Experimental study on the durability of BFRP bars embedded in concrete

Zhu Ying Wu Gang Dong Zhiqiang Wang Xin Wu Zhishen

(1Key Laboratory of Concrete and Prestressed Concrete Structures of Ministry of Education, Southeast University, Nanjing 210096, China.)(2 National and Local Unified Engineering Research Center for Basalt Fiber Production and Application Technology, Southeast University, Nanjing 210096, China.)

Experimental study on the durability of BFRP bars embedded in concrete

Zhu Ying1Wu Gang1Dong Zhiqiang1Wang Xin2Wu Zhishen2

(1Key Laboratory of Concrete and Prestressed Concrete Structures of Ministry of Education, Southeast University, Nanjing 210096, China.)(2National and Local Unified Engineering Research Center for Basalt Fiber Production and Application Technology, Southeast University, Nanjing 210096, China.)

This paper presents an experimental study on the alkali-resistant properties of basalt fiber reinforced polymers (BFRP) bars under a typical concrete environment. BFRP bars were embedded in concrete and exposed to different aggressive environments, including tap water, saline solution and ambient temperature environments, to study the effects of the type of solution and relative humidity (RH) on the durability of BFRP. Meanwhile, BFRP bars were directly immersed in an alkaline solution for comparison. The acceleration factor describing the relationship between the alkaline solution immersion and the moisture-saturated concrete was also obtained. Aging was accelerated with a temperature of 60 ℃. The results show that the chloridion in the saline solution does not have any harmful effects on the degradation of the concrete-encased BFRP bars. Contact with an alkaline (high pH) concrete pore-water solution is the primary reason for the degradation of the BFRP bars. The degradation rate of concrete-encased BFRP bars is accelerated when a high temperature and a high humidity are present simultaneously. The degradation rate of the BFRP bars is relatively quick at the initial stage and slows down with exposure time. Results show that the degradation of 2.18 years in moisture-saturated concrete at 60 ℃ corresponds to that of one year when directly immersed in an alkaline solution (other conditions remaining the same) for the BFRP bars analyzed.

concrete; basalt fiber reinforced polymers (BFRP) bar; durability; alkalinity environment; chloride environment; acceleration factor

In a marine environment, the deterioration of traditional reinforced concrete (RC) structures is primarily caused by corrosion of the steel reinforcement, which is a result of the permeation of chloridion (Cl-) contained in seawater or salt fog; fiber reinforced polymer (FRP) rods have emerged as one of the most promising and affordable solutions to this problem[1]. The degradation mechanisms of FRP rods and steel bars in a marine environment are different due to their different chemical compositions. Further studies on the durability of FRP rods, specifically within a concrete environment, are required[2-6]. Among various FRP composites, the newly developed BFRP composites manufactured with natural volcanic rocks exhibit extraordinary advantages. They are environmentally friendly, require low energy consumption for production, are recyclable, and have a high performance to cost ratio[7]. To date, studies have focused primarily on the short-term mechanical properties of BFRP bars and long-term mechanical properties in severe aggressive environments have not been a concern. However, an understanding of the long-term mechanical properties of FRP bars, specifically within a concrete alkaline environment, is crucial for their application in concrete.

From the literature review, it can be concluded that to evaluate the alkali resistance of FRP bars in concrete, the tests are usually accelerated by immersion of the FRP bars in a simulated concrete pore solution, with a controlled elevated temperature[8-11]. However, previous studies, primarily for glass composites, have shown that this method is too severe and prematurely degrades the FRP bars, leading to limited life expectancies and conservative predictions[12]. For instance, Mufti et al.[13]conducted an outdoor investigation on five in-service concrete bridge structures across Canada (in service for 6 to 8 years). The glass fiber reinforced polymer (GFRP) bar reinforced concrete cores were analyzed with a scanning electron microscope (SEM) and energy-dispersive X-ray spectroscopy (EDS). It was found that the glass fibers and the GFRP/concrete interface were intact. Robert et al.[12]placed cement mortar-wrapped GFRP bar specimens in water with temperature controlled at 23, 40 and 50 ℃; the tensile strength at 40 ℃ and 50 ℃ declined by 10% and 16% after 240 d, respectively, much less than the degradation of GFRP bars immersed in an alkaline solution. However, studies on the durability of a promising alternative material, concrete-encased FRP bars, particularly the newly developed BFRP bars, in seawater are insufficient[14].

This paper presents an experimental study on the durability of concrete-encased BFRP bars. The specimens were placed in tap water, saline solution with an ambient temperature environment to simulate the conditions experienced by a concrete structure in freshwater, seawater and an ambient environment, respectively. The degradation of BFRP bars in a simulated concrete pore-water solution and in moisture-saturated concrete were compared, and the acceleration factor between the two environments was quantified.

1 Experimental Program

1.1 Materials

The ribbed basalt FRP bars used in this paper were manufactured by a Chinese company (Jiangsu GMV New Material T&D Co., Ltd.). The bars were manufactured from continuous basalt fibers impregnated with an epoxy matrix using the pultrusion process and were post cured in a 200 ℃ oven for 2 h. The spacing of ribs wasdand the depth was 0.06d, wheredrepresents the nominal bar diameter of 6 mm. The volume fraction of basalt fiber was 65%, as provided by the manufacturer. The composition of the concrete by weight waswwater∶wcement∶wgravel∶wsand=200∶417 ∶1 159 ∶624. The water-cement ratio was 0.48, and the diameter of gravels used was approximately 10 mm. The pH value of the concrete pore-water was 12.70 to 12.75. It was measured by extracting solutions of crushed and ground concrete powder after aging according to Sun et.al[15].

1.2 Specimens

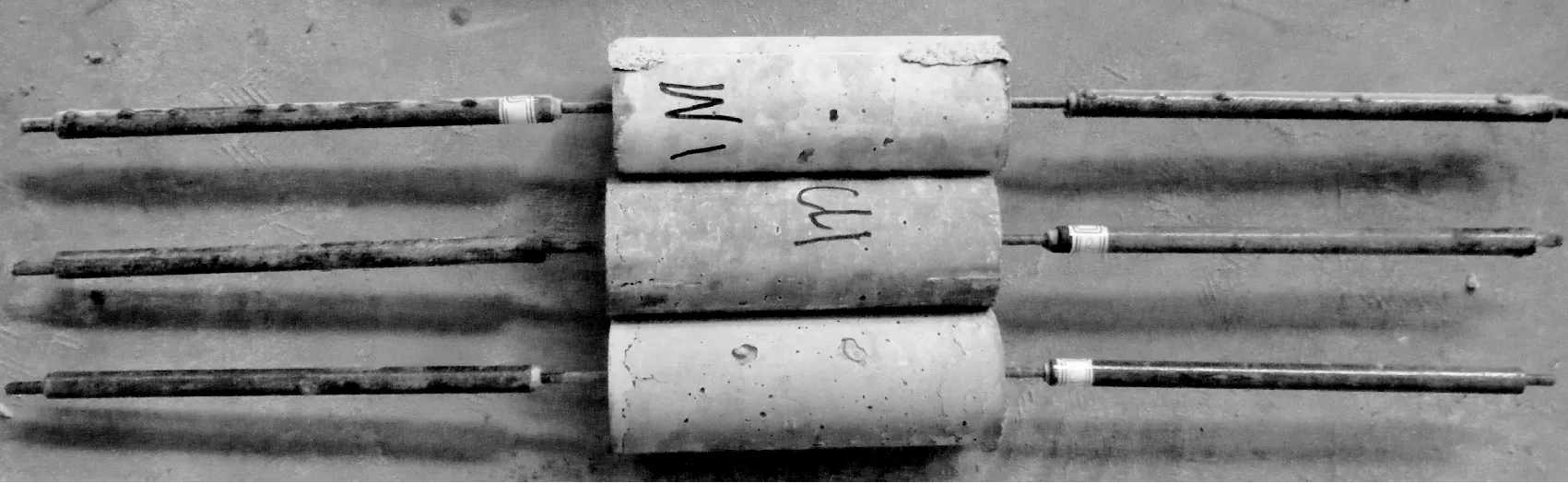

All the bars were cut into 760 mm in length, as specified by the ACI 440.3R—04 B2[16], and were divided into two series: 1) Specimens without concrete case (5 unconditioned and 20 immersed in alkaline solution) and 2) Concrete-encased specimens (65 bars). The concrete was cast around only the middle 200 mm of the bars. The mold was a PVC pipe with an inner diameter of 70 mm. Therefore, the thickness of the cover concrete was 32 mm, which is commonly used in buildings. A layer of waterproof epoxy resin was applied to both ends of the concrete cylinder and to the exposed BFRP. This ensures that the solutions permeated only through the circular side surface. Each end was sand-blasted and placed in a 250 mm long steel tube grouted with an epoxy matrix to create grip ends for axial tension. The prepared concrete-encased specimens are shown in Fig.1.

(a)

(b)

1.3 Test plan

The detailed test plan is shown in Tab.1. The tested specimens were divided into five groups: A, B, C, D and E. Group A samples were embedded in concrete and then immersed in tap water to simulate a humid environment. Group B samples were embedded in concrete and immersed in a saline solution to simulate a marine environment or the use of deicing salts on highway bridges. Group C samples were concrete encased and placed in an ambient temperature. A conventional accelerated aging test in which bare FRP bars are directly immersed in an alkaline solution was adopted for group D samples. The five specimens of group E were first placed at an ambient temperature for 180 d and then immersed in tap water for another 60 d. The accelerated aging was performed by immersing the specimens in a temperature-controlled tank as shown in Fig.2. Because of instrument breakdowns during the initial 7 d, the temperature was maintained at (60+5) ℃, and it was lowered to the specified 60 ℃ for the following exposure times after appropriate adjustment.

Tab.1 Test program

Note: The number 5 represents that there are 5 specimens in each group; — represents no specimens.

Fig.2 Specimens immersed in the temperature-controlled tank

The composition of the alkaline solution consisted of 118.5 g Ca(OH)2, 0.9 g NaOH, and 4.2 g KOH in 1 L of deionized water, as proposed by the ACI 440.3R—04 B2[16]. According to the recommendations of ASTM D1141—98[17], the composition of simulated sea water consisted of 24.53 g NaCl, 5.20 g MgCl2, 4.09 g Na2SO4, and 1.16 g CaCl2in 1 L of deionized water.

For groups A, B and D, the temperature was controlled at 60 ℃ to accelerate the degradation effect of aging. 60 ℃ was lower than the glass transformation temperatureTgand was not intended to produce any thermal degradation mechanisms[18]. The test program started at the beginning of August and finished at the beginning of April of the following year. Thus, the ambient temperature for groups C and E was the temperature in Nanjing, China during the period from August to March (temperatures ranged from -6 to 39 ℃). After each period, the concrete wrap was carefully removed from the middle of each concrete-encased specimen using a pressure testing machine to avoid any additional damage.

2 Test Results

2.1 Visual observation

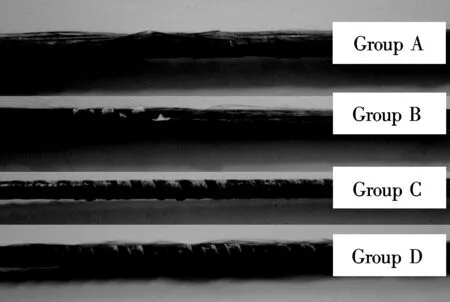

The original BFRP bar was black in color. After exposure, groups A, B and D’s BFRP bars changed from the original black to gold, which is similar to the color of the basalt fibers themselves. This change suggests that the bonding of the resin and fibers was damaged during the corrosion. The surface appearances of specimens after 30 d of corrosion are shown in Fig.3. Loose fibers were observed on the surface of groups A, B and D, and as the

Fig.3 Appearance of BFRP bars after 30 d in different environments

corrosion continued, surfaces in group D became looser, whereas surfaces in groups A and B were unchanged because of the confinement of the concrete. There were no obvious changes to the surface color and configuration of group C specimens.

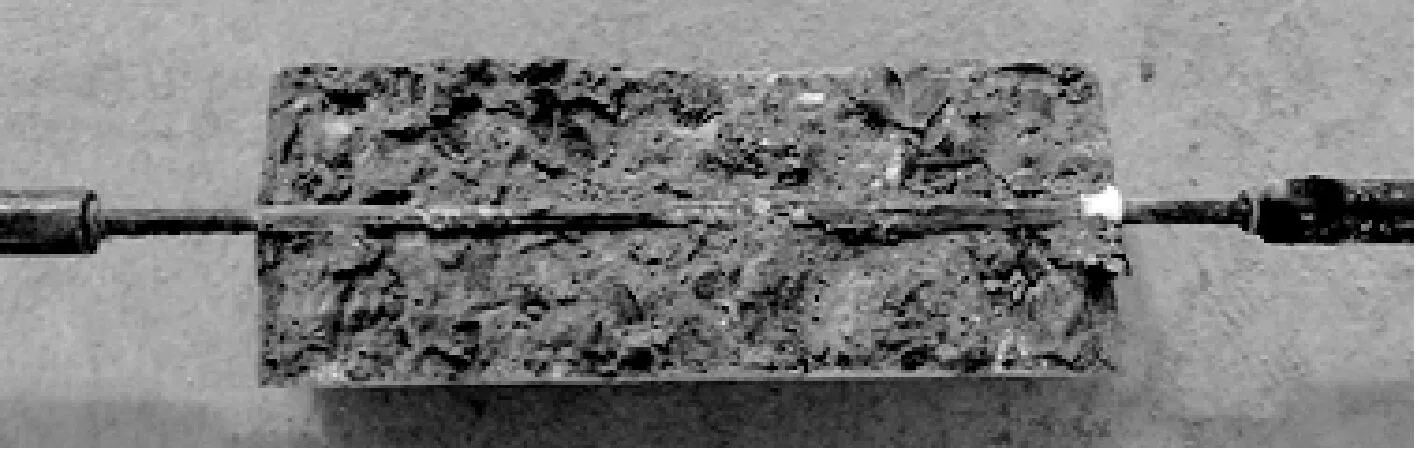

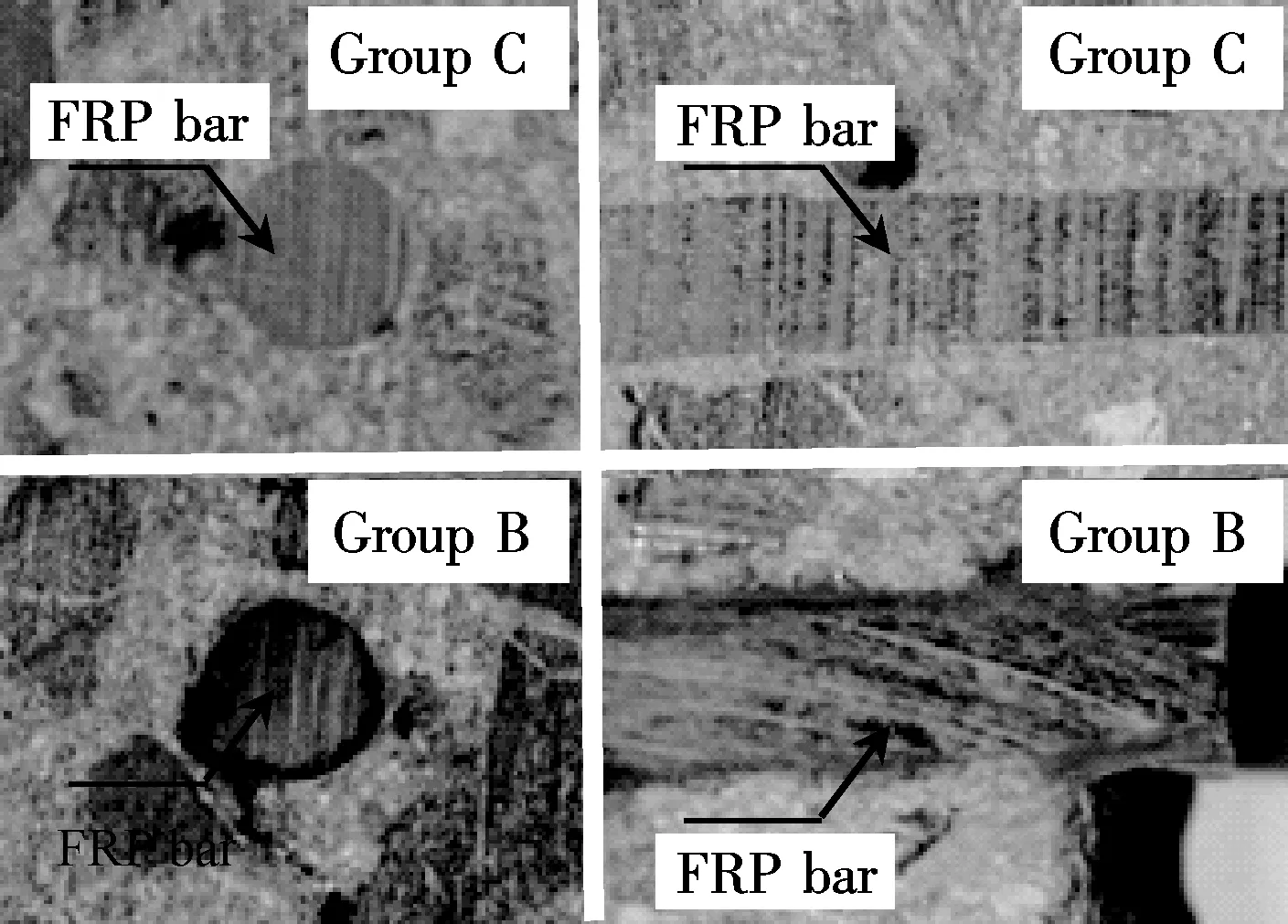

2.2 Interfacial conditions

The typical appearance of the corroded BFRP bar embedded in concrete is shown in Fig.4(a), and the groups B and C FRP/concrete interfaces after 120 d of exposure are shown in Fig.4(b). The group C FRP/concrete interfaces was intact. However, the group B FRP/concrete interfaces was not as tight as those in group C because of the severe corrosion of the BFRP bars.

(a)

(b)

2.3 Tensile properties

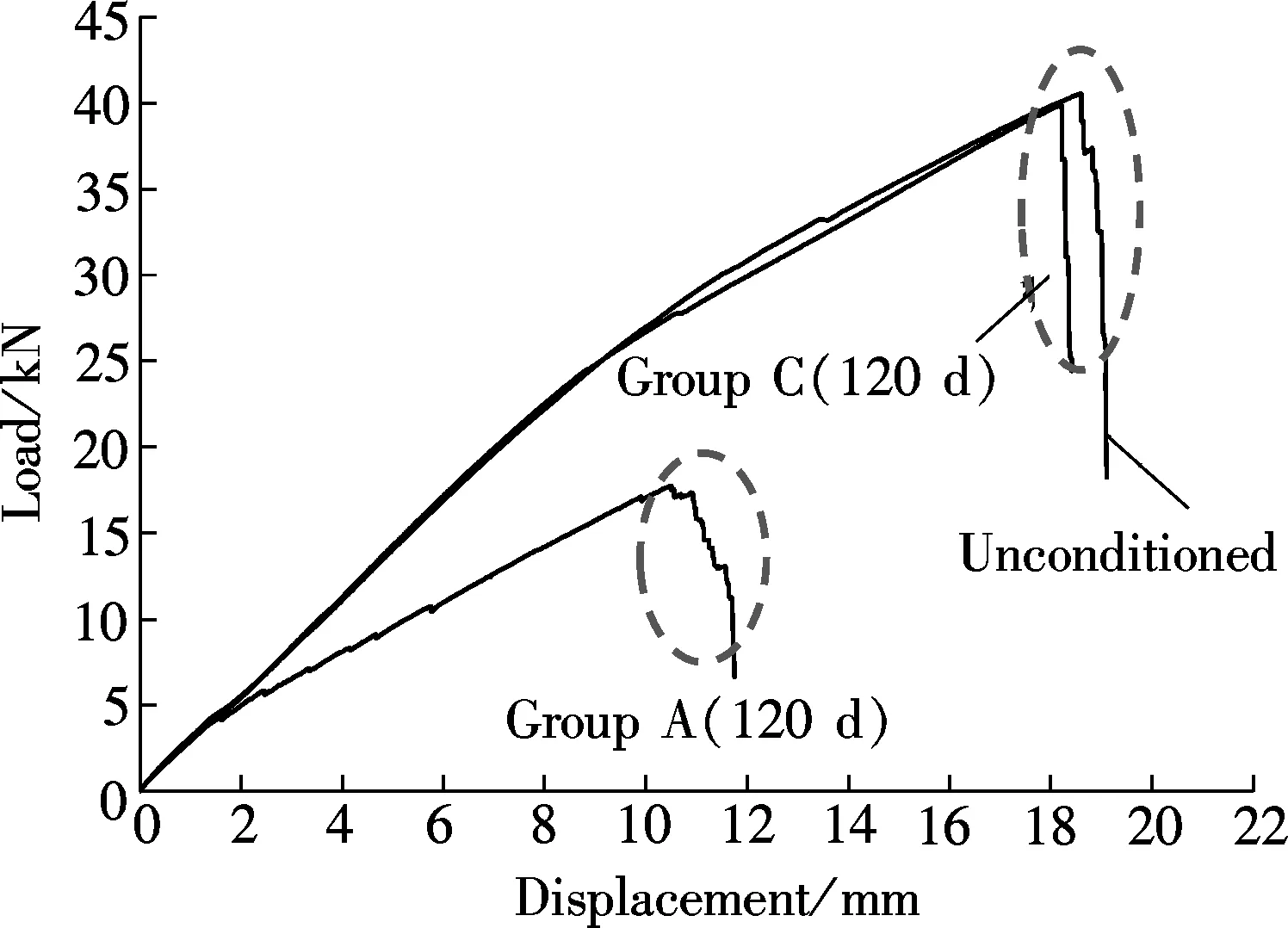

Fig.5 shows typical load-displacement curves for both the unconditioned and conditioned bars from groups A and C after 120 d of exposure. The load-displacement curve of group C was almost coincident with that of the unconditioned BFRP bar with the exception of some degradation of the ultimate tensile strength. The group A’s curve was clearly different from the other two. From the curves, it was found that the failures of unconditioned and group C specimens were catastrophic with a sudden load decline, whereas the declining group A curve was gentler compared to the others.

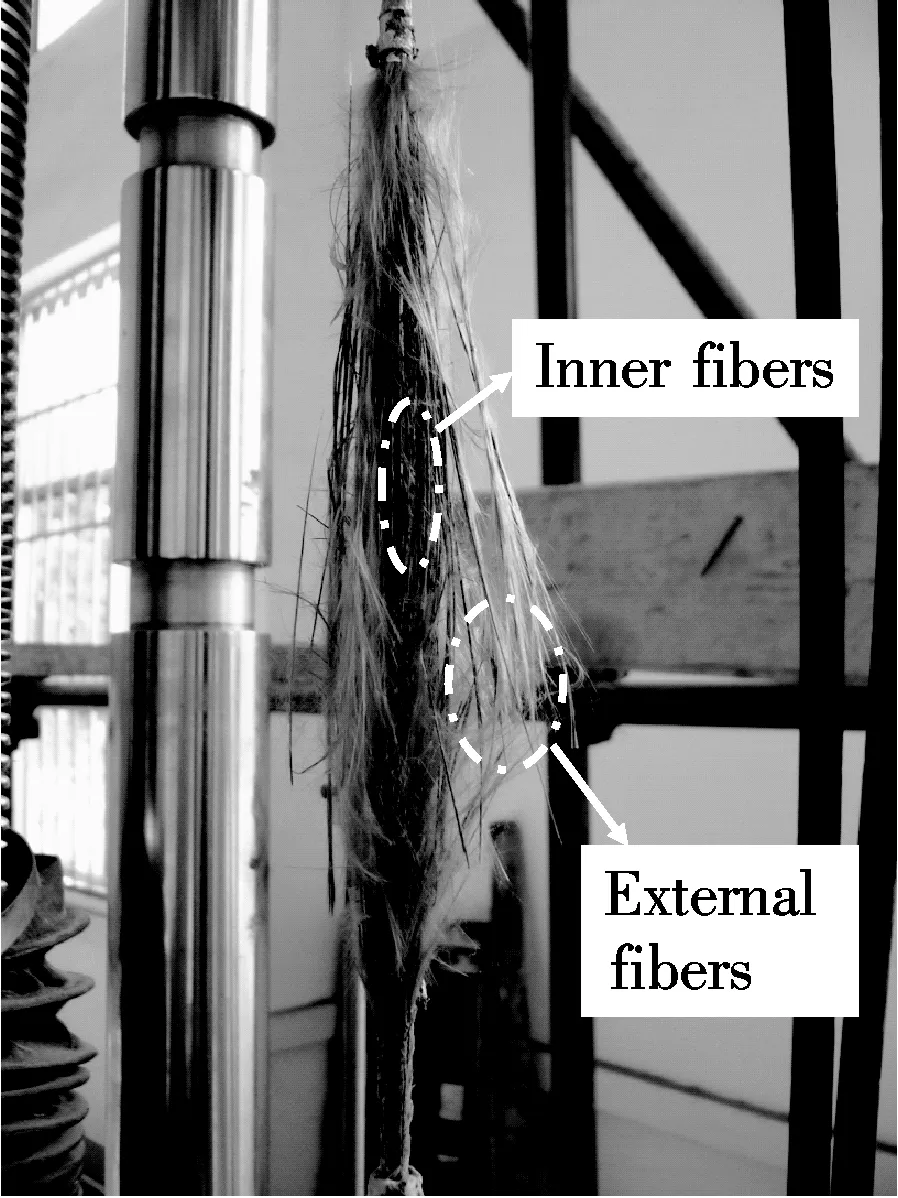

Fig.6 shows the typical failure mode of the group A BFRP bars after 120 d of exposure. It was observed that the outer fibers were gold in color without any resin attachment, and the inner fibers remained black in color with resin attached, revealing that the corrosion of the FRP bars occurred, starting from the outside to the inside

Fig.5 Typical load-displacement curves of conditioned and unconditioned BFRP bars

gradually. During the tensile test of group A specimens, the external exposed fibers bulged and were fluffed out constantly with little noise and the fibers ruptured from the outer to the inner layers gradually. Moreover, slight fluctuations on the load-displacement curve were observed. The tensile test results for the unconditioned and conditioned specimens are summarized in Tab.2.

Fig.6 Typical failure mode of BFRP bar of group A (120 d exposure)

GroupExposuretime/dTensilestrengthAverage/MPaLoss/%CV/%ElasticmodulusAverage/GPaLoss/%CV/%UtimatetensilestrainAverage/GPaLoss/%CV/%Unconditionedbar1398.302.1645.800.780.030502.19A30765.845.21.1043.74.61.610.017542.52.4960711.449.12.3441.98.64.730.017044.34.5690688.250.86.1539.114.74.850.017742.114.08120613.856.17.7539.813.16.510.014552.44.56B30817.141.65.2442.37.82.980.019137.26.0260732.247.61.6443.45.31.440.016944.70.2090643.554.07.7442.08.34.440.014951.35.94120556.860.24.2941.98.64.640.013356.44.28C301377.31.52.9245.01.90.310.0306-0.42.85601341.54.13.0944.62.80.320.03011.32.991201340.84.15.2844.52.92.540.03011.22.932401384.21.01.6145.31.20.350.0308-1.01.26D15813.041.91.4030711.349.17.6460562.259.85.2590469.066.57.10E2401355.13.14.5345.111.60.410.03001.54.23

Note: The elastic modulus and ultimate strain of group D were not measured due to the extreme soft surface and CV means the coefficient of variation.

Tab.2 shows that the degradation of Group D specimens was serious; the loss of strength was 66.5% after direct immersion in the 60 ℃ alkaline solution for 90 d. A comparison with the concrete-encased specimens (group A, B) indicates that direct bathing in this solution accelerated the degradation.

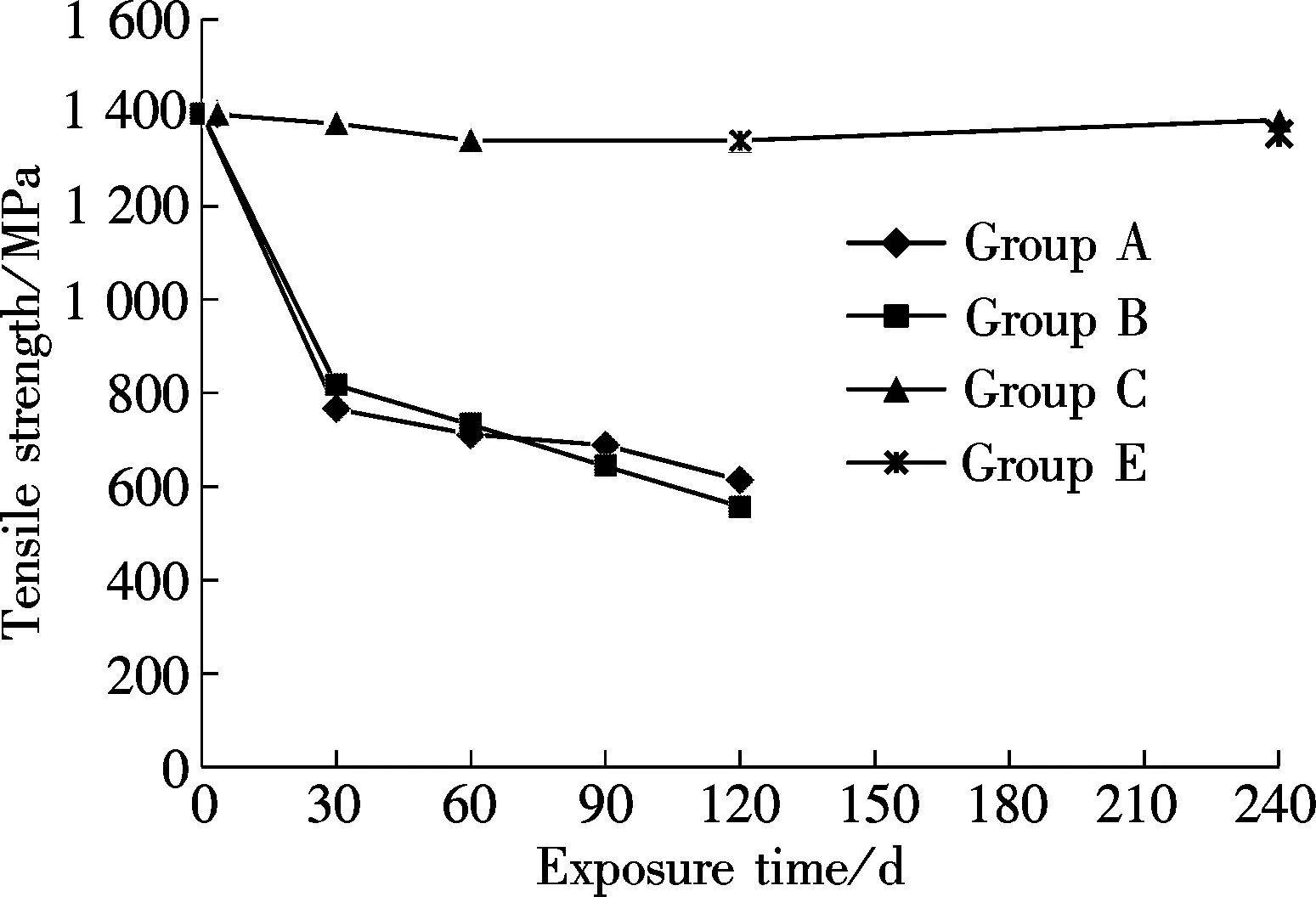

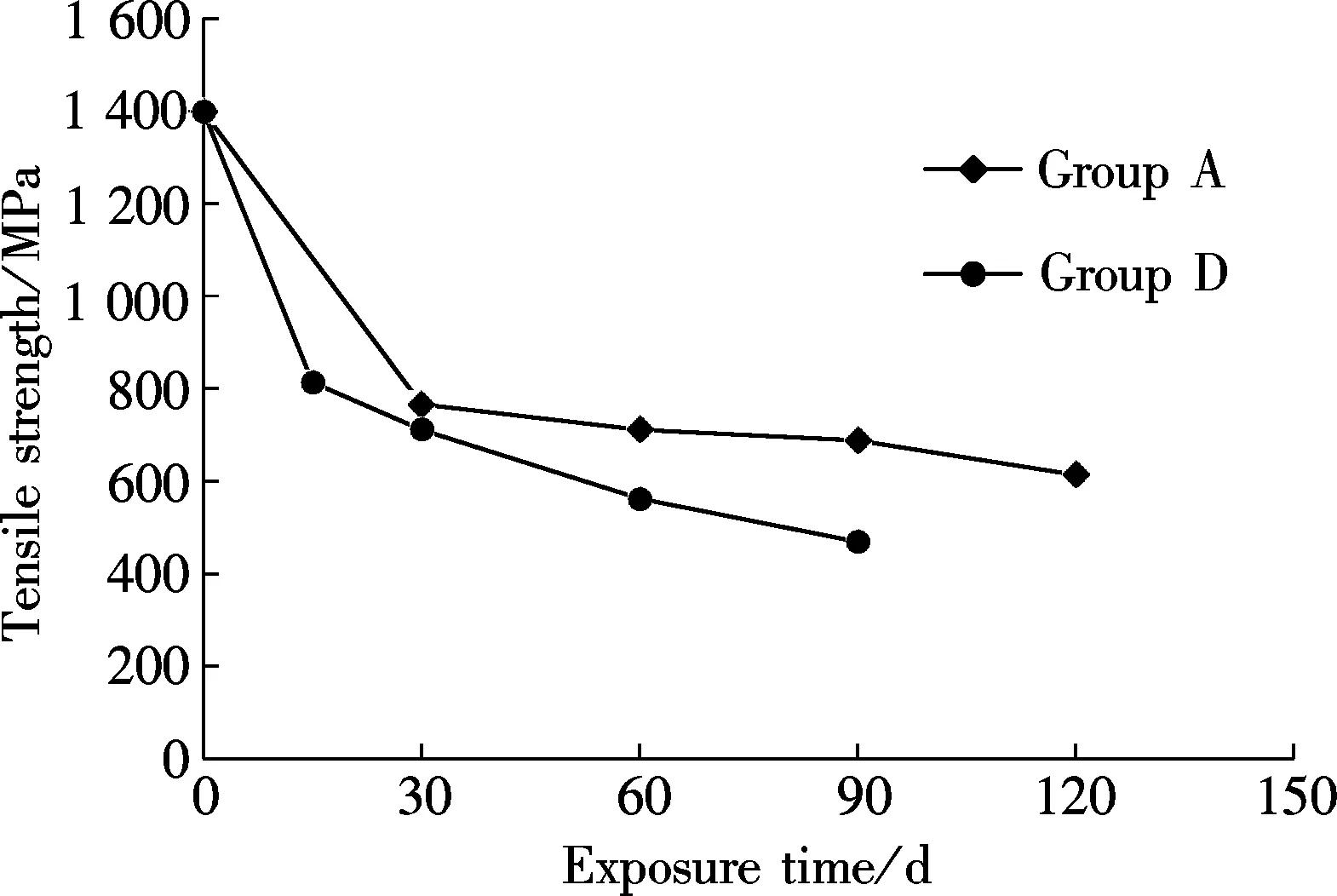

As shown in Fig.7, group A and B specimens showed an obvious tensile strength degradation after 30 d conditioning at 60 ℃. The BFRP bars experienced 45.2% and 41.6% reductions in tensile strength, respectively. However, only a 1.5% reduction was observed for group C specimens. In groups A and B, the degradation rate obviously decreased with the duration of immersion. Similar degradation trends for GFRP bars were observed by Robert et al[14]. In contrast, almost no tensile strength reduction

Fig.7 Tensile strength of BFRP bars embedded in concrete

of group C BFRP bars was observed for as long as 240 d. The observed slight reduction in tensile strength (less than 5%) may have been caused by damage during the concrete crush or because of the discreteness of the material. According to the experimental investigation, it can be concluded that BFRP bars embedded in concrete and placed indoors possess excellent durability performance.

The immersion temperature clearly affected the BFRP bar strength loss. After the additional 60 d immersion in tap water (January and February in Nanjing, China, averaging 5 ℃), the five group E specimens experienced a loss of strength of only 3.1%. Whereas, for the five group A specimens, the loss of strength was 49.1% after immersion in 60 ℃ tap water for 60 d. This phenomenon might be the result of the increased diffusion rate of the pore-water solution into the BFRP bar and of the accelerated chemical reactions with elevated temperatures.

Fig.8 shows the change in the elastic modulus for groups A, B and C. It can be observed that the loss in elastic modulus in group C were negligible (less than 3%). In contrast, group A and B specimens displayed a slightly larger decrease, ranging from 4.6% to 14.7%, and the coefficients of variation were also higher, as shown in Tab.2. It should be noted that the elongation measured by the attached extensometer may have been affected by the serious loose surface, resulting in inaccurate data. Thus, the elastic modulus of group D was not measured.

Fig.8 Elastic modulus of BFRP bars

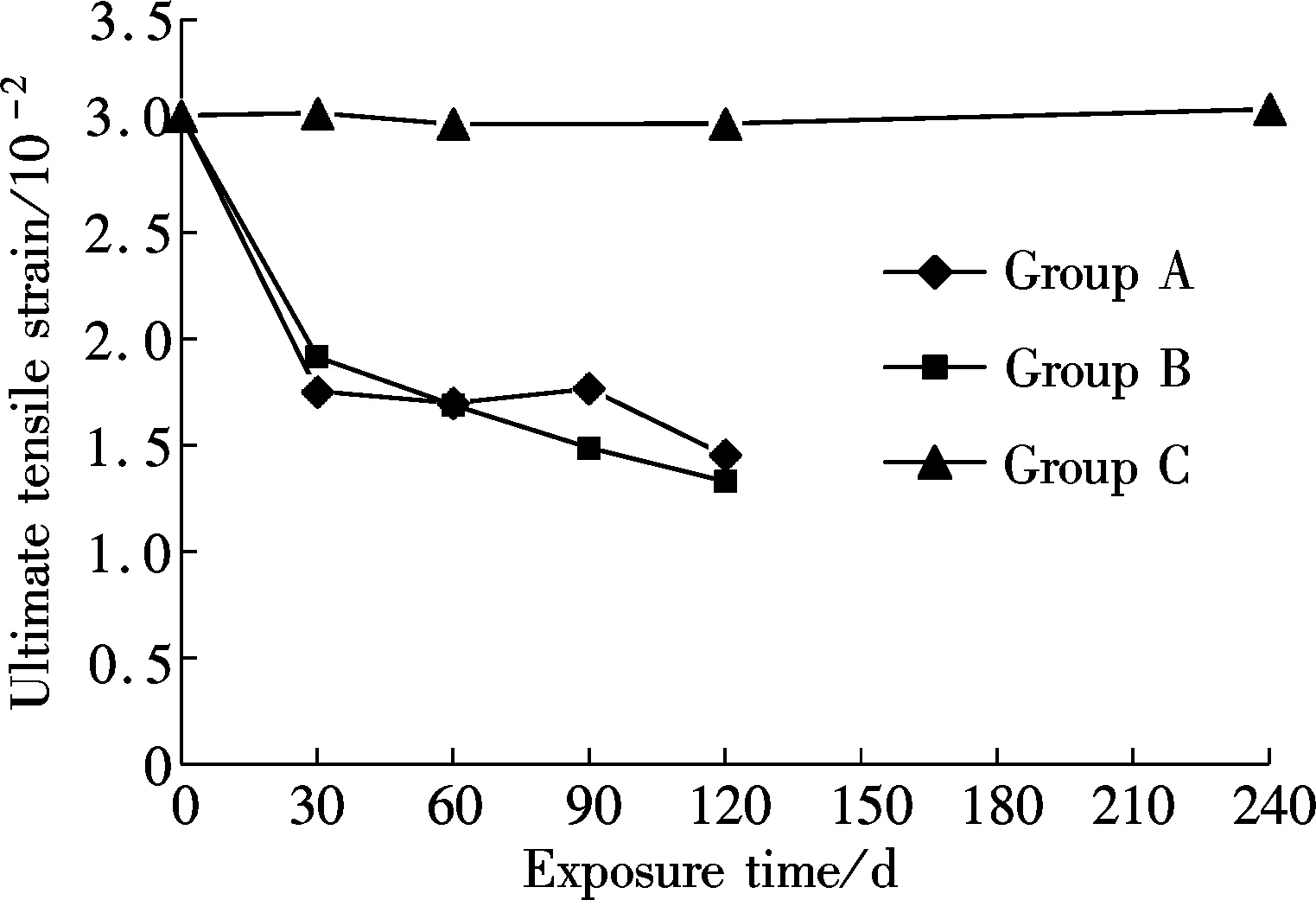

As shown in Fig.9, the ultimate strain remained stable in group C, whereas a strain reduction trend was observed in groups A and B. The reduced ultimate strain trend was similar to the tensile strength trend because of the relatively constant tensile modulus.

Fig.9 Ultimate tensile strain of BFRP bars

3 Discussions

3.1 Effects of humidity

The significant strength loss (56.1%) for the group A specimens after 120 d is a result of both the elevated temperature and the continued bathing (a moisture-saturated concrete environment can provide adequate pore-water, allowing the embedded BFRP bars sufficient contact with the alkaline solution). Nevertheless, when the moisture level of the concrete is low (in Nanjing, the annual mean RH is approximately 76%), the degradation rate will be reduced because of the weakened alkaline environment. High humidity (sufficient moisture) is considered as a pre-condition for a rapid strength loss in BFRP bars. High temperature is another condition essential for the rapid degradation of embedded BFRP bars. In summary, an environment with high humidity and a high temperature simultaneously is extremely unfavorable for the concrete-encased BFRP bars. Conversely, if these conditions do not exist simultaneously, a sound long-term durability can be obtained.

3.2 Effects of chloride ion

The group A specimens were immersed in tap water, whereas the group B specimens were immersed in a saline solution. The degradation trends shown in Fig.7 indicate that there are no significant differences in the decrease in tensile strength of the concrete-encased BFRP bars whether immersed in tap water or salt solution. This conclusion was consistent with the primary experimental results of Robert et al.[14]on GFRP bars. The chloride ion, which is harmful to a RC structure, has no additional adverse influence on the durability of BFRP bars. This provides a significant justification to use FRP bars as an alternative to steel bars, particularly within marine structures.

3.3 Effects of concrete wrap

Bare BFRP bars from group D were immersed in a simulated concrete pore-water solution, whereas group A specimens were concrete-encased and immersed in tap water. As shown in Fig.10, the tensile strength of BFRP bars in group A and group D exhibited similar downtrends, indicating that the degradation mechanism for BFRP bars in the two environments (alkaline solutions and moisture-saturated concrete (RH=100%)) are the same. The strength loss in group D was higher than that in group A, which was 49.1% and 59.8% in group A and group D, respectively, after 60 d of immersion; was 50.8% and 66.5% in group A and group D, respectively, after 90 d of immersion. In a solid porous material such as concrete with a pore solution instead of free water, alkali movements are, to some extent, restricted. Without the restriction of concrete encasement, direct immersion provides degradation acceleration in a moisture-saturated concrete environment.

Fig.10 Tensile strength of BFRP bars

3.4 Acceleration factors

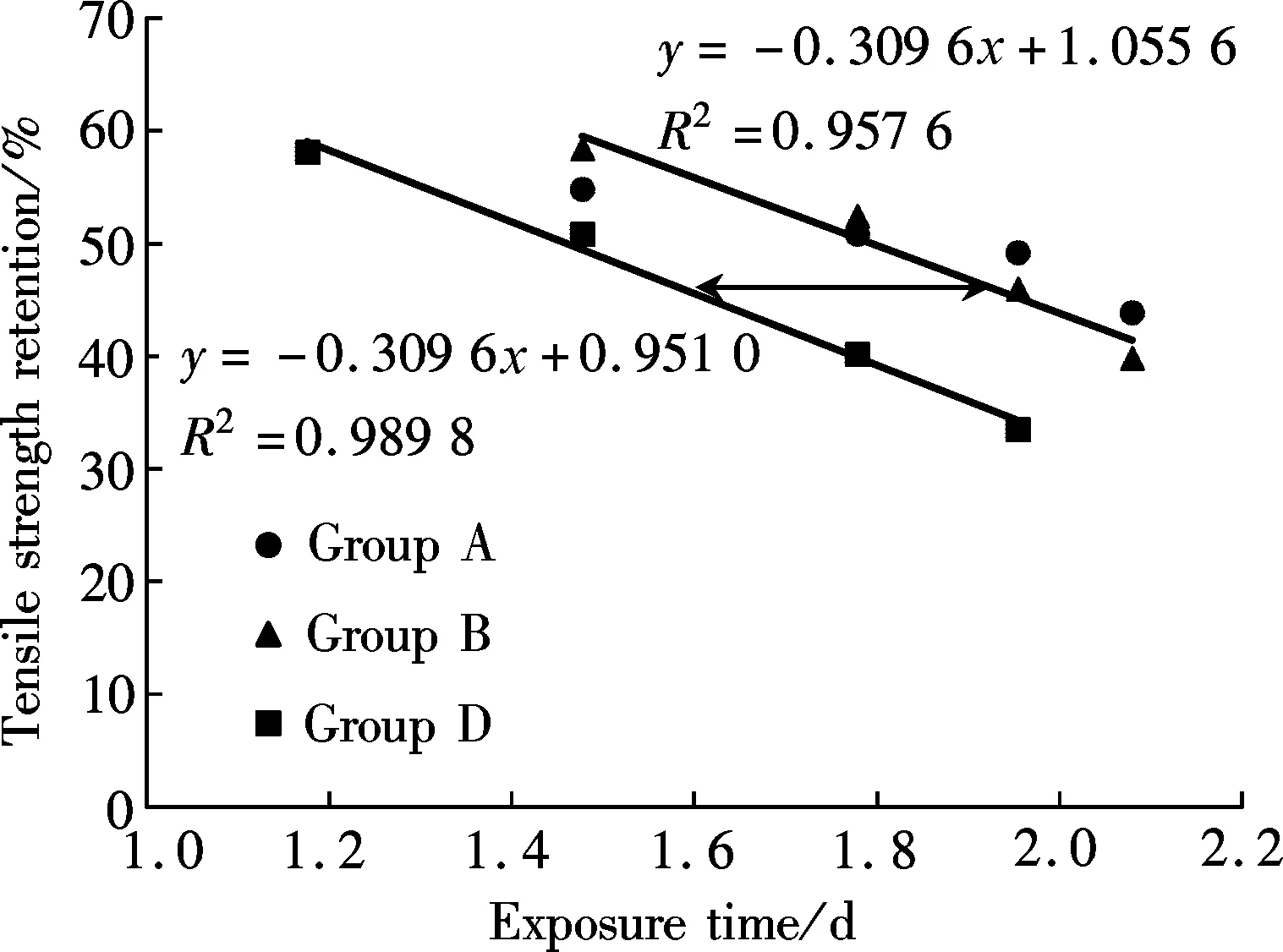

According to the most widely used degradation model for FRP bars presented by Bank et al.[11], and adopted by Davalos et al.[19],the shapes of the strength retention curves were approximated by straight lines based on a logarithmic time scale. The model was first developed by Litherland et al.[20]and was applied to predict the long-term performance of glass fiber concrete (GRC). As shown in Fig.11, the two lines, representing concrete-encased (groups A and B) and bare (group D) specimens, are approximately parallel. However, the degradation rate of group D was accelerated because of the absence of a concrete wrap. In this case, the acceleration factor can be obtained from the distance between the curves. The calculation procedure is

(1)

whereβis the acceleration factor;twis the time for a concrete-encased specimen to reach a given degradation; andtbis the time for a bare specimen to reach the same level of degradation. Comparison of the horizontal displacement

Fig.11 Strength retention versus time for BFRP bar

of the curves gives an acceleration factor of about 2.18. That is, the degradation of 2.18 years of exposure in moisture-saturated concrete results in the same loss of strength of BFRP as that of one year directly immersed in a simulated alkaline solution.

It is complicated and inconvenient, but closer to the real application, to conduct an accelerated aging test on FRP bars encased in concrete. With the acceleration factorβ, the FRP bar loss when embedded in concrete can be calculated using the direct solution immersion data.

4 Conclusions

In this study, an investigation to quantify the durability of concrete-encased BFRP bars is conducted. Test variables included temperature, humidity, exposure time and solution type (tap water and saline water). As a comparison, bare BFRP bars were immersed in simulated concrete pore-water for up to 90 d. Based on the results of this study, the following conclusions (applicable to only the product tested) can be drawn:

1) The aging of BFRP bars occurred from the outer layers to inner layers gradually. The change in the tensile strength of the tested BFRP bars at a high temperature of 60 ℃ was significant within the initial 30 d; it began to stabilize as the immersion duration increased.

2) The degradation of concrete-encased specimens within an indoor environment was negligible. Significant tensile strength loss was obtained after conditioning in moisture-saturated concrete (water or saline water) at a high temperature. High humidity and high temperatures are essential conditions for the rapid degradation of BFRP bars; if these conditions are not met simultaneously, a sound long-term durability can be obtained.

3) There was no significant difference in the durability of the concrete-encased BFRP bars, whether immersed in tap water or in salt solution. The degradation of the BFRP bars was primarily induced by the alkaline pore-water solution instead of Cl-. Therefore, using BFRP bars as a replacement for steel bars is considered an effective approach to improving the durability of concrete structures in Cl-concentrated environments.

4) The aging of BFRP bars in moisture-saturated concrete was less pronounced than those directly immersed in a simulated pore-water solution, even at high temperatures (60 ℃), which makes for a more aggressive environment. According to the preliminary results, for the BFRP bars used in this paper, the degradation of 2.18 years in moisture-saturated concrete at 60 ℃ corresponds to that of one year directly immersed in alkaline solution (All other conditions are the same).

[1]Micelli F, Nanni A. Durability of FRP rods for concrete structures [J].ConstructionandBuildingMaterials, 2004, 18(7):491-503.

[2]Chen Y, Davalos J F, Ray I, et al. Accelerated aging tests for evaluations of durability performance of FRP reinforcing bars for concrete structures [J].CompositeStructures, 2007, 78(1):101-111.

[3]Kamal A S M, Boulfiza M. Durability of GFRP rebars in simulated concrete solutions under accelerated aging conditions [J].JournalofCompositesforConstruction, 2011, 15(4):473-481.

[4]Riebel F, Keller T. Long-term compression performance of a pultruded GFRP element exposed to concrete pore water solution [J].JournalofCompositesforConstruction, 2007, 11(4):437-447.

[5]Kim H Y, Park Y H, You Y J, et al. Short-term durability test for GFRP rods under various environmental conditions [J].CompositeStructures, 2008,83(1):37-47.

[6]Robert M, Benmokrane B. Physical, mechanical, and durability characterization of preloaded GFRP reinforcing bars [J].JournalofCompositesforConstruction, 2010, 14(4):368-375.

[7]Wu Z S, Wang X, Wu G. Advancement of basalt fiber composites towards infrastructural applications (Keynote paper) [C]//ProceedingsoftheInternationalSymposiumonInnovation&SustainabilityofStructuresinCivilEngineering. Xiamen, China, 2011.

[8]Benmokrane B, Wang P, Ton-That T, et al. Durability of glass fibre-reinforced polymer reinforcing bars in concrete environment [J].JournalofCompositesforConstruction, 2002, 6(3):143-153.

[9]Chen Y, Davalos J F, Ray I. Durability prediction for GFRP reinforcing bars using short-term data of accelerated aging tests [J].JournalofCompositesforConstruction, 2006, 10(4):279-286.

[10]Dejke V. Durability of FRP reinforcement in concrete: literature review and experiments [D]. Göteborg, Sweden: Department of Building Materials, Chalmers University of Technology, 2001.

[11]Bank L C, Gentry T R, Thompson B P, et al. A model specification for FRP composites for civil engineering structures [J].ConstructionandBuildingMaterials, 2003, 17(6/7):405-437.

[12]Robert M, Cousin P, Benmokrane B. Durability of GFRP reinforcing bars embedded in moist concrete [J].JournalofCompositesforConstruction, 2009, 13(2):66-73.

[13]Mufti A, Banthia N, Benmokrane B, et al. Durability of GFRP composite rods: results from preliminary field tests don’t match data from accelerated lab tests [J].ConcreteInternational, 2007, 29(2):37-42.

[14]Robert M, Benmokrane B. Combined effects of saline solution and moist concrete on long-term durability of GFRP reinforcing bars [J].ConstructionandBuildingMaterials, 2013,38:274-284.

[15]Sun W, Zhang Y, Liu S, et al. The influence of mineral admixtures on resistance to corrosion of steel bars in green high-performance concrete [J].CementandConcreteResearch, 2004, 34(10):1781-1785.

[16]American Concrete Institute (ACI). ACI 440.3R—04 Guide test methods for fiber-reinforced polymers (FRPs) for reinforcing or strengthening concrete structures [S]. Farmington Hills, Michigan: ACI Committee, 2004.

[17]American Society for Testing and Materials (ASTM). ASTM D1141—98 Standard practice for the preparation of substitute ocean water [S]. West Conshohocken: ASTM Committee, 2008.

[18]Robert M, Wang P, Cousin P, et al. Temperature as an accelerating factor for long-term durability testing of FRPs: should there be any limitations? [J].JournalofCompositesforConstruction, 2010, 14(4): 361-367.

[19]Davalos J F, Chen Y, Ray I. Long-term durability prediction models for GFRP bars in concrete environment [J].JournalofCompositesforConstruction,2012, 46(16) 1899-1914.

[20]Litherland K L, Okley D R, Proctor B A. The use of accelerated ageing procedures to predict the long term strength of GRC composites [J].CementandConcreteResearch, 1981,11(3): 455-466.

混凝土环境中BFRP筋耐久性能试验研究

朱 莹1吴 刚1董志强1汪 昕2吴智深2

(1混凝土及预应力混凝土结构教育部重点实验室,南京210096)(2玄武岩纤维生产及应用技术国家地方联合工程研究中心,南京210096)

针对玄武岩纤维增强树脂基复合筋(BFRP)在混凝土环境中的耐碱性能进行了加速腐蚀试验研究.腐蚀试验环境包括3种,分别为自来水、盐水及室内空气环境,将包裹有混凝土保护层的BFPR筋试件分别放置在上述3种环境中,试验同时采用碱溶液直接浸泡BFRP筋作为对比,对直接碱溶液浸泡环境与混凝土包裹环境之间的加速系数进行了研究.试验采用60 ℃的高温进行加速.试验结果表明:自来水和盐水浸泡对于包裹有混凝土的BFRP筋试件没有明显差异.分析认为,与混凝土内部高碱性的孔隙溶液接触是BFRP筋退化的主要原因,当经受高温和高湿环境共同作用时,混凝土环境中BFRP筋的退化将明显加速;BFRP筋的退化速率在初期较快,随着龄期的增长,退化速率降低.基于试验数据分析表明,对于所采用的BFRP筋,60 ℃饱和吸湿混凝土环境下,BFRP筋2.18 a的退化程度与60 ℃碱溶液直接浸泡环境下1 a的退化程度相当.

混凝土;BFRP筋;耐久性;碱性环境;氯盐环境;加速系数

TU502

s:The National Key Basic Research Program of China (973 Program)(No.2012CB026200), the Key Project of Chinese Ministry of Education (No.113029A), the National Key Technology R&D Program of China during the 12th Five Year Plan Period (No.2011BAB03B09), the Fundamental Research Funds for the Central Universities.

:Zhu Ying, Wu Gang, Dong Zhiqiang, et al. Experimental study on the durability of BFRP bars embedded in concrete[J].Journal of Southeast University (English Edition),2014,30(3):323-329.

10.3969/j.issn.1003-7985.2014.03.013

10.3969/j.issn.1003-7985.2014.03.013

Received 2013-12-18.

Biographies:Zhu Ying (1989—), female, graduate; Wu Gang (corresponding author), male, doctor, professor, g.wu@seu.edu.cn.

Journal of Southeast University(English Edition)2014年3期

Journal of Southeast University(English Edition)2014年3期

- Journal of Southeast University(English Edition)的其它文章

- P-FFT and FG-FFT with real coefficients algorithm for the EFIE

- Compressed sensing estimation of sparse underwateracoustic channels with a large time delay spread

- Improved metrics for evaluating fault detection efficiency of test suite

- Early-stage Internet traffic identification based on packet payload size

- An adaptive generation method for free curve trajectory based on NURBS

- Stability analysis of time-varying systems via parameter-dependent homogeneous Lyapunov functions