The Usability of Polyoxyethylene Stearate as Lubricant for Sizing Cotton Warp Yarns

ZHU Zhi-feng(祝志峰),MENG Na(孟 娜),XU Dong-sheng(许冬生)

1 Key Laboratory of Eco-textile of Ministry of Education,Jiangnan University,Wuxi 214122,China

2 Anhui Key Laboratory of Textile Materials,Anhui Polytechnic University,Wuhu 241000,China

Introduction

As is well known,an unblended size base material like starches or synthetic polymers acting alone will seldom satisfy all of the requirements for a specific sizing application.Therefore,it is a common way to blend the base material with some additives during current sizing operation for increasing one or more desirable properties of sized yarns[1].Lubricant is one of the most commonly used additives in a conventional size formulation.The purpose of using lubricants is to reduce friction and abrasion between adjacent yarns and between yarns and reed,heddles,drop wires,and shuttle[1,2].Generally,different types of lubricants possess different properties as they are imparted to the base material and sized warps.Tallow is composed of glycerides of fatty acids as active principle and will actually weaken starch film[1].For this reason,tallow is seldom used nowadays in spite of being a time-honored lubricant.Sizing cream,an emulsified product with waxes that is based on straight hydrocarbon chains,is now widely used in warp sizing.Although sizing cream usually exhibits good lubrication for sized yarns,it often makes trouble during textile operation.Sizing practice demonstrates that the cream sometimes causes paste delivery tube to be blocked especially when paste cools down.Even though the blockage can be prevented by raising paste temperature,taking care of heatpreservation,and equipping electric heating wire,the measures adopted are rather inconvenient.Furthermore,sizing cream also weakens starch film and makes it more brittle.The defects decrease the serviceability of the lubricants,lower the quality of sized yarns,and reduce the weavability during weaving operation.

Industrial concern on the quality of sized yarns has now resulted in a research impulse in finding new lubricants that offer higher efficiency both for lubrication and production.Polyoxyethylene stearate(POES)is a kind of surfactant and exhibits wetting,smoothing,softening,and plasticizing effects[3].As far as molecular structure is concerned for determining the type of POES,the only variable is condense number of ethylene epoxide.An investigation demonstrates that POES with 10 ethylene epoxides(POES 10)exhibits potential use when the number is considered from 6 to 40[3].It lubricates sized yarns through decreasing their frictional coefficient after being applied to yarn surfaces[3].However,little is known about the changes of adhesion and starch film after POES 10 is incorporated into starch.Accordingly,we made our efforts toward studying the potential use of POES 10 during cotton warp sizing operation and clarifying the influences of POES 10 upon the fundamental behaviors such as adhesion and film characteristics.Apparently,the work will provide scientific basis for POES 10 used in warp sizing.

1 Experimental

1.1 Materials and chemicals

Commercial native cornstarch used was supplied by Yixing Starch Factory(Jiangsu,China)and possessed an apparent viscosity of 47 mPa·s(determined in accordance with Textile Professional Standard FZ/T 15001-2008).Prior to use,the starch was purified according to a method described in Ref.[4].Chemicals such as sodium hydroxide,sodium carbonate,hydrochloric acid,and silver nitrate available commercially were all analytical reagent grades and were used directly.Methanol,chemically pure grade,was available commercially and used as received.Sizing cream was supplied by Zhongheng Starch Co.,Ltd.,(Jiangsu,China)and POES 10 was an industrial product provided by Haian Petrochemical Works(Jiangsu,China).

Pure cotton roving(372 tex,twist factor:98)obtained from Wuxi Qingfeng Textile Group wasused in adhesion estimation.Pure cotton yarns used in sizing test were ring-spun ones and 14.6 tex.Tensile strength and breaking elongation of the yarns were 15.61 cN/tex and 4.63%,respectively.Hairiness indexes of the yarns in the length intervals of 3,4,5,6,7,8,and 9 mm were 16.09,6.53,2.99,1.06,0.53,0.32,and 0.08,respectively.

1.2 Starch acidification

Paste viscosity of native starch should be reduced before sizing so as to reduce its excessive viscosity.Therefore,purified native starch was acidified with HCl solution.The acidification was carried out in an aqueous dispersion by dispersing 300 g starch(dry weight)into 450 mL distilled water.When the dispersion was heated to 50℃,27 mL of 2 mol/L HCl solution was added.The acidification was carried out under mechanical stirring at 50℃ for 4 h.Then,the product was neutralized with 1%NaOH solution,filtered,washed thoroughly with distilled water,dried at 60℃,pulverized,and sieved to pass through a 100 mesh-sieve.The acidified starch had an apparent viscosity of 12 mPa·s and an viscosity stability of 91.7% (also determined according to Textile Professional Standard FZ/T 15001-2008).

1.3 Adhesion to fibers

Roving method was used to measure the adhesion of starch(with or without lubricants)to cotton fibers by impregnating roving with a dilute starch paste and subjecting the slightly sized roving to drawing test to failure.It was the failure loads that were adopted to exhibit the adhesion[5,6].The pasting process of starch and measurement on the loads were described in previous investigation[7].

1.4 Preparation and measurement of starch film

Acidified starch was dispersed with distilled water to form 6%dispersion.Lubricant(if demanded)was added into the dispersion in required amount.The dispersion was heated to 95℃ under continuous stirring and maintained atthe temperature for 1 h.The paste was poured onto a 650 mm ×400 mm polyethylene film spread on a glass plate,and dried at 65% relative humidity and 20℃.Then,the films were collected and tailored into 200 mm × 10 mm strips.After the films had been stood under condition above for 24 h,their tensile strength,breaking elongation,and wear loss were measured in accordance with Ref.[5].Twenty or ten samples were measured for each case in the measurements,respectively,for the determination of tensile behaviors and wear loss.The readings reported were the average of the test results with which abnormal values had been rejected by statistical analysis.

1.5 Warp sizing

A JSSJ-83 MiniatureSizingMachine(Taixian Textile Machinery Plant,Jiangsu,China)was used to size cotton yarns at a speed of 5 m/min with a warp density of 31.7 ends per centimeter.Starch was pasted with mechanical agitation at a concentration of 10%.After starch had been heated to 95℃ for 1 h,the paste was shifted into the sizing box on the machine.The yarns were impregnated with the paste at 95℃ and squeezed with a pair of weighted roller at 680 N/m and 1 060 N/m,respectively,for front and back weighted rollers.Finally,the yarns were dried with 4 drying cans at 100℃.

1.6 Measurement of sized yarns

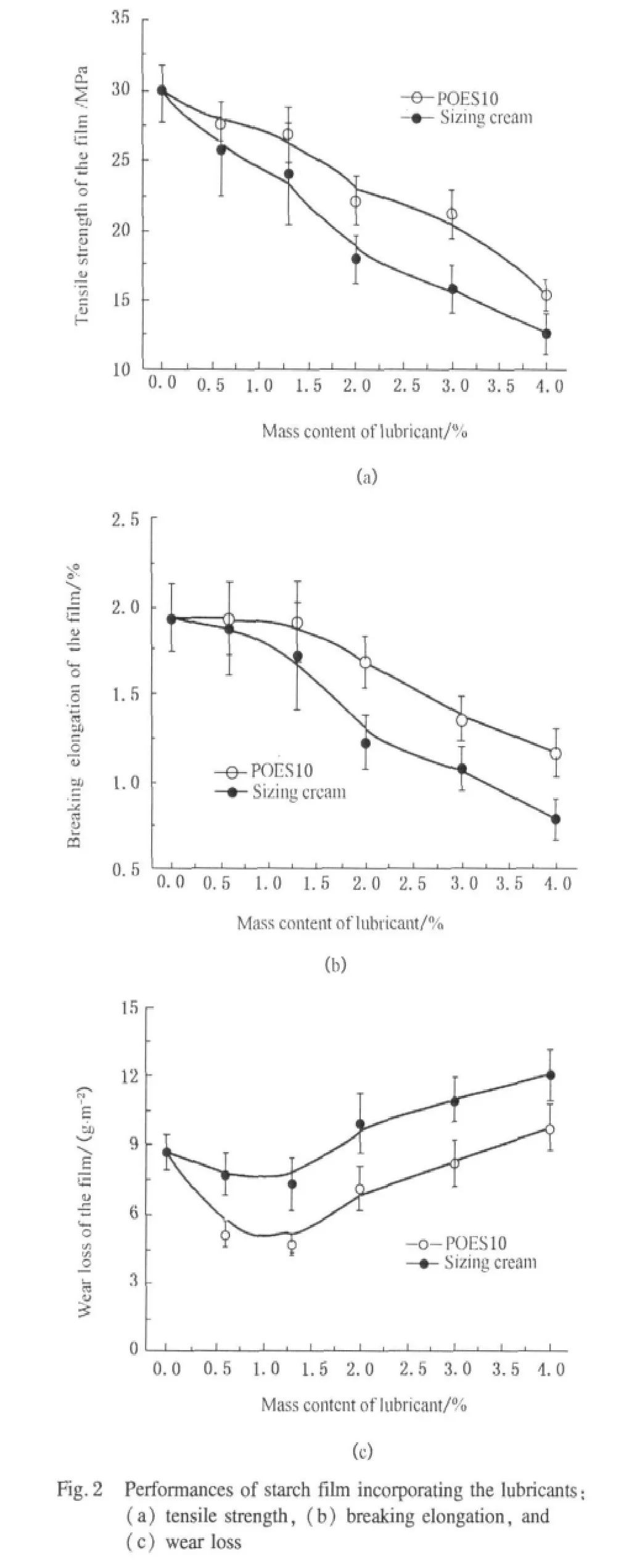

HD021N Tensile Tester(Nantong Hongda Instrument Co.Ltd.,Jiangsu,China)was used to measure tensile strength and breaking elongation of sized yarns at 65%relative humidity and 20℃with a speed of 500 mm/min under a test length of 500 mm and an initial tension of 12.5 N.For each sample,50 pairs of the strength and elongation readings were recorded and their mean values were adopted to calculate the increase in tensile strength and loss in elongation from Eqs.(1)and(2).

where S and S0are the mean values of tensile strength of sized and raw yarns;E and E0are the mean values of the elongations of sized and raw yarns,respectively.

Abrasion resistance of sized yarns was evaluated in average number of abrasion cycles to break.The number was measured with a method indicated in Ref.[8].Hairiness of warp yarns was evaluated in term of the decrease in hairiness and determined with the method described in former publication[8].Size add-on of sized yarns was determined with an acid-desizing method[9].

2 Results and Discussion

2.1 Effect on adhesion to cotton fibers

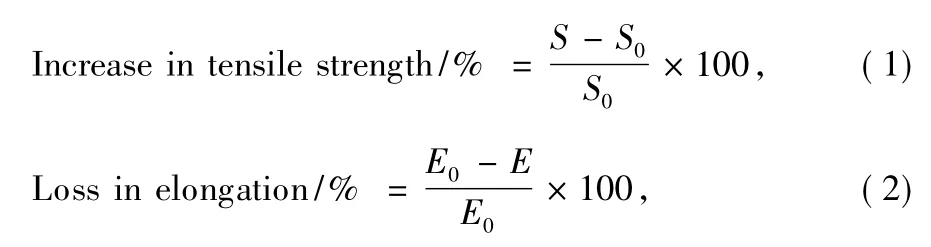

Adhesion of a sizing agent to fibers has received more attention[10,11]since it influences tensile strength,hairiness,and abrasion resistance of sized yarns.It has been revealed that the adhesion determines how heavily a warp must be sized[12].For this reason,the influences of POES 10 and sizing cream on the adhesion of starch to cotton fibers were accessed and shown in Fig.1.

It can be observed that tensile strength and work to break of the rovings do not present significant difference no matter what type ofthelubricants(POES 10 and sizing cream) is incorporated into starch paste.The observation conforms that the influence of POSE 10 on the adhesion of starch to cotton fibers is similar to that of sizing cream.And an overdose of POSE 10 incorporated into starch during sizing operation also results in significant reduction in the adhesion.

Generally,excessively increasing mass content of lubricants induces marked decrease in the adhesion because the surfaces of fibers can absorb a certain amount of lubricants.The lubricants existing on the surface of fiber interfere with or prevent the adsorption of fibers to starch pastes[3].For this reason,the uses of either POES 10 or sizing cream all result in significant decrease in the adhesion.

2.2 Effect on performances of starch film

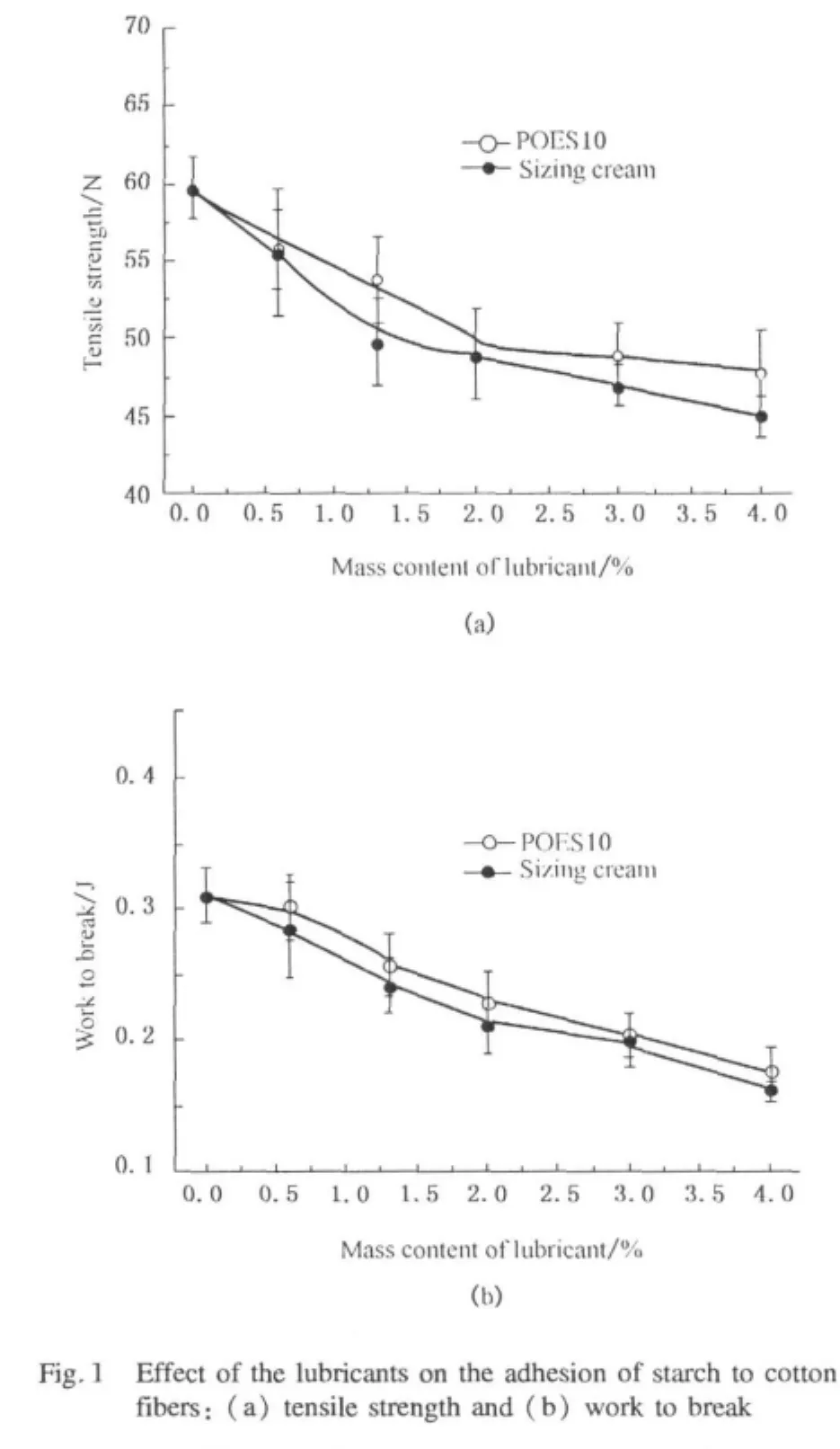

As is well known,starch film on surfaces of sized yarns protects yarns from mechanical abrasion during weaving operations.Desirable films should atleastpossess good extension,high tensile strength,and excellent abrasion resistance[13].The performances such as tensile strength,breaking elongation,and wear loss of starch film containing either POES 10 or sizing cream are shown by indicating the corresponding indexes verse mass content of the lubricants incorporated into starch paste in Fig.2.

It can be seen that tensile strength and breaking elongation of the film decrease as the contents of lubricants increase.When the contents reach and excess 2%,significant difference can be observed.The strength and elongation of the film containing POES 10 are superior to those containing sizing cream.For the wear loss,there exists significant difference between POSE 10 and sizing cream.The loss of starch/POES 10 film is lower than that of starch/sizing cream one.This observation denotes that blending POES 10 into starch makes starch film more resistant to wear as compared with blending sizing cream.Also,the resistance also depends on mass content of the two lubricants incorporated.With the increase in contentof lubricant,the wear loss of the film decreases.This infers that incorporating lubricants into starch pastesisfavorableto enhance abrasion resistance of starch film.Tensile and abrasion tests indicate that POSE 10 is superior to sizing cream in the performances of starch film.

Starch film cast from pure starch is generally coarse on surface and possesses greater frictional coefficient,thereby it exhibits larger amount of wear loss in abrasion test and worse abrasion resistance.For this reason,lubricants are required for increasing the resistance to wear so as to enhance abrasion resistance of sized yarns.If a small amount of lubricants is incorporated into starch pastes,part of lubricants will migrate onto the surface of starch film in the formation of sizing film.The lubricants on the surfaces of starch film decrease its friction coefficient and wear loss.It has been noted that sizing cream is not compatible with starch.The cream forms dispersed phase within the film while starch presents continuous one and encapsulates the dispersed lubricant.In this case,migration of sizing cream from interior onto film surface is limited.POES 10 is water-soluble substance and exists in water stably.Water evaporation induces a migration of the lubricant molecules from interior to film surface in the formation of sizing film.The migration increases the lubricant amount on film surface,provides enhanced lubrication to the film,and reduces the wear loss.The dispersed characteristic of sizing cream is also responsible for the significant difference in tensile properties of starch film since the existence of the dispersed phase reduces real area of cross section of starch film.

2.3 Effect on mechanical properties of sized yarns

Lubricants are usually presented in size formulation for sizing spun yarns since they not only greatly increase the power of abrasion resistance of sized yarns to the motion of various machine partsand adjacentwarps,butalso improvethe application of sizing agents through decreasing the tendency of the size to stick onto drying cylinders and lowering the forces necessary to split the yarns at lease rods[14].However,lubricants also result in the reduction in tensile strength of starch film and adhesion ofasize to fibers.To improve size application,it is believed that special attention must be paid to the adverse effects such as reduced film-performances and decreased adhesion.Industrial sizing practices indicate that one of efficient ways for reducing their adverse effect is to limit their content used.Currently,weight ratio of lubricants to size base materials in a size formula is usually around 2%(the ratio of dry weight).For this reason,the ratio of 2%is used in the following sizing tests.

Table 1 shows a comparison between POES 10 and sizing cream in mechanical properties of sized cotton yarns.Compared with sizing cream,the use of POES 10 increases the tensile strength and abrasion resistance of sized yarns,and results in a decreased loss in elongation.The observation demonstrates that mechanical properties of the yarns sized with starch and POES 10 are superior to those with starch and sizing cream.Starch film on surface of sized yarns protects sized yarns from mechanical wear.The protection will disappear after the film is rubbed away.Naturally,the less the wear loss of the film,the better the abrasion resistance of sized yarns.For this reason,the abrasion resistance of sized yarns is increased.

Table 1 Comparison between POES 10 and sizing cream in mechanical properties of sized yarns

2.4 Effect on hairiness of sized yarns

Usually,weaving efficiency is directly related to the number of hairs on sized yarns,especially for air-jet weaving machines.The hairiness between adjacent warps is inclined to rise with the increase of the number[15].Fewer hairy yarns are preferred because the yarns with fewer hairs often obtain better performance during the weaving procedure[16].Therefore,the effect of the lubricants on hairiness of sized yarns should be evaluated.The influences of POES 10 and sizing cream upon the hairiness of sized cotton yarns are shown in Table 2.The hairs which are longer than 3 mm are evaluated in term of decrease in hairiness at indicated length intervals.It can be seen that the use of POES 10 is favorable to reduce longer hairs.The dada in Table 2 show the advantage of applying POES 10 over that of using sizing cream in reducing longer hairs.The advantage represents that POSE 10 is superior to sizing cream in improving the quality of sized cotton warps because longer hairs are more dangerous than shorter ones during weaving processes especially for air-jet loom.

Table 2 Comparison between POES 10 and sizing cream in hairiness of sized yarns

It is well known that the hairs on surface of warp yarns can be pulled back onto the body of sized yarns through the adhesion ofsizing pastes.Ithasbeen shown thatthe incorporation of POES 10 into starch does not greatly increase the adhesion contrasting with sizing cream.Therefore,the improvement on decreased hairiness is not obtained through the adhesion mechanism.However,the use of POSE 10 in starch decreases the force necessary to split the yarns at lease rods based on experimental observation.It is the decrease that reduces the occurrence of the second hairiness.For this reason,the decrease of long hairs on sized yarns is mainly attributed to the second hairiness.

It is as well to emphasize that POES 10 is non-ionic whereas sizing cream ionic.The characteristic enhances the adaptation of the lubricant in practical uses because it reduces the sensitivity of the lubricants to hard water.The advantage is favorable to the treatment ofpasting water before sizing process.

3 Conclusions

The observation demonstrates thatPOES 10 exhibits potential use as lubricant in cotton warp sizing for improving the quality of sized yarns.POES 10 is superior to sizing cream mainly due to the improvement in the performances of starch film.When sizing cream is replaced with POES 10,starch film shows stronger tensile strength,greater breaking elongation,and more resistant to wear.The influence of POSE 10 on the adhesion of starch to cotton fibers is similar to that of sizing cream.Like many lubricants,incorporating an overdose of POES 10 into starch paste weakens the adhesion and damages tensile properties of starch film.For the mechanical properties of sized cotton yarns,POES 10 is favorable to sizing cream in increasing tensile strength,reducing the loss in elongation,and improving abrasion resistance.The improvement on abrasion resistance of sized yarns is attributed to the decrease in wear loss of starch film.Furthermore,using POES 10 aslubricantin size formulation is capable of decreasing longer hairs on sized yarns.The decrease is achieved through the reduction of the second hairs formed in warp split process at split rod of sizing machine.

[1]Seydel P V.Textile Warp Sizing[M].Atlanta:Phoenix Printing Inc.,1981:90-106.

[2]Zhou Y Y.Knowledge of Textile Warp Sizes[M].Beijing:China Textile& Apparel Press,2004:438-490.(in Chinese)

[3]Meng N.Study on Molecular Structure and Effectiveness of Polyoxyethylene Stearate as Lubricant for Warp Sizing[D].Wuxi:Jiangnan University,2009:1-16.(in Chinese)

[4]Zhu Z F,Zhuo R X.Controlled Release of Carboxylic-Containing Herbicides by Starch-g-Poly(butyl acrylate) [J].Journal of Applied Polymer Science,2001,81(6):1535-1543.

[5]Zhu Z F,Chen P H.Carbamoyl Ethylation of Starch for Enhancing the Adhesion Capacity to Fibers[J].Journal of Applied Polymer Science,2007,106(4):2763-2768.

[6]Aggarwal V K.Evaluation of Starch and Acrylic Size[J].Indian Journal of Textile Research,1987,12(2):97-99.

[7]Zhu Z F,Cheng Z Q,Guo L M.Effect of Electrolyte Impurities within Starch on the Adhesion of Quaternary Ammonium Cornstarch to Fibers[J].Journal of Donghua University,2008,25(3):328-333.

[8]Zhu Z F,Liu Z J.Monophosphorylation of Acid-Thinned Starch to Enhancethe Quality ofViscose Yarns Sized atReduced Temperature[J].Starch/Stärke,2009,61(3/4):139-144.

[9]Zhu Z F,Zhou Y Y,Zhang W G.Synthesis and Sizing Properties of Grafted Starches as Warp Sizing Materials for Polyester/Cotton Blend Spun Yarns[J].Journal of China Textile University,1994,11(1):22-30.

[10]Athar T.Acrylic Size for Polyester Cotton Blends[J].Textile Research Journal,1983,53(12):791-792.

[11]Deroche P.Adhesive Capacity in Sizing[J].Textile Asia,1986,17(7):58-59.

[12]Trauter J,Vialon R,StegmeierT.Correlation between the Adhesive Strength of Sizes and Clinging Tendency[J].Melliand English,1991,72(8):E251-E254.

[13]Slauson S D,Miller B,Rebenfeld L.Physicochemical Properties of Sized Yams:PartⅠ:Initial Studies[J].Textile Research Journal,1984,54(10):655-664.

[14]Walker R P,Perkins W S.Effect of Sizing Wax on Tensile Properties,Abrasion Resistance,and Weaving Performance of Polyester/Cotton Yarn Sized with Polyvinyl Alcohol[J].Textile Research Journal,1985,55(11):667-671.

[15]Friedman H L,Zhou Y Y,Miller B.Development of Hairiness of Sized Warp Yarns during Flexabrasive Wear[J].Textile Research Journal,1989,59(9):495-500.

[16]Ok H,Carr W W,Park H.Single-End Sizing of Yarn Using a Slot Applicator[J].Textile Research Journal,2007,77(9):686-695.

Journal of Donghua University(English Edition)2012年2期

Journal of Donghua University(English Edition)2012年2期

- Journal of Donghua University(English Edition)的其它文章

- A New Design Method for Variable Digital Filter Based on Field Programmable Gate Array(FPGA)

- Clogging Process Caused by Organic Particle Accumulation and Biofilm Growth in Subsurface Wastewater Infiltration System

- A Stochastic Study on the Wicking Phenomena

- Reverse Solution and Parametric Design of the Conjugate Cam Weft Insertion Mechanism Based on VB.NET and UG

- Isothermal Crystallization Behavior of Poly(ethylene terephthalate)/Carbon Black Masterbatch