Ferroelectricity of pristine Hf0.5Zr0.5O2 films fabricated by atomic layer deposition

Luqiu Chen(陈璐秋),Xiaoxu Zhang(张晓旭),Guangdi Feng(冯光迪),Yifei Liu(刘逸飞),Shenglan Hao(郝胜兰),Qiuxiang Zhu(朱秋香),3,‡, Xiaoyu Feng(冯晓钰), Ke Qu(屈可), Zhenzhong Yang(杨振中),§, Yuanshen Qi(祁原深),Yachin Ivry, Brahim Dkhil, Bobo Tian(田博博),¶, Junhao Chu(褚君浩),7,8, and Chungang Duan(段纯刚),9

1Key Laboratory of Polar Materials and Devices(MOE),Ministry of Education,Shanghai Center of Brain-inspired Intelligent Materials and Devices,Department of Electronics,East China Normal University,Shanghai 200241,China

2Zhejiang Laboratory,Hangzhou 310000,China

3Guangdong Provisional Key Laboratory of Functional Oxide Materials and Devices,Southern University of Science and Technology,Shenzhen 518055,China

4Department of Materials Sciences and Engineering,Guangdong Technion-Israel Institute of Technology,Shantou 515063,China

5Department of Materials Science and Engineering,Solid-State Institute,Technion-Israel Institute of Technology,Haifa 3200003,Israel

6Universit´e Paris-Saclay,CentraleSup´elec,CNRS-UMR8580,Laboratoire Structures,Propri´et´es et Mod´elisation des Solides,Gif-sur-Yvette 91190,France

7State Key Laboratory of Infrared Physics,Shanghai Institute of Technical Physics,Chinese Academy of Sciences,Shanghai 200083,China

8Institute of Optoelectronics,Fudan University,Shanghai 200433,China

9Collaborative Innovation Center of Extreme Optics,Shanxi University,Shanxi 030006,China

Keywords: Hf0.5Zr0.5O2 (HZO),ferroelectric,orthorhombic,without annealing

1.Introduction

Storage technologies are approaching physical limits with the continuous reduction of semiconductor process nodes.It is thus urgent to explore new materials and technologies to promote the development of higher density,lower power consumption and faster memory devices.Among new types of memory technologies, ferroelectric-based memory devices demonstrate appealing potential because of their low-writing power, fast-switching speed and high endurance.[1-3]However,traditional perovskite-based(ABO3)ferroelectric materials,like Pb(Zr,Ti)O3(PZT)and BaTiO3(BTO)have difficulty in maintaining ferroelectricity at the nanometer scale.It results in ferroelectric random access memory stagnating at 130 nm node.[4-6]The discovery of unprecedented ferroelectric properties in Si-doped HfO2thin films with a fluorite structure in 2011 quickly piqued intensive attention on HfO2-based ferroelectrics in both academic and industrial communities.[7]In contrast to the perovskite counterparts, HfO2-based ferroelectric films not only can maintain ferroelectricity within ten nanometers but also are compatible with common Sibased complementary metal-oxide-semiconductor (CMOS)processing methods.These merits break the traditional ferroelectric memory’s bottleneck and make HfO2-based ferroelectric films promising for next-generation electronics.

Various fabrication methods have been explored for HfO2-based ferroelectric films over the last decade,including atomic layer deposition (ALD), sputtering,[8-10]pulsed laser deposition(PLD),[11]and chemical solution deposition.[12-14]Among them, ALD stands out as the most established deposition technique for controlling thickness at the atomic level and producing large-scale homogenous films.It is generally accepted that the ferroelectricity of doped HfO2-based films comes from the metastable non-centrosymmetric o-phase that exhibits thePca21space group.To obtain the metastable ferroelectric o-phase, ALD-grown films typically require hightemperature annealing.[15,16]Among various dopants,such as Zr,[16-19]Al,[20-22]Si,[23,24]La,[25,26]annealing temperature for Zr-doped HfO2films is relatively low.[27]

Due to the limitations of large-scale integrated circuits,fabrication temperature is typically restricted to lower temperatures.Therefore,decreasing annealing temperature is of both scientific and technological interest.Using different methods to improve ferroelectricity at low processing temperatures,could be attributed to increasing the o-phase in the film.Elaborate control on experimental parameters,including annealing period, annealing velocity, and pressure, was put forward to tackle this challenge.For instance, by increasing the pressure to 50 atm during annealing, Kimet al.obtained ferroelectric HZO films at a reduced annealing temperature of 450°C.[28]Lehningeret al.prolonged the annealing time to 2 h and reported ferroelectric HZO films under 400°C postthermal processing.[29]The transition from non-ferroelectric tetragonal phase (t-phase) to o-phase under either high pressure or time-extended annealing process accounts for the ferroelectricity in their HZO films.Despite of these inspiring progresses,ferroelectricity acquired under much low temperature processing is still appealing,especially for applications in flexible and wearable electronics.Yuet al.grew 30 nm HZO thin films on flexible substrates and annealed them at 380°C for 120 s.[30]The low thermal conductivity and thermal expansion coefficient of plastic substrate make it possible to enhance the ferroelectric phase ratio of HZO films by optimizing the annealing rate and film thickness.Perssonet al.deposited HZO films on high-mobility InAs semiconductor and decreased the annealing temperature down to 370°C.[31]Takashi Onayaet al.reported 10 nm Hf0.43Zr0.57O2films annealed at 300°C for 60 s,and proposed that nanocrystals with metastable o/t/cubic phases in the as-deposited Zr-doped HfO2films may serve as nuclei sites for ferroelectric phase during annealing process,because plasma-enhanced ALD has stronger oxidizing power than TALD.[32]

Although ferroelectric Zr-doped HfO2films have been reported under 400°C thermal processing,the annealing process is still indispensable for enhanced ferroelectric o-phase.[33]With the elimination of the annealing process, ferroelectric Hf0.34Zr0.66O2films were obtained by Kimet al.using cyclopentadienyl-based precursors growth,[17]while Qiet al.prepared ferroelectric HZO films by adding a TiO2interfacial layer between HZO and TiN at 300°C.[34]These works used either stable precursors or a dielectric layer to trigger the formation of ferroelectric o-phase.Further experiments are still required to directly form the ferroelectric o-phase without extra experimental processing.

Herein,we demonstrate a record low fabrication temperature of 250°C for ferroelectric HZO films without needing a post-annealing process.Grazing-angle incidence x-ray diffraction (GIXRD) measurement and Cs-corrected annulardark-field (ADF) STEM are used to confirm the existence of ferroelectric o-phase in as-deposited HZO films.Polarization versus electric field(P-E)hysteresis loops in the TiN/asdeposited HZO/TiN capacitor further confirm the ferroelectricity.The endurance is up to~107cycles.This finding enables a further decrease of the fabrication temperature for HfO2-based ferroelectric films and avoids undesirable chemical reactions during annealing, offering a new pathway for low-temperature flexible and wearable electronics based on HZO devices.

2.Experimental methods

For metal-ferroelectric-metal (MFM) capacitors, 5 nmthick TiN films are deposited on heavily n-doped Si substrates via magnetron sputtering at room temperature to form the bottom electrode.Subsequently, 15 nm thick HZO films are grown by TALD at 250°C, using Tetrakis(dimethylamino)hafnium (TDMA-Hf) and Tetrakis(dimethylamino)zirconium(TDMA-Zr)as precursors,and H2O as an oxygen source.The cycle ratio between HfO2and ZrO2is 1:1.After ALD deposition, capacitors are prepared by photolithography to obtain 100 µm×100 µm top electrodes.A 50 nm TiN is deposited on the HZO films via magnetron sputtering, followed by photolithography patterning.Besides, several reference capacitors are crystallized by rapid thermal annealing (RTA) with temperatures ranging from 150°C to 750°C in ambient N2for 30 s.

The crystallinity of HZO thin films is investigated via GIXRD using Cu-Kαradiation(λ=1.5405 °A)with an incidence angle of 0.5°.The thickness of HZO films is obtained by x-ray reflectivity(XRR).ADF-STEM images are performed to characterize the capacitors in more detail.P-Emeasurements and endurance tests are performed at room temperature using a ferroelectric analyzer(TF Analyzer 3000)at 1 kHz/5 V and 10 kHz/4.5 V,respectively.

3.Results and discussion

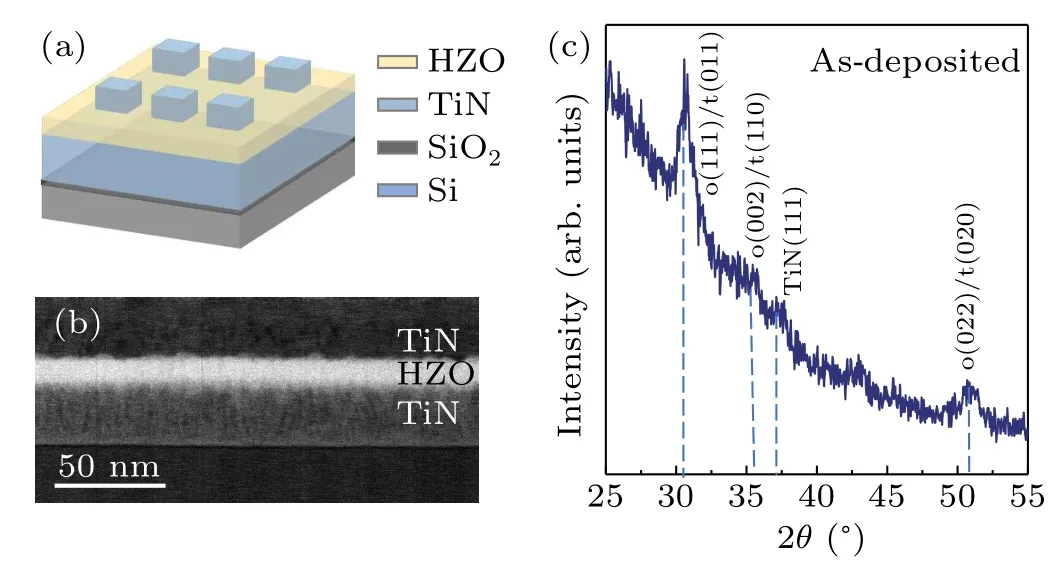

The ferroelectricity of the HZO films is explored in MFM capacitors (Fig.1(a)).Figure 1(b) shows the crosssectional HAADF-STEM image of a TiN/HZO/TiN/SiO2/Si stack, which confirms 15 nm thickness of as-deposited HZO film.The crystallinity and phase identification are investigated by GIXRD measurements.Figure 1(c) displays the GIXRD pattern of as-deposited MFM capacitor.The o (111)/t (011)at~30.5°, o (002)/t (110) at~35.3°, and o (022)/t (020) at~50.8°diffraction peaks of HZO, and TiN (111) at~37.2°reflection can be identified.[35]Therefore, as-deposited HZO film has a polycrystalline structure composed of t-phase and o-phase.

Fig.1.(a) Schematics of the MFM capacitors: TiN (50 nm)/HZO(15 nm)/TiN (50 nm)/SiO2/Si.(b) ADF-STEM image of MFM capacitor.(c)GIXRD patterns of as-deposited MFM capacitors.

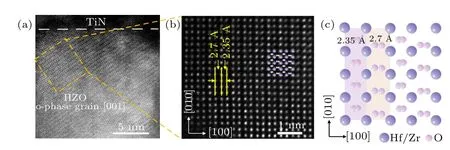

To confirm the o-phase grain in asdeposited HZO film,we perform Cs-corrected STEM imaging for atomic characterization.As shown in Fig.2, cross-section ADF-STEM images exhibit TiN/HZO/TiN stack with an o-phase grain.Zooming into the dashed yellow square in Fig.2(a),the lattice spacings of 2.35 °A/2.7 °A(Fig.2(b))reveal that the o-phase grain possessesPbc21symmetry, which is considered as the origin of ferroelectricity in hafnium-based materials.HAADF-STEM image is taken along the [001] direction and corresponding crystal structure of HZO is shown in Fig.2(c).This result indicates that an o-phase grain could be formed without additional annealing.

Fig.2.(a) Cross-section ADF-STEM image of TiN/HZO/TiN stack,showing an o-phase[001]grain.(b)HAADF-STEM image acquired from the dashed yellow square area in panel(a),demonstrating the Pbc21 phase structure.(c)Crystal structure of HZO viewed along[001]direction.

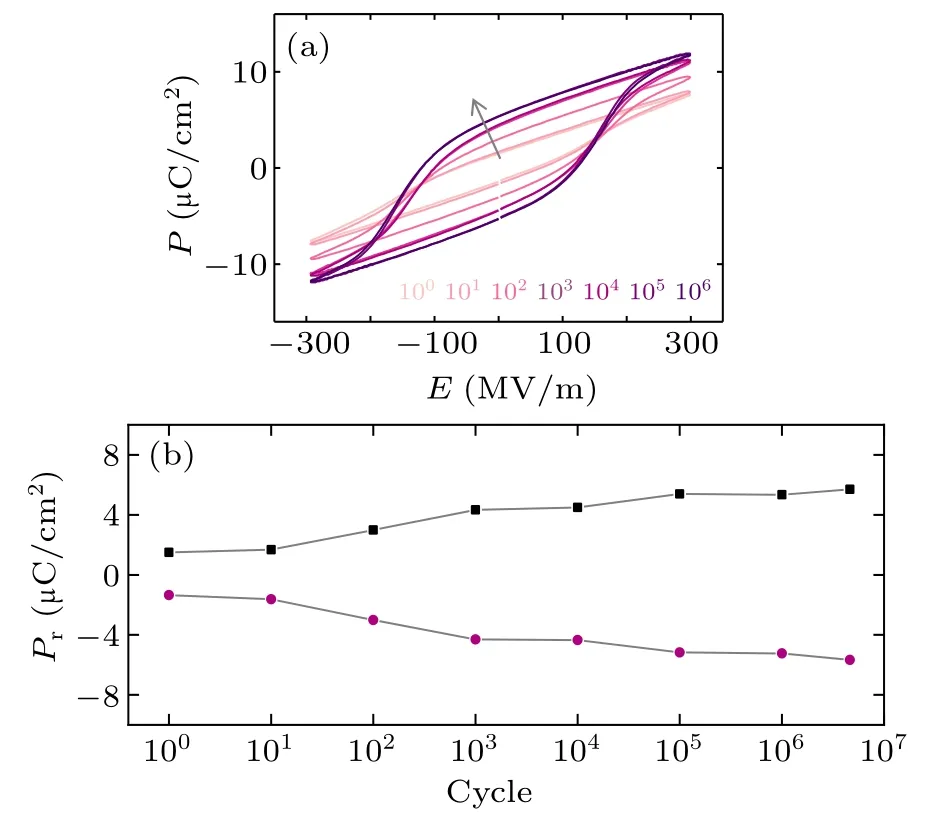

Electrical tests are performed to further confirm the ferroelectricity of asdeposited HZO films.It is also worth noting that, for as-deposited HZO films, theP-Ecurve shows a distinct ferroelectric hysteresis.Figure 3(a) showsP-Ehysteresis loops gradually open along the grey line direction with increasing measuring cycles.Remarkably, thePrvalue of asdeposited HZO films increases significantly as the measuring cycles increase, which becomes quasi-stable with a value of~5 µC/cm2after~103cycles and reaches 5.7 µC/cm2after~107cycles.The gradually increasedPrvalue implies transitioning from t-phase to o-phase during measuring cycles.[36-38]It is worth noting that ferroelectricity survives~107cycles for as-deposited HZO films.

Fig.3.(a) Endurance test results of as-deposited TiN/HZO/TiN capacitors.(b)Pr values are extracted from panel(a)as functions of the number of switching cycles.

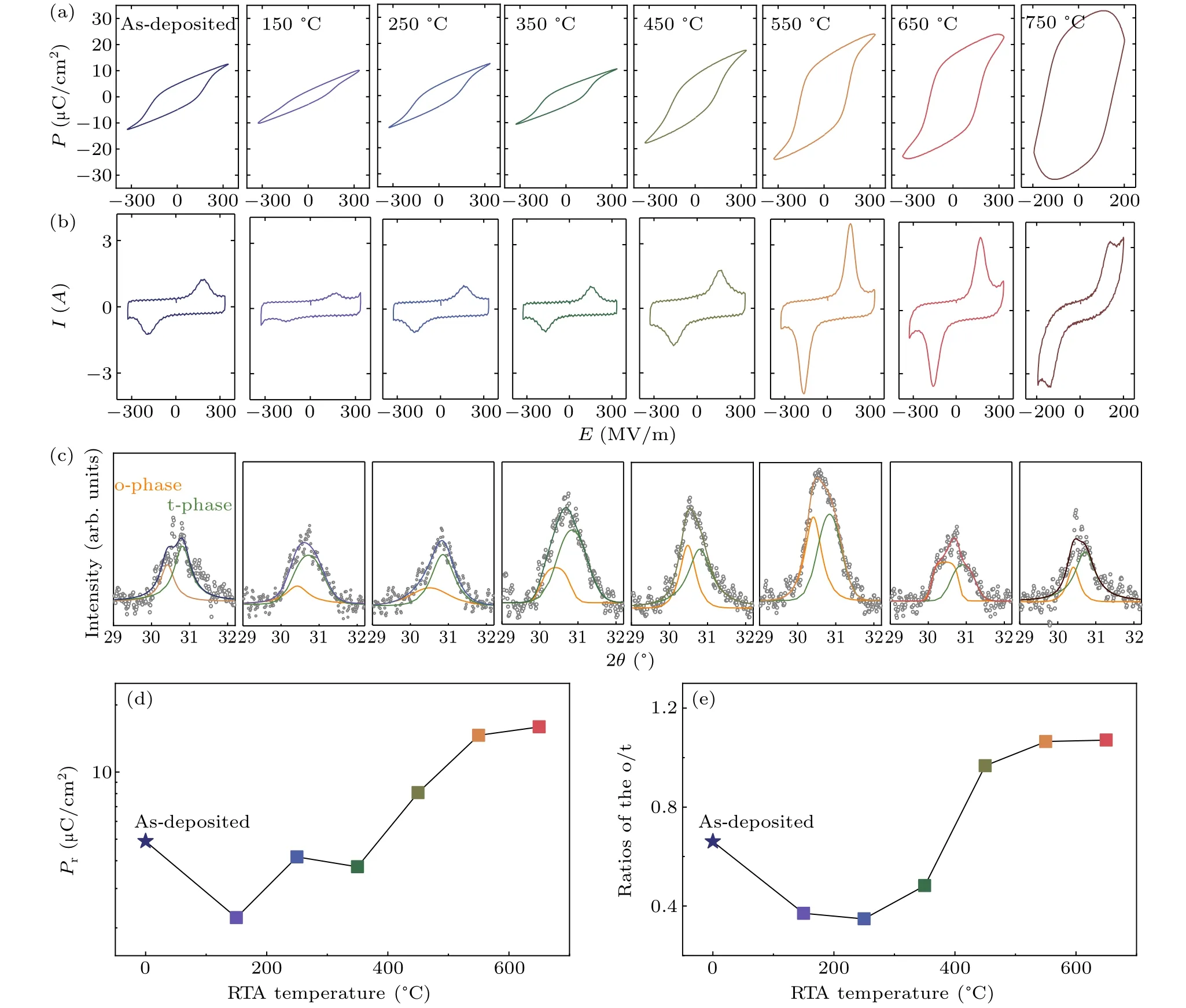

As a comparison, other HZO films suffering post-RTA treatments at temperatures ranging from 150°C to 750°C are also checked.Figures 4(a)and 4(b)showP-Ecurves and correspondingI-Ecurves obtained under 1 kHz conditions.Electric field cycling with 103cycles at 4 V and 5 kHz is preperformed to keep HZO films free of the wake-up effect.[39-42]The hysteresis loops are poor for films after RTA treatment at temperatures between 150°C and 350°C.With increasing RTA temperatures from 450°C to 650°C,the films show enhanced ferroelectricity with a maximum 2Prof~32µC/cm2at 650°C.Further increasing RTA temperature up to 750°C,leakage current becomes noticeable.ThePrvalue obtained fromP-Ecurves is presented in Fig.4(d).To understand the difference inPrvalue among HZO films, GIXRD spectrum, especially in the 2θrange of 29°-32.2°, is analyzed,which can give information about the relative proportion of ophase and t-phase in HZO films.[16,24,43]As shown in Fig.4(c),the fitting of GIXRD patterns by Gaussian-Lorentzian cross product function,with fixed peak positions at 30.4°and 30.8°for o (111) and t (011) respectively, can be used to obtain the o/t phase proportion.[35]The relative proportion of o/t derived from GIXRD fittings is presented in Fig.4(e).Notably,thePrvalue (Fig.4(d)) accords well with the proportion of o/t (Fig.4(e)), supporting that the change of ferroelectricity in our ALD-fabricated HZO films originates from the change of o-phase proportion.Temperature dependences ofPrvalue(Fig.4(d))and proportion of o/t(Fig.4(e))imply that annealing at a low temperature<400°C does not effectively contribute to the crystallization of ferroelectric o-phase.

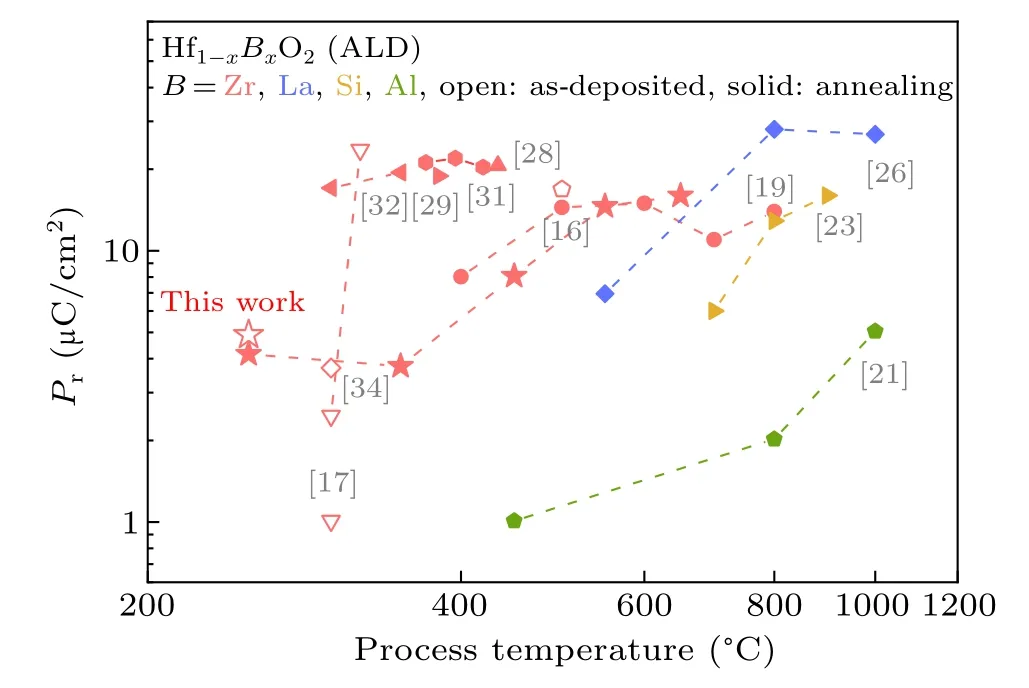

Figure 5 summarizes a comparison of thePrvalue obtained from this work and other reported HfO2-based ferroelectric films.Our work reports the ferroelectricity of HZO films by competitive low temperature processing.

Fig.4.(a)P-E hysteresis curves and(b)I-E curves of TiN/HZO/TiN capacitors with different RTA conditions at 1 kHz/5 V.(c)Ratios of the o-phase/tphase (o/t) for HZO films as-deposited and under different RTA treatment, by fitting the peak at 30°-31° from GIXRD pattern.The orange and green curves are fittings for the o-phase and the t-phase,respectively.(d)Pr and(e)ratios of the o/t for HZO films as a function of RTA temperature.

Fig.5.Comparison of the Pr values of HfO2-based ferroelectric films that are treated at different temperatures.

4.Conclusion

We demonstrate that ferroelectricity in HZO films can be directly obtained by a low-temperature(as low as 250°C fabricating temperature)ALD method without any post-annealing process.The as-deposited HZO films show aPrvalue of>5µC/cm2and an endurance of around 107cycles.Atomic resolution ADF-STEM image directly confirms that o-phase grains are formed in as-deposited HZO films.It gives a clue for reducing the processing temperature for ferroelectric HZO films and extending their compatibility for flexible and wearable applications.

Acknowledgments

Project supported by the National Key Research and Development Program of China(Grant No.2021YFA1200700),the National Natural Science Foundation of China (Grant Nos.T2222025 and 62174053), the Open Research Projects of Zhejiang Laboratory (Grant No.2021MD0AB03), the Shanghai Science and Technology Innovation Action Plan (Grant Nos.21JC1402000 and 21520714100), the Guangdong Provincial Key Laboratory Program (Grant No.2021B1212040001), and the Fundamental Research Funds for the Central Universities.Yachin Ivry acknowledges support from the Zuckerman STEM Leadership Program as well as from Pazy Research Foundation(Grant No.149-2020).

- Chinese Physics B的其它文章

- Corrigendum to“Reactive oxygen species in plasma against E.coli cells survival rate”

- Dynamic decision and its complex dynamics analysis of low-carbon supply chain considering risk-aversion under carbon tax policy

- Fully relativistic many-body perturbation energies,transition properties,and lifetimes of lithium-like iron Fe XXIV

- Measurement of the relative neutron sensitivity curve of a LaBr3(Ce)scintillator based on the CSNS Back-n white neutron source

- Kinesin-microtubule interaction reveals the mechanism of kinesin-1 for discriminating the binding site on microtubule

- Multilevel optoelectronic hybrid memory based on N-doped Ge2Sb2Te5 film with low resistance drift and ultrafast speed