高压切换冻结在食品保鲜中的应用

邹 妍,龙道崎,陶兵兵,赵国华,2,*

(1.西南大学食品科学学院,重庆 400715;2.重庆市农产品加工技术重点实验室,重庆 400715)

高压切换冻结在食品保鲜中的应用

邹 妍1,龙道崎1,陶兵兵1,赵国华1,2,*

(1.西南大学食品科学学院,重庆 400715;2.重庆市农产品加工技术重点实验室,重庆 400715)

高压切换冻结是一种新兴的食品保鲜技术,在冻结过程中利用高压与温度来控制冻结过程,改变冰晶体的大小、形态与分布,从而改善冻品的品质。文章详细阐述了高压切换冻结法的基本原理以及在食品保鲜领域研究的进展,最后分析了该技术存在的问题,以对高压切换冻结技术的进一步研究提供参考。

高压切换冻结,保鲜,食品

Abstract:High-pressure-shift-freezing(HPSF),an emerging food preservation technique,takes advantages of different ice crystals properties such as size,shape and distribution resulting from controlling of high pressure and temperature to improve the quality of frozen food.The basic principle of HPSF as well as the study of technique in food industry was depicted.In addition,the main problems were listed,and it could be a reference for further research of HPSF in food preservation.

Key words:high-pressure-shift-freezing;fresh-keeping;food

如今人们对生鲜食品需求的增加与其易腐蚀性、季节性和地域性等特点之间的矛盾促进了保鲜技术的发展。冷冻保鲜效果好、造价较低、保存时间较长,并且可以最大限度的保持食品的色、香、味和营养价值,成为保持生鲜食品质量的最普遍的方法[1],但是在冻结过程中较大冰晶体的形成与分布不均是食品品质劣化的主要原因。为了获得更小、分布更加均匀的冰晶体,近年来出现了很多冻结的新技术,如超声冻结技术、超高压冻结技术、冰核活性细菌和冰核活性蛋白及抗冻蛋白在食品冷冻过程中的应用等。在高压技术的基础上发展起来的高压冻结技术,不仅很好地解决了高水分食品易冻裂的难题,还能够改善冻品的其他品质。高压冻结有三种类型[2]:高压切换冻结(HPSF-High Pressure Shift Freezing)、高压辅助冻结(HPAF-High Pressure Assisted Freezing)和高压诱导冻结(HPIF-High Pressure Induced Freezing)。高压诱导冻结是利用压力的升高来获得冻结的相转变,用于高级晶型的形成,现在对这种技术的研究较少。高压辅助冻结法中,产品的整个冻结过程在高压下实现,当设置不同的高压与相应的温度时,可以获得不同的冰晶型。通过对高压切换冻结和高压辅助冻结后的冻品进行比较,确定了高压切换冻结在改善冻品品质上的优越性[3],如今在食品工业中被广泛研究。在高压切换冻结中产生的过冷度,可以使样品中形成大量细小而均一的冰晶体,从而减少冷冻过程中食品品质的劣化[4]。

1 高压切换冻结原理及特点

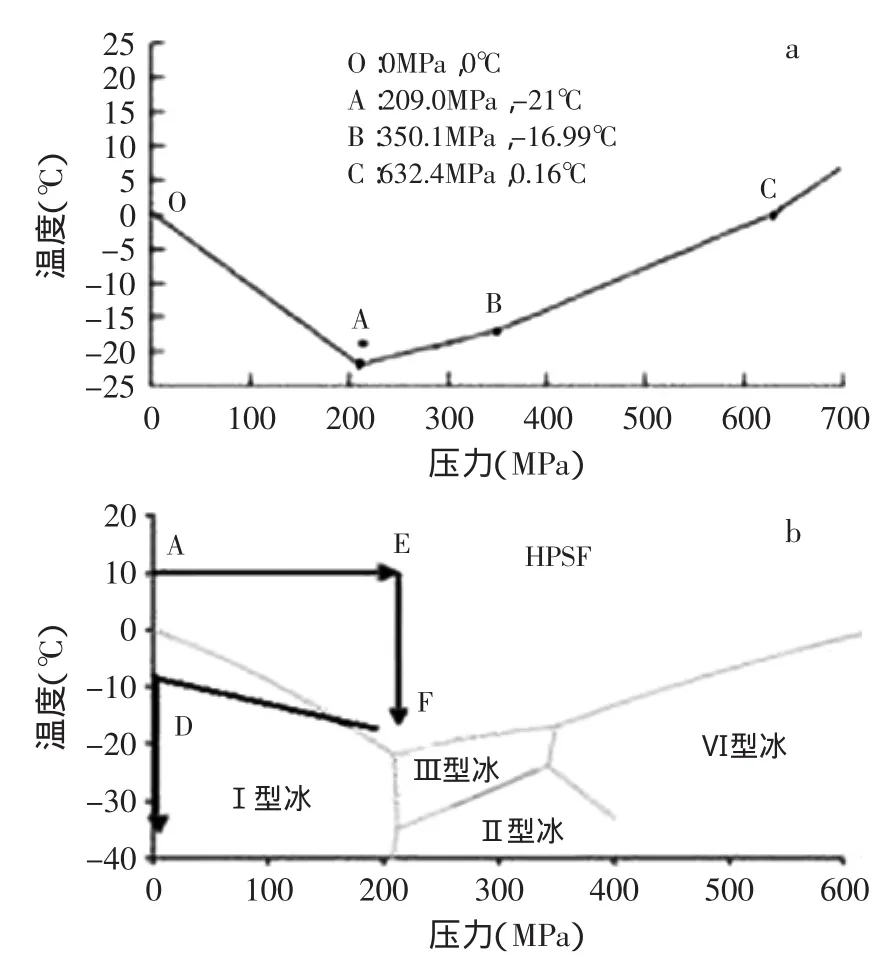

通常情况下,水在0℃形成冰晶为I型,而I型冰晶的密度小于水的密度,导致冰晶体体积增加了9%。Bridgman[5]对高压下水的相行为进行了研究,指出在高压下水会出现多种冰晶型,除了常见的冰I型外,还有冰II~V型等,并且高压下水的冰点也发生变化。由图1a可见,当压力在632.4MPa以上时,会出现0℃以上的冰点。也就是说在0~632.4MPa范围内,水的冰点低于常压下的冰点,形成了一个低于0℃的不冻结区域。

高压切换冻结法就是利用了0℃下的不冻区域,冻结是在压力释放的瞬间开始的,形成大量均匀分布的晶核,在随后的大气压下长大成为冰晶体。高压切换冻结过程如图1b所示:先对容器内的材料进行加压(A→E),当达到预定的压力后,对物料进行预冷冻(E→F),F点的温度必须高于该压力下的初始冻结温度,从而保持低温下的不冻结状态,然后突然释放压力(F→D),此时极大的过冷度促使物料的冻结,相变的潜热释放,使得物料温度升高,在大气压下完成冻结,最后降到预定的冷藏温度[2]。而在食品体系中,由于溶质的存在,使得食品中水的冻结点比纯水的低,相应的冻结曲线也向下移。

高压切换冻结时涉及到晶核的形成与晶体的长大,并且只能获得I型冰晶,整个结晶过程都是由极大的过冷度作为驱动力。而且整个过程处于等压状态,因此晶核分布均匀,形成的冰晶呈球形[6]。研究表明,每1K的过冷度,成核速率提高10倍[7],所以过冷度越大,形成的冰晶体越小。

高压切换冻结法不仅可以降低冰晶体对冻品的机械破坏,还可以降低酶活性[8],减缓或抑制食品中的生化反应。高压作用灭活微生物已有大量研究,而高压与低温共同作用,以及冻结过程中的相转变都有利于提高微生物的灭活率[9]。但是,高压切换冻结会使得蛋白质变性[10],从而导致颜色、持水率、硬度值的变化。

图1 高压下的水相图及高压切换冻结原理图[2,5]Fig.1 Water phase diagram under high pressure and the schematic diagram of HPSF[2,5]

2 高压切换冻结在食品保鲜中的应用

2.1 高压切换冻结在肉类食品中的应用

利用高压切换冻结可以使肉类冷冻食品中形成较小而均匀分布的冰晶体,减少对组织的破坏,从而减少解冻后的水分流失,并且在恒定的低温贮藏过程中冰晶体稳定性好,但当贮藏温度发生波动时,晶体发生重结晶,使得冰晶体数量变小、体积变大[11]。同时,压力与温度的共同作用可以提高灭菌率[12]。而过高的压力会导致肉中的蛋白质变性,使得其硬度值增加,肉色改变,但是熟制后的肉色与新鲜的肉熟制后无差别[13-14]。相关的应用进展见表1。

表1 高压切换冻结在肉类食品中的应用进展Table 1 Application progress of high-pressure-shift-freezing in meats

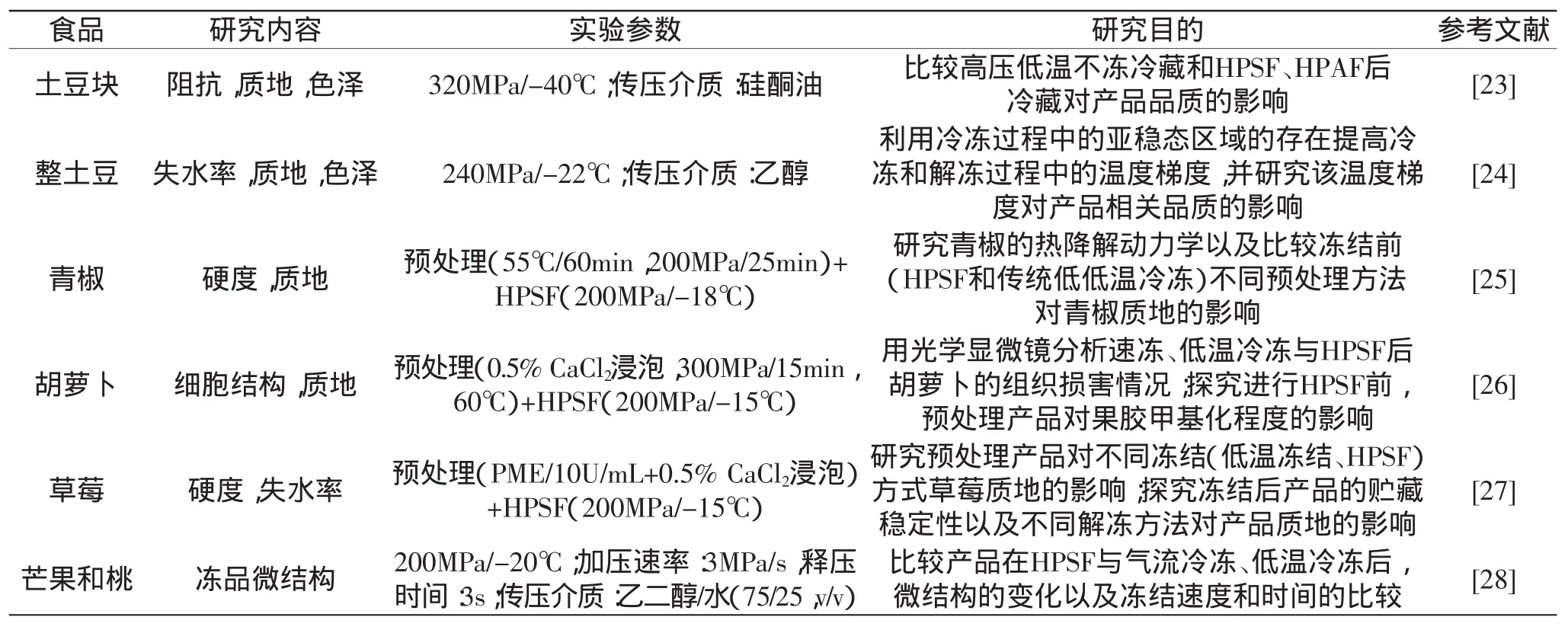

2.2 高压切换冻结在果蔬食品中的应用

高压切换冻结不受果蔬体积的限制,可以在冻品表面与中心形成细小均一的冰晶体[20]。酶的灭活并不能在整个冻结过程中实现,PPO活性会随压力增大呈先增后减的趋势,果蔬的褐变程度与其变化一致[21]。果蔬冻品解冻后硬度的下降可以通过与其他工艺联合应用,如冻结前的热烫、浸钙等来解决,但是在冷藏过程中冰晶体的重结晶会使得硬度值再次降低,这与冻品本身的质地相关[22]。相关的应用进展见表2。

2.3 高压切换冻结在其他食品中的应用

高压切换冻结法可以明显的减小冰淇淋中冰晶体的大小,果糖与海藻酸钠的加入可以减小晶体尺寸,使其外观更加平滑,从而改善冰淇淋口感,并且快速释压有利于较小冰晶体的形成[29]。由此看出乳化液中的成分、冻结时的压力与温度参数、释压时间都是影响高压切换冻结效果的因素。对凝胶类食品的研究也得出相似的结论,并指出当压力为200~500MPa时,凝胶有较好的质地[30-31]。相关的应用进展见表3。

3 展望

高压切换冻结在食品工业中的研究已经证明了它较其他冻结方法在食品保藏中的优越性,能更好的保持食品的新鲜的品质,但其在应用研究上仍有待进一步深入:a.如何有效提高高压切换冻结食品的稳定性,使其在运输、销售过程中保持较小的冰晶体,尽可能避免重结晶的发生;b.水饺、汤圆、馒头等中国传统食品是人们日常选择的主食,速冻产品正提供了其食用的便利性,其中冰晶体大小也是影响冻品品质的因素,而利用高压切换冻结改善品质的探究还是空白,因此高压切换冻结在中国传统食品上的应用将会是一次创新;c.高压对食品成分影响的研究现已有很多,但是在对高压切换冻结法的探究过程中,只对蛋白质有相关报道,在以后的研究中可以对食品中其他的功能性成分进行探究。

表2 高压切换冻结在果蔬食品中的应用进展Table 2 Application progress of high-pressure-shift-freezing in fruits and vegetables

表3 高压切换冻结在其它食品中的应用进展Table 3 Application progress of high-pressure-shift-freezing in other foods

[1]George RM.Freezing processes used in the food industry[J].Trends in Food Science and Technology,1993,4(5):134-138.

[2]Urrutia-Benet G,Schluter O,Knorr D.High pressure-low temperature processing.Suggested definitions and terminology[J].Innovative Food Science and Emerging Technologies,2004,5(4):413-427.

[3]Fernandez PP,Otero L,Guignon B,et al.High-pressure shift freezing versus high-pressure assisted freezing:Effects on the microstructure of a food model[J].Journal of Food Science,2000,65(3):466-470.

[4]Chevalier D,Le Bail A,Ghoul M.Freezing and ice crystals formed in a cylindrical food model:pare II.Comparison between freezing at atmospheric pressure and pressure-shift freezing[J].Journal of Food Engineering,2000,46(4):287-293.

[5]Bridgman PW.Water,in the liquid and five solid forms,under pressure[J].Proceeding of the American Academy of Arts and Sciences,1912,47(13):441-558.

[6]Martino MN,Otero L,Sanz PD,et al.Size and location of ice crystals in pork frozen by high-pressure-assisted freezing as compared to classical methods[J].Meat Science,1998,50(3):303-313.

[7]Kalichevsky MT,Knorr D,Lillford PJ.Potential food applications of high-pressure effects on ice-water transitions[J].Trends in Food Science and Technology,1995,6(8):253-259.

[8]Prestamo G,Palomares L,Sanz P.Frozen foods treated by pressure shift freezing:proteins and enzymes[J].Journal of Food Science,2005,70(1):22-27.

[9]Picart L,Dumay E,Guiraud JP,et al.Microbial inactivation by pressure-shift freezing:effects on smoked salmon mince inoculated with Pseudomonas fluorescens,Micrococcus luteus and Listeria innocua[J].LWT-Food Science and Technology,2004,37(2):227-238.

[10]Fernandez-Martin F,Otero L,Solas MT,et al.Proteindenaturation and structural damage during high-pressure-shift freezing of porcine and bovine muscle[J].Journal of Food Science,2000,65(6):1002-1008.

[11]Tironi V,Lamballeri MD,Le-Bail A.Quality changes during the frozen storage of sea bass(Dicentrarchus labrax) muscle after pressure shiftfreezing and pressure assisted thawing[J].Innovative Food Science and Emerging Technologies,2010,11(4):565-573.

[12]陈淑花,赵启成,夏远景,等.超高压与低温协调作用对黄花鱼品质影响的研究[J].食品与生物技术学报,2009,28(4):517-520.

[13]Zhu Songming,Le-Bail A,Chapleau N,et al.Pressure shift freezing of pork muscle:effect on color,drip loss,texture,and protein stability[J].Biotechnology Progress,2004,20(3):939-945.

[14]Chevalier D,Sentissi M,Havet M,et al.Comparison of airblast and pressure shift freezing on Norway lobster quality[J].Journal of Food Science,2008,65(2):329-333.

[15]Alizadeh E,Chapleau N,Lamballerie MD,et al.Effect of different freezing processes on the microstructure of Atlantic salmon(Salmo salar) fillets[J].Innovative Food Science and Emerging Technologies,2007,8(4):493-499.

[16]Tironi V,Lamballerie MD,Le-Bail A.Quality changes during the frozen storage of sea bass(Dicentrarchus labrax) muscle after pressure shift freezing and pressure assisted thawing[J].Innovative Food Science and Emerging Technologies,2010,11(4):565-573.

[17]Alizadeh E,Chapleau N,De-Lamballerie M,et al.Impact of freezing process on salt diffusivity of seafood:application to salmon(Salmo salar) using conventional and pressure shift freezing[J].Food Bioprocess Technology,2009,2(3):257-262.

[18]Chen CR,ZHU Songming,Ramaswamy HS,et al.Computer simulation of high pressure cooling of pork[J].Journal of Food Engineering,2007,79(2):401-409.

[19]Zhu Songming,Ramaswamy HS,Le-Bail A.High-pressure calorimetric evaluation of ice crystal ratio formed by rapid depressurization during pressure-shift freezing of water and pork muscle[J].Food Research International,2005,38(2):193-201.

[20]Otero L,Solas MT,Sanz PD,et al.Contrasting effects of high-pressure-assisted freezing and conventional air-freezing on eggplant tissue microstructure[J].European Food Research and Technology,1997,206(5):338-342.

[21]Urrutia-Benet G,Balogh T,Schneider J,et al.Metastable phases during high-pressure-low-temperature processing of potatoes and their impact on quality-related parameters[J].Journal of Food Engineering,2007,78(2):375-389.

[22]Buggenhout SV,Messagie I,Loey AV,et al.Influence of low-temperature blanching combined with high-pressure shift freezing on the texture of frozen carrots[J].Journal of Food Science,2005,70(4):S304-S308.

[23]Luscher C,Schluter O,Knorr D.High pressure-low temperature processing of foods:impact on cell membranes,texture,color and visual appearance of potato tissue[J].Innovative Food Science and Emerging Technologies,2005,6(1):59-71.

[24]Urrutia-Benet G,Chapleau N,Lille M,et al.Quality related aspects of high pressure low temperature processed whole potatoes[J].Innovative Food Science and Emerging Technologies,2006,7(1-2):32-39.

[25]Castro SM,Van Loey A,Saraiva JA,et al.Effect of temperature,pressure and calcium soaking pre-treatments and pressure shift freezing on the texture and texture evolution of frozen green bell peppers(Capsicum annuum)[J].European Food Research and Technology,2007,226(1-2):33-43.

[26]Buggenhout V,Lille M,Messagie I,et al.Impact of pretreatment and freezing conditions on the microstructure of frozen carrots:quantification and relation to texture loss[J].European Food Research and Technology,2006,222(5-6):543-553.

[27]Buggenhout SV,Messagie I,Maes V,et al.Minimizing texture lossoffrozen strawberries:effectofinfusion with pectinmethylesterase and calcium combined with different freezing conditions and effect of subsequent storage/thawing conditions[J].European Food Research and Technology,2006,223(3):395-404.

[28]Otero L,Martino M,Zaritzky N,et al.Preservation of microstructure in peach and mango during high-pressure shift freezing[J].Journal of Food Science,2000,65(3):466-470.

[29]Thiebaud M,Dumay EM,Cheftel JC.Pressure-shift freezing of o/w emulsions:influence of fructose and sodium alginate on undercooling,nucleation,freezing kinetics and ice crystal size distribution[J].Food Hydrocolloids,2002,16(6):527-545.

[30]Fuchigami M,Ogawa N,Teramoto A.Trehalose and hydrostatic pressure effects on the structure and sensory properties of frozen tofu(soybean curd)[J].Innovative Food Science and Emerging Technologies,2002,3(2):139-147.

[31]Fuchigami M,Teramoto A.Texture and structure of highpressure-frozen gellan gum gel[J].Food Hydrocolloids,2003,17(6):895-899.

[32]Levy J,Dumay E,Kolodziejczyk E,et al.Freezing kinetics of a model oil-in-water emulsion under high pressure or by pressure release.Impact on ice crystals and oil droplets[J].LWT-Food Science and Technology,1999,32(7):396-405.

[33]Zhu Songming,Ramaswamy HS,Le-Bail A.Ice-crystal formation in gelatin gel during pressure shift versus conventional freezing[J].Journal of Food Engineering,2005,66(1):69-76.

[34]Fuchigami M,Teramoto A,Jibu Y.Texture and structure of pressure-shift-frozen agar gel with high visco-elasticity[J].Food Hydrocolloids,2006,20(2-3):160-169.

[35]Fernandez PP,Martino MN,Zaritzky NE,et al.Effects of locust bean,xanthan and guar gums on the ice crystals of a sucrose solution frozen at high pressure[J].Food Hydrocolloids,2007,21(4):507-515.

[36]Otero L,Sanz PD,Guignon B,et al.Experimental determination of the amount of ice instantaneously formed in high-pressure shift freezing[J].Journal of Food Engineering,2009,95(4):670-676.

Mechanism and application progress of high-pressure-shift-freezing in food preservation

ZOU Yan1,LONG Dao-qi1,TAO Bing-bing1,ZHAO Guo-hua1,2,*

(1.College of Food Science,Southwest University,Chongqing 400715,China;2.Chongqing Key Laboratory of Agricultural Product Processing,Chongqing 400715,China)

TS205.7

A

1002-0306(2012)22-0432-04

2012-06-21 *通讯联系人

邹妍(1989-),女,硕士研究生,研究方向:食品化学与营养学。