A Review on Engineering Transition Metal Compound Catalysts to Accelerate the Redox Kinetics of Sulfur Cathodes for Lithium-Sulfur Batteries

Liping Chen, Guiqiang Cao, Yong Li, Guannan Zu, Ruixian Duan, Yang Bai, Kaiyu Xue, Yonghong Fu, Yunhua Xu, Juan Wang✉, Xifei Li,4✉

ABSTRACT Engineering transition metal compounds (TMCs) catalysts with excellent adsorption-catalytic ability has been one of the most effective strategies to accelerate the redox kinetics of sulfur cathodes.Herein, this review focuses on engineering TMCs catalysts by cation doping/anion doping/dual doping, bimetallic/bi-anionic TMCs, and TMCs-based heterostructure composites.It is obvious that introducing cations/anions to TMCs or constructing heterostructure can boost adsorption-catalytic capacity by regulating the electronic structure including energy band, d/p-band center, electron filling, and valence state.Moreover, the electronic structure of doped/dual-ionic TMCs are adjusted by inducing ions with different electronegativity, electron filling, and ion radius, resulting in electron redistribution, bonds reconstruction, induced vacancies due to the electronic interaction and changed crystal structure such as lattice spacing and lattice distortion.Different from the aforementioned two strategies, heterostructures are constructed by two types of TMCs with different Fermi energy levels, which causes built-in electric field and electrons transfer through the interface, and induces electron redistribution and arranged local atoms to regulate the electronic structure.Additionally, the lacking studies of the three strategies to comprehensively regulate electronic structure for improving catalytic performance are pointed out.It is believed that this review can guide the design of advanced TMCs catalysts for boosting redox of lithium sulfur batteries.

KEYWORDS Lithium—sulfur battery; Redox kinetic; Transition metal compounds catalyst; Multiple metals/anions

1 Introduction

Lithium-ion batteries are the most successful energy storage system developed in the past 30 years for their relatively high energy density and cycle stability.However, the limited theoretical energy density (420 Wh kg-1) of lithium ion batteries does not meet the requirements of some applications such as electric vehicles, and it has been urgent to develop high-performance batteries with higher energy density [1].Lithium—sulfur batteries (LSBs) have been widely concerned since 2009, when Nazar adopted mesoporous carbon as sulfur host, bringing its development possibility for high theoretical specific capacity of 1675 mAh g-1and energy density of 2600 Wh kg-1[2, 3].Liquid electrolyte solves the sluggish kinetic of solid—solid reaction of LSBs from the initial S8directly to the final reaction product of the Li2S.However, challenges of LSBs come along with liquid electrolytes.Various intermediates lithium polysulfides (LiPSs, Li2Sn, 2 ≤n≤ 8) are formed during multi-step charge—discharge process, and their solubility in the electrolyte causes their department from cathode materials [4].The infamous shuttle effect of LiPSs is formed in the electric field, which leads to the loss of sulfur species and capacity fading [5].

Since 2009, carbon materials represented by porous carbon have been used to physically adsorb LiPSs to mitigate the shuttle effect [6, 7].Then, polar materials including doped carbon materials and various transition metal compounds (TMCs) with chemical interaction with LiPSs were introduced to sulfur cathodes, interlayers and modified separators [8, 9].However, physical confinement with weak interaction and chemisorption strategy with limited adsorption sites are still not ideal to solve shuttle effect [2, 10].Additionally, the chemisorption for LiPSs is not a determinant of the cathode performance [11].The conversion of S8→ Li2S8is relatively easy and spontaneous, while the long-chain LiPSs are easily dissolved, and the transformation of Li2S4to Li2S2/Li2S requires high activation energy, which leads to the accumulation of LiPSs, and aggravate the shuttling effect.In addition, the transition from Li2S2to Li2S is slow in charge transfer kinetics due to its insulating properties, which is the most difficult stage and regarded as the rate-limiting step during discharging [12, 13].During the charging stage, the oxidation of Li2S needs to overcome high energy barrier due to its slow kinetics, leading to the high overpotential [14].Therefore, the key factor of the shuttle effect is the sluggish reaction kinetics of LiPSs/Li2S in addition to the solubility of LiPSs [10].If LiPSs is not quickly converted, the active sites will be occupied, resulting in the reduction of adsorption effect [12].Therefore, catalytic effect is regarded as the more promising strategy to fundamentally solve the problem [10].The catalysts can not only anchor LiPSs, but also boost the conversion from LiPSs to Li2S and the oxidation of Li2S, shorten the existence time of LiPSs and reduce the accumulation of LiPSs, effectively alleviating the shuttle effect [5].

2 Advanced TMCs Catalysts

2.1 Characteristics of Catalysts for Sulfur Cathodes

Efficient catalysts for sulfur cathodes should possess the following advantages: high conductivity, rapid electron/ion transfer, moderate adsorption capacity, excellent catalytic activity and abundant active sites to promote the redox of LiPSs/Li2S [15].The catalytic capacity of sulfur catalysts is firstly related to their conductivity.The LSBs involve multielectron reaction, and the high conductivity will promote the electrochemical reaction [16].Secondly, catalysis requires the adsorption of LiPSs to active sites.If LiPSs are weakly adsorbed or cannot fully contact with catalytic sites, the catalytic effect cannot be fully played [12].The interaction of polar materials and LiPSs also promotes charge transfer between them, provides Li2S nucleation sites and regulates its uniform deposition as well as Li2S decomposition [16, 17].In the meanwhile, the transferred electrons determine the strength of the interaction [18].On the other hand, too strong adsorption for LiPSs will occupy active sites and hinder further conversion of LiPSs [12, 19].Most importantly, the intrinsic catalytic activity is the fundamental factor for the catalytic effect [13].Additionally, the fast diffusion rate of Li+not only promotes the electrochemical reaction, but also reflects fast electrochemical reaction kinetics [20, 21].Some catalysts can even adjust the electronic structure of adsorbed Li2S, conferring an insulator-to-metal transition to improve the conductivity of Li2S [22].

2.2 Advantages of TMCs Catalysts for LSBs

At present, tuning reaction kinetics of LSBs has been extensively investigated through electrolyte mediators, non-metal catalyst, and nanostructured metal-based catalysts.Among them, electrolyte mediators can effectively manipulate the conversion behavior of sulfur and Li2S such as reaction pathway, types of LiPSs, voltage polarization, Li2S deposition morphologies, and Li2S activation by controlling solvent species, LiPS dissolvability, salt species and concentration, addition of electrolyte additives as well as solid-state electrolytes.However, the electrolytic liquid system is complicated, and there are contradictions with the compatibility of lithium anodes, ionic conductivity, and viscosity [23].Non-metal materials like black phosphorus and functionalized carbon possess significant advantages in high specific surface area and light weight, the former is conducive to increasing the active area to promote the electrochemical reaction processes, and the latter is beneficial to improving the mass energy density of the battery.Unfortunately, black phosphorus only presents strong adsorption ability for LiPSs at the edge, but weak in the plane, showing the characteristics of edge selective catalysis [24].Similarly, the polar sites on the surface of modified carbon materials are limited.Moreover, the non-metal-Li bond formed between doped anions of functionalized carbon and Li of LiPSs does not play a key role for LiPSs adsorption as S-binding between metal atoms in TMCs and S atoms in LiPSs [25].Additionally, metal-based catalysts include supported single atom catalysts (SACs), metallic nanostructures, and TMCs.SACs with theoretical 100% atomic utilization, unsaturated coordination environment, and unique electronic structure are expected to achieve efficient catalysis for LSBs [1].However, SACs still suffer from the problem of poor stability, easy aggregation and low load due to their high surface energy.Nanostructured metal materials with sulfiphilicity, excellent conductivity and catalytic activity are another kind of excellent catalysts for LSBs [26].Alloys can effectively regulate its electronic structure with different metal elements, such asd-band center, thus improving the catalytic activity [27, 28].However, the enhanced catalytic properties which are closely related to optimized electronic structure via compositional design are rarely in depth studied in LSBs.Simultaneously, the nano-alloy catalysts are lack of the chemical interaction with LiPSs through Li-non-metal bonds, and could not adjusted by non-metal ions.In contrast, TMCs have been extensively studied in LSBs, including metal oxides, sulfides, nitrides, carbides, phosphide, selenides, metal—organic framework (MOFs) due to excellent chemisorption and catalytic effect.Qian revealed that Co-based compounds followed the order of CoP > Co4N > CoS2> Co3O4to accelerate the redox kinetics of LSBs.The essential reason is that thep-band center of CoP was upshifted obviously, reducing the energy gap between thed-band center of Co and thep-band center [29].Metal selenides exhibit similar crystal structure and polarity characteristics to sulfides, while much higher conductivity and catalytic activity [30].All the metal-based catalysts containdorbitals of transition metals that can be hybridized with theporbital of S of LiPSs/Li2S, thereby reducing the reaction barrier by changing the electronic structure of LiPSs/Li2S [31, 32].Moreover, thedandporbitals of TMCs are hybridized with thepandsorbitals of S and Li in LiPSs, forming metal-S bonds and Li-nonmetallic bonds, which makes TMCs possess larger modulation space of electronic structure to anchor and catalyze LiPSs more effectively through introducing metal ions or anions [33, 34].

Most importantly, it is difficult for single-component catalysts with single electron donor or acceptor nature to catalyze multi-step conversions of sulfur cathodes, and different metal cations of TMCs can provide different binding strength, binding preferences and catalytic functions for diverse LiPSs.It is of great significance to construct TMCs catalyst with more components for addressing the complex redox of LSBs through enriching active sites, designing multi-function and synergy effect [23, 35, 36].Additionally, TMCs catalysts with multiple metals/anions can optimize intrinsic catalytic activity with tuned electronic structure, and show huge room for regulation.Consequently, more and more TMCs catalysts with multiple metal ions or anions are proposed to enrich active sites, improve conductivity, chemisorption and catalytic activity.The design principles, structures and properties of various bimetallic compounds used as sulfur host materials, doping modification for carbon materials, C3N4and MXenes, and advances in heterostructure optimization for sulfur cathodes, interlayers and lithium anodes have been reviewed [37—39].However, the ways of introducing more cations/anions to modify TMCs, and the promoted mechanism have not been reviewed.Therefore, engineering strategies of TMCs to boost their catalytic effect as the focus are reviewed, and the unsolved problems as well as the further research is also prospected.

3 Engineering TMCs Catalysts

TMCs nanomaterials involve electronic interactions between metal ions and anions, and the electron density will be redistributed after the metal is coordinated with the anion, thus giving TMCs materials adjustable catalytic activity.Regulating thed-porbital hybridization state of TMCs catalysts and LiPSs/Li2S by changing the electron structure of TMCs, is the essence to improve the catalytic activity.Engineering TMCs catalysts with multiple cations/anions can optimize intrinsic catalytic activity with tuned electronic structure through doping modification, constructing dual-ionic TMCs and TMCs-based heterostructure composites (Fig.1a).These modification will enable TMCs catalysts with the superiority of enhanced catalytic activity, higher binding energies, more active sites, etc.(Fig.1b).

3.1 Doping Modification

Heteroatom doping can not only enhance the electrical conductivity of TMCs, afford more chemical anchoring sites and higher adsorption energies for LiPSs, but also improve the charge transfer compared with undoped ones [40, 41].The catalytic activity is thus enhanced, improving the sulfur utilization and electrochemical performance.According to the types of doped ions, doping modification includes cation doping, anion doping and dual doping.

3.1.1 Cation Single-Doping Modification

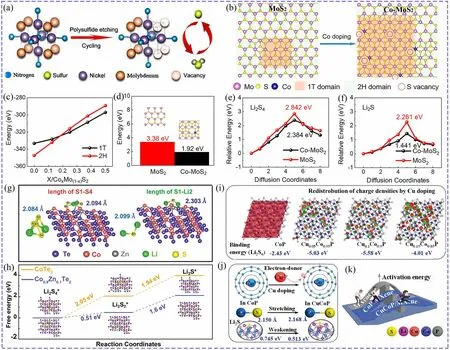

Since cations usually act as active sites, adjusting their electron structure is essential to improve catalytic activity [42].For example, surface defect was introduced into MoS2to enrich active sites by Ni doping, which promoted Li+/e-transfer, chemisorption and catalytic effect of Ni-doped MoS2toward LiPSs, improving the redox kinetics of LSBs.This rendered the sulfur cathodes with Ni-MoS2achieve a higher specific capacity of 1343.6 mAh g-1with retained capacity of 800 mAh g-1at 0.2C for 100 cycles than that of undoped MoS2(1287.8 mAh g-1, 678.3 mAh g-1) [43].Min found that the lattice spacing of Ni0.2Mo0.8N was larger than that of Ni3N and Mo2N due to the changedd-band position, improving the delocalization of electrons and lithium ions transfer.Additionally, because the Mo was more positive at the corners than Ni (Fig.2a), Mo was partially etched by LiPSs during cycling, which generated much vacancies around Ni, accelerating charge transfer and LiPSs conversion.Furthermore, a built-in electric field was formed between the Ni0.2Mo0.8N modified separator and lithium metal due to the higher surface potential of Ni0.2Mo0.8N, which was beneficial for preventing the LiPSs diffusion and promoting Li+transmission [44].Co was also doped into MoS2, rendering the 2H MoS2transform into 1 T phase with sulfur vacancies, as illustrated in Fig.2b.And it was easy for Co-doped MoS2to stabilize the 1 T phase and sulfur vacancies due to their lower formation energy of sulfur vacancies with 1.92 eV than MoS2(3.38 eV) (Fig.2c, d).The electron-rich Co provided electrons for S and promoted the electron transfer, thus effectively boosting the adsorption capacity and catalytic activity, and reducing the decomposition energy barriers of Li2S4/Li2S from 2.842/2.261 to 2.384/1.441 eV (Fig.2e, f).Besides, the 1 T phase of Co-MoS2was increased accompanied by the decrease in sulfur defect when the Co content increased, further improving the adsorption and the electron transfer for LiPSs conversion [45].Cation doping can facilitate the reaction kinetic for both discharge process and charge process.Benefitting from the enhanced catalytic effect, Co-doped SnS2could promote the conversion of LiPSs to Li2S and reverse oxidation of Li2S.This was amply demonstrated by the obvious difference of S K-edge XANES, in which the feature of S—S disappeared during discharging from 2.0 to 1.7 V and re-appeared during charging process for S/NCNT@Co-SnS2[46].

Fig.2 a Schematic of in situ etching Mo-doped Ni3N by LiPSs [44].Copyright: 2022, Elsevier.b Schematic of evolution of Co-doped MoS2.c Relationship of the formation energies of 1 T, 2H MoS2 and doped Co content.d Influence of Co doping on the formation energies of sulfur vacancies in MoS2.The catalytic effect of Co-doped MoS2: e Li2S4 decomposition and f Li2S decomposition [45].Copyright: 2021, American Chemical Society.Effect of Zn doping on the catalytic effect of CoTe2: g S—S bond length of Li2S4 and S—Li bond length of Li2S.h Gibbs free energies [47].Copyright: 2022, John Wiley and Sons.Effect of Cu-doped CoP: i unbalanced charge densities induced by Cu doping.j Schematic of electron transfer and variation of bond length, k Comparison of LiPSs/Li2S conversion barrier [54].Copyright: 2019, John Wiley and Sons

Doping modification may introduce lattice distortion, which can enrich the active sites and regulate the electron structure to enhance the catalytic activity.Xu-doped CoTe2with Zn (Co0.9Zn0.1Te2) and introduced lattice strain, which changed the coordination environment of Co atoms and further reduced thed-band center.Because the adsorption strength is related to thed-band center, and too strong adsorption is not conducive to the further conversion of LiPSs, the decline ofd-band center of Co0.9Zn0.1Te2compared to CoTe2meant more electrons occupied in the antibonding orbitals, which was conducive to the desorption of LiPSs to preserve its effective catalytic active site.Furthermore, the charge number of Te atom near Zn atom was also increased, which enhanced the affinity between Te and Li, improving the anchoring capacity for LiPSs.As shown in Fig.2g, h, the lattice strain enhanced the intrinsic catalytic activity, promoting the break of bonds of LiPSs/Li2S, thus reducing the energy barrier of Li2S4→ Li2S2→ Li2S from 2.05 and 1.94 eV for CoTe2to 0.51 and 1.6 eV for Co0.9Zn0.1Te2[47].Chen dissolved V into TiN lattice and formed solid solution Ti—V—N (TVN) in which V acted as dopant.As a result, Ti-N bonds were shorted while V—N bonds were lengthened, and the lattice parameter of TVN was reduced for the smaller atomic radius of V.More importantly, the structural distortion led to thed-band center of Ti lower while that of V increased, rendering V more effective to adsorb and catalyze LiPSs conversion.The best regulation was achieved at the Ti/V ratio of 4 for the largest structural distortion and highestd-band center of V, endowing the corresponding LSB with a retained capacity of 1036.8 mAh g-1and a high capacity retention of 97.7% at 0.2 A g-1for 400 cycles [48].

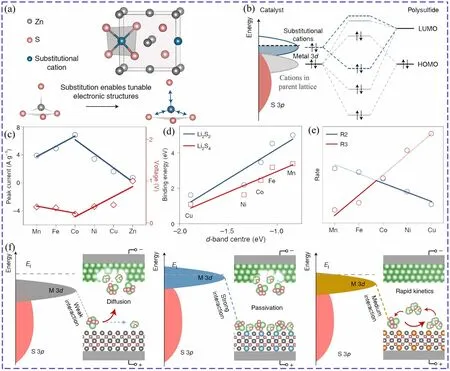

Of course, the catalytic effect is also heavily affected by the type of doping ions.Selecting suitable doping ions is of great significance to optimize the catalytic performance by tuning electronic structures (Fig.3a), especially thed-band due to its electronic interaction with LiPSs (Fig.3b), which also closely relates to adsorption strength.Zhao et al.doped SnSe with kinds of transition metals Ti, V, Mn, Fe, Co, Ni, Cu, Zn, and proved that all the doping significantly improved the adsorption ability toward LiPSs/S8, and promoted LiPSs/S8conversion based on Gibbs free energy results.However, not all doping could reduce the length of Sn—S bond formed between SnSe and LiPSs/S8, indicating different catalytic mechanisms [49].Wang studied the influence of the electron structure on adsorption ability and catalytic performance of SmMn2O5, which was doped with major-group metals Mg, Ga and transition metals V, Cr, Fe, Mo at Mn site.The results showed that the binding energy for Li2S4, which was controlled by charge transfer, electronegativity difference between doped metal and S as well as surface work function of catalysts, had a linear relationship with the overpotential of sulfur reduction.Additionally, doping with Mg and Ga upward shifted thed-band center, while doping with transition metal had little effect [50].Zhang incorporated metal ions (Mn2+, Fe2+, Co2+, Ni2+and Cu2+) into ZnS to study the relationship of catalytic activity and adsorption ability.As a result, the catalytic ability showed a volcano-shaped trend from Mn to Cu-doped ZnS based on the peak current of CV of symmetric cells (Fig.3c).The adsorption ability of doped ZnS exhibited a decreased trend from Mn to Cu with downshift ofd-band centers (Fig.3d), while a volcano plot of reaction rates of LiPSs dissociation and desorption steps was obtained (Fig.3e).This was because that the catalytic activity increased with improved adsorption ability, while too strong adhesion of Li2S passivated catalysts (Fig.3f).Consequently, the catalytic activity showed a volcanoshaped relationship with adsorption ability, and Co-doped ZnS with medium adsorption ability achieved the best catalytic effect [51].

The properties of doping ions that boost the catalytic activity of the materials have also been studied.For promoting LiPSs adsorption and electron exchange, Mn, Fe, Co, Ni with moredelectron numbers than V were doped into VN to adjust the electronic structure of VN by enriching itsdelectrons.As a result, adsorption energy (5.86 eV for Li2S4) and interface electrons transfer (0.32 e) between LiPSs and catalysts were enhanced as Co was doped into VN in contrast to undoped VN (3.52 eV), which was ascribed to the lower filling fraction and higherd-band center of V 3d-band compared with undoped VN.Moreover, the best cathode performance could be obtained by Co-doped VN with retained capacity of 447 mAh g-1at 3C for 500 cycles, which was more stable than other doped samples [52].Regulating the electronic structure of VN withdelectron-rich elements (Mn, Fe, Co, Ni) could indeed improve the LiPSs adsorption and redox reactions.However, the relationship between the number ofdelectrons and catalytic performance is not concluded.

The electron donating ability of dopant ions also plays a key role in improving catalytic activity [53].Li proposed Cu as electron donor to dope CoP/MXene and control the redox kinetics of Li2S by regulating its electron structure and enriching active sites.To be specific, the doped Cu rendered the Co atoms charge accumulation, introducing unbalanced charge distribution and forming more Co/Cu—S bonds, which eventually increased the binding energy from 2.43 to 5.58 eV (Cu0.1Co0.9P), as shown in Fig.2i.On the other hand, the strongly electronegative Co3+(15.26) in CoP was transformed into weakly electronegative Co2+(9.10) by trapping electrons from the Cu atoms.This weakened the Co—S bond energy and lengthened the bond from 2.150 to 2.168 Å (Fig.2j), while producing much lattice vacancy.As a result, the diffusion energy barrier and activation energy of nucleation/decomposition of Li2S were reduced (Fig.2k), improving the redox kinetics of Li2S.With accelerated redox kinetics and enhanced sulfur utilization, the sulfur cathode with Cu0.1Co0.9P could achieve a specific capacity of 1475 mAh g-1at 0.2C and a retention of 73.4% for 100 cycles, superior than that of CoP (57.6%) [54].

Fig.3 Relationship between catalytic activity and adsorption ability: a Schematic of doped ZnS by substituting Zn to tune the electronic structures.b Principle of regulating electronic structure by doping.c Voltage difference and peak current of the CV of symmetric cells.d Relationship of binding energies and d-band center.e Volcano diagram of reaction rates for ZnS doped with different ions (R2: LiPSs dissociation, R3: desorption steps).f Relationship of interactions and catalytic effect [51] Copyright: 2022, Springer Nature

In addition, as the electronegativity affects the ability of TMCs to attract bonding electrons, the binding strength and electron transfer between TMCs and LiPSs are also affected [55].Therefore, electronegativity is also a key factor of doped ions to improve the catalytic performance.Hu-doped NiSe2with Fe with lower electronegativity than Ni and acted as electron donor to enhance the electron transfers from Fe-NiSe2to LiPSs.As a result, Fe-NiSe2improved chemisorption ability with the formed S-Fe and shortened S-Ni and Li-Se bonds between Fe-NiSe2and Li2S6.Additionally, Fe doping resulted in the increase in density of states (DOS) near the Fermi level and antibonding orbitals in conduction band, indicating improved electrical conductivity, which was conducive to catalyzing the redox of sulfur species [41].CoB was doped with Mo with higher electronegativity than Co, forming a metal compound structure, and causing detachment of B and insertion/extraction of Li+to the vacancy during discharging and charging.Co7Mo3B was more prone to anchor long-chain LiPSs with higher binding energies and simultaneously conducive to the dissolution of Li2S2/Li2S with lower binging energy than CoB.As a result, the interaction of Co, B and Mo atoms could bidirectionally promote the redox kinetics [56].In addition, anti-selfdischarge behavior, ionic conductivity and Li+transportation could also be improved by doping modification, such as Ni-doped WS2[40].

The doping amount is also an important factor modifying catalysts.For example, when Fe doping content of TiO2increased from 1 to 5%, the capacity decay rate decreased from 0.27 to 0.08% at 1C for 500 cycles with accelerated kinetic reaction and decreased electrode polarization [57].Zhang et al.doped Fe into Co3O4and formed Co3O4hollow spheres with multi-shell structure and oxygen defects by adjusting the Fe doping amount.As a result, the electronic conductivity of Fe/Co3O4and the chemical adsorption for LiPSs were significantly improved, and catalytic sites were enriched, promoting the LiPSs conversion [58].

In addition to type and content of doping ions, doping site is also a key factor affecting the doping effect.Mn, Fe, Co, Ni etc.were selected to dope MoS2at Mo and S sites, respectively.Doping MoS2at Mo sites could not obviously enhance the binding strength for LiPSs.In contrast, doping at S sites improved the binding energies due to more electrons transferred from the adsorbed LiPSs to doped MoS2, which was ascribed to much stronger orbital overlap of Co-3dand S-3pof Li2S4taking Co-doped MoS2as an example.Furthermore, doped MoS2by substituting S exhibited good catalytic activity for LiPSs conversion with low Gibbs free energies [59].Doping site also has obvious influence on the band structure.Band structure of different types of Ti-doped SiO2were calculated, including substitutional type (Ti(S)-SiO2) and impurities types which connected one O atom (Ti(I1)-SiO2), two O (Ti(I2)-SiO2) and O/Si (Ti(I3)-SiO2).Their band gaps were 4.528, 2.468, 0.483 and 0.955 eV, respectively, which were smaller than that of pure SiO2(5.672 eV) [60].

3.1.2 Anion Single-Doping Modification

Anions doping can also promote the catalytic activity of TMCs with modified electronic structure, such as thed-band center and electron filling of metal ions.Firstly, anions doping can also enhance the electronic conductivity, such as S-doped Co0.85Se (1.05 eV) with lower band gap compared with that of Co0.85Se (1.07 eV).Moreover, the growth of Li2S could be regulated via the synergistic adsorption by Se and S [61].Anions doping can also enhance the chemical interaction with LiPSs.Wu-doped NiCo2S4with high amount of oxygen (37.28%) (Fig.4a), obtaining NiCo2(O—S)4with lower conductivity (30.1 S cm-1) but superior trapping ability for LiPSs than natively oxidized NiCo2S4with O content of less than 10.0% (51.2 S cm-1).Specifically, Co was the dominated LiPSs interaction site of NiCo2O4and NiCo2(O-S)4, while that of NiCo2S4was Ni, which was proved by the intensity changes of Ni/Co XPS peaks before and after interacting with LiPSs (Fig.4b).Electron transferred from the Li2S6to the O atoms, forming Li—O—M.As a result, NiCo2(O-S)4presented the best catalytic effect for promoting the LiPSs conversion than that of NiCo2O4with high charge transfer barrier due to poor conductivity and NiCo2S4for weaker interaction with LiPSs (Fig.4c).As expected, the LSB of NiCo2(O—S)4achieved a preferable cycling stability compared with NiCo2O4and NiCo2S4, maintaining a capacity of 962 mAh g-1after 200 cycles at 0.2C and 922 mAh g-1after 150 cycles at 0.5C [62].

The properties of doped anions and promoted mechanism that enhance the catalytic activity of TMCs have also received attention.N with higher electronegativity than Se was selected to modify CoSe2, which could elongate S—S of LiPSs and Li—S bond of Li2S but shorten Co-S bond, resulting in facilitated conversion of sulfur species both in discharge and charge process.The enhanced chemisorption and catalytic capacity of N-CoSe2was due to less filled antibonding states and facilitated charge transfer with higherd-band center of Co compared to CoSe2(Fig.4d).In addition, the charge number of Co atoms was increased to provide more empty orbitals for adsorbing LiPSs (Fig.4e) [63].N doping could also tune the electron filling state of TMCs to regulate the adsorption ability as well as conversion kinetics for LiPSs.The electron density of Ta around N in N-Ta2O5was increased compared to Ta2O5, because fewer electrons in Tadorbitals flowed into N than O for the relatively weak electron binding ability of N.As a result,dorbitals electron filling of Ta in N-Ta2O5(2.96) was higher than that of Ta2O5(2.87) but lower than that of Ta3N5(3.23), corresponding to the charge transfer amount between Ta of N-Ta2O5, Ta2O5, Ta3N5and S, which imparted N-Ta2O5(3.70 eV for Li2S4) moderate ability to anchor LiPSs compared to that of Ta2O5(6.94 eV) and Ta3N5(2.82 eV).The sulfur cathode with N-Ta2O5exhibited the highest initial capacity of 1252.8 mAh g-1and capacity retention rate of 92.7% at 0.2C for 100 cycles among the studies catalysts [64].

Fig.4 Superior effect of O-doped NiCo2(O—S)4: a sulfidation process NiCo2(O—S)4 and NiCo2S4.b Ratio of M3+/M2+ 2p3/2 peak intensity (Ip) and the rate of Ip change.c NiCo2(O-S)4 with high conductivity and LiPSs affinity greatly reserved the catalysis active surface [62].Copyright: 2022, John Wiley and Sons.Improvement of catalytic effect by N-doped CoSe2: d PDOS of CoSe2 and N—CoSe2.e Charge number of Co in CoSe2 and N—CoSe2 [63].Copyright: 2020, American Chemical Society.P-doped NiTe2-x: f Schematic illustration of P-doped NiTe2-x at Te vacancies.g Difference of Li—Te and S—Ni bond lengths formed between LiPSs and various catalysts.h Charge density difference between Li2S and catalysts, the yellow (blue) distribution corresponds to charge accumulation (depletion) [65].Copyright: 2022, John Wiley and Sons

P with higher electronegativity than Te was also selected to dope NiTe2with Te vacancies.The P atoms occupied Te vacancies instead of taking the place of Te atoms (Fig.4f).The higher electronegativity of P than that of Ni and Te rendered it attract nearby atoms and trigger bonds reconstruction, shortening the Ni-Te of P-NiTe2-x.Additionally, the shortest S-Ni and Li-Te bonds between P-NiTe2-xand LiPSs (Fig.4g) demonstrates the strongest anchoring effect.And electron density of Ni-S was decreased while that of Li-Te was increased when P-NiTe2-xinteracted with Li2S (Fig.4h), meaning a promoted catalytic activity [65].However, Hu et al.doped P with lower electronegativity than Se into NiSe2.As a result, the electron-rich P promoted the electrons transfer from Li2S6to P-NiSe2, and the S at the end of Li2S6showed apparent electron deletion, rendering it present superior catalytic effect than NiSe2[66].Pwas also used to dope MoS2and hybridized with Mo 3dand S 2porbital, resulting in more charge transfer and superior conductivity.This induced stronger Mo—S and P—Li bonds and longer S—S/Li—S bonds of LiPSs/Li2S to accelerate their conversion [67].Similarly, CoS2doped with P with relatively low electronegativity also improved the catalytic activity [68].Therefore, whether the electronegativity of doping ions is the key factor to regulate the catalytic activity of TMCs, and their relationship as well as the promoted mechanism needs to be further studied.

The valence states of TMCs can also be optimized by doping to enhance catalytic activity.Chen’s group modulated the valence states of Ni and Zn for Ni3ZnC0.7by P doping and accompanied Zn vacancies, which remarkably decreased the electron density at Zn sites to anchor LiPSs.Meanwhile, the content of Ni2+species was slightly increased to facilitate electron transfer between Ni2+/Ni(0) and LiPSs, improving the catalytic effect for LiPSs conversion.The LSB with P-doped Ni3ZnC0.7modified separator could present a more stable cycle performance with an initial capacity of 684 mAh g-1and fading rate of 0.0247% at 1C for 1400 cycles, in contrast to that of pristine Ni3ZnC0.7with 583 mAh g-1and 0.0341%, respectively [42].

3.1.3 Dual-Doping Modification

Due to the synergistic effect between doping ions, dual-doping modification could obtain better catalytic performance than single doping.Lee et al.designed Co and P dual-doped MoS2(Fig.5a), in which Co doping changed MoS2phase from 2H to 1 T, improving its conductivity and providing more effective electron conduction (Fig.5b).More importantly, the Co—P coordination formed after P doping further improved the catalytic activity of Mo0.9Co0.1S2.As a result, Co and P co-doping improved the catalytic performance for LiPSs conversion with lower energy barriers (Fig.5c).Benefitting from the synergistic effect of Co and P dualdoping, P-Mo0.9Co0.1S2obtained the best cathode performance.Represented by the rate performance, P-Mo0.9Co0.1S2presented a high capacity of 931 mAh g-1at 6C, in contrast to that of Mo0.9Co0.1S2with 633 mAh g-1and MoS2with 338 mAh g-1[69].Li et al.modified CoSe2with Ni and Zn dual-doping to bidirectionally catalyze the redox of sulfur cathodes.To be specific, the catalytic effect of Ni-doped CoSe2for the LiPSs conversion in the discharge process was better than that of Zn doping modification, while Zn doping achieved better catalytic performance on the Li2S decomposition.In addition, Ni/Zn dual-doping CoSe2had the better catalytic performance than that of the mixture of Ni-doped CoSe2and Zn-doped CoSe2[55].TMCs co-doped by anions was also involved.N, F, and B were co-doped into CoFe2O4and induced rich O vacancies to enhance the conductivity and act as adsorption, catalytic sites for LiPSs.The density functional theory (DFT) results also showed that new electron energy peaks appeared and increased the carrier density after the anions co-doping modification.Consequently, the improved binding energy and catalytic effect of modified CoFe2O4suppressed the shuttle effect and boosted the redox of sulfur cathodes, delivering an excellent electrochemical performance with maintained capacity of 1156 mAh g-1at 0.2C for 300 cycles as separator coating layer, which exceeded that of pristine one with only 825 mAh g-1[70].

Metal ion-doped metal compounds are usually prepared in two ways.The first is to directly add stoichiometric-doped metal salt during the hydrothermal reaction or co-precipitation reaction.For example, Ni-doped MoS2was prepared by hydrothermal treatment of the mixture of oxalic acid, thiourea, (NH4)6Mo7O24·4H2O and Ni(Ac)2·4H2O, and the doping content could be controlled by amount of metal salts [43].The second is adding the metal salt of the doping ions to some solvent along with the pristine metal compound or its precursor, and further replace the metal ions in the metal compound for doping through heating or hydrothermal conditions.Taking doped SiO2as an example, M-SiO2(M = Ti, Al, Sn) were synthesized by hydrothermal treating the mixture of SiO2and stoichiometric metal source in isopropyl alcohol [60].As for anion doping of TMCs, metal compounds and chemical reagents containing doping sources are usually calcined at high temperatures, such as ammonium hydrogen carbonate, sodium hypophosphite and sodium hydrogen sulfite as a nitrogen source, phosphorus source and sulfur source, respectively.For example, N-doped CoSe2was synthesized by calcining the CoSe2accompanied with ammonium hydrogen carbonate [63].Furthermore, anion and cation co-doping can be carried out by single doping of metal ion and then anion doping.

Fig.5 Co, P co-doped MoS2: a Schematic illustration of Co, P co-doped MoS2 (P-Mo0.9Co0.1S2).b HRTEM images of Co, P co-doped MoS2.c Energy barrier of LiPSs conversion [69].Copyright: 2019, John Wiley and Sons.Schematic illustration of the functions of different catalysts: d Ni-doped CoSe2, e Zn-doped CoSe2, and f Ni/Zn-doped CoSe2 [55].Copyright: 2021, John Wiley and Sons

Although reasonably engineering TMCs catalysts could promote the LiPSs conversion, the design and regulation of ideal bidirectional sulfur catalyst is still a great challenge for the difficulty of selecting ions with different functions [71].Different doping ions in TMCs may play various functions, such as improving conductivity, regulating electronic structure, and adsorbing-catalyzing different LiPSs in different stages of LSBs.Moreover, multicomponent co-doping may enrich the active sites and play a synergistically catalytic role [72].However, research on this aspect is lacking, and it is worth further study, especially the selection and matching of multi-doped ions and their synergistic catalysis mechanism through deeply studying the regulation rules of electronic structure.Based on this development, high-entropy doping may be proposed.Additionally, it is found that the external magnetic field could regulate the spin polarization of CoSxcatalyst, drive the transition of Co3+electrons from the low spin state to the high spin state, generating additional unpaired electrons in the 3dorbit of Co and enhancing the hybridization between Co-3dand S-2porbital.As a result, the charge transfer dynamics at the CoSx/LiPSs interface was promoted, and the adsorption-catalytic capacity for LiPSs was significantly improved [73].Doping is also an effective strategy to manipulate spin polarization of catalysts to enhance the catalytic activity [74, 75].Therefore, the adjustment of spin effect induced by doping should be paid enough attention in LSBs.In addition, doping modification may introduce defects such as vacancy in TMCs, which may provide additional adsorption and activation sites [76].It is worth noting that doping may cause changes ind-band center, spin polarization, lattice distortion and vacancy defects at the same time.Therefore, controlling electronic structure through doping is complicated and these factors should be comprehensively investigated.Furthermore, directed doping to specific sites should be developed for higher catalytic activity [77].

3.2 Multi-Ionic TMCs

Multi-ionic TMCs composed of more metal ions or anions also possess enriched active sites, optimized chemical properties, and improved catalytic activity compared with TMCs of one component.In contrast to doping modification which belongs to a kind of defect and retain the phase and crystal structure of the original TMCs, bimetal TMCs with fixed atomic ratios within a certain range are solid solutions and possess unique crystal structures, such as Co3Mo3N, BaTiO3and FeWO4, and only some may be identical to one-component TMCs, such as Ni2Co4P3.Furthermore, doping modification can be achieved by introducing heterogeneous ions, but the synthesis methods cannot be simply transplanted to the preparation of dual-ionic metal compounds.Multi-ionic TMCs are usually not obtained by increasing the content of doped ions in TMCs.Increasing the doping amount may lead to changes in crystal phase besides changed lattice parameter and reconstructed bonds, and even anion aggregation and phase collapse [78, 79].

3.2.1 Multi-Metallic TMCs

3.2.1.1 Bimetallic TMCsCompared with corresponding single-component compounds, bimetallic TMCs can achieve better conductivity and electrochemical activity, which have also been applied to catalyze LiPSs conversion.Zhang synthesized NiCo2S4microspheres, which possessed good electrical conductivity and catalytic activity, ensuring fast conversion kinetics of LiPSs [80].Ni-Co phosphide nanoparticles embedded in carbon hollow nanocages were also designed as adsorption-catalytic sites, promoting redox reaction and Li+diffusion in LSBs [81].The reasons why bimetallic TMCs are superior to monometallic TMCs have also been studied.NiCoP possessed a significantly higher binding energy of 4.24 eV for LiPSs than CoP (1.48 eV), because the natural oxidation of NiCoP formed Ni—O—P and Co—O—P and activated the Co/Ni sites, rendering it bind with LiPSs through Co-S and Ni-S bonds [82].In addition, bimetallic TMCs can also establish more suitable chemical bonds to optimize chemisorption effect.For example, TiO2anchored LiPSs with S—O bonds, while bimetal Li4Ti5O12could form more efficient Ti—S bonds (Fig.6a), resulting in excellent cyclic stability of sulfur cathode at sulfur loading of 4 mg cm-2with 80% capacity retention at 1C for 300 cycles [83].Na2Ti6O13with synergistic coordination of Na and Ti provided double-cations as adsorption sites for promoting LiPSs conversion and preventing their accumulation (Fig.6b).Furthermore, the distortion of TiO6octahedron in Na2Ti6O13generated a large dipole moment, and the internal polarization field in TiO6octahedron was favorable for electron transfer, promoting the conversion of LiPSs and significantly enhancing the adsorption ability compared with TiO2.The LSB with Na2Ti6O13could reach a capacity of 815 mAh g-1at 1C and maintained its capacity at 84% at 0.1C for 100 cycles compared with that of TiO2at 75% [84].Additionally, the conductivity and charge transport could also be improved compared to the monometallic compounds [85].

The fundamental reasons for elevated adsorption and catalytic ability of bimetallic TMCs are further explored.Electron transfer between different metals of bimetallic TMCs can tune the electronic structure such as distribution of electron density, thus adjusting the adsorption and catalytic properties [86].Zhang designed Co3Mo3N by calcinating Mo-doped ZIF-67, and the electron redistribution was occurred with the introduction of Mo due to its greater electronegativity than Co.As a result, electron transferred from Co and Mo to N atoms, and the electron density around Co was decreased while that of N was increased, facilitating the adsorption and conversion of LiPSs [20, 87].

In addition, tuned valence state is also an important reason for enhanced catalytic capacity of bimetallic TMCs.For example, electron transfer was occurred from Co to Sn in CoSn(OH)6due to their different electronegativity, which increased the Co3+and decreased the valence state of Sn compared with Co(OH)2and Sn(OH)4.As a result, the chemical interaction between Co and S were enhanced, while that of Sn and S was weakened for CoSn(OH)6after discharge—charge, presenting a moderate adsorption capacity, which promoted the LiPSs diffusion for conversion [86].Chemical valence could also be varied after interaction with S/LiPSs to boost the redox of sulfur species.Co3+and Ni3+were in situ formed attributed to the interaction between nickel—cobalt double hydroxide (NiCo-DH) and sulfur, which was conducive to the oxidation of initially formed LiPSs and the formation of thiosulfates.The reversible redox between thiosulfates and LiPSs could confine LiPSs and catalyze their conversion.Moreover, NiCo-DH underwent a redox with Li2S6, partially reducing Co3+and Ni3+to Co2+and Ni2+.The electron transfer and strong coupling effects between Ni and Co in NiCo-DH rendered it a smaller redox potential [88].LixMoOywas in situ synthesized by electrochemically activating MoO3at about 2.6 V, which subjected to a conversion between Li0.042MoO3and Li2MoO4at about 2.2 V, thus accelerating the redox of LiPSs with the potential overlap [89].

Interaction between metal sites can also regulate thed-band electron filling andd-band center, thus improving chemisorption and catalytic property for LiPSs.Zhang alloyed Co to Ni2P to improve thed-band of Ni2Co4P3(Fig.6c), in which the Co 3d-band in Ni2Co4P3was higher than the Ni 3d-band in Ni2Co4P3and Ni2P.Because Co 3dhad lower electron fill number and higherd-band center than Ni 3d (Fig.6e), Ni2Co4P3was endowed with enhanced interaction with LiPSs and reduced activation energy for LiPSs conversion (Fig.6d).Additionally, Ni2Co4P3formed a shorter metal-S bond with LiPSs and weakened S—S bonds of LiPSs, reducing the energy consumption of S—S bonds and energy barrier for conversion reaction compared with Ni2P.The crystal orbital overlap population of S—S bond at both ends showed that the electron filling of antibonding state of Li2S4on Ni2Co4P3was higher than Ni2P (Fig.6f) [90].

For host materials with relatively low conductivity but strong interaction with LiPSs, such as metal oxides, the surface diffusion of LiPSs/Li2S is vital for electrochemical reactions [19].Fortunately, bimetallic TMCs can also promote the diffusion of Li2S.For example, BaTiO3delivered a much lower diffusion energy barrier of Li2S than TiO2, showing superior surface diffusion kinetics and more uniform dispersion of Li2S.More importantly, BaTiO3with inherent self-polarization showed promoted redox kinetics of LiPSs/Li2S than TiO2(Fig.9g).As a result, the LSB equipped with BaTiO3could deliver an initial capacity of 896 mAh g-1with remained capacity of 466.1 mAh g-1at 1C for 1000 cycles, exceeding that of TiO2with retained capacity of 210 mAh g-1[91].Similarly, Bi4Ti3O12with inner electric field induced by spontaneous polarization showed excellent catalytic activity for promoting LiPSs conversion [92].The intermolecular polarization of CoIn2S4and Li2S4introduced by their strong interaction was regarded as an essential reason of reduced conversion barrier and enhanced charge transfer from CoIn2S4to Li2S4[93].Additionally, Li+diffusion can also be promoted.Compared to Ni3C, Ni3ZnC0.7could provide Ni, Zn sites as sulfiphilic sites and lithiophilic sites, respectively, which reduced energy barriers of Li+diffusion and improved catalytic property [94].

Bimetallic TMCs may also combine the advantages of the two metal ions or corresponding monometallic TMCs.Liu designed Co3V2O8to make use of V, Co binary active sites to anchor LiPSs and catalyze their conversion [95].FeWO4nanorods was designed for combining the merit of Fe2O3with strong affinity and WO3with good catalytic property, delivering a faster Li+diffusion rate, stronger chemical binding and better redox kinetics for LiPSs.Thanks to the simultaneous satisfaction of adsorption and catalysis, Li2S6cathode with FeWO4obtained more stable cycling properties with retained capacity of 519 mAh g-1at current of 3.2 mA after 600 cycles than that of Fe2O3only with 502 mAh g-1after 150 cycles [96].For MoWS catalyst, 1 T phase structure with better electron conductivity possessed higher catalytic activity, while 2H phase was beneficial for Li+diffusion [87].Mo0.5W0.5S2composed of 2H-1 T mixed phase, possessed both superior catalytic activity for LiPSs conversion and a faster electron transport, delivering a better reaction kinetic than that of MoS2and WS2[97].Bidirectional catalysts can also be constructed with bimetallic TMCs.For example, Shu introduced Mo into NiO and constructed NiMoO4with increased electron density, which led to the decrease in bandgap from 2.51 eV (NiO) to 0.56 eV (NiMoO4) and the improvement of metallic properties.Furthermore, NiMoO4rendered the S—S bonds and Li—S bonds of adsorbed Li2S4and Li2S longer, and Gibbs free energy of the rate-determining step (Li2S2→ Li2S) and Li2S decomposition barrier for NiMoO4(0.90 eV, 0.19 eV) reduced compared with NiO (1.15 eV, 1.73 eV), simultaneously facilitating the conversion of LiPSs and Li2S oxidation (Fig.6h) [98].

Introducing metal ions may also affect the morphological structure to help optimize the cathode performance.Zhang prepared NiCo hydroxide polyhedrons by etching ZIF-67 with Ni(NO3)2·6H2O because of its lower pH than Co(NO3)2·6H2O in ethanol.The obtained NiCo hydroxide with denser and miniaturized nanosheets along the polyhedral shells, facilitated the exposure of enriched active surfaces for chemical anchoring LiPSs and catalyzing their reactions.Consequently, bimetallic NiCo hydroxide hollow polyhedra was more conducive to improving the electrochemical performance of LSBs, endowing the corresponding sulfur cathode with a higher capacity of 763 mAh g-1after 100 cycles at 0.1C than that of Co hydroxide of only 406 mAh g-1[99].

MOFs with the merits of tunable pore structures, structural diversity as well as functional versatility, are extremely suitable for chemical anchoring and physical confining LiPSs with Lewis acid—base interaction and porous structure, and catalyzing the LiPSs conversion [100, 101].Furthermore, bimetallic MOFs can improve its electronic conductivity, enrich active sites, and plays synergistic effects.For example, considering that Al3+in Al-MOF was coordinatively saturated and hardly to bind extra LiPSs, coordinatively unsaturated Cu2+with sulfiphilicity was introduced to construct bimetallic Al/Cu-MOF, which generated additional sites for anchoring LiPSs and enhanced the interaction [102].A Zr-Fc MOF possessed positively charged Zr sites provided by uncoordinated Zr-O defects and positively charged oxidized Fc+, to electrostatically adsorb LiPSs.At the same time, acidic protons in the defect sites of Zr-O nodes could also anchor LiPSs.These abundant anchor sites and electrocatalytic activity of Zr-Fc MOF enabled the LSBs a superior cycle stability compared to Zr-MOFs [103].

To catalyze multi-step redox process, catalyst with two kinds of catalytic sites were proposed.NiCo-MOF was thus designed by combining the different catalytic function of Ni-MOF and Co-MOF.As shown in Fig.7a-c, Ni-MOF preferred to bind the long LiPSs and delivered lower Gibbs free energy for their conversion, while Co-MOF anchored the short LiPSs stronger, facilitated their reduction and Li2S oxidation.Furthermore, NiCo-MOF possessed better conductivity (Fig.7d) and improved catalytic activity, because charge redistributed between Ni and Co (Fig.7e, f) for their asymmetric interaction with the bridge O, and led to the change of the unfilled metal electron orbitals [104].Wang also designed NiCo-MOF and the charge transfer from Co to Ni due to the higher electronegativity of Ni2+than Co2+, which rendered electron density increase in the Ni center.NiCo-MOF achieved the best adsorption effect and catalytic capacity for LiPSs conversion as a result of synergistic effect.To be specific, the Ni-MOF showed the better catalytic effect on LiPSs conversion than Co-MOF, while Co-MOF exhibited a stronger interaction with LiPSs than Ni-MOF [105].To realize effective adsorption and catalysis, Mai adjusted the metal sites by constructing bimetallic Zn/Co-ZIF (Fig.7g).Specifically, Co site delivered better catalytic activity and Zn site could anchor LiPSs more strongly.By adjusting the Zn:Co ratio and using the Zn/Co-ZIF with a mole ratio of 0.9 as a separator modification layer, optimized cycling and rate performance of LSBs could be achieved.Its initial capacity was 1304 mAh g-1and could maintain at 1141 mAh g-1after 100 cycles [12].The interaction between bimetallic MOFs and sulfur species can be optimized by adjusting the types of incorporated metal ions and tuning the electronic structure of metal sites with changed coordination environment.For example, a series of bimetallic MnM-MIL-100 (M = Co2+, Ni2+, Zn2+, Pb2+and etc.) were synthesized, in which Co could modify the electronic structure of Mn, and the decrease in Ni content changed the electronic environment of Ni2+[106].

3.2.1.2 Medium/High-Entropy TMCsTMCs with more than two kinds of metal cations are also designed for LSBs.For example, Cu2ZnSnS4with Cu, Zn and Sn as active sites was prepared to adsorb LiPSs and promote the redox reaction [107].Considering the combination of various advantages of different TMCs and the cooperating effect of multi-metals, high-entropy materials (high-entropy alloys and high-entropy ceramics) containing more than five kinds of metal elements are also applied in LSBs.High-entropy materials with a single-phase crystal, possess significant advantages of lattice distortion and ‘cocktail’ effect, presenting a distinguished synergistic effect and incomparable catalytic activity [108].Considering that Co-doped ZnS, CoS, and Cu-based materials are known catalytic materials for LSBs, Abruna combined Zn, Co, and Cu with In, Ga into the sulfide material to balance the charge, and designed high-entropy sulfide Zn0.30Co0.31Cu0.19In0.13Ga0.06S to facilitate the redox kinetic and alleviate the shuttle effect of LSBs.As a result, the high-entropy sulfide exhibited superior catalytic properties than any constituent metal sulfides in both discharge and charge stages.It was noteworthy that although GuGaS2and CuInS2had catalyzed the reduction reaction, no metal sulfides catalyzed the oxidation reaction, and the high-entropy sulfide showed significantly improved oxidation kinetics due to the synergistic interaction between the components of the high-entropy sulfide [109].Qiao designed high-entropy oxide composed of highly dispersive Ni, Mg, Cu, Zn and Co, which exposed abundant active sites, and could strong anchor LiPSs with Li—O and S—Ni bonds and catalyze LiPSs conversion of (Fig.6i) [110].High-entropy metal nitride of V, Cr, Nb, Mo and Zr was also applied as sulfur host.The electron transferred from Sx2-(4 ≤x≤ 8) to high-entropy metal nitride, and the XPS peaks of X3+-N bond (X = Nb, Mo, Cr, V, and Zr) all shifted to lower binding energies with similar shift value, meaning the homogeneity and equality of those metals [111].The (Mg0.2Mn0.2Co0.2Ni0.2Zn0.2)Fe2O4nanofiber could provide large number of active sites for adsorbing LiPSs and synergistically promoting LiPSs conversion, Li2S deposition and decomposition, which was superior to that of NiFe2O4and (Ni1/3Co1/3Mn1/3)Fe2O4[112].

In addition, more than two kinds of metal ions can also be introduced into MOF materials to further enrich their active sites, improving their electrochemical properties.Pang designed FeCoNi prussian blue analogs (PBA), in which Fe, Co, and Ni could all act as binding sites for Li2S4(Fig.7h), achieving highest adsorption energy than that of FeCo-PBA and FeNi-PBA [113].Furthermore, Pang constructed PBA ranging from binary to high entropy to explore the effects of different metal on the coordination environment, the mechanism of LiPSs conversion and the cathode performance.As a result, Fe coordinated with C, while Co, Ni, Cu, Mn and Zn all participated in N coordination.More importantly, high-entropy PBA delivered faster Li+diffusion, minimum charge transfer resistance and faster LiPSs conversion, promoting the corresponding LSB to achieve the best cycle performance with an initial capacity of 1335.6 mAh g-1and residual capacity of 570.9 mAh g-1after 200 cycles at 0.1C, which was better than the LSBs with NiFe-PBA (1129.0 mAh g-1, 339.5 mAh g-1), NiCuFe (1169.1 mAh g-1, 389.8 mAh g-1), and CoNiCuFe (1218.3 mAh g-1, 467.0 mAh g-1) [114].

All in all, the study of high-entropy materials for LSBs is still in its infancy.Although high-entropy materials show better catalytic performance than their constituent components, the functions of each component, the synergies between each component and the mechanism of how to play the catalytic role are worthy of more in-depth discussion, which is conducive to the selection and matching of components of high-entropy materials to design efficiently multi-functional sulfur catalysts.For example, high-entropy alloy FeCoNiMnZn as catalyst had been shown to simultaneously improve the reaction kinetic for both in discharge and charge process of LSBs.This could be ascribed to the optimized electronic structure, that is, thed-band center of FeCoNiMnZn moved upward than that of FeCoNi and Zn, thereby increasing the adsorption energy and electrons transfer toward LiPSs.The electron density differences combined with partial projected density of states (PDOS) further displayed that Zn acted as an electron reservoir, Mn dominated the conduction band and promoted electron consumption, and other elements played the role in regulating charge distribution [115].In addition, the chemical and structural stability of high-entropy materials in the charging and discharging process of LSBs should be considered.It was found that the copper in Zn0.30Co0.31Cu0.19In0.13Ga0.06S was leached out as an ionic species, accompanied with the smaller particles and lower crystallinity of high-entropy sulfide, gives a good indication that stabilizing cations could prolong the life of catalysts and improve the capacity retention ability [109].Furthermore, the significant lattice distortion is also one of the key factors for the excellent catalytic performance of high-entropy materials.Nevertheless, how to control the lattice distortion of high-entropy materials and the relationship between it and catalytic activity has not been studied.Additionally, more high-entropy TMCs should be designed, such as high-entropy fluorides, high-entropy chlorides [116, 117].

Moreover, given that the composition range of highentropy alloys is very large (1050 possible alloy components based on elements commonly used in the periodic table) and the traditional trial-and-error approach is too cumbersome for the design of high-entropy materials, high-throughput theoretical calculations combined with machine learning is an effective approach and has been widely used in the composition design and optimization of high-entropy catalyst in recent years [118, 119].For example, using DFT calculations, Singh considered more than 1280 adsorption sites on the designed FeCoNiCuMo catalyst, developed three machine learning models to predict the adsorption of some important intermediates in the CO2reduction process, and further analyzed the structure-performance relationship of catalysts to CO2reduction [120].Guo’s group proposed a first principles computational theory method for machine learning-aided design to study the oxygen reduction reactivity of millions of reaction sites on the surface of six kinds of high-entropy alloys, accurately predicting the catalytic activity of millions of reaction sites [121].Luo and Chen revealed the atomic distribution, surface atomic structure and local coordination environment of high-entropy alloys based on machine learning, and further revealed the origin of highly efficient alkaline hydrogen oxidation reaction properties of high-entropy alloys combined with the DFT calculation [122].Unfortunately, the research of highthroughput technology combined with machine learning has been rarely reported in the field of LSBs, which may be the future research hotspot of high-entropy materials applied to LSBs, due to the adsorption and catalytic mechanisms that can be used for reference.

3.2.2 Bi-anionic TMCs

Just like the implant of metal ions, TMCs with suitable dual-anions will also improve the conductivity and electrochemical activity [123].Most importantly, the adsorption for LiPSs and the catalytic effect can also be well regulated by modifying the anions [29].Zhou introduced Se into MoS2lattice by anion substitution, which led to many anion vacancies and an increase in interlayer spacing due to the difference of radius and electronegativity of Se and S atoms (Fig.8a).MoSSe delivered much higher binding energies (Fig.8b) with sulfur species than MoS2and MoSe2and possessed higher conductivity with lowest bandgap (Fig.8c).Furthermore, experiment results also demonstrated accelerated redox kinetics and alleviated LiPSs shuttle, as well as great lithiophilicity for lithium electrodeposition (Fig.8d, e).As a result, MoSSe could simultaneously accommodate sulfur and lithium (Fig.8f), and the corresponding full cell could achieve a discharge capacity of 637.3 mAh g-1at 1C for 1000 cycles and stable cycle (Fig.8g) [124].The high binding energy of Li2S2/Li2S on MoNx(7.34/4.66 eV) only allowed their easy deposition, while hindered the reversible catalytic conversion of LiPSs.Oxygen-modulated metal nitride (MoNx-O) were proposed to optimize the binding ability (4.54/4.33 eV for Li2S2/Li2S), effectively immobilizing and reversibly catalyzing LiPSs with the lowest decomposition energy barrier of 0.55 eV compared to MoOx(0.66 eV) and MoNx(0.91 eV) [125].To conduct Li+with S atoms and adsorb LiPSs with O atoms, Ce2O2S with O-Ce-S was considered to be more suitable than CeO2with single O-Ce.Due to the additionally formed Li—S and S—S bonds between LiPSs and Ce2O2S, Ce2O2S presented a better adsorption effect for LiPSs and promoted LiPSs conversion with a higher conversion free energy compared to CeO2[126].

BiOX (X = Cl, Br and I) with Bi located at outer surface of the molecular and X with larger electronegativity at inter, provided vacant orbitals of Bi as active sites and accepted electrons from LiPSs, showing excellent ability to adsorb LiPSs and catalyze their conversion [127].Among them, BiOI was more suitable for its good conductivity with a smaller bandgap (1.9 eV) compared to BiOBr (2.9 eV) and BiOCl (3.5 eV).Furthermore, BiOI achieved better ability to capture LiPSs and bidirectionally promote their conversion.This could be proved by higher binding energies, smallest Tafel slope, larger nucleation capacity of Li2S, highest current and smallest polarization displayed in Li2S6symmetrical cells compared with the others [128].

Fig.8 a XRD of rGO/MoS2, rGO/MoSSe and rGO/MoSe2.b Comparison of binding energies of LiPSs and MoS2, MoSe2, MoSSe (V).c DOS states.d, e In situ Raman characterization of cells with rGO/MoS2 and rGO/MoSSe.f Schematic of rGO/MoSSe as a host for both sulfur and lithium.g Cycling performance at 1C [124].Copyright: 2022, American Chemical Society

Because too strong interaction between Ti3C2and S8/LiPSs caused the decomposition of sulfur species, Ti3C2must be modified with surface terminating groups.Therefore, functionalized Ti3C2T2(T = N/O/S/F/Cl) withd-phybridization between Ti and T were studied as sulfur host.The binding energies were in the sequence of Cl < F < N < O < S, and the kinetic evaluation and Li+diffusion got worse in the order of Ti3C2S2> Ti3C2O2> Ti3C2F2> Ti3C2N2> Ti3C2Cl2, which were closely associated with their interactions with sulfur species [129].Compared with Ti2NO2(2.07 eV taking Li2S as an example), Ti2NS2(3.42 eV) possessed larger adsorption energies with sulfur species, which mainly provided by the interaction between Li atoms of LiPSs and S atoms of Ti2NS2.In addition, the Ti2NS2exhibited metallicity that derived from thedorbital of Ti and theporbital of S, and could maintain a high conductivity even after adsorbing LiPSs to facilitate the electrochemical reactions [18].

Hydroxyl oxides, a kind of compounds made up of oxygen ions, hydroxide ions and a metal ion, has also been applied in LSBs.Hydroxy iron oxides (FeOOH) with Fe—O, Fe—OH bonds and good conductivity were used to accommodate sulfur, in which transition metal and hydroxyl acted as adsorption sites for LiPSs and accelerated electron transfer between the catalyst and LiPSs, exhibiting good effect for capturing and catalyzing LiPSs [130, 131].Similarly, MnOOH with Lewis acid sites Mn3+cation could anchor LiPSs by forming Mn-S bond [132].Moreover, the TMCs with dual-cations and dual-anions were designed.For example, LiVPO4F was applied to boost the kinetic of sulfur species, which provided bothporbitals anddorbitals of O, V, F, P atoms to interact with LiPSs [133].

In conclusion, compared to TMCs with single cation/anion, dual-ionic TMCs possess higher conductivity, better chemisorption effect and multiple active sites for catalyzing LiPSs conversion.However, the dual-ionic TMCs still lack in design basis, especially for the bidirectional catalysts.Additionally, there is a lack of research on the optimization of catalytic sites and catalytic activity by regulating the band structure, valence state, electron density of dual-ionic TMCs by adjusting the ions type, content, electronegativity, and ion radius difference.It is worth noting that thed-band center, spin polarization, and other electronic structures of dual-ionic TMCs can also be regulated by changing ion species, which is worthy of further exploration.Furthermore, although doped ions may not be able to form dual-ionic TMCs, and doping and dual-ionic TMCs are similar ways of modifying TMCs by introducing heterogeneous ions, the modification effects and mechanisms of the two should be compared, possibly by regulating the content of introduced heterogeneous ions.Furthermore, high-entropy materials with multi-anions are also of great interest but have not been widely studied [116].Additionally, more modification methods should also be introduced to further improve dual-ionic TMCs, such as bimetallic TMCs quantum dots [134].Bimetallic TMCs can also be combined with doping modification strategy to construct multi-functional sulfur hosts, such as N-doped CuCo2O4[135].

3.3 TMCs-Based Heterostructure Composites

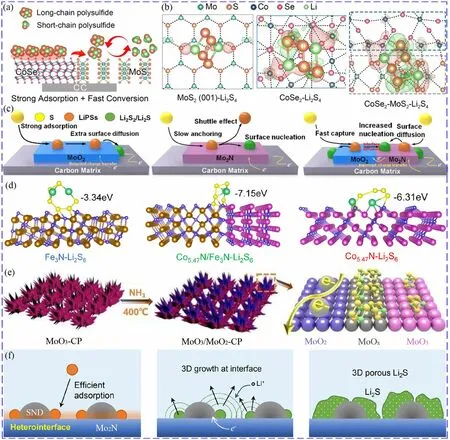

When a kind of TMCs cannot simultaneously meet the needs of chemical binding with LiPSs and catalyzing their transformation, the heterostructure composites of two kinds of TMCs can be constructed with complementary advantages.For example, MoSe2has excellent electrical conductivity and catalytic performance, but lacks sufficient chemisorption for LiPSs, while MoO2has superior chemical binding effect.Therefore, the synergistic effect of efficient capture and catalytic transformation for LiPSs could be achieved with MoSe2/MoO2heterostructure [136].The edge sites of MoS2possess high catalytic activity, while the basal planes have little activity.Zhang et al.grew CoSe2on the base surface of MoS2to form heterostructure, synergistically utilizing the superior chemisorption capacity of CoSe2and the excellent catalytic activity of MoS2edge sites (Fig.9a).The CoSe2/MoS2interface also had higher binding energy with LiPSs than CoSe2and MoS2, which was confirmed by much more accumulated electrons at adsorption regions (Fig.9b).As a result, compared to CoSe2and MoS2, the LSB equipped with CoSe2/MoS2delivered a most stable cycle performance with initial capacity of 825.5 mAh g-1at 2C and retained capacity of 714.5 mAh g-1after 600 cycles [137].Similarly, Zhao et al.constructed Ni/Ni2P heterostructure to combine the strong adsorption of Ni2P for LiPSs and catalytic activity of Ni [138].A kind of heterostructure composed of 0D bimetallic CoZn-Se nanoparticles on 2D nitrogen-doped MXene was designed, providing double lithiophilic—sulfiphilic binding sites through forming Co—S, Li—Se, Ti—S and Li-N/Li—O bonds to adsorb LiPSs and catalyze their conversion [139].Typically, when one component had good adsorption performance and the other component possessed excellent catalytic activity, the adsorption—diffusion—catalysis process of LiPSs could be completed smoothly across the heterostructure interface, thus boosting the redox kinetic, as shown in Fig.9c, such as MoO2—Mo2N [140], MoS2—MoN [141], and Nb4N5—Nb2O5[142].

In addition to combining the advantages or complementing disadvantages of different TMCs, heterostructure composites can also balance the contradictions between them.Considering that too weak interaction is not conducive to interfacial charge transfer, and too strong interaction may hinder it, the chemical interaction should be moderate and balanced with the catalytic capacity.MoO2:Co2Mo3O8heterostructure was prepared by doping Co, in which MoO2possessed strong adsorption ability while Co2Mo3O8delivered superior catalytic property and fast Li+diffusion.To balance the interaction strength and catalytic capacity, the component of heterostructure composite was regulated by changing the cobalt content, and 9MoO2:2Co2Mo3O8achieved the dynamic balance of adsorption-diffusion-conversion, delivering the best catalytic capacity for LiPSs conversion and the smallest Li2S nuclear barrier [143].Similarly, the capturing capacity of WO3and catalytic ability of WS2were balanced in WS2—WO3heterostructure by tuning the sulfurization degree of WO3, and the LSBs with 3WO3:1WS2achieved the highest conversion efficiency [144].

Heterostructures composites can not only combine the advantages of two kinds of materials, but also possess the virtue of the interfacial effect, such as promoting charge transfer, diffusion of Li+and LiPSs as well as adsorption capacity [145].More importantly, the electronic properties of heterostructure can be optimized compared with the monomers, promoting the catalytic activity.The DOS of Co5.47N/Fe3N heterostructures clearly showed a higher DOS value at the Fermi level than that of Co5.47N and Fe3N, indicating a superior electrical conductivity.Additionally, Co5.47N/Fe3N presented the highest binding energy with Li2S6(Fig.9d), implying the synergistic effect at heterointerfaces [146].Heterostructure interfaces also allow rapid diffusion of LiPSs from one component to the other.V2O3/V8C7heterostructure was constructed to rapidly transfer the LiPSs strongly trapped by V2O3to V8C7through the interface, achieving efficient conversion [21].MoO3/MoO2heterostructure was synthesized by partially reducing MoO3and transformed the non-conductive MoO3into conductive MoO2, obtaining the defective MoOx(2 ≤x≤ 3) interface with abundant oxygen vacancies (Fig.9e), which presented greater adsorption capacity with binding energy of 1.78 eV for Li2S4than that of MoO3(1.13 eV) and MoO2(1.00 eV).Benefitting from the different advantages of MoO2and MoOx, the Li2S8electrode with MoO3/MoO2heterostructure achieved the best electrochemical properties, which could retain a capacity of 828.1 mAh g-1at 0.5C after 500 cycles with a capacity decay rate of 0.016%, in contrast to the MoO3with 0.070% and MoO2with 0.083% [147].In addition, heterostructure interface can also provide Li2S nucleation sites, facilitate the nucleation and regulate the three-dimensional growth of Li2S to avoid the passivation of catalyst surface, increasing deposition capacity [148].Lv revealed that Li2S precipitated nonuniformly on the surface of Mo2N with thick layer and a rough morphology.Surprisingly, when small SnO2nanodots anchored on Mo2N microbelt and formed highly active heterointerfaces, the growth of Li2S was guided in a 3D model, avoiding surface passivation of the catalyst (Fig.9f) [149].

Heterostructures composites with enhanced adsorption and catalytic ability can improve cathode performance compared to their components, due to higher electric conductivity with optimized energy band structures (Fig.10a, b), boosted interfacial charge transfer kinetics, accelerated ion diffusion, and more active sites [150, 151].More importantly, the heterostructures induce internal electric fields, and the electron is redistributed as electron transfer occurs and local atoms are arranged [152, 153], such as NiCo-LDH/Co9S8(Fig.10c).ZnS—FeS heterostructure was designed with large energy bandgap offset between ZnS (intrinsic energy bandgap of 4.9 eV) and FeS (0.8 eV).The strong built-in electric field at the heterointerface could effectively promote the charge transfer in redox reaction, thus improving catalyzing capability for LiPSs conversion [154].Electrons redistribution occurs at the binary interface and the electronic structure of the TMCs is regulated, elevating the catalytic activity and chemisorption ability [53, 155].

Fig.9 a Synergistic adsorption and catalysis of CoSe2/MoS2 heterostructure for LiPSs.b electron density differences of Li2S4 on MoS2, CoSe2 and CoSe2/MoS2 (the red and green regions represent negative and positive change [137].Copyright: 2021, John Wiley and Sons.c Comparison of LiPSs conversion and Li2S precipitation on MoO2, Mo2N and MoO2—Mo2N [140].Copyright: 2020, Elsevier.d Binding energies between Fe3N, Co5.47N/Fe3N, Co5.47N and Li2S6 [146].Copyright: 2022, Elsevier.e Schematic diagram of MoO3/MoO2 [147].Copyright: 2020, Royal Society of Chemistry.f Li2S growth at the SnO2—Mo2N interfaces in 3D model [149].Copyright: 2021, American Chemical Society

Fig.10 Band structure of a ZnSe and b CoSe—ZnSe [151].Copyright: 2021, John Wiley and Sons.c Electron density difference of NiCo-LDH/Co9S8 [153].Copyright: 2020, Elsevier.Energy band of TiN and TiO2 d before and e after placing in contact [158].Copyright: 2020, John Wiley and Sons.f DOS of Mo of V-MoN and MoN [159].Copyright: 2018, John Wiley and Sons.g XPS of Ti 2p peaks of TiO2/rGO and TiO2-Ni3S2/rGO.h PDOS of Ti and S atom of the Ni3S2/TiO2 interface [164].Copyright: 2020, John Wiley and Sons.i Schematic diagram of TiN-VN@CNFs used as both Li host and S host to construct full battery [165].Copyright: 2019, John Wiley and Sons

It has been proved that it is the Fermi energy levels difference of two materials that caused built-in electric field and electrons transfer through the interface [156].A Mott—Schottky heterostructure was constructed with positively charged CoFeP and negatively charged C3N4.The difference in Fermi levels rendered electrons transfer from C3N4to CoFeP to balance their work function at the interface.As a result, the energy bands of C3N4upward bended at the interface and an electric field formed from C3N4to CoFeP.The charge was redistributed at the interface, promoting the catalytic activity and Li+diffusion [157].A Mott—Schottky catalysts (TiON) was also built by spontaneous oxidation of TiN due to the lower work function of TiO2compared to TiN (Fig.10d).The charge redistribution at the interface could promote the adsorption and catalytic ability (Fig.10e) [158].Qiao designed MoN-VN heterostructure, which achieved higher adsorption capacity for LiPSs than MoN, due to the regulated electronic structure.To be specific, the Epposition (nearest peak to Fermi level) of the Mo of MoN-VN became higher (Fig.10f), resulting in higher antibonding states compared with MoN [159].This was because the higher Epposition, the lower antibonding orbital occupancy, leading to stronger interaction between LiPSs and catalysts [160].The theoretical calculations for Co3S4/MnS also showed that the introduction of Mn tuned the electronic structure of Co3S4with higher Epposition, contributing to more effectively adsorb LiPSs, facilitate charge transport and improve the conversion kinetics [161].

Considering that different TMCs can catalyze the reaction in different stages of LSBs, heterostructure composites can comprehensively facilitate the reaction kinetics with different catalytic activities of various TMCs.CoO/NiO heterostructure was constructed, in which NiO could accelerate the solid—liquid conversion, and CoO was more conducive to improving the liquid—solid reaction kinetics [162].For MoSe2@F-doped carbon@Mo2C heterostructure, MoSe2and Mo2C selectively catalyzed the conversion of long-chain LiPSs, and F-doped carbon tended to catalyze the reduction of short-chain LiPSs, realizing multi-step catalysis [163].Heterostructure composites can also be used as bidirectional catalyst.It was proved that a CoSe—ZnSe heterostructure could not only accelerate sulfur reduction with a reduced energy barrier of 0.43 eV compared to ZnSe (0.54 eV), but also facilitate Li2S decomposition with a lower oxidation energy barrier of 0.93 eV than that of ZnSe (1.04 eV), thus bidirectionally catalyzing sulfur conversion reactions [151].Yang et al.designed a TiO2-Ni3S2heterostructure, in which strong electronic interactions was occurred between TiO2and Ni3S2(Fig.10g), due to the hybridization between theporbital of S atom of Ni3S2and thedorbital of Ti of TiO2(Fig.10h).TiO2-Ni3S2possessed bidirectional catalytic effect, that is, TiO2captured LiPSs and Ni3S2catalyzed LiPSs conversion during the reduction process, and both of them showed catalytic activity for Li2S oxidation during charging process [164].Moreover, TiO2-Ni3S2as well as TiN-VN could serve as not only sulfur hosts to boost the redox of sulfur cathodes, but also lithium host to facilitate uniform lithium deposition and significantly inhibit dendrites, thus matching Li—S full-batteries with superior electrochemical performance (Fig.10i) [165, 166].

Until now, plentiful heterostructure composites have been explored, especially constructed by TMCs with same anion but different metal ions (such as MoS2/Ni3S2[167]) or same metal ion but different anions (such as Mn3O4-MnPx[168], Fe9S10/Fe3O4[169]).For TMCs-based heterostructure materials composed of different anion and cation, one of the compounds can be prepared first, and then another metal compound can be grown on its surface.Taking SnO2—Mo2N as an example, Mo2N was firstly synthesized and dispersed in water, which was then mixed with SnCl2·2H2O in a mixed solution of HCl and water, and SnO2—Mo2N was obtained by heat treating the mixture in Ar atmosphere.Heterogeneous composites with the same anion and different metal ions can be prepared by adding different metal sources at the same time, and then hydrothermal or solid phase sintering treated according to the state of the raw material (aqueous solution or solid state), and the product type can be controlled by controlling the proportion of raw materials.The MoO2: Co2Mo3O8heterostructure was obtained by drying the mixture of the ammonium molybdate solution and cobalt acetate solution, and then sintering in N2[143].For heterostructures with different anions of the same metal, single-component metal compounds can be prepared first, and then prepared by adjusting the sintering atmosphere, temperature and time, or sintered with chemical reagents containing the anions at high temperatures, such as adding thiourea to prepare sulfide heterojunctions.For example, MoO2-Mo2N was prepared by annealing the prepared MoO3in NH3atmosphere and passivating in O2/N2[140].Similarly, precursors containing anions of heterostructure material are synthesized, and then to prepare the heterostructure with different anions using the resulting gas during high-temperature sintering.For example, MoO2, MoO2/MoC and MoC were synthesized by annealing the synthesized precursor Mo3O10(C6H8N)2·2H2O in Ar for 4 h at different temperatures of 600, 650, and 700 ℃, respectively [149].