Numerical Calculation on the Influence of the Slot Size of Air Injection on Micro Bubbles Drag Reduction for Transitional Craft

WANG Jia-mei,ZHANG Ling

(School of Transportation,Wuhan University of Technology,Wuhan 430063,China)

1 Introduction

The drag reduction by air cavity craft has been confirmed by lots of experimental study,numerical calculation and full scale ship research.There are many factors that influence the micro-bubble drag reduction,such as bubble diameter,bubble volume fraction,main flow velocity,air flow rate and jet form,etc.Some research shows bubble diameter has little effect on drag reduction and the main factors are air injection rate and the distribution of static pressure in boundary layer.Under the same Re(Reynolds number),bubble volume fraction has significant influence on the drag reduction of plate in turbulent boundary layer,and the drag reduction ratio can get up to 22%.Under the same condition,the drag reduction effect caused by jet both from bow and middle is better than that jet from bow only,and the total drag reduction ratio can get up to 32.8%.The public literatures demonstrate a consistent conclusion on the research of micro bubble drag reduction effected by bubble volume density,main flow velocity,air flow rate and gravity.But they also have different conclusions on the influence of air injection hole,slot size,and air bubble size,etc.

2 Physical model and numerical method

2.1 Physical model

The physical model for numerical calculation is a fine transitional craft.The scale ratio is 1:13.The principal dimensions of model as follows:waterline L is 2.692m,half-breadth B is 0.238m and depth T is 0.092m.Considering the surface pressure distribution of original model testing,the air jet slot is arranged at the 7th section,0.3 L away from the bow as the front of step,the range of step is shown in Fig.1 and created by parallel shifting up 4mm vertically.The computational domain is 4L×1L,given in Fig.2.In this paper,the grid is drawn by using sub-block method,and the structure hexahedron grid is used in the whole calculation domain.In order to simplify the question,the ship is supposed to be floating and no drift,the influence of free surface is neglected and the resistance of viscous flow is concerned only.

2.2 Numerical method

2.2.1 Governing equation

The continuity equation,momentum equation and component equation of two-phase flow(micro bubble and water)are respectively shown as follows:

whereρm=γbρb+γwρwandare the density and average velocity of the mixed fluid,respectively.γwandγbare the volume fraction of water and air bubble.The subscripts b,w and m represent the air bubble,water and mixed fluid,respectively.

whereμm=γbμb+γwμwis the viscosity coefficient of mixed fluid.are the drift velocity of water and air bubble;p is the pressure.

The slipping between water and air bubble shows the interaction of the two phases;the relative velocity between water and air bubble is defined as slip velocity.

The following function shows the relationship between drift velocity and slip velocity of air bubble.

2.2.2 k-εturbulent model

The tensor form of turbulent kinetic energy k equation and turbulent dissipation rateεequation show as follows:

In the formulas:k,ε,ui,ρ, μandμtrespectively show the mixed fluid’s turbulent kinetic energy,turbulent dissipation rate,time-averaged velocity,density,dynamical viscous coefficient and the turbulent kinetic viscosity.And t is time.σkandσεshow the mixed fluid’s Prandtl number corresponding to turbulent kinetic energy and turbulent dissipation rate,respectively.Gkis the generation item of turbulent kinetic energy caused by average velocity gradient.C1εand C2εare empirical constants.

2.2.3 Boundary condition

Inlet boundary condition:velocity inlet u=u∞;v=w=0;air bubble velocity inlet:ub=ujet;Outlet condition:outlet boundary is

The wall surface satisfies velocity non-slipping condition:u=v=w=0,others are symmetry boundary condition:Vn=0,∂k/∂n=0,∂ε/∂n=0;

Here u,v and w are the velocity vector’s component along the x,y and z directions,respectively.

2.2.4 Numerical method

In this paper,the governing equation is figured out by using finite volume method based on the unit center.The pressure-velocity coupling adopts SIMPLIC algorithm.The component equation and the dissipation rate equation are calculated by adopting the first-order upwind scheme,while the turbulent kinetic energy equation is calculated by using the second-order upwind scheme.

3 Numerical calculation result and analysis

Relative slot width is defined as B1=B/δ,Froude number.Reynolds number Re=VL/ν.Relative air jet velocity:V1=Vb/V.Where:B is the absolute slot width.δis the boundary layer thickness at slot,calculating from empirical equationδ=0.37(ν/V)1/5x4/5.V is main flow velocity.νis kinematic viscosity coefficient of water.L is ship length.Vbis the absolute average jet velocity.

Under the condition of jet and no jet,three dimensional viscous flow around transitional craft with a step on bottom is calculated numerically by neglecting the influence of free surface.Some flow cases including different relative slot breadth B1,Froude number Fr and relative air injection velocity V1 are considered in this paper.

3.1 The influence of relative air injection velocity and Froude number

The reduction ratio of friction drag is defined as Cn=1-Cf/Cf0.Cfand Cf0are the calculation values of friction drag coefficient with air jet and without air jet.The reduction ratio of friction drag Cnunder different Frand V1 is plotted for B1=0.064 in Fig.3.For fixed Fr,Cnincreases with V1 gradually.When Fr=0.778,Cnhas a peak value.Namely for certain V1,if Fr>0.778,Cnwill reduce.This indicates that Froude number has a critical value Fr0where the drag reduction ratio gets up to the maximum value at certain V1 and B1.This result is consist with the rule of plate obtained from numerical simulation.

The numerical result shows the distribution of air bubble in the bottom of ship is similar under different Fr.The air bubble comes out from slot,moves down stream and to the both sides owing to the buoyancy,and the bubble density is higher there.The phenomenon of air bubble moving to both sides is weaker near stern.The air bubble volume density and coverage area gradually increase as V1 rises,and the drag reduction ratio also increases.Fig.4 shows one result of air bubble volume fraction distribution on the bottom surface.No obvious difference of side escaping of air bubble is observed at different V1.

3.2 The influence of relative slot breadth

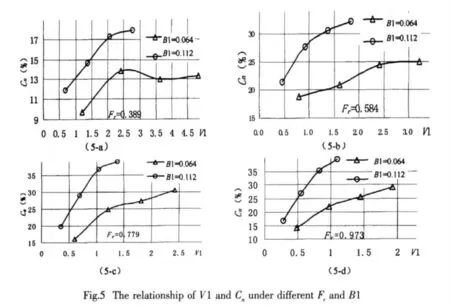

It is shown that Cnchanges with V1 at different Frand B1 in Fig.5.For same Frbut different B1,Cnincreases with the increase of V1 gradually;For all calculated Fr,the curves(Cn·V1)of B1=0.064 are lower than that of B1=0.112.

For every Fr,there is a corresponding B1=B10which guarantees Cnto get maximum value C10from all possible V1 gets.The relationship between Frand C10is presented in Fig.6 now.

Air bubble craft will consume engine power and air injection effect is related with the injection pressure and injection volume.To find the minimum injection volume or relative injection velocity while keeping the same drag reduction ratio is a challenge work for energy conservation.Fig.7 shows relationship between B1 and V1 under the same Fr(Fr=0.973)and drag reduction ratio.

It is shown in Fig.7:For drag reduction ratio is 25%,V1 has an asymptotic value while B1 increases.When relative slot size B1 is about 0.112,the curve trends to about V1=0.4.According to the results of all cases in this paper,the air flow rate reaches minimum while jet slot size is 0.112 at Cn=25% and Fr=0.973.Considering both drag reduction and energy consumption,the following conclusion could be drawn:B1=0.112 is a favorable slot size and V1=0.4 is a favorable relative jet velocity.The slot size is one of the key parameter of drag reduction,and the results will provide reference on the slot size design of model test and full scale application.

4 Conclusions

According to the results of all cases in this paper the conclusions are listed as follows:

(1)Relative air injection velocity has positive influence on drag reduction.Under the same Fr,drag reduction ratio gradually increases with increase of the relative air injection velocity.When the relative air injection velocity increases,the bubble volume fraction on bottom surface will also increase,and friction resistance will decrease.

(2)In the same Fr,relative air injection velocity has little influence on the side escaping of air bubble.The air flow rate reaches minimum while jet slot size B1 is 0.112 at Cn=25%and Fr=0.973.

(3)The minimum power of air injection is needed for the goal of drag reduction ratio 25%under Fr=0.973,if the relative slot size B1=0.112 is adopted.

[1]Dong Wencai,Guo Rixiu.The development of drag reduction with micro-bubble[J].Journal of Ship Mechanics,1998,2(5):73-78.

[2]Huang Yanshun,Wang Zhen.Trends in research of drag reduction by micro-bubbles controlling turbulent boundary layer[J].Ship Engineering,2003,25(1):1-5.

[3]Shen Xiaochun,Steven L,Ceccio,Mare Perlin.Influence of bubble size on micro-bubble drag reduction[J].Experiments in Fluids,2006,41:415-424.

[4]Antonino,Said Elghobashi.Reynolds number effect on drag reduction in a microbubble-laden spatially developing turbulent boundary layer[J].J Fluid Mech,2005,543:93-106.

[5]Wang Jiamei,Jiang Mansong,Zheng Xiaowei,Zhan Dexin.Study of drag reduction of vessel model by microbubble with different injection forms in the towing basin[J].Journal of Huazhong University of Science and Technology,2004,32(12):78-80.

[6]Guo Feng,Bi Yi,Cao Ge.Numerical simulation of friction resistance reduction of a flat plate by micro-bubbles[J].Journal of Naval University of Engineering,2004,32(12):78-80.

- 船舶力学的其它文章

- An Overview of Verification and Validation Methodology for CFD Simulation of Ship Hydrodynamics

- Application of Particle Swarm Optimization Theory in the Hydrofoil Design

- CFD Simulation of the Unsteady Performance of Contra-Rotating Propellers

- Application of Wavelet Denoising in the Modeling of Ship Manoeuvring Motion

- Local Wave Applied to Detect and Characterize Acoustic Emission Signals

- Vibration of Cracked Plates under Tensile or Compressive Load