Cutting force measurement based on tool embedded Ni-chrome thin-film micro-sensors

WU Wen-ge, CHENG Yun-ping, DU Xiao-jun

(School of Mechanical and Power Engineering, North University of China, Taiyuan 030051, China)

CuttingforcemeasurementbasedontoolembeddedNi-chromethin-filmmicro-sensors

WU Wen-ge, CHENG Yun-ping, DU Xiao-jun

(SchoolofMechanicalandPowerEngineering,NorthUniversityofChina,Taiyuan030051,China)

Abstract:Cutting force measurement has become a crucial activity for enhancing machining process performance.This paper described the design and fabrication of embedded Ni-chrome thin-film micro-sensors in tool holders to measure the cutting force in machining operations.A Ni-chrome thin-film sensor device is embedded within a substrate structure through a dynamic brazing process, which consists of a Ti6Al4V substrate, a nickel-chromium thin-film sensor and an alumina insulating layer.The Wheatstone bridge which consists of four sensors would produce the output voltage when the thin film caused deformation by the cutting forces.The relationship between input and output voltages was theoretically analyzed.Accordingly, an in-process cutting force measurement system is established.The results show that the thin-film sensor had good linearity and less mutual interference, and it is suitable for all kinds of turning forces under the measurement conditions.

Key words:thin-film micro-sensor; cutting force measurement; theoretical analysis

CLDnumber: TP212; TG806Documentcode: A

The measured cutting force information is essential to monitoring the operational status of the equipment, determining the process regime, and improving the reliability, which contributes to better quality products and higher productivity.Recently, there have been significant advances in the area of micro-sensors technology.Because small-size micro-sensors respond more quickly than ordinary macro-sensors, thermo-mechanical responses can be measured very efficiently by using thin-film micro-sensors due to some advantages of the absence of adhesive material, flexibility to tailoring the properties of the sensor material in thin-film form, good linearity, improved strain sensitivity, and fast response[1-3].There are reports about micro-fabrication and characterization of metal-embedded thin-film thermo-mechanical micro-sensors applyied in hostile manufacturing environments[4].Moreover, the micro thin-film thermocouple sensors are embedded into poly-crystalline cubic boron nitride (PCBN) tool insert to study the tool behavior[5].

In this paper, we present a new approach that embeds thin-film mechanical micro-sensors into metal substrates to measure the cutting forces.The system design is discussed in details.

1 Configuration of measurement system

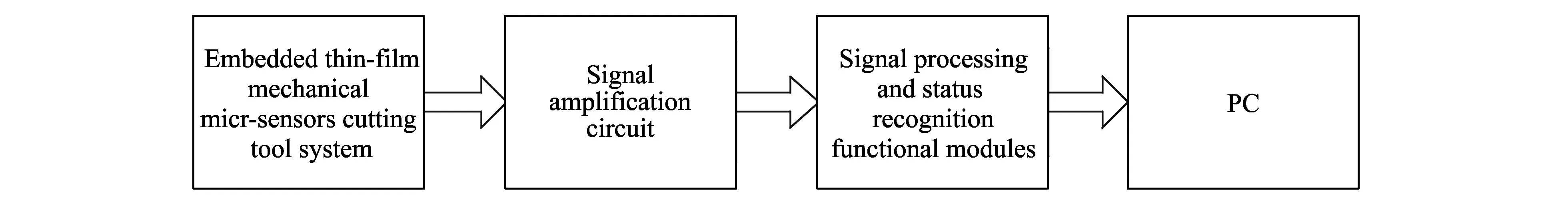

Generally, an in-process cutting force measurement system contains an embedded thin-film mechanical micro-sensors cutting tool system, signal amplification circuit, signal processing and status recognition functional modules, as shown in Fig.1.

Fig.1 Configuration of cutting force measurement system

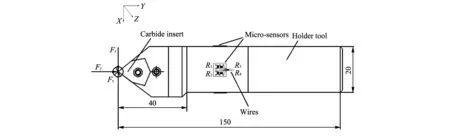

Cutting forces' effects on cutting tools will result in a deflection of the strain gauge, and the developed strain makes the resistance of the gauge change.The change in the resistance of each sensor element is detected as change in the output voltage of a Wheatstone bridge circuit.The all output voltages of the bridge circuit are sent to a PC through an amplifier and signal processing and status recognition functional modules.The embedded thin-film mechanical microsensors cutting tool system is shown in Fig.2.The microfabrication and characterization of tool embedded thin-film mechanical microsensors are vital techniques.As depicted in Fig.2, the tool system is typically made up of a holder, inserts, micro-sensors, wires, etc.It will be described in detail in the following.

Fig.2 Diagram of embedded thin-film mechanical micro-sensors cutting tool systems within Cartesian coordinate system

2 Design of thin-film micro-sensor

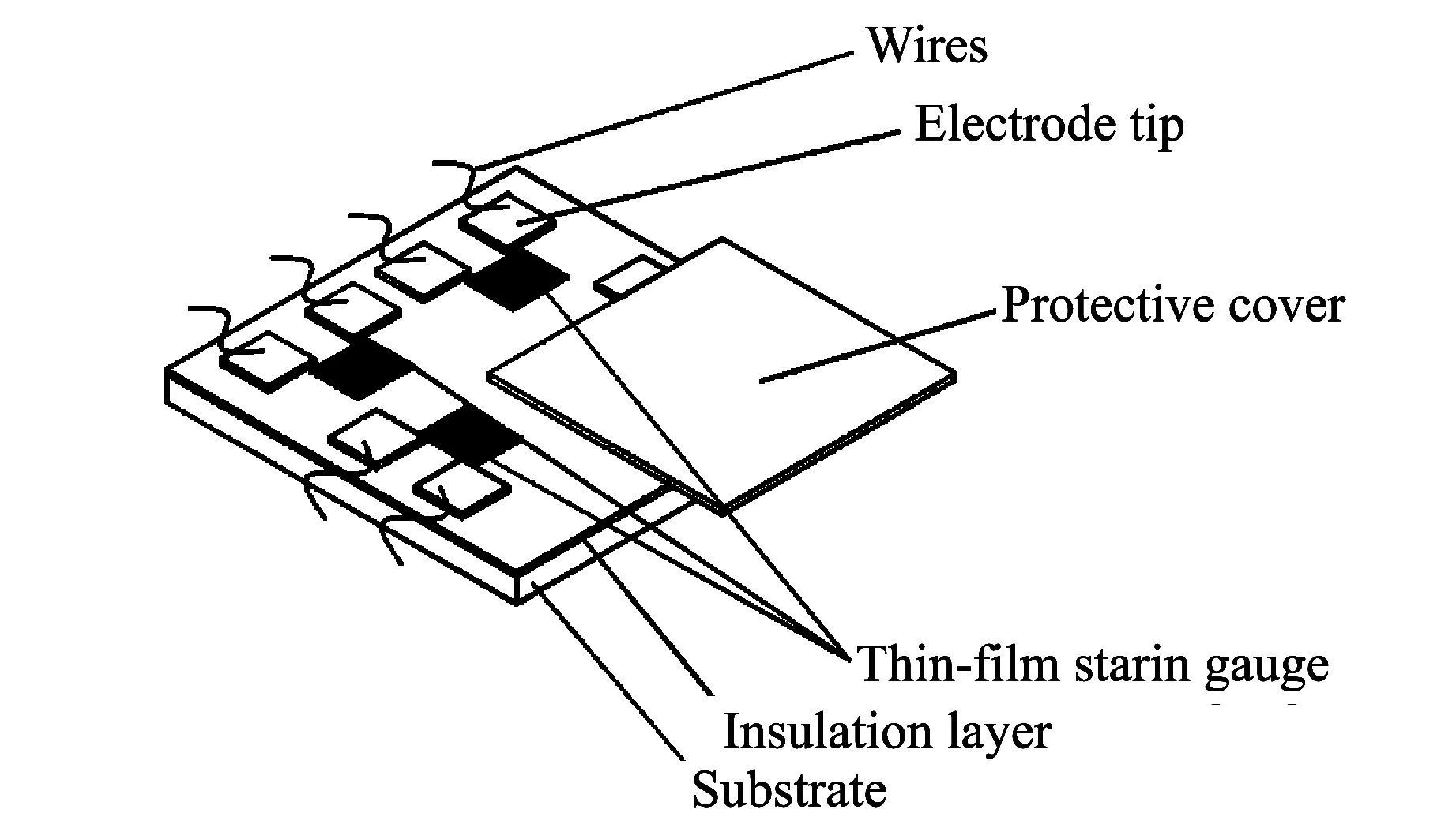

The thin-film micro-sensor consists of four layers: the substrate, insulating layer, strain gauge layer and covering layer, as shown in Fig.3.

Fig.3 Structure of sensor unit layers

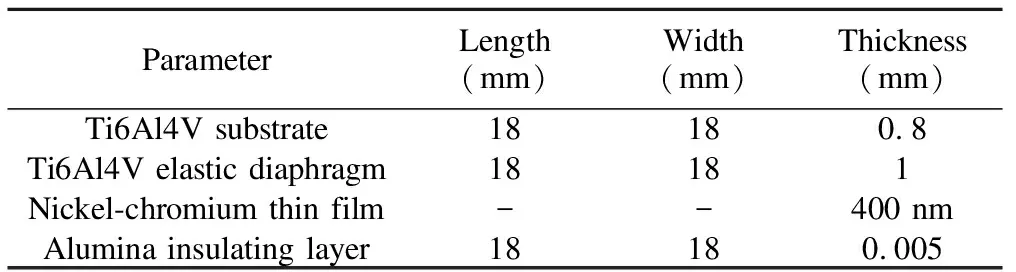

Ti6Al4V titanium alloy substrate as selected due to its excellent performance.Thin-film sensors should be fabricated on an insulating layer.The selection of insulating films is crucial to sensor survival and stability.This layer will isolate the sensor electrically from the underlying metallic substrate and from the final protective embedding layer.Electron beam evaporated Al2O3film was found as an insulating layer due to its excellent thermal stability and good thermal coefficient matching with metal substrates[6].Initially, 0.5 μm thick aluminum oxide membrane layer was deposited by magnetron sputtering.On top of this layer, a thin layer of nichrome (NiCr 80/20 wt.%) was deposited using magnetron sputtering and patterned to form the strain gauge layer.The thin-film strain gauge was designed.The layout of thin-film and size diagram of cell were designed[7].The size and parameters of designed micro-sensors model are shown in Table 1.

Table1Sizeandparametersofdesignedmicro-sensorsmodel

ParameterLength(mm)Width(mm)Thickness(mm)Ti6Al4V substrate18180.8Ti6Al4V elastic diaphragm18181Nickel-chromium thin film--400 nmAlumina insulating layer18180.005

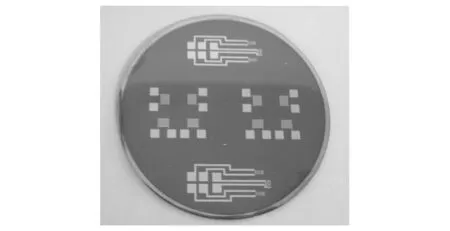

The entire fabrication of micro-sensor was performed in class 100 and 1 000 clean rooms.Fig.4 shows the thin-film sensors on Ti6Al4V substrate before embedded.The substrate size is 50 mm circular base tab separated with wire-electrode cutting process into the required size as 18 mm×18 mm.

Fig.4 Thin-film sensors on Ti6Al4V substrate (before embedded)

One micro-sensor cell is made up of four gauge elements and every gauge element has two electrodes.As Fig.3 shows, one sensor element is mounted onto the upper surface of cutting tool holder in proper position.The other sensor element is mounted under the surface of holder.In the same way, the left and right surface of holder have one sensor, respectively.Finally, the thin-film micro-sensors were bonded with holder through ultrasonic welding and brazing process.

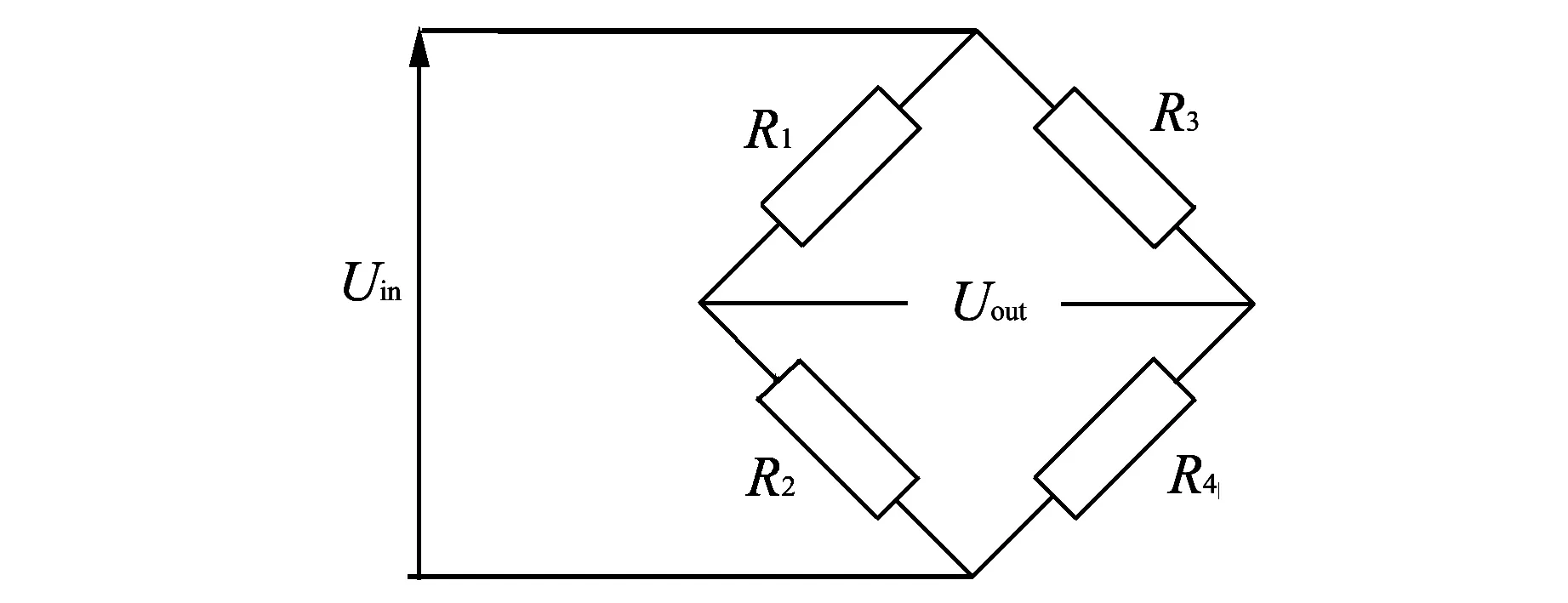

Four strain gauges are connected in a half-Wheatstone or full-Wheatstone bridge circuit arrangement.As the force is applied on the strain gauge, the membrane deflects inducing strain across the bridge arms, which in turn results in a change in the resistance on the bridge arm.When there is any small change in the resistances of the bridge arms, the output voltage will not be nonzero.The Wheatstone bridge circuit in the device was electrically connected, as shown in Fig.5.

Fig.5 Schematic of Wheatstone bridge circuit

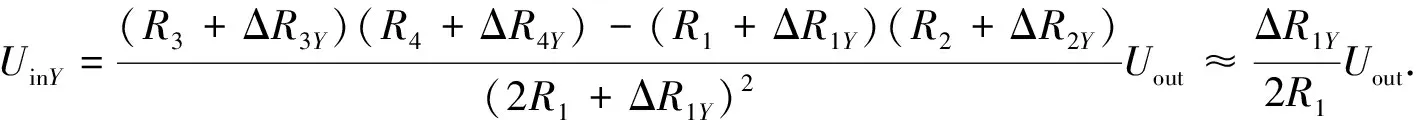

Four strain gauges with resistances ofR1,R2,R3andR4, respectively, are defined asRwith equivalent resistance when Wheatstone bridge circuit is in balance.Identical initial voltage was loaded on the four sensor units, when the input voltageUinwas loaded, the relationship betweenUinandUoutcan be defined as

(1)

As depicted in Fig.2, when the tangential force (Zdirection force) was loaded on the external turning tool tip, the resistance would change, and the Eq.(1) can be rewritten as

(2)

When the axial force (Xdirection force) and the radial force (Ydirection force) were loaded on the external turning tool tip, respectively, the relationship between input and output voltages is

(3)

(4)

The output voltage caused by the forcesFZandFYcan be measured through No.1 sensor (on the upper surface of holder) and No.2 sensor (under the surface of holder), and the output voltage caused by the forceFXandFYcan be measured through No.3 sensor (left surface of holder) and No.4 sensor (right surface of holder).Each component force can be calculated according to the output voltage measured by four sensors.

3 Conclusion

This paper describes the fabrication, embedding, and characterization of the metal embedded thin-film micro-sensors for turning force measurements.Thin-film mechanical micro-sensors have been successfully fabricated and embedded into tool structures by ultrasonic welding and brazing.Thin-film mechanical micro-sensors have high sensiuivity and linearity.We should note the differential output of the micro-sensors, which refers to the amount of bending, torsion and tension passing through the tool tip at the cutting point.The real tri-axial force values need further experimental investigation by the configuration of the cutting force measurement systems.

[1] Lei J F, Will H A.Thin-film thermocouples and strain-gauge technologies for engine applications.Sensors and Actuators A, 1998, 65: 187-193.

[2] Biehl S N, Staufenbiel S, Hauschild F, et al.Novel measurement and monitoring system for forming processes based on piezoresistive thin film systems.Microsystems Technology, 2011, 16(5): 879-883.

[3] Kazi I H, Wild PM, Moore T N, et al.The electromechanical behavior of nichrome (80/20 wt.%) film.Thin Solid Films, 2003, 433: 337-343.

[4] Choi H, Datta A, CHENG Xu-dong, et al.Microfabrication and characterization of metal-embedded thin-film thermomechanical microsensors for pplications in hostile manufacturing environments.Journal of Microelectromechanical Systems, 2006, 15(2): 322-329.

[5] Guha A, LI Hang, SUN Zhen-guo, et al.Wireless acquisition of temperature data from embedded thin film sensors in cutting insert.Journal of Manufacturing Processes, 2012, 14(3): 360-365.

[6] Shamala K S, Murthy L C S, Rao K N.Studies on optical and dielectric properties of Al2O3 thin films prepared by electron beam evaporation and spray pyrolysis method.Materials Science and Engineering B, 2004, 106(3): 269-274.

[7] LI Xue-rui, WU Wen-ge, CHENG Yun-ping, et al.Design and research of a nickel-chromium thin film sensor for measuring the cutting force of a kind of 45° straight cylindrical Turning tool.Manufacturing Automation, 2014, 36(6): 120-123.

刀具嵌入镍铬合金薄膜微传感器切削力测量的研究

武文革, 成云平, 杜晓军

(中北大学 机械与动力工程学院, 山西 太原 030051)

摘 要:切削力的测量旨在改进和提高切削加工性能。 本文设计和制备了一种镍铬合金薄膜微传感器, 将其焊接嵌入刀具的刀杆上以测量加工中的切削力。 该传感器由Ti6Al4V钛合金基体、 镍铬合金薄膜层及氧化铝绝缘层组成。 切削力引起的薄膜变形使四个电阻栅组成的惠斯通电桥产生输出电压, 对其输入和输出电压之间的关系进行了理论分析。 构建了切削力测量系统。 研究结果表明, 该薄膜传感器具有良好的线性度和更小的相互干扰, 适合于各种条件下车削力的测量。

关键词:薄膜传感器; 切削力测量; 理论分析

引用格式:WU Wen-ge, CHENG Yun-ping, DU Xiao-jun.Cutting force measurement based on tool embedded Ni-chrome thin-film micro-sensors.Journal of Measurement Science and Instrumentation, 2014, 5(4): 16-19.[doi: 10.3969/j.issn.1674-8042.2014.04.004]

Article ID:1674-8042(2014)04-0016-04

10.3969/j.issn.1674-8042.2014.04.004

Receiveddate: 2014-07-25

Research Project Supported by Shanxi Scholarship Council of China (No.2013-086)

Corresponding author:WU Wen-ge (3wwwg@163.com)

Journal of Measurement Science and Instrumentation2014年4期

Journal of Measurement Science and Instrumentation2014年4期

- Journal of Measurement Science and Instrumentation的其它文章

- Research on measuring time constant of NANMAC thermocouple

- Empirical model of correction for zenith tropospheric delay

- Detection technique of moving target based on passive millimeter wave

- Mosaic line-scan camera based on FPGA

- Polarization state measurement based on photoelastic modulation

- Measurement and control system for servo pressure pulse testing equipment