Comparative analysis of perpetual pavement structures based on pavement performance and life cycle cost

Zhu Yuqin Ni Fujian Gu Xingyu

(School of Transportation, Southeast University, Nanjing 210096, China)

Comparative analysis of perpetual pavement structures based on pavement performance and life cycle cost

Zhu Yuqin Ni Fujian Gu Xingyu

(School of Transportation, Southeast University, Nanjing 210096, China)

Pavement performance and economic efficiency are researched on the perpetual test pavement of Yijiang-Suzhou Express Highway in Jiangsu province, China. Test sections were continuously monitored. The conditions and developing laws of deflection, rutting and cracking are compared among the perpetual pavement with the rich binder layer (RBL), the perpetual pavement without the RBL, and the conventional semi-rigid asphalt pavement in the past eight years after opening for traffic. Economical evaluation is conducted via life cycle cost analysis (LCCA). Based on the performance comparison and LCCA analysis, sections with the RBL have good crack resistance, but they are not very satisfactory in the aspect of permanent deformation; the conventional semi-rigid asphalt pavement is the least economic one due to requiring more frequent maintenance. Research results show that the perpetual pavement without RBL is a more appropriate structure for the test site.

perpetual pavement; rich binder layer; pavement performance; life cycle cost analysis

The perpetual pavement in this study is defined as an asphalt pavement designed and built to last 50 years

or more without requiring major structural rehabilitation or reconstruction[1-3]. In this study, three test sections under the conception of the perpetual pavement are studied as the potential pavement alternatives in the future for Jiangsu province, China. The test site is located on the Yijiang-Suzhou Express Highway (YJ-SZ21), south of Suzhou City, Jiangsu province, China. The coordinates of this site are 31°17′58″N (latitude) and 120°37′11″E (longitude). During the design period, the 30-year accumulated traffic is 1.64×107equivalent single axle loads (ESALs) based on estimated AADT and an annual 7.1% traffic increment rate. In order to research the long term pavement performance, field data has been collected annually since 2005. The collected pavement performance data include pavement deflection, cracking and rutting.

1 Section Structure Information

The Yijiang-Suzhou Express Highway was completed in 2004. Detailed structures for the three test sections and the conventional semi-rigid AC pavement section are shown in Tab.1.

Tab.1 Summary of pavement structure of each section

2 Pavement Deflection

The average deflection basins collected in 2008 for perpetual section Ⅰ, section Ⅱ, section Ⅲ and the conven-

tional section are shown in Fig.2. Section I has significantly higher maximum deflection than the perpetual pavement with the RBL and the conventional section. The maximum deflection of section Ⅱ is higher than that of Section Ⅲ. Fig.2 shows that the perpetual pavement with higher asphalt content in the RBL has better structural condition. And the gradient in the middle part of the profile shows that the base modulus of section Ⅱ is smaller than that of the conventional section, and larger than that of section Ⅰ, while it is kept very close to that of section Ⅲ[4].

A weaker structure strength in section Ⅰ may be mainly caused by two reasons: first, the absence of the binder in the flexible base of section I weakens its structural integrity; secondly, section I is the longest of the four, and it may contain some weaker sub-sections with broken upper layer or base.

Fig.1 FWD basins for each section in 2008

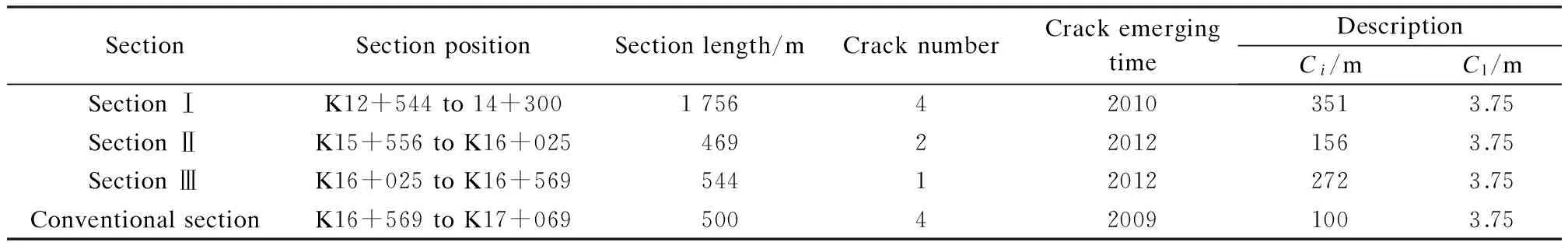

3 Transverse Cracking

Transverse cracking surveys of the test site were conducted from 2005 to 2012. The results of the latest survey in November, 2012 are listed in Tab.2. In Tab.2,Ci=L/(Cn+1),Cl=Ctl/Cn. Here,Ciis the average crack interval in a certain section;Cnis the total crack number in a certain section;Clis the average crack length in a certain section;Ctlis the total length in a certain section. From the results, the sequence of the average cracking interval for these four sections is section Ⅰ>section Ⅲ>section Ⅱ>conventional section. The time of the first crack emerging is also a meaningful indicator. From Tab.2, the conventional section was the earliest to bear cracks after opening for traffic 5 years, and section Ⅰ followed in 2010. Section Ⅱ and section Ⅲ were the latest. The results reflect that the perpetual test sections have better crack resistance than conventional semi-rigid asphalt pavements. Although the perpetual pavement without the RBL began to crack earlier than the ones with the RBL, its crack condition developed slowly in the aspect of amount[5]. In general, section Ⅰ has a better crack resistance than the other three sections.

Tab.2 Transverse cracking survey of the pavement

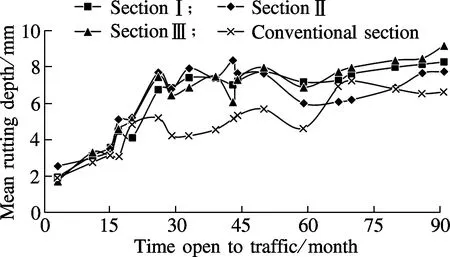

4 Pavement Rutting

The trends of the mean rutting value of each test section and the conventional section are presented in Fig.3. The rutting of section Ⅱ and section Ⅲ was very close during the first two years, deeper than that of section Ⅰ, and then their gap has grown a bit in the recent four years. However, the rutting of the conventional section was the smallest almost through the period. Generally, at the primary stage, the rutting of these sections developed at high speed by the initial consolidation within the surface course and the middle course, due to the same upper structure shared by the four sections, and their rutting was close to each other in the first 15 to 20 months. At the second stage, the structure of the flexible base started to be influenced by the cooperation of traffic loads and high temperature. The on-growing rutting for the perpetual pavement was compounded with the permanent deformation of the upper AC layer and the underlying flexible base. However, the rutting of the conventional section was mainly restricted in the upper AC layers. There was a decrease in the rutting depth of the conventional section, after opening for traffic for about 18 months and 72 months. The reason is that at the first time point, a seal preventive maintenance was conducted, and at the second time point, a thin overlay was done. Other single-point decrease was mainly caused by potential bias in the detection process. The superiority of the anti-rutting for semi-rigid asphalt pavement was revealed after about 25 months open to traffic. Moreover, the reason why the rutting at section Ⅲ was deeper than that at section Ⅱ may be that higher asphalt content in the RBL made the modulus drop sharper at high temperature[6]. That section Ⅰ performed comparatively better rutting resistance than section Ⅱ and section Ⅲ can be also explained by its thinner HMA layer in the structure. As a result, the sequence of the rutting resistance ability is the conventional section>section Ⅰ>section Ⅱ>section Ⅲ.

Fig.2 Rutting comparison of section Ⅰ, section Ⅱ, section Ⅲ and conventional section

5 Life Cycle Cost Analysis

The method of present value(PV) determining is the most commonly applied in LCCA. In this method, the present value is a calculated lump-sum of the initial and future pavement costs[7-9]. The PV in this study includes initial cost, maintenance fees, rehabilitation fees and salvage value. Road user fees are excluded. A 50-year analysis period is selected as recommended in the FHWA technical bulletin. A typical value of 4% is used for discount rateDr.

The calculation formula of the PV method is as follows:

wherePnis the present value of total cost in the analysis period;Icis the initial cost;Riis the rehabilitation cost;Miis the maintenance cost;fnis the present value coefficient of discount rate afternyears,fn=1/(1+Dr)n;knis the present value coefficient of equivalent payment afternyears,kn=((1+Dr)n-1)/((Dr(1+Dr)n);Snis the salvage value.

The initial construction costs for four pavement alternatives are obtained from the construction bid records. No highway has reached 50-year service life in China, and there is no historical (M&R) information available for perpetual pavements in Jiangsu province, either. The M& R activities and practices are estimated based on the monitored results of pavement disease and performance and experienced engineers’ recommendations[10-11]. The supposed M&R timings and costs are listed in Tab.3.

Tab.3 Initial construction costs and maintenance arrangements

The PV and PV ratio (the ratio of each perpetual section’s PV to AC section’s PV) are presented in Fig.3. Based on the LCCA results, the perpetual pavement with-out the RBL is a more cost-effective alternative than the conventional AC pavement over the 50-year analysis period. The PV of the perpetual pavement is about 82% of the conventional AC pavement. The PV ratio of the perpetual pavement to the conventional AC pavement decreases with the pavement service life. On the other hand, user fees during the maintenance of perpetual sections will be also less than that for conventional AC pavements thought it is not taken into account in this analysis process. The sequence of the PV is as follows: section Ⅲ > section Ⅱ > conventional section > section Ⅰ.

Fig.3 PV and PV ratio in 50 years concerning MAR options for each section

6 Conclusion

There is not very severe destruction in the structure of the three test perpetual sections after 8 years service. The sequence of the rutting resistance ability is the conventional section> section Ⅰ> sectionⅡ> section Ⅲ. The sequence of average cracking intervals for these four sections is section Ⅰ> section Ⅲ> section Ⅱ> conventional section. Based on the LCCA results, the sequence of the PV is section Ⅲ> section Ⅱ> conventional section> section Ⅰ. The perpetual pavement without the RBL is the most cost-effective alternative. From all above, the perpetual sections without the RBL can effectively reduce cracking distress and rutting depth with the lowest financial investment. It delivers superior performance over other two test sections and the conventional AC pavement for the test site in this study.

[1]Tarefder R A, Bateman D. Design of optimal perpetual pavement structure [J].JournalofTransportationEngineering, 2012, 138:157-175.

[2]Cui P, Sun L J, Zhang L. Perpetual pavement design criterions[C]//InternationalConferenceonTransportationEngineering. Chengdu, China, 2007, 2007:106-111.

[3]El-Hakim M Y, Tighe S L. Sustainability of perpetual pavement designs [J].TransportationResearchRecord, 2012, 2304: 10-16.

[4]Gopalakrishnan K, Thompson M R. Use of deflection basin parameters to characterize structural degradation of airport flexible pavements [J].GeotechnicalSpecialPublication, 2005, 130-142:1-15.

[5]Zhou L, Ni F J, Zhao Y J. Evaluation method for transverse cracking in asphalt pavements on freeways [J].TransportationResearchRecord, 2010, 2153:97-105.

[6]Zhou L, Ni F J, Zhao Y J. Impact of environment temperature and vehicle loading on rutting development in asphalt concrete pavement [J].JournalofHighwayandTransportationResearchandDevelopment, 2011, 28(3):42-47. (in Chinese)

[7]Mandapaka V, Basheer I, Sahasi K, et al. Mechanistic-empirical and life-cycle cost analysis for optimizing flexible pavement maintenance and rehabilitation [J].JournalofTransportationEngineering, 2012, 138(5): 625-633.

[8]Lee E-B, Kim C, Harvey J T. Selection of pavement for highway rehabilitation based on life-cycle cost analysis [J].TransportationResearchRecord, 2011, 2227:23-32.

[9]Federal Highway Administration. Life-cycle cost analysis in pavement design[S]. Washington, DC: Federal Highway Administration, 1998.

[10]Chen C, Flintsch G W. Fuzzy logic pavement maintenance and rehabilitation triggering approach for probabilistic life-cycle cost analysis [J].TransportationResearchRecord, 2007, 1990: 80-91.

[11]The Ministry of Transportation of China. JTG H10—2009 Highway maintenance technical specifications[S]. Beijing: People’s Communications Press, 2009.

基于路面使用性能和全寿命周期费用的永久性路面结构对比分析

朱玉琴 倪富健 顾兴宇

(东南大学交通学院,南京210096)

研究了江苏省沿江高速公路永久性路面试验段的路面使用性能和经济适用性.对试验段路面性能进行连续监测,对比了通车以后8年内含有富油抗疲劳层(RBL)的永久性路面、不含富油抗疲劳层的永久性路面与普通半刚性基层沥青路面的弯沉、裂缝和车辙状况及发展规律,并通过全寿命周期费用分析法(LCCA)对各路段进行经济评价.通过性能对比和LCCA分析发现:含富油抗疲劳层的沥青结构具有良好的抗裂缝性能,但是抗永久性变形能力不足;传统的半刚性基层沥青路面因在服务寿命内需要更频繁的养护而经济性不足.研究结果表明:不含富油抗疲劳层的永久性路面结构是本地较为适用的一种永久性路面结构.

永久性路面; 富油抗疲劳层; 路面使用性能; 全寿命周期费用分析

U416.217

The Science and Technology Project of Jiangsu Provincial Communications Department (No.7621000078).

:Zhu Yuqin, Ni Fujian, Gu Xingyu. Comparative analysis of perpetual pavement structures based on pavement performance and life cycle cost[J].Journal of Southeast University (English Edition),2014,30(1):84-87.

10.3969/j.issn.1003-7985.2014.01.016

10.3969/j.issn.1003-7985.2014.01.016

Received 2013-11-01.

Biographies:Zhu Yuqin (1988—), female, graduate; Ni Fujian (corresponding author), male, doctor, professor, ifujian@gmail.com.

Journal of Southeast University(English Edition)2014年1期

Journal of Southeast University(English Edition)2014年1期

- Journal of Southeast University(English Edition)的其它文章

- Speech emotion recognitionusing semi-supervised discriminant analysis

- Shape retrieval using multi-level included anglefunctions-based Fourier descriptor

- Performance analysis of ammonia-water absorption/compression combined refrigeration cycle

- Optimization of cross-coupling reaction for synthesis of antitumor drug vismodegib

- Flexural behaviors of FRP strengthened corroded RC beams

- Notes on well-posedness for the b-family equation