Review on Development of Pressure Injury Prevention Fabric

XING Lin(邢 琳), NORSAADAH Zakaria, WAN Syazehan Ruznan

1 School of Design, Taylor’s University, Selangor Darul Ehsan 47500, Malaysia 2 Institute of Design and Art, Hebei Academy of Fine Arts, Shijiazhuang 050011, China 3 School of Industrial Technology, University Technology MARA, Selangor Darul Ehsan 40450, Malaysia

Abstract:Pressure injury is a common postoperative complication of wheelchair users. It has a high incidence rate and can induce sepsis and even death. The fabrics that touch patients’ skin directly have a profound impact on their skin surfaces. This review summarizes the research in the last five years on the relationship between pressure injuries and fabrics. Following the preferred reporting items for systematic reviews and meta-analyses(PRISMA) statement, a systematic literature search is conducted in nine databases, including SCI (Web of Science), IEEE, ASTM, Taylor &Francis, ProQuest, Wiley, SpringerLink, PubMed and SAGE. The research objects, experimental equipment and survey results are investigated in this review, in which twenty-four different textiles and seven different test methodologies are involved. The test methodologies include five kinds of performance tests and two kinds of observational studies. Two studies showed that the particular fabric was helpful to reduce the pressure on the skin surface, and twelve studies revealed that the multi-layer fabric with good air permeability, heat dissipation and moisture dissipation was helpful to prevent pressure injury. This review confirms the correlation between the fabric properties and the occurrence of postoperative pressure injury in wheelchair users. Further experiments are needed to reasonably integrate the fabric characteristics of pressure injury prevention into the mass-produced pressure injury prevention clothes for wheelchair users.

Key words:pressure injury prevention; wheelchair user; fabric property; medical fabric; meta-analysis

0 Introduction

A pressure injury, known as pressure sore, pressure ulcer, or pressure ulceration, is a common postoperative complication in patients with activity restriction. The National Pressure Ulcer Advisory Panel (NPUAP, USA) released a terminology change statement on April 13, 2016. The term “pressure ulcer” was changed to “pressure injury” and defined as a local injury of the skin and soft tissue at the bone apophysis or under medical or other instruments. The “pressure injury” presents as intact skins or open ulcers that may be painful[1]. The statement redefined pressure injury development into four stages. Stage Ⅰ is complete skin with erythema; stage Ⅱ is part of the cortex missing and the dermis being exposed; stage Ⅲ is total cortical loss; stage Ⅳ is tissue loss.

Many factors are related to the occurrence and development of pressure injuries, but their exact role needs to be further verified. The statement (NPUAP, 2016) mentioned that the damage was caused by intense or persistent pressures or combined shear forces. Therefore, the tension, the shear force and the friction are the leading causes of pressure injuries. The incontinence and the temperature increase the friction. In high-pressure positions of the medical equipment (e.g.wheelchairs), the local pressure and friction increase, the mobility is limited, and the blood flow is reduced. And the frequency of these impairments increases in the elderly. Paralyzed wheelchair users are at a high risk for pressure ulcers, as are intensive care unit (ICU) patients and bedridden patients.

The pressure injury significantly increases the suffering of patients and even increases the risk of sepsis and death[2]. Nurses have taken more appropriate care measures in the caretaking of paralyzed patients. They add cushions to the parts prone to pressure sores to reduce the pressure received by the body, help patients clean up excreta in time, ensure dry skin, massage patients regularly to promote blood circulation, and so on[3]. The use of materials with antimicrobial, blood-repelling and odor-removing properties is advised for nursing items[4]. The nursing association trains nurses in professional nursing of pressure injury[3]and formulates more scientific guiding principles[5], but still cannot achieve zero incidence of pressure injury prevention. The incidence of pressure injuries in developed countries is as high as 9.2%-15.0%. Rodgersetal.[2]surveyed acute care hospitals in Australia and New Zealand and found that the incidence of pressure injuries was 12.9%. Moreover, in the United States, nearly 2.5 million people got pressure injuries from January 1990 to September 2009[3]. In some parts of Swedish county, the death rate from pressure injuries was as high as 44.0%[6]. In China, the tetraplegia prevalence rate ranged from 37.4% to 82.0%, while the total injury prevalence rate ranged from 14.1% to 73.9%, respectively[7]. The in-hospital mortality rate reported from SCI-related papers(published before March 15, 2020) ranged from 1.1% to 18.4%[7]. The pressure injury is a constant threat to people’s lives.

In addition to routine care, the environment between the fabric and the skin impacts the occurrence of pressure injuries. When the contact surface structure does not provide cushioning and support for the convex part of the bone, this part is easy to form local high pressure. The fabric with poor heat and moisture dissipation will lead to the formation of a high temperature and high humidity environment on the skin surface, making the skin barrier fragile. Fabrics with high friction coefficients can directly damage delicate skin and form surface ulcers. So it is necessary to research the performance of the material against the pressure injury.

1 Determination of Research Scope and Objects

In previous studies, the concept of contact surface for wheelchair users is the wheelchair seat cushion[8]. This review defines the concept of “contact surface feature” as the physical and chemical characteristics of the fabric in direct contact with the skin of wheelchair users’ lower limbs based on the published papers in primary searches to explore the relationship between fabrics and pressure injuries. To exclude the influence of other diseases of paralyzed wheelchair users on the incidence of pressure injuries, in addition to paralysis caused by spinal cord injury, the cases reported with other conditions such as hypertension and diabetes are not included in this review.

In addition, the local high temperature and humidity increasing on the skin surface is also the influence factor to increase friction[9-10]. Therefore, the literature related to thermal and wet comfort experiments is included in this review.

2 Methods

The primary analysis methods include literature retrieval and online discussion. The published literature on the relationship between pressure injuries and skin contact fabrics was systematically reviewed. The searched databases included SCI (Web of Science), IEEE, ASTM, Taylor &Francis, ProQuest, Wiley, SpringerLink, PubMed and SAGE. In addition, “self-reports” from self-created websites by wheelchair users were included and the rehabilitation and medical staff were contacted. The researchers in this analysis were scholars majoring in fabric ergonomics, orthopedics and rehabilitation. They conducted a meta-analysis with research objects, materials, research methods, relevance, limitations,etc.

2.1 Search key words

Medical and rehabilitation papers were selected based on the key words in titles and abstracts containing wheelchair user, paralyzed wheelchair user, pressure injury, pressure sore, pressure ulcer, pressure ulceration, prevention of pressure ulcer, paralyzed rehabilitation, patient fabric, patient trousers, paralyzed fabric, adaptive fabric, pressure ulcer surface fabric, barrier-free fabric, or wheelchair user trousers.

2.2 Preferred reporting items for systematic reviews and meta-analyses statement

The preferred reporting items for systematic reviews and meta-analyses (PRISMA) statement[11]was used in meta-analysis to review the related papers systematically. The PRISMA statement consists of a list of 27 items and a four-stage flow chart (retrieval, primary screening, inclusion and synthesis) and aims at the systematic evaluation of randomized controlled trials. It is also suitable for other types of periodic evaluation reports, especially for assessing interventions.

As shown in Fig.1, in this review, 403 papers were searched. After excluding 281 papers with relatively weak correlation and 6 non-experiment papers, 116 papers were full-text downloaded and analyzed. After screening the research objects and methods of the papers, 102 papers were identified as insufficient relevance. The primary justification for exclusion is that the objectives of these investigations run counter to the key concepts of this review. Although these investigations are connected to fabrics and pressure injuries, there has not been much in-depth study. In the full-text download literature study, researchers deleted non-medical care papers.

Fig. 1 PRISMA diagram

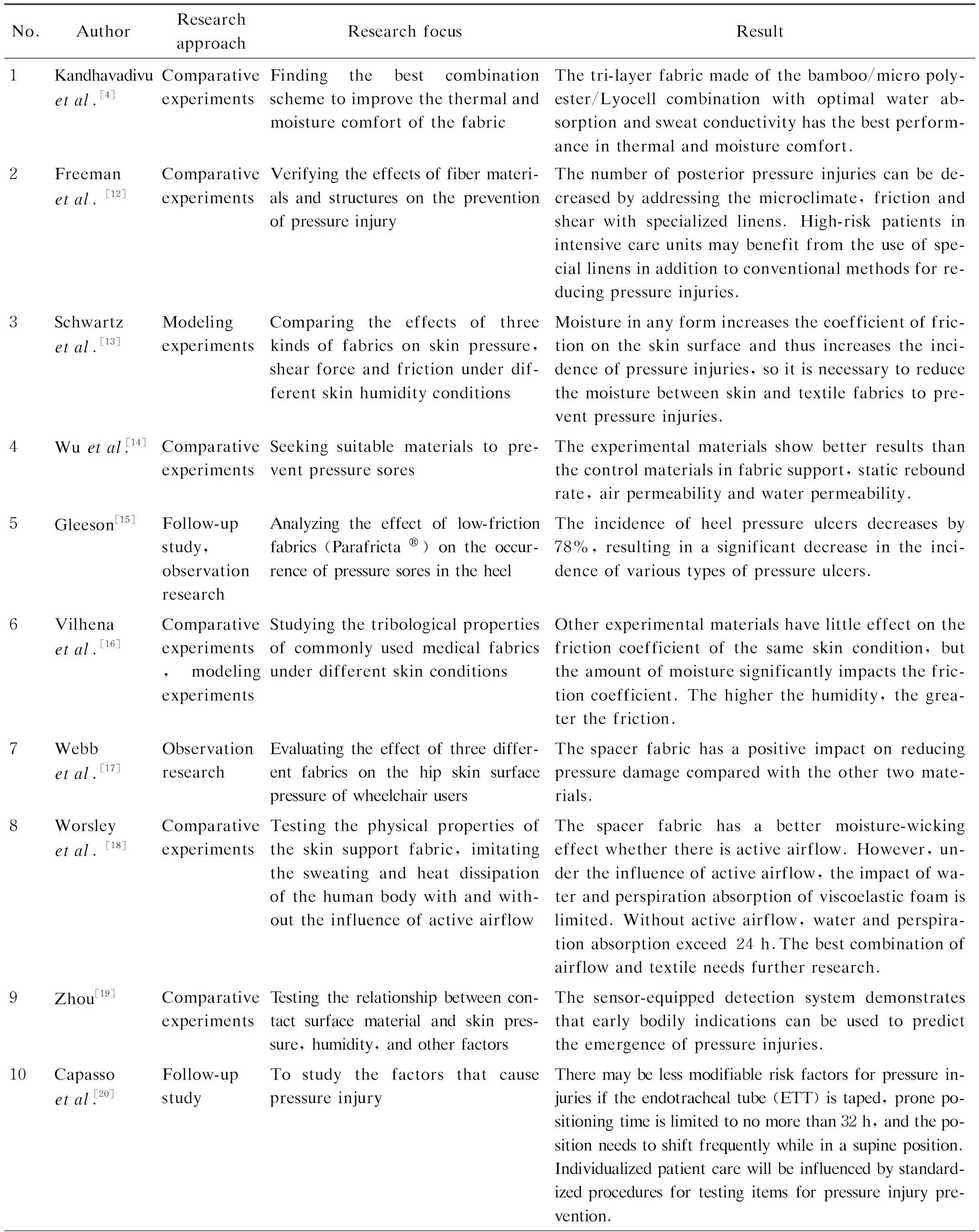

Screened by the PRISMA method, 14 papers met the requirements most in terms of research contents, research methods and research relevance, as shown in Table 1.

Table 1 Meta-analysis

(Table 1 continued)

Among these papers, three papers (Refs. [15,17,20]) are qualitative studies on finished materials, mainly through observation and analysis and follow-up investigation of patients, to verify their effects on preventing pressure injuries. The research objects of the other 11 papers are the influence of the composition and the structure of fabrics on the ability to prevent pressure injuries and quantitative research methods such as modeling, simulation and experimental comparison.

3 Results

3.1 Study characteristics

There were 4 177 participants and 24 fabric samples in all studies. Two cross-sectional qualitative studies use a single experimental material for historical comparison experiments. Other studies were quantitative experimental studies with experimental samples. The researchers determined the air permeability, thermal conductivity, and friction coefficient of the fabric by changing its composition, spatial structure, inter-layer and surface roughness.

3.2 Fabric material for pressure injury prevention

The researchers showed that the Parafricta fabric and the special linen fabric had a positive effect on preventing pressure injury. The Parafricta fabric is a new material made of polyester. It is primarily distinguished by its antibacterial characteristics and mimicry of the touch of silk. In the study of the Parafricta fabric[15], according to the inpatient medical records in 2011 in St Helens and Knowsley Teaching Hospitals NHS Trust, United Kingdom,without the intervention of experimental materials, there were 125 patients with pressure injuries, including 50 patients with heel pressure injuries, accounting for 67%, as the control group of the Parafricta fabric.

With the same nursing care, the incidence rates of pressure injuries in the control group and the experimental group decreased by 7.2% and 55.2%, respectively; while those of heel pressure injuries decreased by 32.0% and 78.0%, respectively. It shows that with the use of the Parafricta fabric, the incidence of pressure injuries is reduced, compared with that in the control group, indicating that the Parafricta fabric is helpful to alleviate pressure injuries at use sites. In the study of special linens[12], the material intervention reduced the overall incidence rate of pressure injuries from 7.7% to 5.3%, with a reduction in the incidence rate of posterior pressure injuries from 5.2% to 2.8%. It shows that the intervention of the special linen fabric has no adverse effect on alleviating the occurrence of pressure injuries.

3.3 Fabric structure on pressure injury prevention

3.3.1Composition

There are three references on measuring the effect of fabric composition on preventing pressure injuries. Through experiments on hygroscopicity and moisture dispersion, Kandhavadivuetal.[4]found that fabrics with a high cellulose content had a poor effect on preventing pressure injuries with an impact rate of about 0.97%. Schwartzetal.[13]found that the standard polyurethane foam increased the risk of skin pressure injuries by about 54.2% under dry or wet conditions compared with the high-cellulose fabric. Vilhenaetal.[16]compared different fabrics and found that hospital fabrics had a better protection effect against pressure damage, 1.4 times that of the worst experimental materials.

3.3.2Inter-layer

Only one paper dealt with the influence of fabric inter-layer environment on skin pressure injuries. Worsleyetal.[18]improved the heat dissipation of the fabric threefold by adding active airflow and side openings. The experimental results show that this method is effective, but it is limited to the fabric with a specific thickness and thus needs further innovation.

3.3.3Surfaceroughness

The surface roughness of the fabric directly affects the friction coefficient between the skin and the fabric. Through measurement, Vilhenaetal.[16]found that the friction coefficient between the skin and the fabric increased with the increase of moisture. Under the same dry and wet conditions, the friction between the hospital fabric and the skin is minimal. The hospital fabric was not described in detail in the study, and it was only a porous plain fabric observed under an optical microscope.

4 Discussion

Fabric properties such as support, air permeability, heat conduction and moisture absorption, according to the findings, have a significant impact on the occurrence of skin pressure injury. These properties are determined by the fabric’s material, structure and weaving process. In general, the medical linen materials, the knitted columnar structure and the silk imitation technology help to improve the fabric performance in terms of pressure injury prevention.

4.1 Evaluation

The findings of this study will serve as a guide in choosing postoperative nursing supplies for paraplegic wheelchair users and bedridden quadriplegic patients.

1) Using medical pressure injury prevention materials can successfully lower the risk of bedsores in postoperative care, as well as the suffering of patients and the workload of nursing personnel. According to Ref. [25], the presence of postoperative problems (e.g.pressure sores) deals patients a second blow that makes it difficult to create a positive psychological environment for patients and may worsen the effects of physical rehabilitation therapy. Consequently, further research on pressure injury prevention fabrics can help patients live better lives.

2) The development of medical bed sheets, medical mattresses, wheelchair cushions and specific clothes for paralyzed people receives technical support from research on materials to avoid pressure injuries. The widespread use of this technology opens up greater opportunities for the research and development of related medical devices as well as for the market category of medical textiles.

4.2 Limitation

Researchers did not strictly follow the test standards recommended by common parameters when conducting various experiments, reducing the statistical significance of cross-sectional data in standardized measurements. The quasi-static compression and pressure tests strictly followed the test standard and performed well. However, the tests for air permeability, heat dissipation, water vapor permeability, friction coefficient,etc.need to be improved. The existing condition of the instrument has a significant influence on the experimental results, which leads to the lack of broader comparison in the experiment.

5 Conclusions

Most of the materials involved in the papers are based on the materials used in existing medical practices for performance optimization research. The comparison presented is the performance difference among different optimizations. Specific optimization directions include increasing air permeability, improving skin tissue support and encapsulation, and lowering the coefficient of friction.

In the fabric properties of air permeability and heat dissipation, the usage of bamboo charcoal yarns improves the air permeability by 5.3%. The hexagonal mesh structure has the best performance, which improves the air permeability of the fabric by 350.0%[14].

In terms of decompression and support, the two-way stretch structure can reduce hip pressure by 24.6%[17]. The 3D spacer structure has the most significant impact on the yield strength of the fabric, which is 3.5 times that of a high-density polyurethane sponge, which can provide a more vital wrapping property[14]. The efficiency of spacer fabrics in lowering the pressure received locally can reach 95%[14].

The low-friction performance of the fabric is affected by the interaction of the fiber composition and the yarn structure, and the excellent support effect mainly depends on the elastic design of the fabric layer structure. The intervention of low-friction coefficient fabrics reduced the incidence of postoperative pressure injuries by about 31.2%[15].

At present, the research on the properties of fabrics to prevent pressure injuries is usually based on a single factor. However, in medical practice, the factors leading to pressure injuries are often the results of the comprehensive action of many factors. Based on the current research results, how to use bamboo charcoal yarns as raw material to form hexagonal mesh in the horizontal direction and the 3D spatial structure in the vertical direction and to show the comprehensive properties of the biaxial tension and low friction needs further research.

Journal of Donghua University(English Edition)2023年4期

Journal of Donghua University(English Edition)2023年4期

- Journal of Donghua University(English Edition)的其它文章

- Image Retrieval with Text Manipulation by Local Feature Modification

- Multi-style Chord Music Generation Based on Artificial Neural Network

- Polypyrrole-Coated Zein/Epoxy Ultrafine Fiber Mats for Electromagnetic Interference Shielding

- Design of Rehabilitation Training Device for Finger-Tapping Movement Based on Trajectory Extraction Experiment

- High-Efficiency Rectifier for Wireless Energy Harvesting Based on Double Branch Structure

- N-gamboyl Gemcitabine Inhibits Tumor Cells Proliferation and Migration