonic extraction,gas purge liquid phase microextraction and gas chromatography–mass spectrometry.The sample was extracted using ultrasonic techniques in ethyl acetate for 5min and was later extracted to 1 0μL of n-hexane using GP—MSE at a gas flow rate of 2 mL/min and a sample temperature of 250℃for 3min.The extract was directly injected into GC—MS.The recoveries of the 28organophosphorus pesticides reached 80.2%to 1 22.6%,with RSD values of 1.6%to 12.1%.The method exhibited a low detection limit,agood linear relationship,and comparable results with SPE.The analysis system effectively utilized the advantages of GP—MSE(less solvent consumption,short extraction time,good separation and purification function and enrichment function).This system was suitable for the rapid determination of organophosphorus pesticides residues in vegetables for food safety.

1 Albero B,Sánchez-Brunete C,Tadeo J L.Determination of endosulfan isomers and endosulfan sulfate in tomato juice by matrix solid-phase dispersion and gas chromatography[J].J.Chromatogr.A,2003,1 007:137~143.

2 Alcudia-León M C,Lucena R,Cárdenas S,et al.Stir membrane extraction:a useful approach for liquid sample pretreatment[J].Anal.Chem.,2009,81:8 957~8 961.

3 ColuméA,Cárdenas S,Gallego M,et al.Semiautomatic multiresidue gas chromatographic method for the screening of vegetables for 25organochlorine and pyrethroid pesticides[J].Anal.Chim.Acta.,2001,436:153~162.

4 Díaz A,Vàzquez L,Ventura F,et al.Estimation of measurement uncertainty for the determination of nonylphenol in water using solid-phase extraction and solid-phase microextraction procedures[J].Anal.Chim.Acta,2004,506:71~80.

6 Hoeck E V,David F,Sandra P.Stir bar sorptive extraction for the determination of pyrethroids in water samples:A comparison between thermal desorption in a dedicated thermal desorber,in a split/splitless inlet and by liquid desorption[J].J.Chromatogr.A,2007,1 157:1~9.

7 Kaushik G,Satya S,Naik S N.Food processing a tool to pesticide residue dissipation:a review[J].Food Research International,2009,42:26~40.

8 Latif Y,Sherazin S T H,Bhanger M I.Assessment of pesticide residues in commonly used vegetables in Hyderabad,Pakistan[J].Ecotox.Environ.Safe,2011,74:2 299~2 303.

9 Lee W O,Law M L M,Wong S K.Determination of methamidophos residues in food remnants[J].Food Addit Contam,1996,13:687~694.

10 Li X,Lee H K.Solvent-bar microextraction—Using a silica monolith as the extractant phase holder[J].J.Chromatogr.A,2009,1 216:5 483~5 488.

11 Li H,Lee H K.Application of static and dynamic liquid-phase microextraction in the determination of polycyclic aromatic hydrocarbons[J].J.Chromatogr.A,2002,976(1~2):377~385.

12 Mekebri A,Grane D B,Blondina G J,et al.Extraction and analysis methods for the determination of pyrethroid insecticides in surface water,sediments and biological tissues at environmentally relevant concentrations[J].Bull Environ ContamToxicol.,2008,80:455~460.

13 Nerín C,Battle R,Cacho J.Determination of pesticides in highwater-content samples by off-line supercritical fluid extractiongas chromatography-electron-capture detection[J].J.Chromatogr.A,1998,795:117~124.

14 Ouyang G F,Zhao W N,Janusz P.Kinetic calibration for automated headspace liquid-phase microextraction [J]. Anal.Chem.,2005,77:8 122~8 128.

15 Piao X Y,Bi J H,Yang C,et al.Automatic heating and cooling system in a gas purge microsyringe extraction[J].Talanta.,2011,86:142~147.

16 Shinger M I,Elbashir A A,Ahmed H E,et al.Simultaneous determination of cypermethrin and fenvalerate residues in tomato by gas chromatography and their applications to kinetic studies after field treatment[J].Biomed.Chromatogr.,2012,26:589~593.

17 Valverde-Garcia A,Fernández-Alba A R,Contreras M,et al.Supercritical fluid extraction of pesticides from vegetables using anhydrous magnesium sulfate for sample preparation[J].J.Agric.Food Chem.,1996,44(7):1 780~1 784.

18 Vázquez P P,Mughari A R,Galera M M.Application of solidphase microextraction for determination of pyrethroids in groundwater using liquid chromatography with post-column photochemically induced fluorimetry derivatization and fluorescence detection[J].J.Chromatogr.A,2008,1 188:61~68.

19 Wang J,Willis C,Daniel L.Application of ultrahigh-performance liquid chromatography and electrospray ionization quadrupole orbitrap high-resolution mass spectrometry for determination of 166pesticides in fruits and vegetables[J].J.Agric.Food Chem.,2012,60:12 088~12 104.

20 Wang Y,Jin H Y,Ma S C,et al.Determination of 195pesticide residues in Chinese herbs by gas chromatography-mass spectrometry using analyte protectants[J].J.Chromatogr.A,2011,1 218:334~342.

21 Wang Y,Kwok Y C,He Y,et al.Application of dynamic liquid-phase microextraction to the analysis of chlorobenzenes in water by using a conventional microsyringe[J].Anal.Chem.,1998,70:4 610~4 614.

22 Wu Y L,Xia L B,Chen R,et al.Headspace single drop microextraction combined with HPLC for the determination of trace polycyclic aromatic hydrocarbons in environmental samples[J].Talanta.,2008,74:470~477.

23 Yang C,Piao X Y,Qiu J X,et al.Gas purge microsyringe extraction for quantitative direct gas chromatographic-mass spectrometric analysis of volatile and semivolatile chemicals[J].J.Chromatogr.A,2011,1 218:1 549~1 555.