Nonlinear Study on the Mechanical Performance of Built-Up Cold-Formed Steel Concrete-Filled Columns under Compression

Oulfa Harrat ,Yazid Hadidane ,S.M.Anas ,Nadhim Hamah Sor ,Ahmed Farouk Deifalla ,Paul O.Awoyera and Nadia Gouider

1Civil Engineering Laboratory,Faculty of Technology,Department of Civil Engineering,Badji Mokhtar-Annaba University,P.O.Box 12,Annaba,23000,Algeria

2Department of Civil Engineering,Faculty of Engineering and Technology,Jamia Millia Islamia(A Central University),New Delhi,110025,India

3Civil Engineering Department,University of Garmian,Kalar,46021,Iraq

4Department of Civil Engineering,Harran University,Sanliurfa,63510,Turkey

5Structural Engineering and Construction Management Department,Future University in Egypt,New Cairo,11835,Egypt

6Department of Civil Engineering,Covenant University,Ota,112233,Nigeria

ABSTRACT Given their numerous functional and architectural benefits,such as improved bearing capacity and increased resistance to elastic instability modes,cold-formed steel(CFS)built-up sections have become increasingly developed and used in recent years,particularly in the construction industry.This paper presents an analytical and numerical study of assembled CFS two single channel-shaped columns with different slenderness and configurations(backto-back,face-to-face,and box).These columns were joined by double-row rivets for the back-to-back and box configurations,whereas they were welded together for the face-to-face design.The built-up columns were filled with ordinary concrete of good strength.Finite element models were applied,using ABAQUS software,to assess mechanical performance and study the influence of assembly techniques on the behavior of cold-formed columns under axial compression.Analytical approaches based on Eurocode 3 and Eurocode 4 recommendations for un-filled and concrete-filled columns respectively were followed for the numerical analysis,and concrete confinement effects were also considered per American Concrete Institute (ACI) standards for face-to-face and box configurations.The obtained results indicated a good correlation between the numerical results and the proposed analytical methodology which did not exceed 8%.The failure modes showed that the columns failed due to instabilities such as local and global buckling.

KEYWORDS Cold-formed steel;built-up sections;slenderness;rivets;welded;axial compression;analytical approaches;confinement;buckling

Nomenclature

CF-CFS Concrete-filled cold-formed steel

CFS Cold-formed steel

CFST Concrete-filled steel tube

At the end of the party, he invited her to have coffee with him, she was surprised but due2 to being polite, she promised. They sat in a nice coffee shop, he was too nervous to say anything, she felt uncomfortable, and she thought to herself, Please, let me go home...

B Width of the cross-section

bpWidth of the profile

H Height of the cross-section

Concrete-filled steel tube(CFST)columns find frequent application in civil construction as a reliable solution to address buckling issues,owing to their geometrical qualities,outstanding compression and fire performance,excellent strength,and ductility compared with reinforced concrete or ordinary steel sections[27–30].The appropriate combination between steel and concrete,especially in the case of tubular columns,offers a commendable concrete confinement effect,particularly when contrasted with square columns,due to the favorably low width/thickness ratio[31].While the confinement effect of the steel tube on the concrete core improves the concrete’s resilience,the concrete core in the steel tube mitigates or retards the onset of local buckling in the steel tube[32].Various researchers found that the confinement effect between the outer steel tube and the concrete fill is a key factor for CFST columns,which implied that the concrete inside these tubes required no additional formwork or reinforcement,as its outer surface is shielded from any exterior influences [33,34].Also,local buckling of the steel tube is postponed,since it can only occur within the concrete,which itself can only deform on the outside[35].

R Bend radius

t Thickness of the cross-section

Beware of it! The prince read and bared his head and lifted his hands in supplication to Him who has no needs, and prayed, O Friend of the traveller! I, Thy servant, come to Thee for succour

B’ Width of the concrete

He took the precaution of surrounding the palace with a dense32 cloud, and then hastened to his Court, where his prolonged absence was causing much anxiety

The fool, however, spoke up, and said that he could do so quite easily, and the king then came forward with the six bushels of money which the youth had lent him

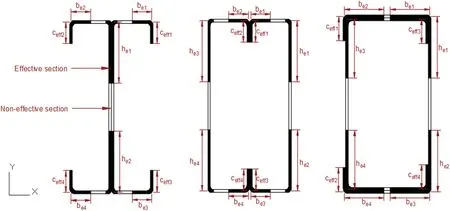

The design process was based mainly on determining the critical elastic loads for these failure modes.The effective cross-sections of the models studied were of Class 4 and under compression as presented in Fig.7.

The guy was devastated10, as it was a complete loss. Why did fate played such cruel games with him? He cursed the heaven for taking her away from him, denying even one last look at her! How cruel he cursed! How he damned the God!! How he hated himself... for taking so long to realize his mistake!! That was in 1996.

EsYoung’s modulus of steel

νsPoisson’s ratio of steel

I believe that big boar would be of more use here than I am, he thought, and lo! at the wish the wild boar came and began to push hard against the wall

fcCompressive strength of unconfined concrete

εcCompressive strain of unconfined concrete

flThe confining pressure of the concrete

EccModulus of elasticity of concrete

νcPoisson’s ratio of concrete

fccCompressive strength of confined concrete

εccCompressive strain of confined concrete

k3Material degradation parameter

AeffEffective cross-sectional area

Nc.RdCompressive strength

So they were married, and in the middle of all the festivities and rejoicings the bride s father came home and was not a little surprised at finding his daughter celebrating her wedding

βACoefficient of reduction of the section

At the end of this time he had fallen in love with a charming Princess, but that when he had shut himself up into a room with her, and had thrown off his snake s skin, her parents had forced their way into the room and had burnt the skin, whereupon the Prince, changed into the likeness29 of a dove, had broken a pane of glass in trying to fly out of the window, and had wounded himself so badly that the doctors despaired of his life

AcCross section of concrete

AsCross-section of steel

γM1,γcPartial material safety factor of steel 1.1 and concrete 1.5,respectively

NcrThe elastic critical normal force for the relevant buckling mode,calculated with the effective flexural stiffness(EI)e

He spoke very excitedly,saying that their evil propensities4 would not be destroyed, norwould the fire be extinguished, and they should never find rest

(EI)eThe flexural rigidity of the composite column relative to the buckling plane considered

lfBuckling length of the column

EcmThe secant modulus of elasticity of the concrete

γcThe safety coefficient for stiffness which was equal to 1.35

NPl,RThe value of the plastic resisting normal force NPl,Rdcalculated by setting all partial safety factorsγM1,γcequal to 1(i.e.,using the characteristic strengths of the materials)

He had now to begin all his work over again, but by this time it only wanted an hour of evening, when the witch was to be expected home, and he easily saw that it was impossible for him to be finished by that time

γDensity

fyYield strength of steel

She kept the house in order for them; in the mornings they went to the mountains and looked for copper and gold, in the evenings they came back, and then their supper had to be ready

fuTensile strength of steel

εyYield strain of steel

εuUltimate strain of steel

fctmAverage tensile strength

χdThe reduction coefficient

fctk0.05,fctk0.95Characteristic tensile strengths of concrete

1 Introduction

In recent years,the utilization of cold-formed steel(CFS)components in the construction industry has surged,primarily due to advancements in manufacturing technology,which encompass superiorquality steel,intricate section designs,and enhanced forming techniques [1,2].These developments have not only enhanced the competitiveness of this structural solution but have also resulted in a growing market share on a global scale[3,4].Cold-formed steel materials are commonly shaped into a variety of sections,such as Z-sections,C-channel sections,hat sections,and other specialized profiles[5,6].Typically,these shapes are achieved by cold-forming steel sheets through either bending or rolling processes to attain the desired configurations [7–10].Thin-walled CFS sections,in particular,are increasingly establishing a presence in the steel construction industry owing to their lightweight nature,rapid and straightforward assembly,precision in dimensionality,and wide range of achievable shapes[11–14].However,it is important to note that these thin-walled elements,especially those featuring open cross-sections,are highly susceptible to structural instabilities like local and distortional buckling.Consequently,to support significant loads,the use of assembled elements becomes indispensable[15].

In the construction industry,the significance of CFS built-up elements has grown substantially in recent times driven by their numerous advantages,including enhanced strength and rigidity,underpinning their employment when hot-rolled or CFS individual sections cannot support the applied loads[16–18].Assembled sections generally consist of two or more sections connected either back-to-back to create open sections or face-to-face to produce closed sections[19,20].It is noteworthy that the axial compressive capacity of built-up elements is typically twice as robust as that of their constituent parts.Furthermore,closed sections exhibit superior torsional rigidity compared with open sections[21].

Cold-formed profiles come with certain drawbacks,notably their elevated slenderness(width/thickness ratio),which can lead to instability modes within the cross-section,including local,distortional,and global buckling [22,23].When these profiles are subjected to forces applied in their plane,part of the cross-section in compression may buckle long before reaching its elastic limit,although,the presence of this buckling is not automatically accompanied by the ruin of the member.Through buckling,the cross-section of a member is deformed,and this deformation causes rotations without any translation(pure rotation)[22,24].Furthermore,global buckling is characterized by a translation as a rigid body(translation and/or rotation without undergoing deformations)without an invariability of the cross-section at the level of the flanges and the web.In contrast,buckling by deformation affects part of the corners and stiffeners,leading to lateral displacement[25,26].

C Length of dropped edge

Recently,the development of concrete-filled cold-formed steel(CF-CFS)built-up columns offers the flexibility of combining in diverse geometric configurations,as this pairing of steel and concrete not only augments the load-bearing capacity of the structural element under compression but also elevates the structure’s fire resistance and safety.Consequently,these composite solutions have the potential to overcome instability problems,further exploit the mechanical properties,and promote the utilization of high-strength steel [36].Rahnavard et al.[37–40] investigated the performance of cold-formed steel built-up columns filled with concrete under various parameters,encompassing compression,fire resistance,and equivalent temperature.Their obtained results showed a good accuracy between the experimental results and the proposed methodology.Craveiro et al.[41] investigated the factors influencing the fire performance of concrete-filled built-up cold-formed steel columns including dimensions,properties,and geometry.The findings demonstrated that the combination of steel and concrete components provided improved fire resistance,delaying structural failure,and ensuring the columns’integrity during fire events.Chen et al.[42]investigated how axial compression loads affect the structural behaviour of built-up cold-formed steel section stub columns filled with concrete.To assess the columns’load capacity,deformation,and failure modes,experimental tests were carried out.Additionally,the behaviour of the column was examined by considering some factors,such as column dimensions,steel thickness,and concrete grades.In the research by Teoh et al.[43],the cold-formed concrete-filled box columns were put through experimental tests to determine their deformation characteristics,load-carrying capacity,and failure modes.The findings shed important light on these columns’structural reaction and failure mechanisms,as well as on how to improve their design and use them in building projects.In addition,Senthilkumar et al.[44]studied the effect of longitudinal stiffeners under compression on the cold-formed steel square columns filled with concrete for various slenderness values,both numerically and experimentally.It demonstrated that there was a positive impact of the stiffeners within the slenderness range,attributed to a reduction in the buckling factor.

According to the literature,EN 1994-1-1[45]addresses fundamental concepts and related design methods of hot-formed composite columns (steel-concrete).However,there is a notable absence of research regarding the behavior of cold-formed steel columns filled with concrete.To strengthen the understanding of this category,a very powerful numerical model has been developed that takes into consideration the fabrication process of cold-formed elements and aims to identify the most efficient design to reduce column instability.

When a slender member with a small thickness is subjected to axial compressive loading,it may locally buckle at certain points along its length where the stresses are highest.Therefore,it is necessary to analyze factors contributing to local buckling,such as the applied loads,and boundary conditions.All recent studies neglected to consider the influence of the assembly method on the behavior of coldformed steel built-up columns filled with concrete.The behavior of rivets was replaced by interactions,which do not reflect the reality in practice.This paper presents a nonlinear numerical and analytical study of double-C columns constructed from cold-formed steel in different configurations (backto-back,face-to-face,and box) of various lengths (600,1200,1800,and 2000 mm).The addition of concrete in these built-up columns could significantly enhance the mechanical performance of CFS sections and reduce instability-induced deformations.The nonlinear numerical simulation was based on the finite element method and was performed using ABAQUS software.To validate the numerical results,an analytical approach based on the specifications of EN 1993-1-3[46]and EN 1994-1-1[45]was employed,along with the use of ACI[47]to integrate the confinement theory.Additionally,the paper examines the effects of local buckling on stress distribution and lateral strains in the assembled columns,highlighting the redistribution of stresses following buckling.

2 Analytical Investigations

The main objective of civil engineering is to create more economical and resistant elements.This is achieved through research into new profile shapes,calculation methods,and assembly techniques.As a result,modern techniques are converging toward composite sections.This study was devoted to determining the mechanical strength of cold-formed composite columns,both un-filled and filled with concrete.Each column was comprised of two cold-formed steel C-profiles with different configurations.These composite columns were then filled with ordinary,non-reinforced concrete,which had a density of approximately 2400 kg/m3.

Several types of research have confirmed that the un-filled cold-formed steel built-up column filled with concrete is a better solution that can be used.The analytical part of this investigation was based on Eurocode 3 Part 1-3 [46],which covers the construction of cold-formed steel buildings and civil engineering structures.Eurocode 4 Part 1-1 [45] covers the design methods for composite elements(steel-concrete).

2.1 Geometry Details of the CFS Built-Up Columns

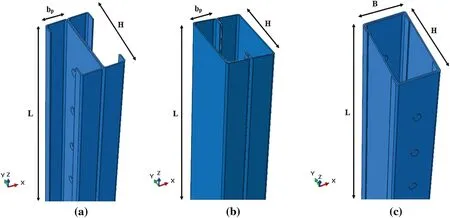

Our research focused on studying the behavior of cold-formed built-up columns through the effect of slenderness (Fig.1).Three positions of assembled cold-formed columns were investigated:the first was a back-to-back configuration(Fig.2a),where the two C-sections were connected at the web using double row flat-head rivets with a transverse pitch of 35 mm.However,the longitudinal pitch between the rivets was 50 mm as shown in Fig.2d.The second configuration involved a face-to-face arrangement with connections made through ordinary welding(Fig.2b).The rivets used were 6 mm in diameter and of nuance S235,with a tensile strength at rupture of 400 MPa.In the box configuration,the rivets were placed in the upper and lower flanges at 50 mm spacing in a single row(Fig.2c),and the use of this configuration offered many advantages such as stiffening the flanges of the assembled element and eliminating the need for concrete formwork during pouring.

NPl,RdThe plastic resistance

Figure 1:Three-dimensional geometry of CFS built-up un-filled profiles:(a)Back-to-back;(b)faceto-face;(c)box

Figure 2:Cross-section of assembled CFS un-filled models:(a)Back-to-back;(b)face-to-face;(c)box;(d)longitudinal view of the back-to-back model

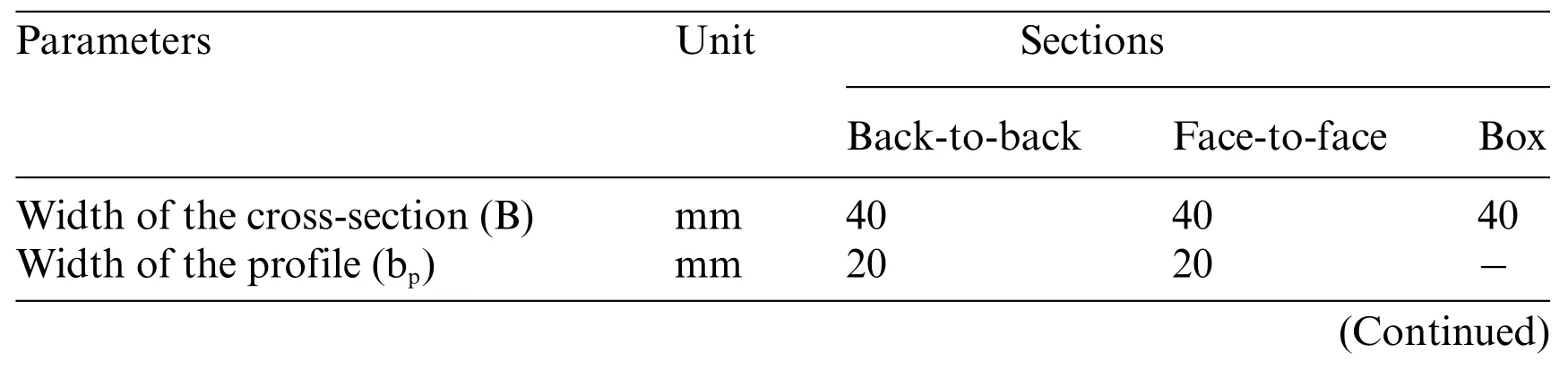

The three models shown in Fig.1 were filled with concrete of strength class C25/30,as depicted in Fig.3.The cross-sectional geometry of the un-filled and concrete-filled columns is shown in Figs.2 and 4,respectively.The dimensions were chosen following the rules and limitations of Eurocode 3 Part 1-3 [46].Therefore,we studied cold-formed double-C columns of different lengths (600,1200,1800,and 2000 mm) with a thickness of 1.2 mm.The steel quality was CR250,classified as Class 4.All geometrical properties of the un-filled and concrete-filled models are presented in Table 1.

Table 1:Geometrical properties of cold-formed steel built-up C-sections

2.2 Concrete

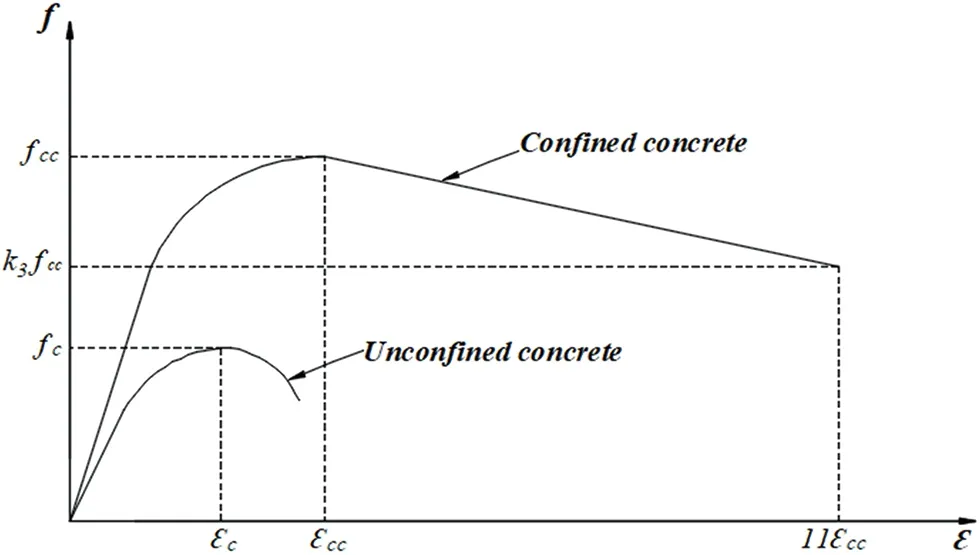

The behavior of concrete-filled columns presented in Fig.5 was based on the theories of confined concrete,which were abstracted from the ACI(American Concrete Institute)Committee 318(1999)[47].From the stress-strain relationship curves,the compressive strength fcof unconfined concrete and its corresponding strain εc,which equals 0.003 according to the ACI,were smaller than those of confined concrete(fccand εcc).This indicated the use of confinement parameters.

Figure 3:Three-dimensional geometry of CFS built-up profiles filled with concrete:(a)Back-to-back partially encased with concrete;(b)face-to-face filled with concrete;(c)box filled with concrete

Figure 5:Stress-strain relationship of unconfined and confined concrete

As derived from Mander et al.[48],the termination of the compressive plastic strain and strength of confined concrete is suggested in Eqs.(1)and(2):

wherek1andk2are constants based on the study by Richart et al.[49]and which were set as 4.1 and 20.5,respectively;εcandfcare the compressive strain and strength of unconfined concrete,respectively;εccandfccare the compressive strain and strength of confined concrete,respectively;flis the confining pressure of the concrete.

The B/t ratio significantly influences the behavior of concrete-filled columns,especially in minimizing local instabilities.When the B/t ratio is high,reinforced columns are more likely to experience local buckling compared with those with a low B/t ratio[31]:

where B is the width of the cross-section;t is the thickness of the cross-section;fyis the yield strength of steel.

I was cleaning out my sleigh() before my trip this year and came across this package that was supposed to be delivered on December 25, 1925. The present inside has aged12, but I felt that you might still wish to have it. Many apologies for the lateness of the gift.

For concrete-filled rectangular sections,the material degradation parameter,k3,is given by[31]:

The studied sections were classified as Class 4,influenced by the ability of the cross-sections to plasticize,wherein local buckling limits the compressive strength for axially loaded elements.The determination of the effective cross-section properties was based on the effective width method detailed in Eurocode 3 Part 1-3[46].

48. Kind heaven help us now!: Gretel prays for heavenly assistance. Once again, these religious references were added by the Grimms.Return to place in story.

2.3 Effective Section

The determination of the effective cross-section was based on the effective width method according to EN 1993-1-3 [46] and the study by Ye et al.[24].In the effective width approach,rather than considering the non-uniform distribution of stress across the width of the element,it is assumed that the entire load is supported by an effective width be,which is subjected to uniformly distributed stress equal to the stress at the edge of the plate[50,51],as illustrated in Fig.6.

Figure 6:Evolution of the stress distribution during the loading of a stiffened element

The calculation of the post-critical force of a stiffened planar element was thus simplified to determine the effective width.Also,strength reductions due to local buckling effects were considered.For the C-section,the effective width was determined for each compression part and then the ultimate load of the section could be obtained by assuming that the load was taken up only by the effective sectors.The effective cross-section for a C-section was determined by the following equation:

whereχdis the reduction coefficient.

H’ Height of the concrete

2.4 Buckling Resistance according to Eurocode 3 and Eurocode 4

For the Class 4 un-filled built-up short columns,local buckling in one or more cross-sections prevents the attainment of the plastic flow load,limiting the design compressive strength to the local buckling resistance.The compressive strength is given by:

where Aeffis the effective cross-sectional area,and Nc.Rdis the compressive strength.

Figure 7:The effective cross-sections of the studied columns

For compressed slender columns,resistance verification according to Eurocode 3[46]was based on the buckling lengths for each of the two main axes,depending on the connections at their ends.Furthermore,the minimum moment of inertia required to withstand the critical Euler loads was used to pre-dimension the element.The verification formula given in Eq.(9)was then applied,where the reduced slendernessand the coefficientχwere calculated based on the profile’s fabrication process and edge thicknesses,using one of the buckling curves and the slenderness.

whereβAis the coefficient of reduction of the section,Asis the cross-section of steel.

To determine the design buckling resistance Nsdfor composite columns which was specified in EN 1994-1-1[45],the reduction coefficientχwas calculated according to EN 1993-1-3[46]presented in Eq.(11).

There is a complete interaction between the steel section and the concrete section,right up to the point of failure.Geometric and structural imperfections were considered in the calculation,and the straight sections remained flat when the column was deformed.The compressive strength in the case of concrete-filled columns proposed by EN 1994-1-1[45]was obtained by adding the plastic strengths of the constituent elements(steel plus concrete)of that section.Cold-formed steel profiles are classified as Class 4 according to EN 1993-1-3[46],so the effective cross-section was the one that was performed.Therefore,Eqs.(12)and(13)were for sections

Computer Modeling In Engineering&Sciences2024年6期

Computer Modeling In Engineering&Sciences2024年6期

- Computer Modeling In Engineering&Sciences的其它文章

- A Study on the Transmission Dynamics of the Omicron Variant of COVID-19 Using Nonlinear Mathematical Models

- Novel Investigation of Stochastic Fractional Differential Equations Measles Model via the White Noise and Global Derivative Operator Depending on Mittag-Leffler Kernel

- Saddlepoint Approximation Method in Reliability Analysis:A Review

- A Review of the Tuned Mass Damper Inerter(TMDI)in Energy Harvesting and Vibration Control:Designs,Analysis and Applications

- Recent Advances on Deep Learning for Sign Language Recognition

- A Survey on Blockchain-Based Federated Learning:Categorization,Application and Analysis