南川方竹笋? 世界餐桌的山野珍馐

Nanchuan Square Bamboo Shoots,

A Wild Dainty for the World

By Yang Yan/The World and Chongqing

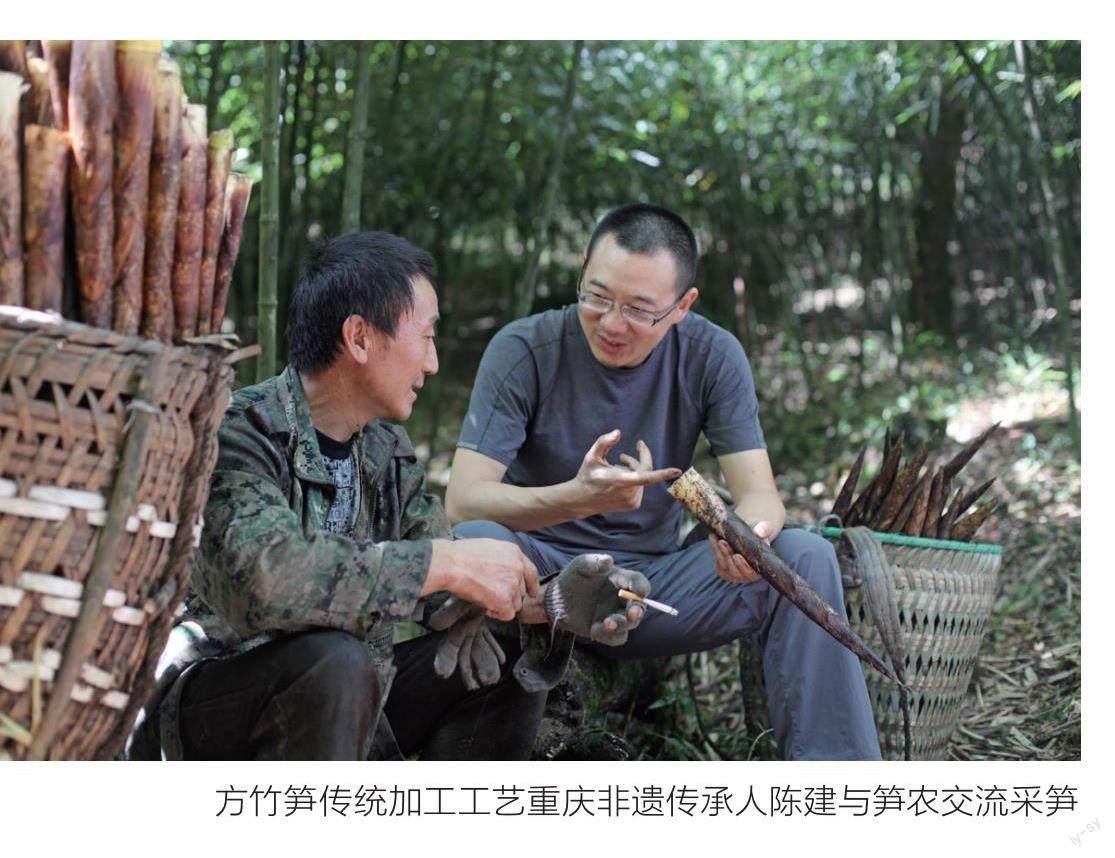

At the product conference of “Chongqing Gifts—Premier Gift of Mount Jin Fo” held in January this year, Chen Jian, inheritor of traditional processing technology of Mount Jin Fo square bamboo shoots and chairman of the board of directors of Chongqing Tezhen Food Co., Ltd, introduced “Premier Gift of Mount Jin Fo” products to the guests. In particular, the Mount Jin Fo square bamboo shoots listed as “2022 Chongqing Gifts for Foreign Affairs” are also at the conference, attracting guests to stop and taste and winning numerous praises.

Ancient Tribute & Current Delicacy

The Mount Jin Fo Square Bamboo Shoots of Nanchuan in Chongqing are renowned as “The King of Bamboo Shoots” by being a purely natural mountain delicacy for being round inside and square outside.

Historical documents show that Nanchuan square bamboo shoot boasts a history of over 900 years. Nanchuan County Annals tells us that the Nanchuan square bamboo shoot was a court tribute in the Jiaqing period of the Qing Dynasty. Botanist professor Yang Rong praised it as “the most delicious bamboo.” The square bamboo shoot business has become one of Nanchuan Districts “3+2” agricultural specialty industries.

The square bamboo shoot has a strict requirement for its growing environment. It grows only in the high-altitude region above 1,400 m. Rainfall in autumn brings a boom in bamboo shoots. August of each year is the harvest season when square bamboo shoots become mature and fresh. They rise above the ground, either show their sharp tops or stand nearly 33 cm high. The bamboo shoot farmers, wearing straw hats, move across forests and are heartened by the harvest.

“There are two difficulties when dealing with the Nanchuan square bamboo shoots. The one is the difficulty of harvesting them because they only grow in high and steep mountains. The other is that it is seasonal and hard to preserve, turning stale and bad after being harvested for 3-5 days. Chen Jian said that to retain the freshness of square bamboo shoots and create more convenience for preservation, farmers in the past set up a cauldron in a bamboo shoot shed, drying them after two days and nights. It is time-consuming and laborious to make 6 kg fresh bamboo shoots into 0.5 kg dried ones, the prices of which are even 30% lower than the fresh ones. A rough estimation shows that the bamboo shoot production volume of Mount Jin Fo in Nanchuan is close to 30,000 tons a year, with only around 10% of the shoots sold as fresh yearly.

Technology Breakthrough & All-Year Selling Boom

The workshops of Chongqing Tezhen Food Co., Ltd. in Nanchuan District are filled with bamboo shoot fragrance. In these workshops, bamboo shoots are processed through steps such as screening, processing, and packaging, into delicacies like smoked bamboo shoots, white oil bamboo shoots, stewed pig feet with square bamboo shoots, bamboo shoots with wild vegetables, preserved pork with sliced bamboo shoots, roast chicken with bamboo shoots for thousands of households meals.

“These are all indigenous square bamboo shoots from Nanchuan.” Chen Jian shared that Tezhen Food has built bamboo shoot processing lines with a yearly processing volume of 6,000-odd tons to promote the fine processing of Mount Jin Fo square bamboo shoots.

Recent years have witnessed the rapid development of the Nanchuan square bamboo shoots industry. Based on traditional dried bamboo shoot production and fresh bamboo shoot preservation, a complete set of scientific systems of raw material treatment, slip drying, rinsing, draining, and drying of square bamboo shoots, as well as bamboo shoot preservation and deep processing, has been developed to produce a variety of square bamboo shoot products with several flavors.

At the fresh storage area, the journalist finds that the square bamboo shoots produced last year are still fresh and tender after the quick-freezing processing. “Nanchuan, combining its industrial layout and focusing on its supply chain services, has been supporting its agricultural product processing enterprises in building processing facilities for storage, preservation, freezing, etc. Quick-freezing and preservation practices with ultra-low-temperature liquid nitrogen technology and intelligent and precise control are widely promoted.” According to Chen Jian, the fresh square bamboo shoots harvested at high mountains can be stored for a long time in general freezers after several minutes of processing.

Owing to such a mature technology, the square bamboo shoots, without being processed by traditional baking and antiseptic technology, can still maintain their primitive nutrients and flavors for more than a year. This makes it possible to break the tradition that fresh square bamboo shoots can only be sold and processed in September and October and offers a guarantee for off-peak sales, deep processing, quality and price increases, thus giving birth to the all-year selling boom of fresh square bamboo shoots.

Nowadays, Mount Jin Fo square bamboo shoots have been transformed from “initial processing” to “deep processing” and from “rough processing” to “fine processing”, which creates a brighter future for developing this industry. Consumers deeply favor the square bamboo shoots harvested in forests after being processed into packaged noodles, biscuits, and fiber foods after washing, slicing, drying, etc.

Produced in Nanchuan & Sold Around the World

The nurturing of square bamboo shoots for several years has promoted the development of related industries such as tourism, transportation, and food, making it the pillar industry of Nanchuan. A total of 200,000 Nanchuan bamboo shoot farmers have planted 300,000 mu of square bamboo shoots with an annual output of 15,000 tons, many of which are exported to Hong Kong, Macao and Taiwan, as well as countries such as the U.S., Japan, Singapore, Malaysia, and Russia, creating an annual output value of RMB160 million.

The Mount Jin Fo square bamboo shoots are also frequently shown in large exhibitions such as the China International Modern Agricultural Exhibition and the Western China (Chongqing) Agricultural Products Fair. Its related products have won honors like the “Brand-Name Agricultural Products,” “Excellent Quality Agricultural Products,” and “The Most Popular Products.” At the 24th China Agricultural Products Processing Industry Investment and Trade Fair, the Nanchuan “Tezhen Food” square bamboo shoots were rated as excellent quality products.

To this day, square bamboo shoots have been sold overseas in diversified forms, while the square bamboo shoot dishes are used to welcome tourists all over the world with their luxurious processing techniques. Chen Jian was once invited to Anuga FoodTec, the largest global professional food grand gathering in Germany, where he has broadened his horizons by interacting with the international food industry players. This gathering exhibited the products and demands of the food and drink industry, enabling him to know more about the developing trend of FMCG. “Though there is still a gap in domestic food processing and trade compared with those of the advanced countries in the world, I still have confidence in agricultural product processing and its future development,” said Chen Jian.

Photo/The Interviewee

文/本刊记者 杨艳

在今年1月举行的“重庆好礼—金佛山首礼”产品发布会上,金佛山方竹笋传统加工工艺重庆市非物质文化遗产第六代传承人、重庆特珍食品有限公司董事长陈建向嘉宾们推介“金佛山首礼”产品。其中,入选“2020重庆好礼·外事礼品”的金佛山方竹筍位列其中,吸引现场嘉宾驻足观赏、仔细品鉴,收获一大波赞誉。

古时贡品今为佳肴

重庆南川金佛山方竹笋,因其主杆截面内圆外方而得名,是纯天然山珍佳肴,被喻为“笋中之王”。

史料显示,南川方竹笋已有900多年历史。《南川县志》记载,南川方竹笋在清嘉庆时期为朝廷贡品。植物学家杨嵘教授赞其“味居竹类之冠”。如今,方竹笋已成为南川区“3+2”特色农业产业之一。

方竹笋对生长环境要求苛刻,只在1400米以上的高海拔地域生长。一场秋雨,一茬秋笋。每年八月,方竹笋肥美鲜嫩,正值收获的季节,破土而出的方竹笋或露出尖尖角,或长出一尺高。笋农戴着草帽,穿梭在竹林间,虽汗如雨下,却满脸喜悦。

“南川方竹笋一直有两大痛点:一是长在高山险峻处,采收难;二是季节性强,采收3—5天后就会变老变坏,保存难。”陈建介绍,为了留住方竹笋的鲜美,更便于保存,过去笋农需在笋棚里支起大锅,经两天两夜炕制成笋干。12斤鲜笋炕成1斤干笋,不仅费时费力,干笋价格还比鲜笋低30%。据粗略统计,南川金佛山每年产笋近3万吨,只有约10%以鲜笋形式销售。

技术突破全年“通吃”

位于南川区的重庆特珍食品有限公司,车间内弥漫着浓郁的竹笋清香,一根根竹笋经过筛检、加工、打包等环节,成为柴火烧笋、白油笋、方竹笋炖猪蹄、野菜笋丝、腊肉笋片、笋烧鸡公等佳肴,端上千家万户的餐桌。

“这都是南川土生土长的方竹笋。”陈建介绍,为了推动金佛山方竹笋精加工,特珍食品建立了竹笋加工生产线,年加工竹笋超过6000吨。

近年来,南川方竹笋产业迅速发展,在传统笋干制作、鲜笋保存的基础上,研发出一套完整的方竹笋原材处理、杀青、漂洗、沥干、烘干及鲜笋保存与深加工科学体系,生产出多种风味的方竹笋产品。

在特珍食品保鲜仓储区,记者发现,经过速冻工艺处理、产于去年的方竹笋依然鲜嫩如初。“南川结合产业布局,聚焦供应链保障,积极扶持农产品加工企业建设贮藏、保鲜及冷冻等初加工设施,广泛推广以超低温液氮技术、智能精准控制为核心的速冻保鲜技术。”陈建说,高山采下的新鲜方竹笋,仅需几分钟处理,就能实现普通冻库长期保存。

依托这一成熟工艺,方竹笋不靠传统烘烤与防腐技术,原生态的营养成分、口感味道也可以保持1年以上,还打破了新鲜方竹笋只能在9月、10月集中上市、集中加工的传统规律,为错峰销售、精深加工、提質增价提供了保障,实现了新鲜方竹笋全年“通吃”。

如今,金佛山方竹笋从“初加工”转向“深加工”,从“粗加工”转向“精加工”,产业发展之路越走越宽。林间的方竹笋经过清洗、切片、烘干等工序,还变身挂面、饼干、纤维食品,深受消费者喜爱。

产自南川远销世界

经过多年培育,方竹笋带动了旅游、运输、食品工业等相关产业的发展,已成为南川的支柱产业。20万南川笋农种植方竹笋面积30万亩,年产量1.5万吨,产品远销至港澳台等地区,及美国、日本、新加坡、马来西亚、俄罗斯等国家,年产值达到1.6亿元。

金佛山方竹笋也频频亮相中国国际农业博览会、重庆·中国西部农产品交易会等大型展会,其系列产品获得“名牌农产品”“优质农产品”“最受消费者喜爱产品”等荣誉称号。在第24届中国农产品加工业投资贸易洽谈会上,南川“特珍食品”牌方竹笋被评为优质产品。

时至今日,方竹笋以各种制品远销海外,方竹笋全宴以其近乎奢侈的工艺迎接全世界游客。陈建曾受邀参加全球规模最大的专业食品盛会——德国科隆国际食品展览会,国际食品行业的交流让他大开眼界,展会上展示了食品饮料行业的产品和需求,让他对快消品的发展趋势有更多了解。“尽管国内食品加工及贸易与世界先进国家相比仍存在差距,但我依然对我们的农产品加工及未来的发展充满信心。”陈建表示。

图/受访者提供

——重庆山水都市旅游