Effect of Soy Lecithin,Glucose Oxidase,and Transglutaminase on Dough Rheology and Quality Properties of Steamed Bread Enriched with Potato Pulp

CAO Yanfei,LU Jinshuai,ZHAO Shengpeng,LI Siqi,LI Hongjun

(1.College of Agriculture and Forestry Technology,Weifang Engineering Vocational College,Qingzhou 262500,China;2.School of Agricultural Engineering and Food Science,Shandong University of Technology,Zibo 255000,China)

Abstract: This study aimed to assess the effect of soy lecithin (Soy L,0.2%–1.0%),glucose oxidase (GOX,0.3–1.5 U/g),and transglutaminase (TG,0.3–1.5 U/g) on dough elongation properties and texture qualities of steamed bread.The optimum formulation of steamed bread prepared from wheat flour (50%) and potato pulp (50%) was investigated.Results showed that Soy L and GOX significantly (P <0.05) affected the specific volume and hardness of steamed bread,whereas TG significantly (P <0.05) affected the resistance to extension and extensibility of dough,as well as the springiness and cohesiveness of steamed bread.The optimum formulation consisting of 0.65% Soy L,0.92 U/g GOX,and 0.96 U/g TG increased the viscoelasticity and fermentation characteristics of dough and improved the specific volume,texture,and porosity of steamed bread enriched with potato pulp.

Keywords: potato pulp incorporated steamed bread;rheological properties;response surface methodology;fermentation characteristics

Due to the growing consumer demand for healthy foods,wheat staple foods such as bread,noodles,steamed bread,and cakes are receiving increased concern.More and more substitutes are being added to wheat flour to develop staple foods.Potatoes has lower calorie,higher vitamin and mineral content,and relatively balanced amino acid composition compared with wheat flour[1].Therefore,potato has the potential to improve the nutritional value of wheat-staple foods.

However,the addition of potatoes decreases the quality of the product and is unaccepted by consumers due to lack of gluten.Liu Xingli et al[2]reported that the incorporation of potato flour into wheat flour could decrease the dough stability and specific volume of steamed bread.Pu Huayin et al[3]reported that noodles enriched in potato flour below 40% are acceptable.Our previous study[4]has reported that the addition of 30%–50% potato pulp into wheat flour reduces the elasticity of dough and quality properties of steamed bread.The lack of gluten in wheat dough leads to a series of problems related to the absence of viscoelasticity such as decreased extensibility and gas retention capability,resulting in bread with lower volume,poor texture,and sensory characteristics[5].Therefore,adding emulsifiers and enzymes to simulate the viscoelasticity of gluten is necessary to improve the quality of potato-staple products.

Lecithin is a natural mixture of phosphatidylcholine with different fatty acid side chains such as stearic acid,palmitic acid,and oleic acid[6].Choline is considered to be an important nutrient component of lecithin because it is essential for various physiological functions (cell membranes and fat transport)[7].Lecithin could interact with protein to enhance dough strength.Soy lecithin (Soy L) has been reported to be used in the development of whole wheat noodles and bread[5].Glucose oxidase (GOX) and transglutaminase (TG) are considered as natural and healthy additives and are used in the baking industry.Bender et al[8]found that the addition of GOX into gluten-free breads from rice promoted protein crosslinking and improved bread quality.Various studies have shown that TG could improve the processing properties of low-quality gluten or gluten-free product[5].

However,little literature is available regarding the application of emulsifiers and enzymes in potato-staple products.Thus,the present study aimed to investigate the influence of Soy L,GOX,and TG combinations on the quality characteristics of steamed bread containing 50% potato pulp and also to optimize the formula of the potato pulp steamed bread by response surface methodology (RSM).

1 Materials and Methods

1.1 Materials and reagents

Wheat flour (11.1% moisture,9.5% protein) Yunhai Co.Ltd.(Shandong,China);Yeast Angel Yeast Co.Ltd.(Yichang,Hubei,China);Fresh potatoes (cultivar: Shepody) Laoling Xisen Potato Industry Co.Ltd.(Laoling,Shandong,China);Soy L Henan Wan Bang Industrial Co.Ltd.(Zhengzhou,Henan,China);GOX (20000 U/g,Aspergillus niger),TG (20000 U/g,Streptoverticillium mobaraense) Shandong Gukang Bioengineering Co.Ltd.(Jinan,Shandong,China).

The potatoes were washed,peeled,and homogenized in 0.2% ascorbic acid to prepare potato pulp.The moisture and protein contents of the obtained potato pulp were 80.8% and 1.8%,respectively.

1.2 Instruments and equipment

KNX2110 rheometer UK Malvern Instrument Co.Ltd.;TA-XT2i texture analyser UK Stable Micro Systems Co.Ltd.;F4 rheofermentometer Franc Chopin Technology Co.Ltd.;Sirion200 scanning electron microscopy (SEM) USA Thermo Fisher Scientific Co.Ltd..

1.3 Methods

1.3.1 Steamed bread making

Dough was formulated with a mixture of wheat flour and potato pulp (50 g/100 g and 50 g/100 g respectively,mixture basis) and 0.85 g/100 g of yeast.Additives including Soy L,GOX,and TG were added based on the mixture weight (Table 1).The formulation produced without additive was considered as a control.Steamed bread was prepared by mixing,fermenting,sheeting,dividing,shaping,resting,and steaming according to our previously described method[4].

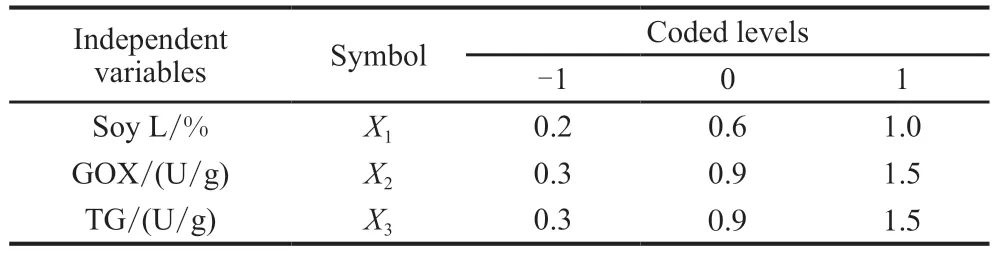

Table 1 Levels and codes of independent variables used for Box-Behnken design

1.3.2 Rheological properties of dough

1.3.2.1 Dynamic rheological properties

Fundamental rheological measurement was conducted on a KNX2110 rheometer fitted with 40 mm plate and a 2 mm gap.The test was performed at 25 ℃,0.1% strain and 0.1–10 Hz.Mixed dough (without yeast) was allowed to rest for 30 min and then loaded between plates.The edges of dough were trimmed and coated with a Teflon envelope.Elastic modulus (G′) and the viscous modulus (G″) were determined.

1.3.2.2 Elongation properties

Elongation properties were examined with a TA-XT2i texture analyser equipped with SMS/Kieffer extensibility rig.The dough fermented for 1 h was pressed in the mould,and resultant dough strips (at least 10 for each sample) were determined.Pretest speed,test speed,post-test speed,distance,and trigger force were set at 2.0 mm/s,3.3 mm/s,10.0 mm/s,75.0 mm and 5.0 g,respectively.The resistance to extension and extensibility parameters was recorded.

1.3.2.3 Fermentation properties

An F4 rheofermentometer was used to measure the parameters of dough fermentation properties.The maximum dough height (Hm) and the gas retention coefficient (Rc) were recorded.Mixed dough (315 g) for making steamed bread was placed into the rheofermentometer basket (32 ℃,3h) with a 2000 g cylindrical piston.

1.3.3 Steamed bread characteristics

Specific volume and texture parameters including hardness,cohesiveness,and springiness of steamed bread were measured according to the methods reported by Parenti[9]and Cao Yanfei[4]et al,respectively.

Crumb structure of steamed bread was measured by the ImageJ software according to the method of Espinosa-Ramirez et al[10].Images of the centre of steamed bread slice (30 mm × 30 mm × 2 cm) were acquired at a resolution of 300 dpi.The crumb structure parameters studied were the means of cell area (mm2) and crumb porosity (%).

The microstructures of the steamed bread were examined by a Sirion200 SEM.The samples were dried at the critical point and coated with sputtered gold before subjecting to SEM observation at an energy of 20 kV.

1.4 Experimental design and statistical analysis

The optimum content of Soy L (X1,0.2%–1.0%),GOX (X2,0.3–1.5 U/g) and TG (X3,0.3–1.5 U/g) for producing steamed bread enriched with 50% potato pulp were investigated by using RSM with Box-Behnken design (Table 1).The responses measured were dough elongation properties and steamed bread characteristics,including specific volume,hardness,springiness,and cohesiveness.Minitab 19.0 software was used for statistical analysis.The secondorder model for each response (Y) was predicted by the following equation[11]:

whereβ0is a constant term,βiis defined as the linear terms,βiiis the quadratic coefficient,andβijis the interaction coefficient (i=1–3;j=1–3).

The contour plots for responses were developed using Design-Expert 8.0.Prediction errors were calculated based on the following equation:

Data were analysed by one-way Analysis of Variance and Duncan’s multiple-range tests using SPSS 22.0 software.AP<0.05 was statistically significant.Experimental data were conducted at least in triplicate.

2 Results and Analysis

2.1 Model fitting

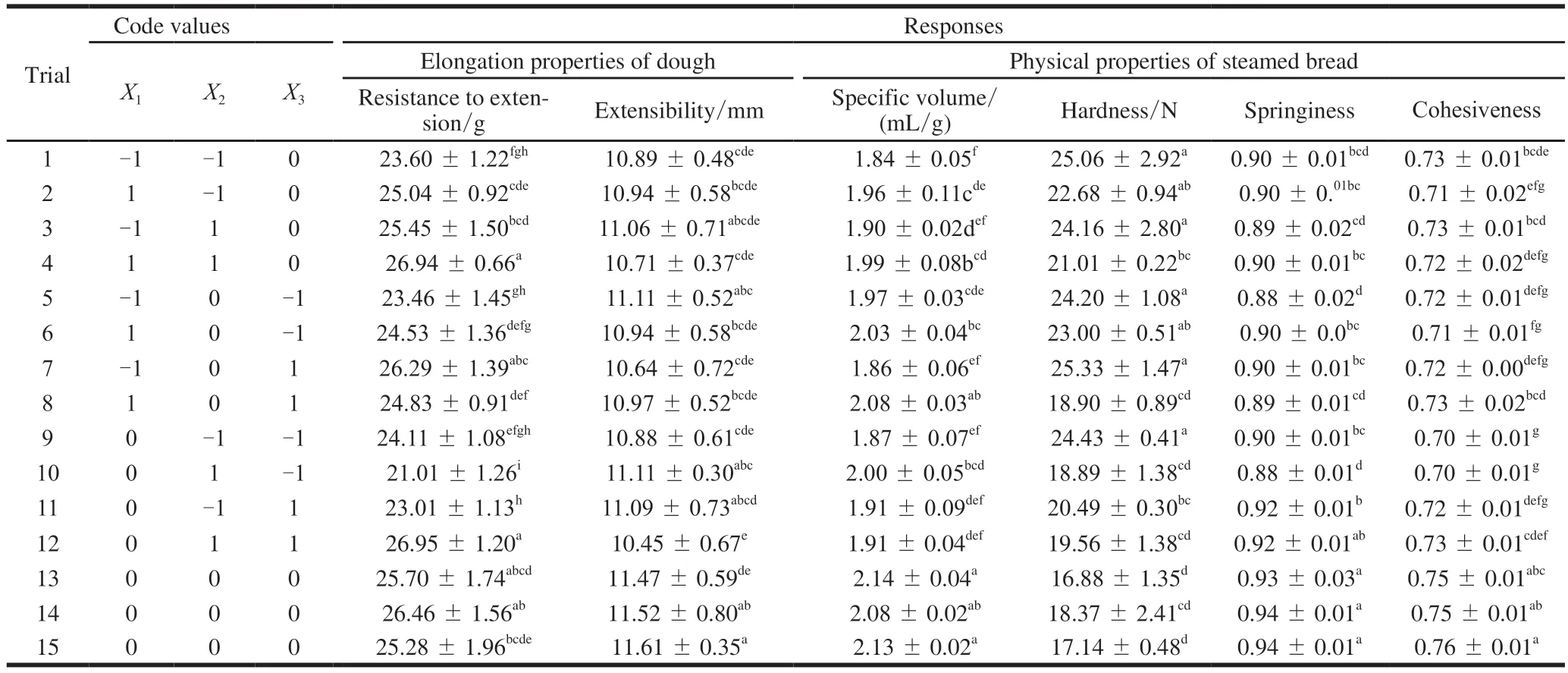

The results of the effect of Soy L,GOX,and TG on the elongation properties of dough and physical properties of steamed bread enriched in potato pulp are listed in Table 2.Different models were tested by fitted response values.Analysis of variance showed that all regression models were considered adequate because they had highR2values within the range of 0.91–0.98 and satisfactory levels of model significance,possessing non-significant lack of fit (Table 3).

Table 2 Box-Behnken design with responses

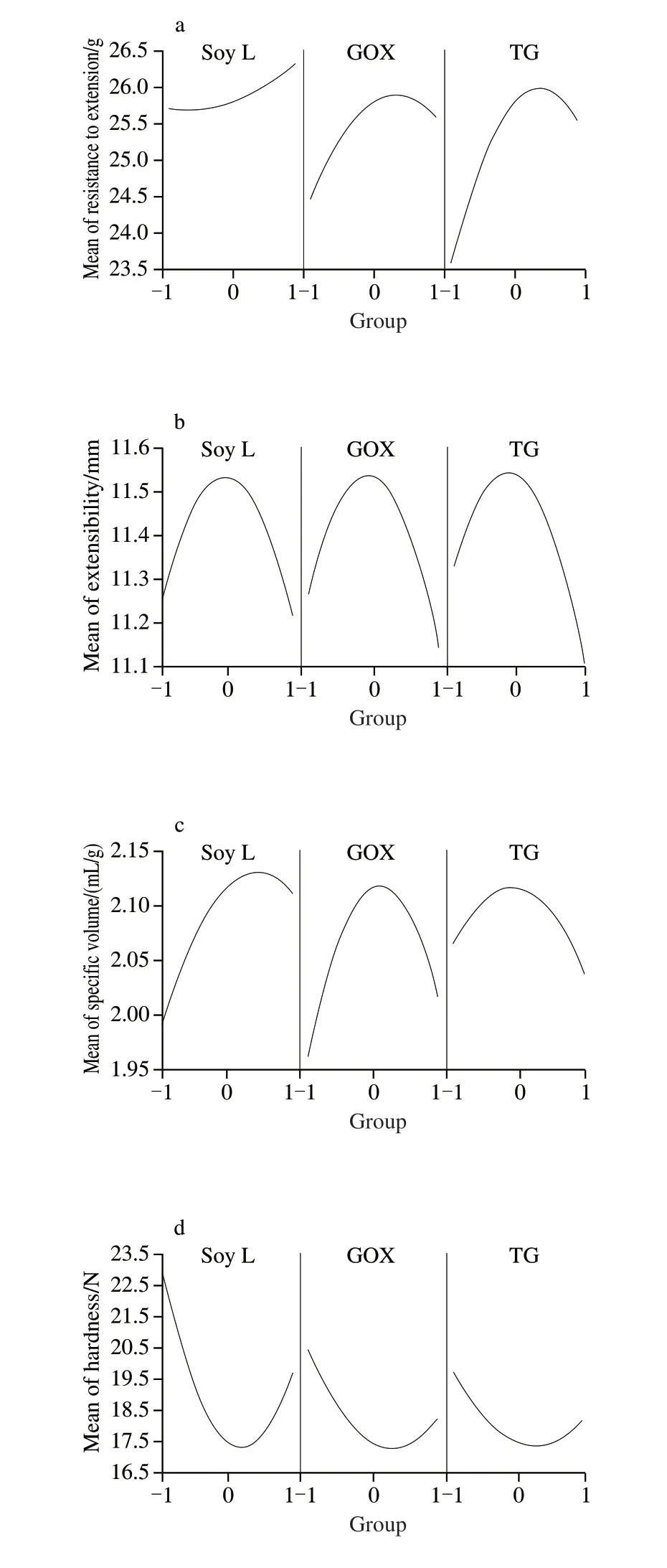

Table 3 Regression coefficients and analysis of variance of quadratic polynomial models

2.2 Effect of Soy L,GOX,and TG on the elongation properties of dough

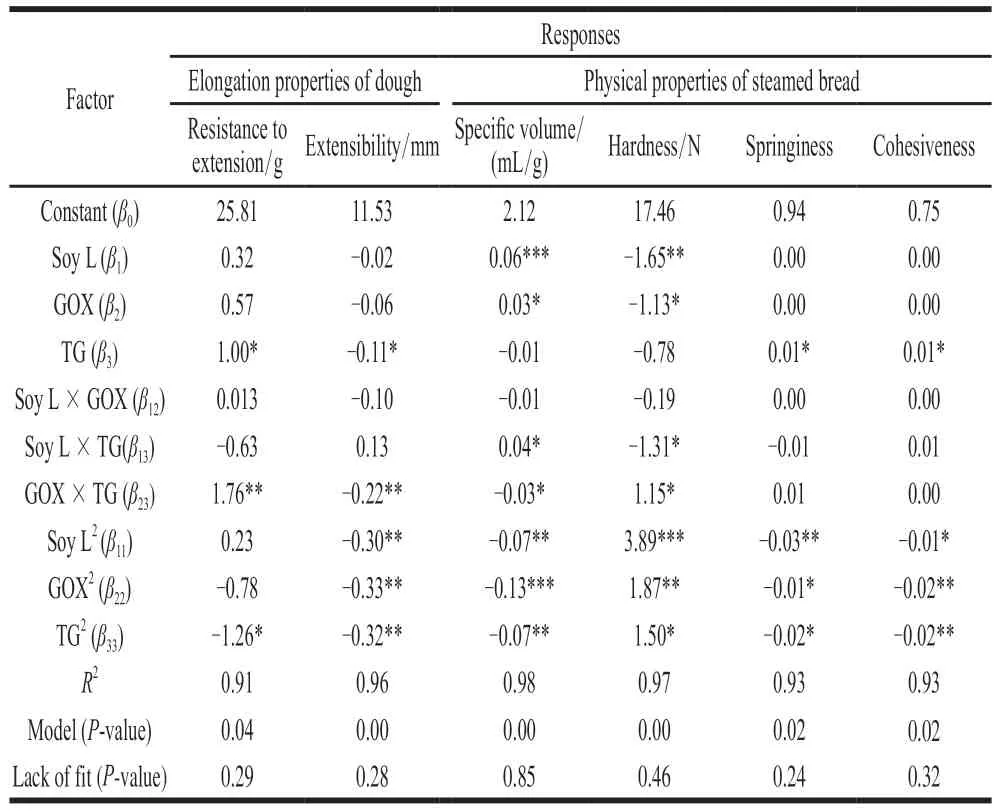

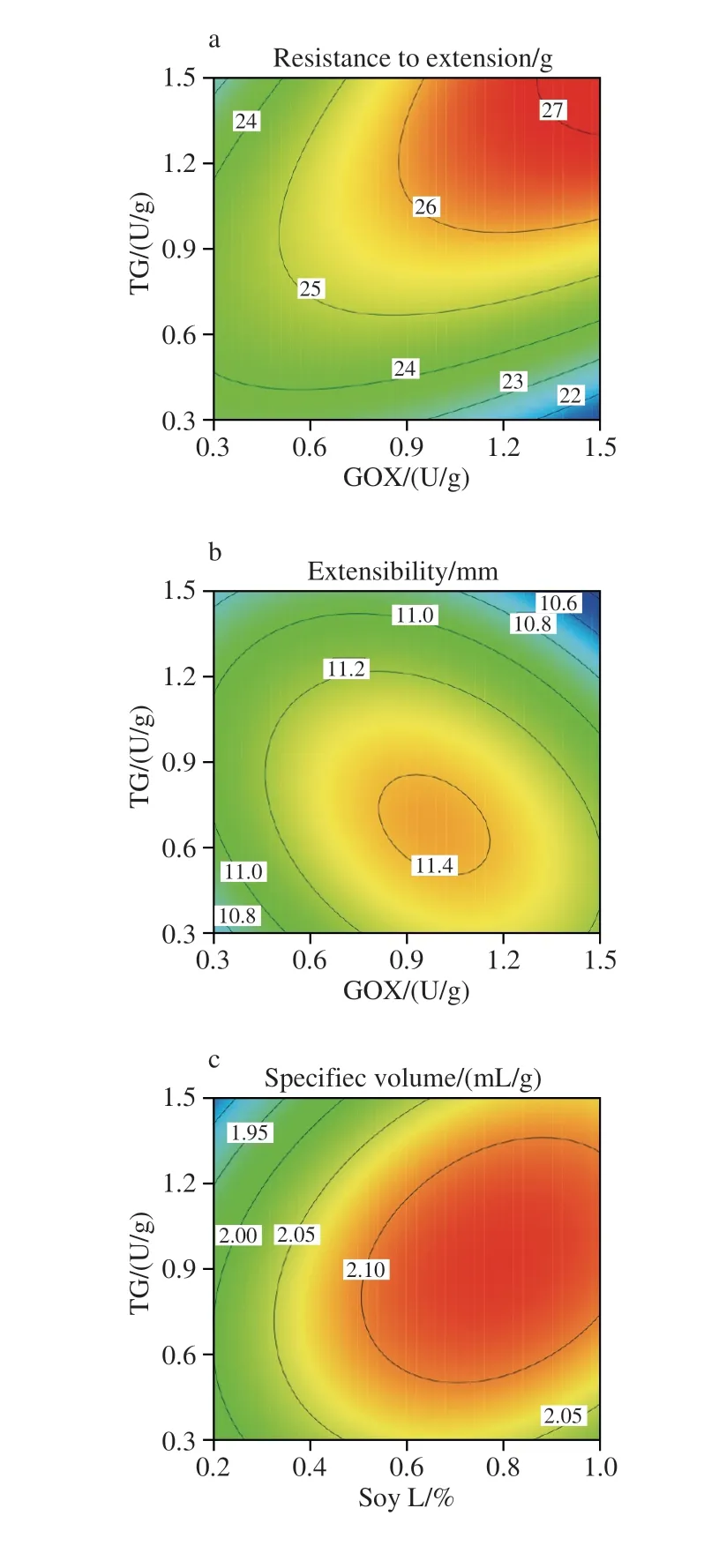

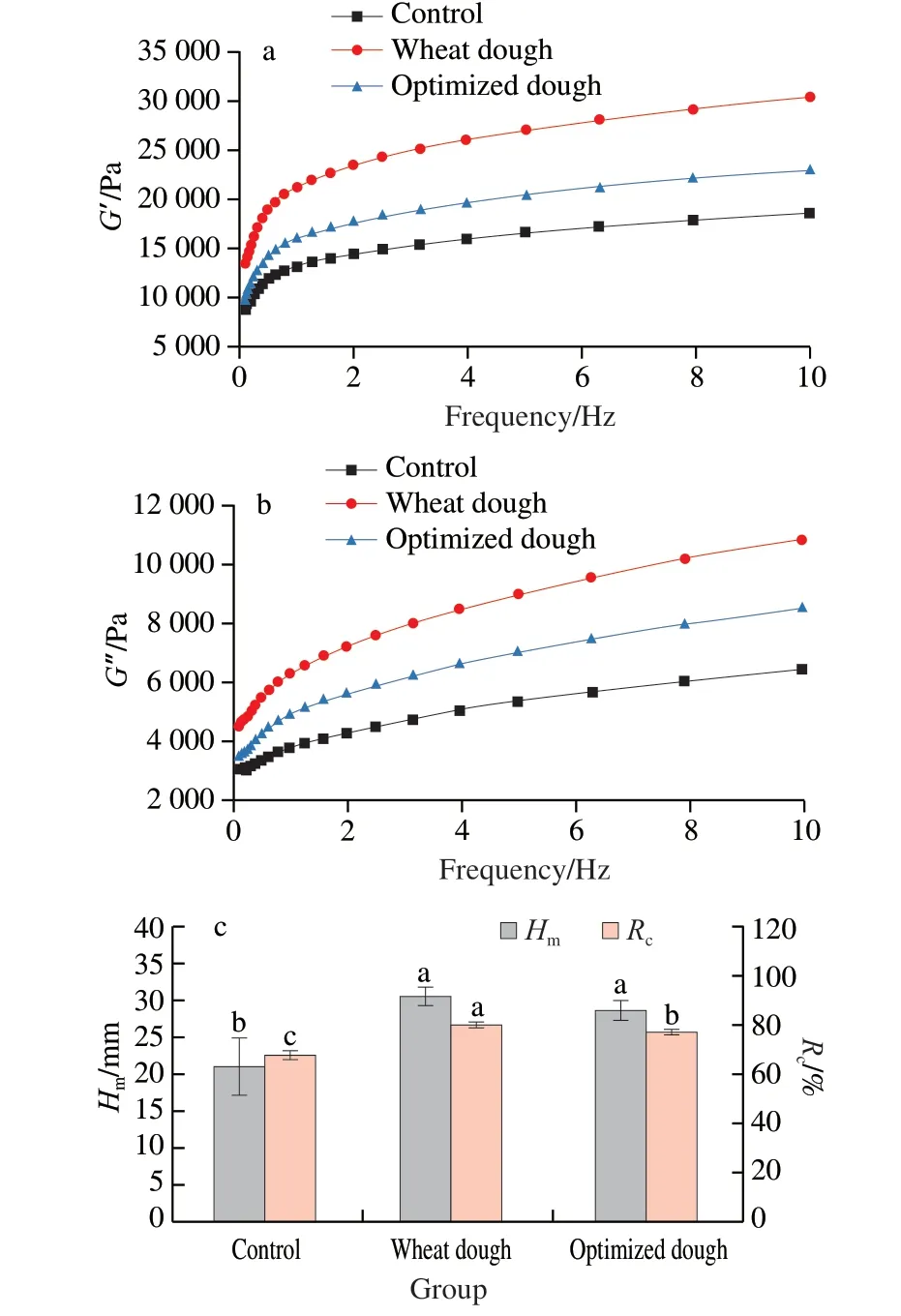

Regression models of elongation properties were significantly affected by the linear term of TG and the interaction terms between GOX and TG (Table 3).The addition of high-level TG increased the resistance to extension and decreased the extensibility of dough compared with low-level of TG (Figs.1a and 1b),indicating the stronger dough.Li Jinxin[12]and Dizlek[13]et al reported that the addition of TG produced more resistant and less extensible of dough.This finding may be attributed to the improvement in the gluten network.TG could promote the covalent crosslinks between glutamines and lysine residues,thereby enhancing the gluten network and an increase of dough strength[14].

The contour plot showed that the inclusion of GOX and TG at a level of 1.5 U/g could raise resistance to extension (Fig.2a) and reduce the extensibility (Fig.2b) of dough,which indicating that the interaction of GOX and TG contributed to the improvement in dough strength.Addition of GOX enhanced gluten strength by promoting the formation of disulphide linkages and the crosslinks between gluten proteins[8].The addition of GOX to TG containing samples enhanced the gluten network because both of them could promote the crosslinking of protein.Similar results was obtained by Niu Meng et al[14]who reported that higher added levels of TG and GOX could enhance gluten strength and promote protein polymerisation,resulting in increased dough strength and resistance.

2.3 Effect of Soy L,GOX,and TG on steamed bread qualities

Specific volume is considered to be the most important visual characteristic of steamed bread as it directly affects the acceptance of consumers.The hardness of steamed bread was negatively related to specific volume,which was in turn related to consumers’ perception of product freshness.Regression model showed that not only linear terms of Soy L and GOX and quadratic terms of Soy L,GOX,and TG significantly affected the specific volume and hardness of steamed bread,as well as the interaction terms between Soy L and TG or GOX and TG.The medium addition of Soy L and GOX showed that the largest specific volume (Fig.1c) and the lowest hardness (Fig.1d),above which specific volume and hardness might decrease and increase,respectively.Soy L could interact with protein through its fatty acid chains,which could promote protein aggregation and strengthen the gluten network[7].The optimum addition of Soy L and GOX could form good gluten-network structure,contributing to confer dough machinability and improvement in the specific volume and softness of the steamed bread.Similar effects have been found regarding Soy L addition to sweet potato[15]bread and of GOX to rice[8]and millet[16]bread.However,the addition of Soy L and GOX in amounts exceeding the optimum could lead to the formation of a much stronger gluten network,thereby inhibiting the expansion of dough and yielding poorquality steamed bread[6].

Fig.1 Major effects of Soy L,GOX,TG on dough elongation properties (a–b) and steamed bread quality (c–f)

The regression coefficient showed that Soy L and TG exerted a significant synergistic effect on specific volume of the steamed bread but an antagonistic effect on hardness.The addition of Soy L to the sample containing TG could increase the specific volume (Fig.2c) and decrease the hardness (Fig.2d) as shown in the contour plot.These results may be attributed to the fact that Soy L probably counteracted the strengthening effect of TG by simultaneously acting on protein,contributing to the better dough formation during fermentation.In addition,Tebben et al[15]further reported that the addition of emulsifiers along with the enzymes could further increase specific volume and decrease hardness.The regression coefficients indicated that GOX and TG could reduce specific volume and increase hardness.The addition of GOX and TG at a level of 1.5 U/g produced more resistant dough as indicated in Section 3.2,which attributed to their strengthening effect on the gluten network.Too high resistance hindered the expansion of the gas cells during fermentation and led to the infamous hardening of bread[17].Springiness and cohesiveness are important texture parameters to evaluate the quality of steamed bread.Steamed bread with low springiness and cohesiveness is susceptible to fracture and crumble,which negatively affect consumers’ acceptance of products[18].TG significantly (P<0.05) affected the values of springiness and cohesiveness,whereas a significant interaction of all factors on these two values were not observed (Table 3).The addition of high-level TG increased springiness (Fig.1e) and cohesiveness (Fig.1f) of the steamed bread compared with the low-level of TG was observed the main effect plots.Li Jinxin et al[12]also indicated that the presence of TG resulted in a significant increase in cohesiveness and springiness of bread crumb.Therefore,the addition of TG could improve the texture characteristics of steamed bread to a certain extent.

Fig.2 Contour plots showing the interactive effects of Soy L,GOX,TG on dough elongation properties (a–b) and steamed bread quality (c–f)

2.4 Optimization of potato pulp bread formulation

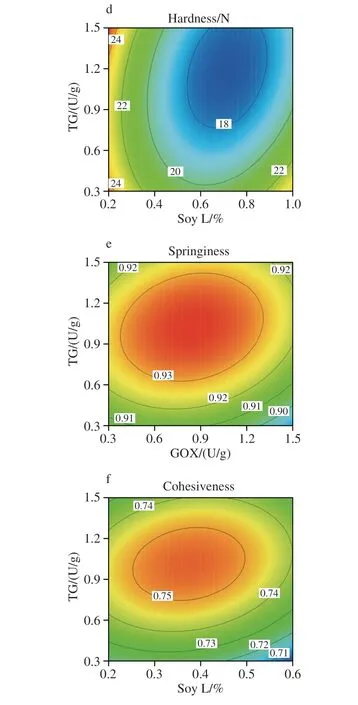

The optimum combination of Soy L,GOX,and TG to be added to the potato pulp steamed bread was determined using Design-Expert software.Extensibility,specific volume,springiness,and cohesiveness were selected to the maximum value as the target.Hardness was set at the minimum,whereas resistance to extension was selected within the target range of 23.50–26.50 g.It was found that the optimum formula combination was 0.65% Soy L,0.92 U/g GOX,and 0.96 U/g TG (Table 4).Using this optimized formulation,the predicted responses were 25.97 g,11.51 mm,2.12 mL/g,17.20 N,0.94 and 0.75,respectively for the resistance to extension,extensibility,specific volume,hardness,springiness,and cohesiveness.Experimental values under the optimum condition were similar to the predicted values due to that the prediction errors of all responses being less than 10%,indicating the veracity of the model predicted results and suitability of RSM in developing an optimized potato pulp steamed bread formulation.

Table 4 Comparison of predicted and experimental values of dough elongation properties and texture properties of steamed bread with and without Soy L,GOX,and TG

2.5 Processing characteristics of optimized steamed bread with potato pulp

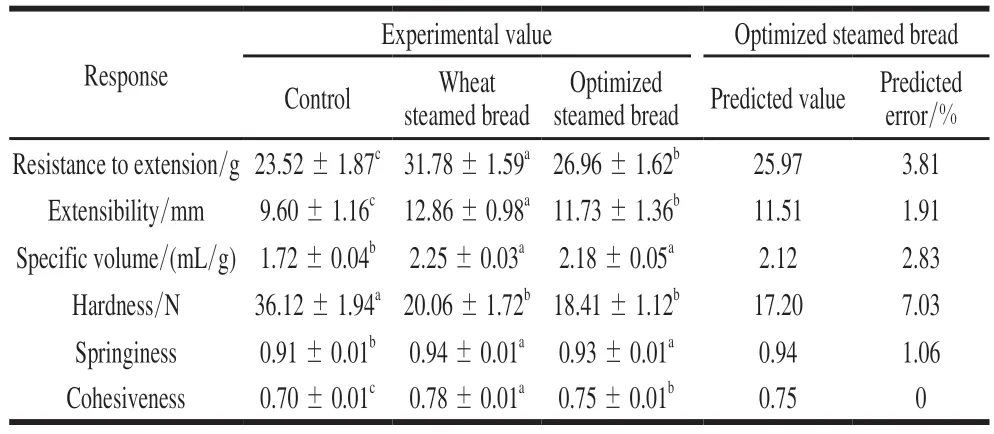

2.5.1 Rheological properties of dough

The viscoelasticity of the dough sample is shown in Figs.3a and 3b.TheG′ was above theG″ for all dough samples,indicating that the solid-elastic behavior of the dough.The optimized dough showed higher viscoelastic modulus than the control,indicating a stronger dough.The increased of viscoelasticity in the optimized dough may be attributed to the enhancement in gluten strength[19].Hackenberg et al[20]reported that a reduced resistance to extension and extensibility of dough indicated a weakened gluten-network structure.The elongation properties of the dough significantly increased (P<0.05) compared with that of the control,confirming an improved gluten-network structure.

Fermentation is regarded as a key step in steamed bread making,during which dough expands and crumb cellular structure is developed[21].Hmduring the fermentation is related to the specific volume of bread,which is considered as an important parameter for evaluating the final-product quality[22].No significant difference (P>0.05) inHmwas found between optimized dough and wheat dough,whereas theHmandRcof optimized dough were significantly (P<0.05) higher than those of the control (Fig.3c).The expansion and gas retention capacity of dough during fermentation depended on the viscoelasticity of dough[23].Therefore,the increase in dough viscoelasticity may contribute to the improvement in dough fermentation characteristics.

Fig.3 Rheological properties of wheat flour+potato pulp dough,wheat flour dough,and wheat flour+potato pulp dough with Soy L,GOX,and TG

2.5.2 Quality characteristics of steamed bread

The optimized steamed bread had higher specific volume,springiness,and lower hardness than the control,and no significant (P>0.05) difference in these indices was found between the optimized steamed bread and the wheat steamed bread (Table 4 and Fig.4).The viscoelastic properties of optimized dough were good because of the improvement in the gluten-network structure could retain the CO2produced and promote dough expansion during fermentation.This phenomenon was conducive to increase the volume of steamed bread,thereby enabling the potato pulp steamed bread to obtain a similar texture to wheat steamed bread.

Fig.4 Cross-sectional images of steamed bread samples

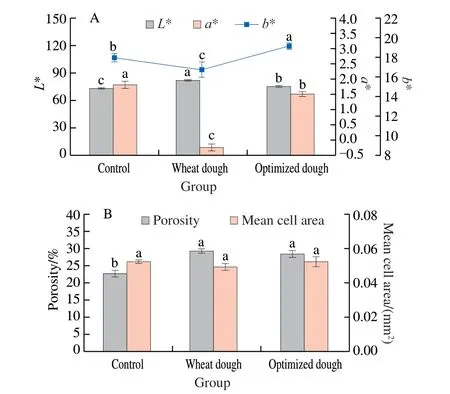

Crumb color of steamed bread was measured in the brightness (L*),redness (a*) and yellowness (b*) color scale,and results are shown in Fig.5A.The crumb color of the control and the optimized steamed bread was darker,redder,and yellower than the wheat steamed bread due to the color of the potato pulp itself.The optimized steamed bread had higherL* anda* values and lowerb* values compared with the control.The increase in brightness and the decrease in redness may be attributed to the fact that GOX catalyzed the reaction of phenolic compounds and polyphenol oxidase,resulting in the decreased polyphenol oxidase activity and interfering with the color browning of potato pulp[24].The crumb color of the optimized steamed bread was yellower than that of the control,which may be due to the contribution of the color of Soy L.

Fig.5 Physical properties of steamed bread prepared from wheat flour+potato pulp dough,wheat flour dough or wheat flour+potato pulp dough with Soy L,GOX,and TG

The crumb structure of steamed bread was determined by image analysis.Digital images were pre-processed to calculate the porosity and mean cell area of steamed bread by a binary conversion.Digital images (Figs.6a and 6b) combined with SEM micrographs (Fig.6c) revealed that the control sample had a few large pores and non-uniform pore distribution.This finding may be attributed to the fact that the added potato pulp diluted gluten protein,resulting in decreased disulfide bonds,which was not conducive to the formation of the gluten-network structure.The restriction of gluten may have led to lower gas retention and thus a lower specific volume,as confirmed by the specific volume in Section 2.4 and the fermentation properties in Section 2.5.1.The wheat steamed bread and optimized steamed bread had a more porous and homogenous crumb structure,as reflected by the latter’s lower mean cell area and higher the porosity of crumb.Nevertheless,there was no significant difference (P>0.05) in mean cell area was found in all steamed bread samples (Fig.5B),the crumb porosity of the optimized steamed bread and wheat steamed bread was higher than that of control.The increase in porosity might be attributed to the fact that improvement of gluten-network structure could stabilize bubbles in the dough and prevent cell coalescence during fermentation and steaming[24].

3 Conclusion

Steamed bread enriched with 50% potato pulp could be formulated by the incorporation of Soy L,GOX,and TG,which were comparable to that of wheat steamed bread.RSM was used to optimize the formulation of potato pulp steamed bread.Soy L and GOX significantly (P<0.05) affected the specific volume and hardness of steamed bread,whereas TG significantly (P<0.05) affected the dough elongation properties,springiness,and cohesiveness of steamed bread.This study had indicated that the optimum formulation for improving the quality characteristics of steamed bread enriched with 50% potato pulp was with the inclusion of 0.65% Soy L,0.92 U/g GOX,and 0.96 U/g TG.The optimized steamed bread showed higher technology characteristics in terms of viscoelasticity,fermentation characteristics,specific volume,hardness,springiness,and cohesiveness compared with the control.