Robust optimal dispatch strategy of integrated energy system considering CHP-P2G-CCS

Bin Zhang,Yihui Xia,Xiaotao Peng

1.School of Electrical Engineering,Naval University of Engineering,Wuhan 430000,P.R.China

2.School of Electrical Engineering,Wuhan University,Wuhan 430072,P.R.China

Abstract: Integrated energy systems (IESs) can improve energy efficiency and reduce carbon emissions,essential for achieving peak carbon emissions and carbon neutrality.This study investigated the characteristics of the CHP model considering P2G and carbon capture systems,and a two-stage robust optimization model of the electricity-heat-gascold integrated energy system was developed.First,a CHP model considering the P2G and carbon capture system was established,and the electric-thermal coupling characteristics and P2G capacity constraints of the model were derived,which proved that the model could weaken the electric-thermal coupling characteristics,increase the electric power regulation range,and reduce carbon emissions.Subsequently,a two-stage robust optimal scheduling model of an IES was constructed,in which the objective function in the day-ahead scheduling stage was to minimize the start-up and shutdown costs.The objective function in the real-time scheduling stage was to minimize the equipment operating costs,carbon emission costs,wind curtailment,and solar curtailment costs,considering multiple uncertainties.Finally,after the objective function is linearized with a ψ-piecewise method,the model is solved based on the C&CG algorithm.Simulation results show that the proposed model can effectively absorb renewable energy and reduce the total cost of the system.

Keywords: Combined heat and power;Power-to-gas;Carbon capture system;Integrated energy system;Robust optimization

0 Introduction

Reducing carbon emissions has become a global consensus with the increasingly severe energy crisis and global warming problems.China proposed the “dual carbon” target in September 2020 and promised to peak its carbon dioxide emissions by 2030 and achieve carbon neutrality by 2060[1-3].Energy substitution is essential for achieving the carbon peak and neutrality goals.In recent years,the installed capacity of wind and solar power in China has increased annually,effectively reducing the consumption of fossil fuels and carbon emissions.

However,wind and solar power have intermittent and anti-peak regulation characteristics.With an increase in the installed capacity of wind power and solar power,power dispatching has became more complex,and curtailment of wind power and solar power has occurred in some areas.Recently,integrated energy systems have been widely studied for the flexible conversion of different energy sources through rational scheduling,which can improve the absorption rate of renewable energy [4-7].

Reference [8] established a comprehensive demand response model that takes multiple microgrid systems as the leader and each load aggregator as the follower to form a master-slave interactive equilibrium model and then proved the existence and uniqueness of the game equilibrium solution.References [9-11] focus on the multienergy-flow problem in the integrated energy system and the operational constraints of the energy-supply network were considered in the optimization problem.Reference [12]proposed an integrated energy-optimal dispatching strategy,including combined cooling,heating,and power (CCHP),and considered the security constraints of natural gas systems.In [13],a two-stage scheduling method combining multi-objective optimization and comprehensive decisionmaking was proposed for the economic emission scheduling problem of cogeneration.Reference [14] introduced the concept of integrated demand response.Reference [15]considers the security constraints of the integrated energy system and proposes a mixed integer programming method considering the N-1 uncertainty calculation of both the electricity and natural gas systems.

The above studies have achieved remarkable results in the model establishment and optimization of integrated energy systems;however,these papers mainly focus on methods that reduce carbon emissions through energy substitution at the source,ignoring carbon capture.To overcome the above problems,[16] proposed a low-carbon economic dispatch model of the integrated electricityheat energy system considering the flexibility and lowcarbon nature of the carbon capture power plant,proving that the carbon capture power plant can significantly improve wind curtailment and low-carbon emissions,and the carbon cost introduced can improve the economy of the model.Reference [17] considered the synergy of powerto-gas (P2G) and carbon capture power plants in heat exchange and proved that P2G can effectively reduce the energy consumption of carbon capture power plants,and a carbon tax can achieve a balance between economy and low carbon.Reference [18] introduced oxygen-enriched combustion technology to the electricity-gas-heat integrated energy system and established a low-carbon economic dispatch model to balance the economy and low carbon.Based on the above research,[19] proposed a combined heat and power (CHP) model that considers P2G and a carbon capture system (CCS).The model captures CO2emitted by the CHP and converts CO2into natural gas through P2G,which not only improves the electric-thermal coupling characteristics of the CHP but also reduces carbon emissions and CO2transportation costs.However,this study did not consider uncertainties in wind and solar power.

Based on the above studies,a CHP considering the P2G and CCS (CHP-P2G-CCS) model is constructed in this study,and the electric-thermal coupling characteristics and P2G capacity constraints of the model are derived.A two-stage robust optimal scheduling model for an IES was established and solved using the C&CG algorithm.The following improvements were made in this study∶

1.The derivation results of the electric-thermal coupling characteristics and the P2G capacity constraint of the model proposed in the paper are more accurate;

2.The introduction of energy storage devices enriches the elements of the integrated energy system model;

3.A two-stage robust optimal scheduling model of an integrated energy system is constructed,which enhances the robustness of the optimization results.

1 Modeling and characteristic research of CHP-P2G-CCS

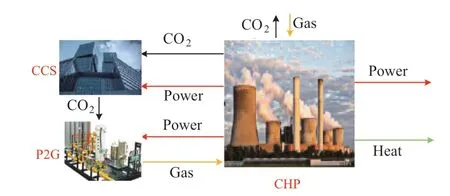

To reduce carbon emissions and CO2transportation costs,a CHP,P2G,and CCS system was developed.The model is shown in Fig.1.As illustrated in Fig.1,CHP generates electricity and heat by consuming natural gas;P2G obtains electricity and CO2from CHP and the nearby carbon capture system (CCS),respectively,and converts CO2into natural gas by consuming electricity,which can reduce carbon emissions and improve energy efficiency;CCS can capture the CO2produced by CHP and transport the CO2to P2G,which consumes electrical energy in the process.Because CCS is located beside P2G,long-distance transmission and storage of CO2is avoided,reducing CO2transportation and storage costs.

Fig.1 Schematic diagram of CHP-P2G-CCS model

The electric energy produced by CHP is mainly used in three ways∶ consumed by users after being connected to the grid,provided for P2G to produce natural gas,and used by the CCS to capture CO2,which can be expressed as

wheretis the time,Pcis the electric energy generated by the CHP,Pc1is the output of electric energy,Pc2is the energy consumed by P2G,Pc3is the energy consumed by the CCS.CCS captures CO2by consuming electrical energy,and the amount of CO2captured can be considered approximately proportional toPc3,which is expressed by [20]

whereCCCSis the amount of CO2captured by CCS andαis the capture efficiency.

The CO2captured by the CCS is transported to the P2G system to produce natural gas.The amount of natural gas produced by the P2G system and the electrical energy consumed in the production process are approximately proportional to the amount of CO2,which can be expressed as [21]

whereβandχare the proportional coefficients.

From (2) and (4),(1) can be rewritten as

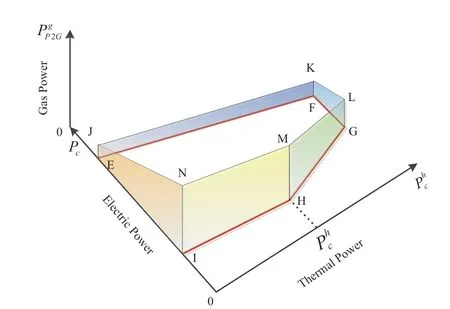

During CHP operation,the power generation and heat production should meet certain constraints,which are called the electric-thermal coupling characteristics of the CHP,as shown by the blue line in Fig.2.As shown in Fig.2,the electric-thermal coupling characteristic of the CHP is expressed as[22]

Fig.2 Electric-thermal coupling characteristics of CHP and CHP-P2G-CCS

wherePc,maxandPc,minare the maximum and minimum values of CHP power generation,respectively;is the value of CHP heat generation;is the heat generation value corresponding toPc,min;is the maximum CHP heat generation;cv1,cv2,andcmare the electric-thermal conversion coefficients of the CHP.

Substituting (5) into (6),which is expressed as (7) ∶

The power consumption of the P2G converter satisfies the capacity constraint,which is limited to∶

wherePc2,maxandPc2,minare the maximum and minimum values of P2G power consumption,respectively.

Substituting (8) into (7),the electric-thermal coupling characteristic of CHP-P2G-CCS is expressed as (9)∶

The electric-thermal coupling characteristics of the model can be drawn from (9),as indicated by the red line in Fig.2∶ The operating range for the CHP electrical and thermal power was ABCD,whereas that for the CHPP2G-CCS was EFGHI.Compared (9) with (6),it is clear that GHI is obtained by downward of BCD,of which the downward amplitude is (1+αχ)Pc2,max,and EF is obtained by downward of AB,and the downward amplitude is (1+αχ)Pc2,min.Since (1+αχ)Pc2,min<(1+αχ)Pc2,max,the area of EFGHI is bigger than that of ABCD,which means the adjustment range of electrical power becomes larger,and the electricthermal coupling characteristics are weakened.

The constraint conditions for P2G natural gas production can be obtained from (3),(4),and (8),which is expressed as follows∶

It can be seen from (9) and (10) that when the CHPP2G-CCS operates on the operation boundary GHI,Pc2takes the maximum value,;When the CHP-P2G-CCS runs on the running boundary EF,Pc2takes the minimum value,.Therefore,natural gas production is constrained by P2G power consumption and CHP electrical power,whereas electrical power is constrained by thermal power.

The constraint relationship between electric power,thermal power,and natural gas output can be obtained by combining (3),(4),(5),and (6),which is expressed as (11)∶

The corresponding relationships among the electric power,thermal power,and natural gas output can be obtained from (11),and the relationships among the three are shown in Fig.3.

Fig.3 Operation characteristic curve of CHP-P2G-CCS

This shows that the feasible region of electric power,thermal power,and natural gas output is EFGHI–JKLMN and that there is a coupling relationship between the three.

The net CO2emission of the CHP-P2G-CCS can be defined as the difference between the CO2emissions of the CHP and the CO2capture of the CCS,which can be expressed as

whereCCHPis the CO2emission of the CHP,aCO2,bCO2,cCO2are the emission factors of the CHP.

It can be seen from (12) and (13) that the net CO2emission of CHP-P2G-CCS is related to the electric power and thermal power,and there is a coupling relationship between the three.It can be seen from the formula (11) that if and only ifPc1(t)=Pc,max-cv2Phc(t),CC-P-C(t)=CCHP(t);WhenPc1(t) ≠Pc,max-cv2Phc(t),CC-P-C(t) <CCHP(t).Therefore,the CHP-P2G-CCS can reduce CO2emissions.

2 Two-stage robust optimal scheduling model

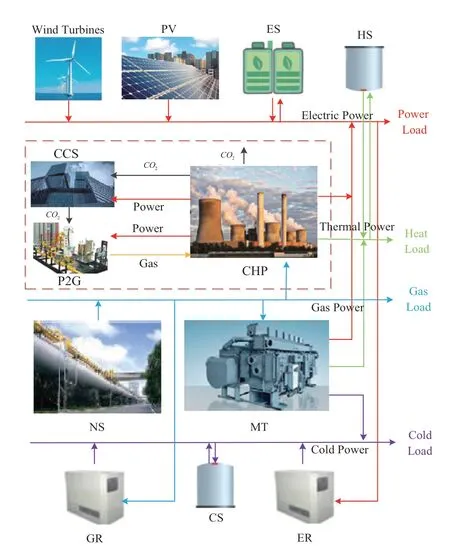

The structure of the integrated energy system is shown in Fig.4.The integrated energy system comprises four energy networks∶ electricity,heat,gas,and cold energy.Wind power,photovoltaics,CHP-P2G-CCS,natural gas sources (NS),micro-gas turbines (MT),electric refrigerators(ER),and gas refrigerators (GR) are essential components of integrated energy systems.To improve the efficiency of energy utilization and reduce the operating cost of the system,a two-stage robust optimal scheduling model for an IES was constructed in this study.

Fig.4 The structure of the integrated energy system

2.1 Objective function

In the day-ahead dispatching stage,the minimum startup/shut-down cost is considered an objective function to determine the start-up/shut-down state of the controllable equipment.In the real-time dispatching stage,the output of the controllable equipment is adjusted according to the actual output of wind and solar power,considering multiple uncertainties based on the result of the day-ahead dispatching.The minimum equipment operation cost,carbon emission cost,wind curtailment cost,and solar curtailment cost are taken as objective functions,as shown in (14)– (16).

wheref1andf2are the objective functions in the day-ahead dispatching and real-time dispatching stages;Iiis the onoff state of theith controllable equipment;Cs,iis the startup cost of theith controllable equipment;CopandCCO2are respectively the equipment operation cost and carbon emission cost;Tis the scheduling time period;cwandcsare respectively wind power curtailment cost and solar power curtailment cost;ΔPwand ΔPsare the wind power curtailment and solar power curtailment respectively.

The equipment operation cost includes the operation cost of the CHP-P2G-CCS,NS,MT,ER,GR,and energy storage(ES) equipment,which is expressed as

whereIis the collection of CHP-P2G-CCS,NS,MT,ER,GR,and ES;a1,iis the unit operation cost of equipmenti;Piis the input power of equipmenti.

The cost of carbon emissions is determined by carbon emissions and carbon emission quotas,which can be expressed as

wherea2is the unit cost of carbon emissions,Pmtis the power generation of the micro gas turbine,dCO2is the CO2emission coefficient of the micro gas turbine,andqis the carbon emission quota per unit of power generated.

2.2 Constraints

(1) Power balance constraints

wherePdisandPchare the discharge and charge capacity of the energy storage device,respectively;Pe-cis the power consumption of ER;is the heat production of MT;andare the discharge and charge capacity of the heat storage device respectively;is the heat load;is the gas supply of the NS;andare the gas consumption of P2G,MT and GR respectively;is the gas load;anddo the MT,ER and GR generate the cold power respectively;andare the cooling power discharged and charged by the cold storage device respectively;is the cold load.

(2) Equipment capacity and ramp constraint

The capacity and ramp constraints are satisfied for energy generation equipment,such as CHP,MT,and GR,which are expressed as [23-25]∶

wherePiis the input power of theith capacity equipment;Pi,minandPi,maxare the lower and upper limits of the input power,respectively;Ri,downandRi,upare the landslide and climbing constraints,respectively;Si,onandSi,offare the durations of the startup and shutdown states,respectively;Ti,on,minandTi,off,minare the minimum startup and shutdown times,respectively.

(3) Energy coupling constraints

The energy coupling equipment can realize the mutual conversion of electricity,heat,gas,and cold.The energy conversion process satisfies certain constraints,which can be expressed as

wherejrepresents the collection of energy forms,including electricity,heat,gas and cold;Pi,jrepresents the magnitude of the input power converted into thejth energy form by theith energy coupling device;ηi,jis the conversion efficiency.

(4) Energy storage device constraints

Energy storage equipment includes Electrical Storage(ES),Hot Storage (HS),and Cold Storage (CS),which satisfy charge-discharge constraints,capacity constraints,and initial–final power deviation constraints,which can be expressed as [26-28]∶

where∶s∈[ES,HS,CS];Ps,chandPs,disrespectively represent charging and discharging power;Is,chandIs,disrespectively represent charging and discharging States,which are 0-1 variables;Ps,ch,minandPs,ch,maxrespectively represent the lower and upper limits of energy charge;Ps,dis,minandPs,dis,maxrespectively represent the lower and upper limits of energy discharge;Esis the energy storage capacity;δs,ηs,chandηs,disare the self-loss rate and charge/discharge efficiency of energy storage respectively;Es,minandEs,maxare the lower limit and upper limit of energy storage capacity respectively;Es,a,maxis the maximum deviation allowed by the energy storage device in a scheduling period.

3 Model solution

3.1 Linearization of the objective function

The carbon emission cost in the objective function is a quadratic function that is transformed into a linear function to simplify the model.Let the general expression of the quadratic function be

wherea,b,care the coefficients of the quadratic function.

Using theψ-piecewise equation mentioned in reference[29],the expression of the functionfin the subinterval[xmin+nΔx,xmin+(n+1) Δx] is obtained as follows∶

whereψis the number of subintervals for linearization of quadratic function,and the largerψis,the higher the accuracy of function fitting is.Forψ=5,the maximum error of the fitting function is less than 1%.

3.2 Construction of Uncertainty

Wind power,solar power,and load all have uncertainties;however,the uncertainty of the load is weak,and the accuracy of the prediction is high,which will not cause significant errors in the calculation results.Therefore,load uncertainty was not considered in this study.The uncertainty sets of wind and solar power can be expressed as [30,31]∶

wherePi,aandPi,rare the actual and predicted values;Pi,uandPi,lare the upper and lower bounds of the uncertainty set,respectively;ΓLis the adjustable parameter of the uncertainty.

3.3 Model solving method based on the C &CG algorithm

The robust optimal dispatch model of the integrated energy system constructed in this study can be organized into a matrix form,which is expressed as

wherexrepresents the start-up and shut-down states of the controllable unit,which is a 0-1 variable;yrepresents the output of the controllable equipment;wrepresents the uncertainty of wind power and solar power;aandbare coefficient matrices in the objective function;DandEare coefficient matrices of equality constraints;eis a constant column vector of equality constraints;A,B,CandFare coefficient matrices of inequality constraints;c,d,andfare constant column vectors with inequality constraints.

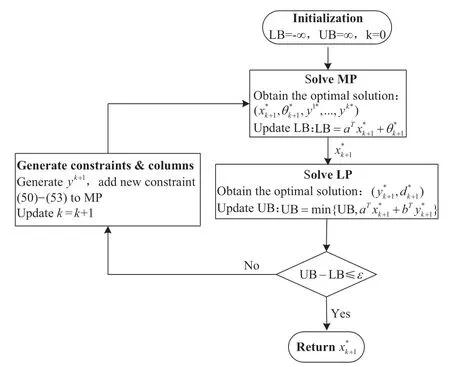

To improve the solution efficiency,this study uses the C&CG algorithm proposed in [32] to divide the two-stage robust optimal scheduling model into a master problem and a sub-problem.The main problem can be expressed as

whereθis the auxiliary variable,which is used to replace the sub-problem target;kis the number of iterations;ylis the recourse variable added to the main problem at theith iteration;wlis the uncertainty parameter,which is obtained by calculating the sub-problem.

The main problem was a linear mixed-integer programming problem that could be solved directly using MATLAB and other software packages.

The sub-problem is expressed as∶

wherex*is the solution of the main problem as a given parameter of the sub-problem.

The sub-problem is a bi-level problem whose inner layer is linear and can be transformed by KKT conditions or the strong duality law.In this study,the KKT conditions were used to transform the bi-level sub-problem into a singlelevel equivalent sub-problem,which can be expressed as

whereα,β,δare the dual operators of (55)-(57) respectively;m,n,qare the indices of constraints and parameters.

(60) and (62) contain the product of the dual operator and parametery,which is a nonlinear function that can be linearized using the big-M method.Taking (61) as an example,it can be transformed into

whereMis an immense constant,andξis an auxiliary variable.

(64)-(66) show that whenξn=0,δn=0 andFy≤f,whenξn=1,δn≤ 0 andFy=f.Therefore,(64)-(66) are equivalent to (61).

After the above changes,the sub-problem is transformed into a linear mixed-integer programming problem that can be solved directly using MATLAB and other software.The proposed optimal dispatch framework for the integrated energy system is shown in Fig.5.

Fig.5 The flow chart of the proposed model-solving method

4 Example analysis

4.1 Example parameters

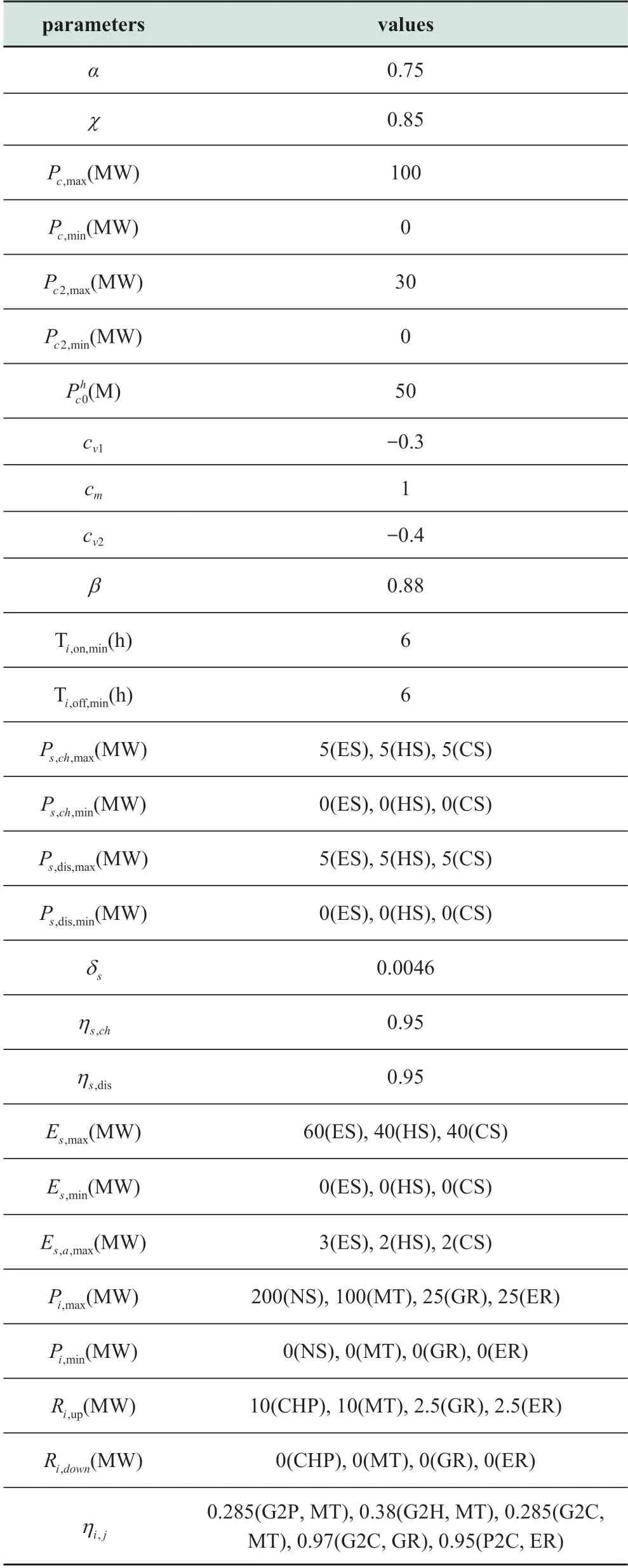

The structure used in the example is shown in Fig.4,and the relevant parameters are listed in Table 1.In Table 1,G2P represents the conversion of natural gas into electrical energy,G2H represents the conversion of natural gas into heat energy,G2C represents the transformation of natural gas into cold energy,and P2C represents the transformation of electric energy into cold energy.

Table 1 The parameters of the models

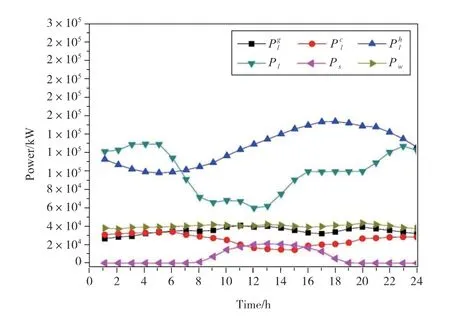

The predicted curves of the wind power,solar power,electric load,heat load,gas load,and cold load are shown in Fig.6.

Fig.6 Prediction Curve of wind power,solar power,and load

4.2 Result analysis

(1) Analysis of model validity and the influence of robust parameters on optimization results.

Three optimization models were compared to verify the validity of the model.

Model 1∶ CHP without P2G,CCS.

Model 2∶ CHP systems with P2G and CCS are located in different places and have no coupling relationships.

Model 3∶ CHP with P2G and CCS forms a whole system located at the exact location (model proposed in this paper).

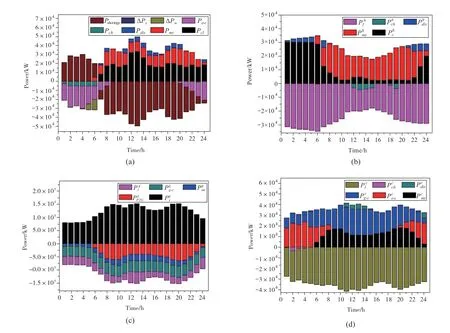

By changing the upper and lower uncertainty limits and adjustable parameters of the model,the result of renewable energy consumption power and operation cost of different models can be obtained,as shown in Fig.7,where the“Robustness” in Fig.7 (a) and Fig.7 (b) represents the ratio of the upper and lower uncertainty limits to the predicted value,and the upper limit and the lower limit are equal.

Fig.7 Effect of changing the robust parameters on the operation result

The uncertainty constraints corresponding to the worst-case scenario worsen with increased robustness and adjustable parameters.The integrated energy system is expected to consume more wind power and photovoltaic power,and the unit capacity of some energy-coupling equipment will increase,leading to an increase in operating costs;the corresponding expected consumption of wind power and solar power will also increase.Therefore,as shown in Fig.7,when the robustness and adjustability parameters are increased,the renewable energy consumption power and operating cost of the three optimization models are increased.

Because model 1 has no P2G or CCS,compared with models 2 and 3,the cost of model 1 is higher,and renewable energy consumption is smaller.Compared with Model 2,the cost of Model 3 is lower,and the consumption of renewable energy is higher because Models 2 and 3 have the same components in the system;the difference is that CHP,P2G,and CCS in Model 2 are located in different places and have no coupling relationship,but in Model 3,they form a whole system and are located in the same place,which proves that the CHP-P2G-CCS model proposed–this model can not only reduce the operation cost of the integrated energy system but also improve the regulation range of electric power and increase the absorption capacity of renewable energy,as proposed in Section 2.It was verified that Model 3 has more advantages than Model 2.

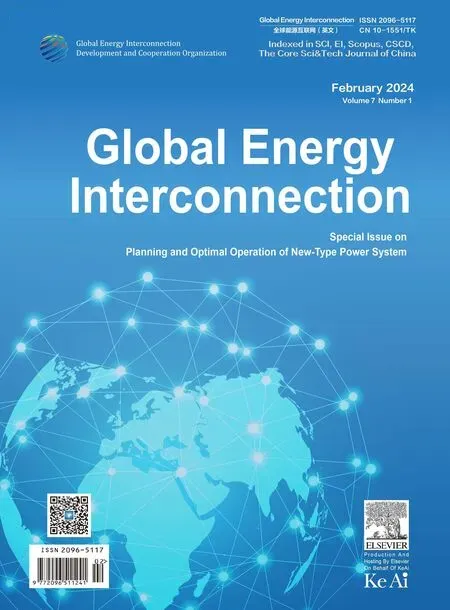

(2) Operation results

The adjustable and robust parameters were set to 8 and 20%,respectively.The electric load balance of the integrated energy system is shown in Fig.8 (a),wherePshortageis the difference between the electric load and the sum of wind power and solar power.From 1 to 6 o’clock,the sum of wind and solar power exceeds the electrical load,and the system must absorb too much renewable energy.To solve this problem,the first step is to reduce the output of other power supply equipment.It can be found that,except for a small output of MT at 6 o’clock,the output of power supply equipment at other times is 0.The second is to increase the charging power of the energy storage device and electrical equipment.From 1 to 6 o’clock,the energy storage equipment is charging,and the electrical refrigeration equipment is working at full load.The third is the curtailment of wind and solar power.When these two methods cannot fully absorb renewable energy,there is a small amount of wind and solar power curtailment at 2 and 4–6 o’clock.From 7 to 24 o’clock,the electric load was greater than the sum of wind and solar power.To solve the problem of power supply and demand balance,the first step is to increase the output of the power supply equipment.The CHP and MT are in a full power state most of the time;the second is to improve the discharge power of the energy storage device,which is in a discharge state in a plurality of time periods;the third is to reduce the output of the power consumption equipment,and the electric refrigeration equipment only has an output in a short time.

Fig.8 Load Balance Diagram of Integrated Energy System

Through calculation,it is found that the integrated energy system consumes 2 640.614 MW of renewable energy,and the total power of wind and solar curtailment is 19.4 MW,accounting for only 0.73%,indicating that the model in this paper can effectively consume renewable energy.Meanwhile,when the electric load exceeds the sum of the wind power and solar output,the integrated energy system meets the load demand of 565 MW through the energy coupling equipment,accounting for 18.46% of the total load,which can help the system achieve real-time load balancing.

A balance diagram of the heat,gas,and cold loads of the integrated energy system is shown in Fig.8(b)–(d).It can be seen that the model in this study can realize a realtime balance of the heat load,gas load,and cold load by adjusting the output of each energy coupling equipment and the charge/discharge power of the energy storage devices;the output of each unit and the charge/discharge power of the energy storage devices are within the constraints.

5 Conclusions

In this paper,the CHP-P2G-CCS model is constructed,and compared with the traditional CHP model,it is proved that the model can improve the electric-thermal coupling characteristics and enhance the regulation range of electric power.A two-stage robust optimization model was established and solved based on the C&CG algorithm.The following conclusions are drawn based on the simulation results∶

(1) As the robustness of the model increases,both the renewable energy consumption and operation cost of the integrated energy system will increase,and a trade-off needs to be made between the two.

(2) Compared to the traditional CHP model,the CHPP2G-CCS model in this study can absorb more renewable energy and has a lower operating cost.

(3) The CHP-P2G-CCS model constructed in this study could effectively absorb renewable energy and satisfy the load demands of users.

Acknowledgments

This study was supported by the National Natural Science Foundation of China (Grant number 51977154).

Declaration of Competing Interest

We declare that we have no conflict of interest.

Global Energy Interconnection2024年1期

Global Energy Interconnection2024年1期

- Global Energy Interconnection的其它文章

- Double-ring high-frequency common-mode switching oscillation current sensor for inverter-fed machine winding insulation monitoring

- Multi-source heterogeneous data access management framework and key technologies for electric power Internet of Things

- A digital twin model-based approach to cost optimization of residential community microgrids

- Integrated strategy for real-time wind power fluctuation mitigation and energy storage system control

- Optimal operation of Internet Data Center with PV and energy storage type of UPS clusters

- Optimal scheduling of a township integrated-energy system using the adjustable heat-electricity ratio model