深度油炸对食用油中反式亚油酸含量的影响

侯俊财 江连洲 王 芳 张春伟

(东北农业大学食品学院1,哈尔滨 150030)

(东北农业大学国家大豆工程技术研究中心2,哈尔滨 150030)

深度油炸对食用油中反式亚油酸含量的影响

侯俊财1,2江连洲1,2王 芳1张春伟1

(东北农业大学食品学院1,哈尔滨 150030)

(东北农业大学国家大豆工程技术研究中心2,哈尔滨 150030)

选用我国消费最普遍的压榨大豆油和三级浸提大豆油为试验材料,研究不同大豆油经反复油炸对反式亚油酸含量的影响及其含量随油炸次数增加的变化规律。试验分为2组,反复油炸40次,每炸5次采集1次油样,每组测定3个重复。薯条油炸温度为180~185℃,油炸时间为32 h。试验结果表明,压榨大豆油和三级浸提大豆油中总反式亚油酸含量分别为0.18 g/100 g和0.08 g/100 g,前者极显著高于后者(P=0.001),9-cis,12-trans C18:2和9-trans,12-cis C18:2是2种大豆油中主要的反式亚油酸。深度油炸极显著提高大豆油中反式亚油酸含量(P=0.000),在反复油炸40次后,压榨大豆油和三级浸提大豆油中总反式亚油酸含量分别为1.11 g/100 g和0.68 g/100 g,且前者极显著高于后者(P=0.008)。压榨油反式亚油酸经油炸增加幅度高于三级浸提大豆油。

大豆油 深度油炸 反式脂肪酸 反式亚油酸

反式脂肪酸(trans fatty acids,TFA)主要来源于氢化油和反刍动物乳和肉[1-2]。深度油炸也是其主要来源之一[3-5]。然而,流行病学调查研究表明TFA摄入与冠心病有关[6]。也证明其能提高血液中LDL - 胆固醇和降低 HDL - 胆固醇浓度[7-8]。

油炸不仅是现代食品工业的主要加工工序,也是家庭食品烹调常用方式之一,尤其是快餐食品加工的必备工序。国内已对煎炸油中极性化合物的生成、油炸过程与油炸食品品质的动态关系以及煎炸油及其加热产生的极性物质致突变性进行了研究[9-11],但国内对深度反复油炸对反式脂肪酸影响及变化规律报道较少,对反式亚油酸影响更是鲜有报道。因此,本研究拟以压榨大豆油和三级浸提油为原料,研究深度油炸对食用油中反式亚油酸含量的影响,以便为今后的油炸食品中反式脂肪酸控制提供理论指导和技术支持。

1 材料与方法

1.1 材料与仪器

反式亚油酸异构体甲酯混和标准品:美国Supelco公司;压榨大豆油、三级浸提大豆油和薯条:哈尔滨市超市;甲醇、氢氧化钠、无水硫酸钠:均为分析纯:三氟化硼、乙醚:均为化学纯。

气相色谱仪6890N:美国安捷伦公司;CP Sil 88(100 m ×0.25 mm ×0.2 μm)毛细管柱:美国 Varian公司;油炸锅:XW-80A型漩涡混合器:上海医科大学仪器厂;氮吹仪:上海医用分析仪器厂。

1.2 油炸方法

每种大豆油设3个重复,油炸温度为180~185℃,油炸时间总计32 h,分4 d完成,每天油炸8 h。每天油炸前预热1 h,预热温度为180~185℃,每次油炸50 g薯条,油炸时间为3~4 min,油炸间隔时间为30 min,每天油炸10次,油炸次数总计40次。

1.3 采样方法

每炸5次采集油样1次,油样用滤纸过滤,去除杂质。取5 mL油样放于-80℃冰箱用于分析脂肪酸组成。

1.4 脂肪酸分析

脂肪酸甲酯制备参照Liu等[12]方法,脂肪酸分析方法参照Bansal等[5],样品中反式亚油酸的识别参照标准样品。

1.5 数据分析

数据是3个重复的平均值,数据分析采用SPSS13.0的Duncan多重比价方法,显著水平为P<0.05。

2 结果与讨论

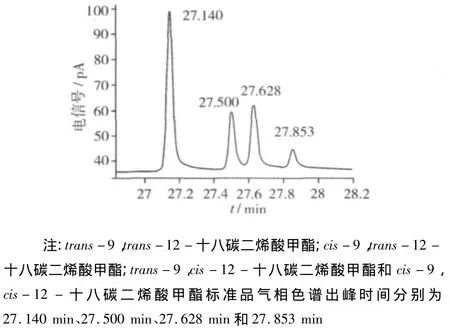

2.1 色谱分析条件优化

亚油酸4种异构体得到了较好的分离,详见图1。由图1可见,4种亚油酸异构体出峰顺序为trans-9,trans-12 - 十八碳二烯酸甲酯(27.140 min)、cis-9,trans-12 - 十八碳二烯酸甲酯(27.500 min)、trans-9,cis-12-十八碳二烯酸甲酯(27.628 min)和cis-9,cis-12-十八碳二烯酸甲酯(27.853 min)。可见选择的脂肪酸分离条件适合于本研究。

图1 脂肪酸甲酯标准品气相色谱图

2.2 大豆油鲜样反式亚油酸组成

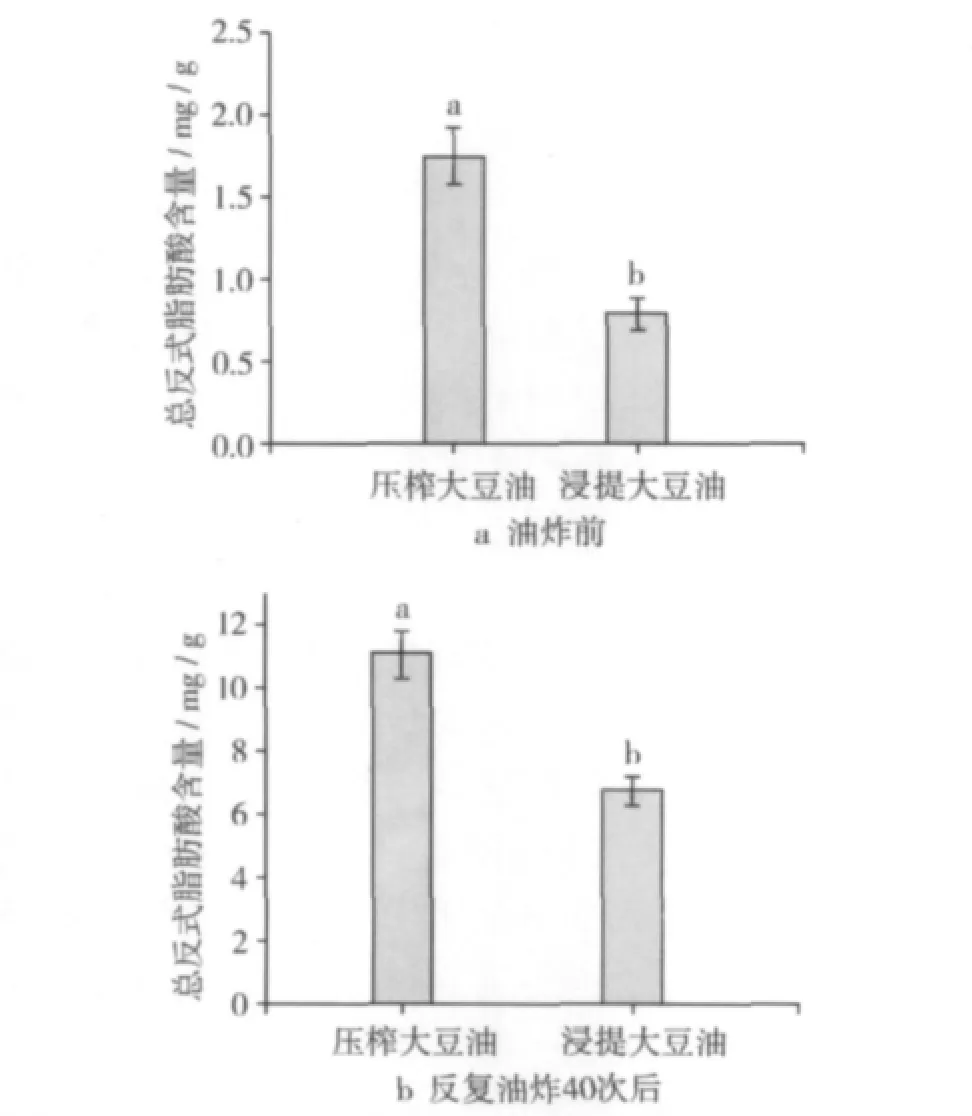

由表1和表2可知,压榨大豆油和三级浸提大豆油中主要检出了cis-9,trans-12 C18:2和trans-9,cis-12 C18:2两种脂肪酸,而 trans-9,trans-12 C18:2没有检出,可见 cis-9,trans-12 C18:2和trans-9,cis-12 C18:2是大豆油中主要的反式亚油酸,这与Sebedio等[13]报道结果一致。Wallingford等[14]报道,我国大豆油中含有较高的反式亚油酸(1.8%),与哥斯达黎加2003年报道数据(1.7%)相似。而本研究测得的压榨大豆油和三级浸提大豆油中总反式亚油酸含量分别为0.18 g/100 g和0.08 g/100 g(表1和表2),低于上面测定的结果,说明我国的大豆油加工企业的反式脂肪酸控制技术得到了显著提高。另外,本研究还发现压榨大豆油总反式亚油酸显著高于三级浸提大豆油(P=0.001)(图2a)。

图2 压榨油和浸提油中反式亚油酸含量

2.3 反复油炸对大豆油中反式亚油酸含量的影响

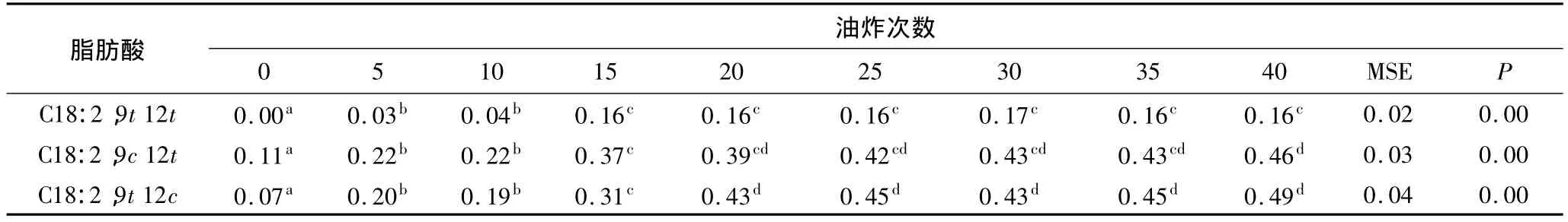

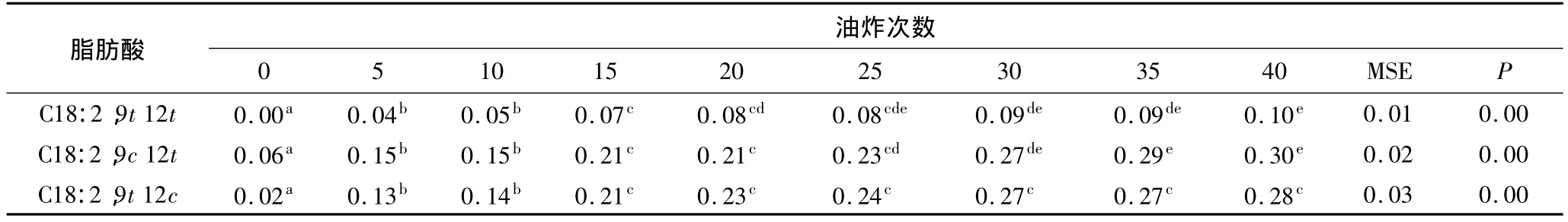

压榨大豆油和三级浸提大豆油反复油炸后,反式亚油酸含量变化见表1和表2。由表1和表2可见,压榨大豆油和三级浸提大豆油中反式亚油酸异构体含量随油炸次数增加呈现显著增加(P=0.000)。这与Tsuzuki 等[3]、Aladedunye 和 Przybylski[4]和 Bansal等[5]报道结果一致。由表1和表2可见,压榨大豆油和三级浸提大豆油中trans-9,trans-12 C18:2由0次油炸到15次油炸期间的增加幅度最大,但在15次到40次增加的幅度很小;而 cis-9,trans-12 C18:2和trans-9,cis-12 C18:2两种脂肪酸在0次到5次增加的幅度最大,在10次大40次油炸增加幅度偏小。压榨大豆油经反复油炸40次后 cis-9,trans-12 C18:2和trans-9,cis-12 C18:2分别增加4倍和7倍;而三级浸提大豆油中经反复油炸40次后,cis-9,trans-12 C18:2和 trans-9,cis-12 C18:2 分别增加5倍和14倍。在反复油炸40次后,压榨大豆油和三级浸提大豆油中总反式亚油酸含量分别为1.11 g/100 g和0.68 g/100 g,且前者极显著高于后者(P=0.008)(图2(b))。导致这种原因可能是大豆油提取所采用的压榨法和浸出法工艺不同所致,因为采用压榨工艺提取的大豆油中含有的化学组分比浸提大豆油复杂[15],这样势必会加剧反式脂肪酸的生成。

表1 压榨大豆油经反复油炸后,反式亚油酸含量(g/100 g)的变化

表2 三级有机溶剂浸提大豆油反复油炸后,反式亚油酸含量(g/100 g)的变化

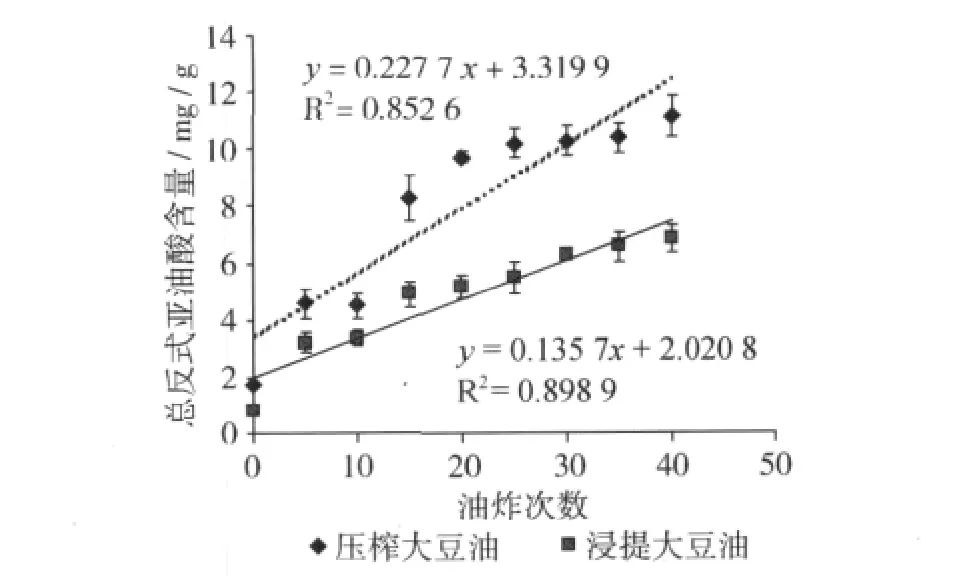

压榨大豆油和三级浸提大豆油中总反式亚油酸与反复油炸次数线性关系见图3。压榨大豆油和三级浸提大豆油与油炸次数的决定系数R2值分别为0.852 6和0.869 0,经显著性检验大豆油与油炸次数极显著相关(P<0.01),这也充分证明随着油炸次数增加与食用油中总反式亚油酸含量增加,且压榨大豆油中总反式亚油酸增加幅度要比三级浸提大豆油高。

图3 压榨油和浸提油中反式亚油酸含量随油炸次数增加的变化规律

3 结论

cis-9,trans-12 C18:2 和 trans-9,cis-12 C18:2是压榨大豆油和三级浸提大豆油中主要反式亚油酸;深度油炸极显著提高压榨大豆油和三级浸大豆油中总反式亚油酸含量;压榨油反式亚油酸经油炸增加幅度高于三级浸提大豆油。

[1]Laura Z,Cecilia P,Luciana C,et al.Effect of radical stress and ageing on the occurrence of trans fatty acids in rats fed a trans - free diet[J].Free Radical Biology & Medicine,2008,44(4):594-601

[2]Ascherio A,Katan M B,Zock P L.Trans fatty acids and coronary heart disease[J].New England Journal of Medicine,1999,340(25):1994 -1998

[3]Tsuzuki W,Matsuoka A,Kaori U.Formation of trans fatty acids in edible oils during the frying and heating process[J].Food Chemistry,2010,123(4):976 -982

[4]Aladedunye F A,Przybylski R.Degradation and nutritional quality changes of oil during frying[J].Journal of American Oil Chemist's Society,2009,86:149 -156

[5]Bansal G,Zhou W B,Tan T W,et al.Analysis of trans fatty acids in deep frying oils by three different approaches[J].Food Chemistry,2009,116(2):535 -541

[6]Kummerow F A,Zhou Q,Mahfouz M M,et al.Trans fatty acids in hydrogenated fat inhibited the synthesis of the polyunsaturated fatty acids in the phospholipids of arterial cells[J].Life Science,2004,74(22):2707 -2723

[7]Khor G L,Mohd E N.Trans fatty acids intake:Epidemiology and health implications[M]//Dijkstra A J.,Hamilton R J.,Hamm W.Trans fatty acids.Oxford:Blackwell Publishing,2008:25-45

[8]Mensink R P,Katan M B.Effect of dietary trans fatty acids on high-density and low-density lipoprotein cholesterollevels in healthy subjects[J].New England Journal of Medicine,1990,323(7):439 -445

[9]周雅琳,周令国,李智,等.影响煎炸油中极性化合物生成因素的研究[J].中国粮油学报,2010,25(3):50 -53

[10]杨铭铎,邓云,石长波,等.油炸过程与油炸食品品质的动态关系研究[J].中国粮油学报,2006,21(5):93-97

[11]刘元法,穆昭,单良,等.煎炸油及其加热产生的极性物质致突变性研究[J].中国粮油学报,2010,25(6):51-55

[12]Liu W H,Inbaraj B,Stephen,et al.Analysis and formation of trans fatty acids in hydrogenated soybean oil during heating[J].Food Chemistry,2007,104(4):1740 - 1749

[13]Sebedio J L,Ratnayake W M.Analysis of trans mono- and polyunsaturated fatty acids[M]//Dijkstra A J,Hamilton R J,Hamm W.Trans fatty acid.Oxford:Blackwell Publishing,2008:102-128

[14]Wallingford J C,Yuhas R,Du S,et al.Fatty acids in Chinese edible oils:value of direct analysis as a basis for labeling[J].Food Nutr Bull,2004,25(4):330 -336

[15]丁福祺.食用油压榨法和浸出法工艺的区别[J].中国油脂,2005,30(1):5 -6.

Effect of Deep Frying on Trans-linoleic Acid Content in Edible Oil

Hou Juncai1,2Jiang Lianzhou1,2Wang Fang1Zhang Chunwei1

(College of Food,Northeast Agricultural University1,Harbin 150030)

(National Research Soybean Engineering and Technology Center2,Harbin 150030)

With the testing materials of the most common pressed soybean oil and three-level leached soybean oil consumed in our country,the article aims was to research the influence of repeated soybean oil frying on translinoleic acid content and the increasing principles of the content along with oil frying.The testing materials were divided into two groups and fried repeatedly for 40 times.Oil samples were taken for every 5 frying times,and each group was tested for three times.Potato strips were fried intermittently at 180 ~185 ℃ with total frying time of 32 h.It was found that the initial amounts of total trans- linoleic acids were 0.18 g/100 g and 0.08 g/100 g in the pressed soybean oil and the three-level leached soybean oil respectively.The total linoleic acids contents of the pressed soybean oil was significantly higher than that of the three - level leached soybean oil before frying(P=0.001).9 - cis,12 -trans C18:2 and 9 - trans,12 - cis C18:2 were the major trans - linoleic acids in soybean oil.Repeated deep frying significantly enhanced the content of trans- linoleic acids(P=0.000)in soybean oil.After 40 times of repeated frying in oil,the contents of trans- linoleic acids in the pressed soybean oil and the three - level leached soybean oil were respectively 1.11 g/100 g and 0.68 g/100 g,and the former was much higher than the latter(P=0.008).So,after frying,the content of trans-linoleic acids in the pressed soybean oil increased in a larger extent than that in the three-level leached soybean oil.

soybean oil,deep frying,trans fatty acids,trans- linoleic acids

TQ646

A

1003-0174(2012)01-0062-04

863计划(2010AA101503),“十一五”国家科技支撑计划(2009BADB9B08-1)

2011-03-17

侯俊财,男,1975年出生,博士,副教授,油脂加工

江连洲,男,1958年出生,博士,教授,博士生导师,油脂加工和大豆蛋白加工