Discussion on Dust Removal (Suppression) System of Crushing Station in Open-Pit Coal Mine

Hong ZHANG, Lin LIN, Bo CAO

Shenyang Engineering Company, China Coal Technology Engineering Group (CCTEG), Shenyang 110015, China

Abstract This paper introduces the method of coal dust treatment in crushing station and the present situation of dust removal system in typical open-pit coal mine crushing station in China, and expounds the research idea of determining comprehensive dust removal (suppression) system in crushing station inspired by the working principle of "range hood". Based on the design example and link optimization of the crushing station of open-pit coal mine I of Thar coalfield, this paper finally draws some conclusions on the key technologies of dust removal (suppression) system of open-pit coal mine crushing station. This study has certain reference value for the technical innovation of dust removal (suppression) system in crushing station, the realization of green mining in "crushing link", and the reduction and avoidance of ecological environment pollution in mining area.

Key words Crushing station, Closed dust cover, Wind curtain wall, Air volume simulation, Dust suppression by spraying

1 Introduction

Semi-continuous mining technology has the advantages of flexibility, strong gradeability, high production efficiency and low operating cost[1]. With the continuous maturity of technology and equipment, it is a rapidly developing equipment technology in recent years. Crushing station is the core equipment and middle link of semi-continuous mining technology, and it is generally set near the mining field of open-pit mine to serve as a connecting link between the preceding and the following, and an "intersection" point between discontinuous technology and continuous technology, that is, materials enter the production system from crushing station by truck.

At present, the open operation of trucks in the process of coal unloading will produce a large amount of disorderly coal dust[2], which leads to the deterioration of equipment working conditions and makes it easy to fail. At the same time, the unorganized emission and accumulation of coal dust cause hidden dangers of fire and explosion, which brings a series of problems such as endangering the health and safety of workers and causing environmental pollution, having become the focus of national and local control. There is "zero" tolerance in the face of environmental protection, and many coal production enterprises have been stopped for rectification due to over-limit coal dust in crushing stations.

2 Present situation of dust removal (suppression) in crushing station

2.1 Coal dust treatment method of crushing stationThere are three methods to solve the problem of dust pollution in crushing stations in domestic open-pit mines, such as dust source sealing, high-pressure spray dust suppression and dry bag filter. Dust source sealing method is to set up buildings on the unloading platform of crushing station to seal and control dust. The truck goes in and out and unloads, it can’t be completely closed, so the dust removal effect is not good. High-pressure spray dust suppression method is to install ultrasonic atomizer to suppress dust in buildings that produce dust, which has good dust suppression effect, but its operation cost and management cost are high and regional climate is greatly affected. Dry bag filter method is to use dry bag filter for dust removal, which has high efficiency, but it needs frequent replacement and maintenance[3].

2.2 Dust removal system of crushing station in domestic open-pit coal minesAt present, the receiving pit of crushing station in open-pit mines in China has set up systematic closed dust removal facility and it is a simple suppression cover. Dry spray dust suppressor or environmental protection spraying gun or mobile sprayer are installed around the discharge outlet to achieve the purpose of dust suppression.

Rectangular colored "covers" are set at the receiving outlet of the first-class crushing stations in Heishan Open-pit Coal Mine in Xinjiang. The "covers" are used to control the back of the coal trucks, and the unloaded coal dust is basically controlled in the colored "covers". The two-way unloading areas are respectively set with "soft curtains" to suppress dust. In addition, two environmental protection water cannons for dust removal are installed on both sides of the colored "cover" to spray when the coal truck unloads, so as to "actively" reduce the diffusion of coal dust. Rectangular colored "cover" is set at the receiving outlet of the first-class crushing station in Shengli No.1 Open-pit Coal Mine to suppress dust, and dry fog dust removal is adopted at the same time. Dry fog dust suppression devices are installed around the discharging outlet of the first-class crushing station in Huolinhe Open-pit Coal Mine, and mobile spraying vehicles are added in the coal unloading area. Anjialing Open-pit Coal Mine adopts mobile spraying vehicle to reduce dust in crushing station. The dust removal method of crushing stations in Heidaigou and Ha’erwusu open-pit mines is dust control with protective dust suppression net + dust locking with water spray + dust removal with guide chute dust collector.

3 Study on dust removal (suppression) system of crushing station

In the process of crushing, the dust produced mainly diffuses and escapes from the receiving and discharge outlets, causing pollution[4]. Since the crushing station of large-scale open-pit coal mine was put into operation in China, various dust reduction measures have been taken, such as setting dust suppression "cover", spraying water (dust suppressant), installing bag filter, and dry fog dust removal. However, all the measures have poor dust suppression (reduction) effect or high cost, and are greatly influenced by regional factors such as easy hardening of filter cloth, lack of real-time monitoring of dust, cold climate and monsoon, so there is no perfect comprehensive dust removal solution. Therefore, under the "green, safe, harmonious, intelligent and efficient" construction idea, in order to realize environmental friendly and civilized production of open-pit coal mine and promote technical progress of the industry, a comprehensive dust removal system in the receiving process of crushing station should be done well, which can reduce and avoid ecological environment pollution in mining areas, protect and comprehensively harness ecological environment in mining areas, with good social and economic benefits.

3.1 Purpose of the study(i) Effectively reducing the concentration of coal dust in crushing station, reducing the damage of dust to crushing station, reducing the failure rate of equipment, shortening the maintenance time, improving the operation efficiency of equipment, indirectly saving costs and ensuring safe production.

(ii) Reducing the harm of dust from crushing stations to the health of employees.

(iii) Through the remote real-time monitoring system, realize that the crushing station area can be operated in an unattended manner, thus reducing the labor intensity of workers.

(iv) Using the Internet, 5G technology and artificial intelligence technology to finally realize comprehensive early warning and control platform for coal dust with four in one ("monitoring, early warning, control and linkage").

(v) Promoting the innovation of dust removal technology in crushing stations and realizing the green mining for "crushing links" in open-pit mines.

3.2 Research ideasIn order to solve the problems of high investment, high energy consumption, weak adaptability and poor dust suppression effect in the existing dust removal technology of crushing station, in accordance with the working principle of "range hood", the research ideas are as follows:

(i) Analysis of coal dust characteristics in crushing station.

(ii) The research contents of dust removal system in crushing station, including the range of dust cover, the structure form of dust cover, the research of system air volume and the selection of fan, the dry (wet) treatment mode of coal dust, the treatment mode of coal dust and wastewater, the entrance and exit mode of truck with dust cover,etc.

(iii) The "four-in-one" early warning and management platform (monitoring-early warning-control-linkage).

4 Design examples

Based on I Open-pit Coal Mine of Thar Coalfield, Pakistan, the dust removal (suppression) system of crushing station is deeply studied according to the research ideas of dust removal (suppression) system of crushing station.

4.1 Introduction to the production systemThe construction scale of open-pit mine is 7.80 Mt/yr, and the semi-continuous mining process of single hopper-truck-movable crushing station is adopted for coal mining. The coal product is raw coal with grain size of 0-300 mm, and it is used in pithead power plant. The production capacity of crushing station is 2 000 t/h, the loading equipment is truck with load of 60 t, and the crushing station is equipped with three unloading areas[5].

4.2 Principle of dust removal (suppression) systemThere are two kinds of dust removal methods in crushing station: unclosed scheme and closed scheme. The unclosed scheme mainly refers to dry fog dust removal, which has good dust removal effect, but its main disadvantage is high operating cost. The dust removal method mainly studied in this paper is a closed dust removal (suppression) system.

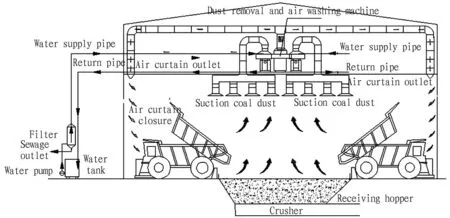

There is a large amount of coal dust produced by the coal truck in the process of unloading coal in the crushing station. In order to improve the working environment, using the existing domestic and foreign technical theories, air fluid, aerodynamics, aerosol theories[6], combined with the working condition characteristics of coal dust produced during the unloading process of the coal truck in the open-pit mine crushing station and the working principle of "range hood"[7], a steel structure sealing cover is installed above the coal unloading pit of the crushing station, and a large amount of coal dust produced during the unloading process of the coal truck is collected by grating sensing and variable frequency start-stop equipment. The mixed gas containing coal dust is pumped out by the pressure of the air blower and then discharged after being treated by the dust collector, and the exhaust outlet is installed at the highest pressure part in the dust cover (eliminating positive pressure). The height of the sealing cover is determined according to the convenience of on-site maintenance and operation. Coal discharging outlets are reserved at the positions of the three reversing areas, and the coal unloading truck is sealed in the dust cover as a whole to prevent dust from spreading to a larger area. The purified air is not discharged to the atmosphere, but is recycled by forming a return air curtain wall to prevent the leakage of coal dust.

To sum up, the dust removal method determined by the project is a comprehensive dust removal method of setting a closed dust cover + a dust collector around the discharge outlet, and its principle is shown in Fig.1.

Fig.1 Principle of dust removal (suppression) system in crushing station

4.3 Dust removal (dust suppression) system scheme

4.3.1Dimensions of dust cover. The size of the receiving hopper in the crushing station of this project is 9 m×9 m. According to the size of unloading platform, truck loading and unloading mode, lifting hopper range, dust sealing and suppression effect, coal dust explosion-proof requirements and other factors, the scheme of dust suppression and sealing at the receiving outlet of crushing station, the tail of coal truck hopper, the whole coal truck and the whole unloading platform is put forward. Considering the range of the closed dust cover, the maintenance space of the dust collector, the process layout, the dust suppression effect and the engineering cost of the dust cover,etc., the optimization and comparison shows that the range of the closed dust cover is to seal the whole body of the coal truck, as shown in Fig.2.

4.3.2Dust cover structure. Considering the weak processing capacity of structural steel in Thar Mining Area of Pakistan (structural steel materials cannot be purchased), the closed dust cover adopts reinforced concrete frame structure, the wall and roof adopt steel purlin and color steel plate for enclosure, with the reinforced concrete as independent foundation.

4.3.3Calculation of exhaust air volume of dust suppression hood. Considering the closed dust cover of reinforced concrete frame structure requires all the dust-producing space to be sealed as far as possible, the suction direction should be the same as the movement direction of polluted airflow as far as possible for dust collection and removal. The height difference of three unloading areas is 9 m, the water content of coal is 40.2% (external water), the load of coal truck is 60 t, the capacity of first-class crushing station is 2 000 t/h, the calculated dust emission capacity is 298.6 kg/h, and the actual exhaust volume is 85 289 m3/h.

4.3.4Comparison and selection of dust removal schemes. The types of dust collectors are divided into dry dust collectors and wet dust collectors. Dry dust collectors mainly include bag dust collectors and electrostatic dust collectors; wet dust collectors mainly include dry spray dust collectors, dust nozzles, water film dust collectors and dust collectors (vibrating wire dust collectors and wet dust removal and air washing machine)[8].

Considering dust removal efficiency, water quality requirements and investment factors, it is determined to adopt wet dust removal and air washing machine, that is, under the action of mechanical force, the washing liquid is atomized into fine droplet particles, which are combined with coal dust particles by impact at a certain speed or emulsifier[9], so as to achieve the purpose of purification. After the dust removal and air washing machine in the dust removal system runs, the dust-containing gas is piped to the dust removal and air washing machine, cleaned and purified by the dust removal and air washing machine to the return air curtain box, and blown out from the air curtain opening.

4.3.5Return air curtain. Soft sealing of open dust production link by air curtain can effectively inhibit smoke dust escape. In accordance with the settings of wet dust removal and air washing system, a return air curtain box is installed above the head of the coal truck, and an air curtain opening is installed below the air curtain box, so that the purified middle air is blown downward to form a wind wall, which separates the inner and outer areas of the closed dust cover, seals the dust and controls the external leakage.

4.3.6Sealing mode of entrance and exit for truck with dust cover. The entrance and exit for coal trucks with closed dust cover can be equipped with rubber curtain, automatic multi-stage lifting gate, air curtain (water curtain),etc.Considering the factors such as the entrance and exit frequency of coal trucks, sealing effect, ancillary facilities of water treatment and project cost, it is determined to use return air curtain to seal the entrance and exit for trucks.

4.3.7Centralized coal dust treatment, water supply and water treatment. After calculation, the water consumption of the air washing machine is 640 m3/d, and the water consumption of the air washing machine is guaranteed by the drainage water of the open-pit mine. After the waste water is collected, it is sent to the treatment room for treatment. The core process of treatment is traditional coagulation + sedimentation + filtration, it is reused after purification, and the treatment scale is 40 m3/h.

5 Optimization of design examples

In the design of dust removal (suppression) system for crushing station of open-pit mine in Thar Coalfield, the core equipment is dust removal and air washing machine. Through market research, communication with relevant dust removal equipment manufacturers, combined with the research of dust removal (suppression) system in crushing station, the original dust removal and air washing machine in the design example is replaced by centralized "shower" aerosol dust removal and air washing machine (the diameter of aerosol water particles for dust removal is 1-10 μm, which is only 1/8 of that of spray water particles for dust removal, and it is easier to combine with coal dust molecules[10]). That is, the air blower unit actively "collects" a large amount of coal dust generated instantly during the unloading process of the coal truck, which is changed into slime water after dust reduction treatment by the centralized "shower" spraying coal reduction system, and the slime water is automatically discharged to the slime pool by the return water pipeline, and the sewage and wastewater are recycled after treatment. See Fig.3 for its optimization principle. When the temperature is low in cold area, it is necessary to add antifreeze to the circulating water system, which can ensure the normal operation of the system in the low temperature environment of -30 ℃.

6 Conclusion

(i) Inspired by the working principle of "range hood", combined with the size of unloading platform of crushing station, truck loading and unloading mode, lifting hopper range, closed dust suppression effect, coal dust explosion-proof requirements and other factors, it is reasonable to recommend using closed dust cover to completely seal the whole coal truck body.

(ii) The closed dust cover structure can be in the form of steel structure and frame structure, and it should be designed according to the actual situation of the project site.

(iii) It is economical and reasonable to seal the entrance and exit for the truck by blowing the return air curtain downward to form a wind curtain wall, so as to isolate the inside and outside of the dust suppression hood.

(iv) This paper studies two schemes, and the core is to establish the flow field model in the dust suppression hood, that is, to "collect" a large amount of coal dust instantaneously generated during the unloading process of coal trucks in time. According to our investigation, there is no application example of dust removal and air washing machine in open-pit coal mine at present, and it is more economical and adaptable to use centralized "shower" spraying coal reduction system instead of dust removal and air washing machine.

(v) Because of the limitation of the paper, this paper only studies the content of the dust removal system of the crushing station, but does not thoroughly study the four-in-one coal dust comprehensive early warning and control platform to finally realize "monitoring, early warning, control and linkage". The establishment of coal dust comprehensive early warning and control platform is an indispensable link for green mining and smart mines in the future.

(vi) At present, there is not a solution with strong adaptability, good effect and low cost in the dust removal (suppression) system of crushing station. This paper puts forward a comprehensive solution idea of dust removal (suppression) system of crushing station, which is of great significance to realizing the green mining of "crushing link" of this project and reducing the pollution of ecological environment in Thar mining area, and also provides a new reference for the comprehensive technical innovation of dust removal system of the first-class crushing station in open-pit coal mine.

Asian Agricultural Research2024年2期

Asian Agricultural Research2024年2期

- Asian Agricultural Research的其它文章

- Food Security Problems and Solutions in China Based on the Strategy of Sustainable Agricultural Development

- Effects of Fungi Fusarium sp. to Rhizosphere Soil and Physiological Characteristics of Camellia oleifera Abel.

- Promoting High-quality Development of Grain and Oil in Ethnic Areas of the Yangtze River Economic Belt from the Perspective of Agricultural Power

- A Comparative Study on Factors Influencing Food Security in China and India

- Animal Safety Test of Bacillus thuringiensis BT Protein

- Study on Germplasm Resources of Peach Cultivars