Effects of pre-aging on microstructure evolution and deformation mechanisms of hot extruded Mg–6Zn–1Gd–1Er Mg alloys

Wei Kang ,Liwei Lu ,Longiao Feng ,Fengchi Lu ,Chunlei Gan,∗∗ ,Xiaohui Li,c,d,∗∗

a School of Materials Science and Engineering,Hunan University of Science and Technology,Xiangtan 411201,PR China

b Guangdong Institute of Materials and Processing,Guangdong Academy of Sciences,Guangzhou 510650,PR China

c School of Mechatronics Engineering and Automation,Foshan University,Foshan 528000,PR China

d Guangdong Tsing Impulse Science and Technology Co.Ltd.,Foshan 528226,PR China

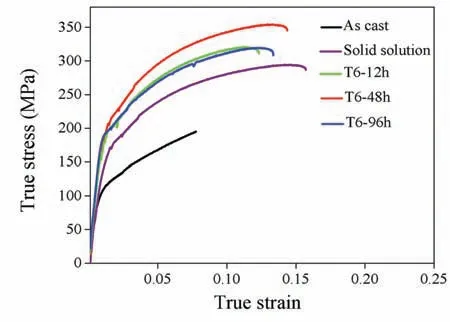

Abstract The influenc of pre-aging treatment on the microstructure,texture and mechanical properties of the Mg–6Zn–1Gd–1Er (wt.%) alloy was investigated.The microstructure analysis shows that the presence of pre-aging is beneficia to {10¯12} twin nucleation at the early stage of extrusion and inhibits the growth of twins and promotes the formation of [10¯10]-fibe texture components,thus accelerating the complex process of recrystallization.In the middle stage of extrusion,the extruded samples under the condition of solid solution were subjected to dynamic precipitation during severe shear deformation.The precipitation of the second phase particles followed the particle stimulating nucleation (PSN) mechanism,which increased the volume fraction of DRX grains during extrusion.In the extruded samples under the peak-aged condition,the particles appear dissolved during the severe shear deformation strain,which slows down the DRX process.In the later stage of extrusion,the small rod-shaped particles followed the PSN mechanism,and finall formed the strong fibe texture.The extruded alloy exhibits the strongest mechanical properties under the peak-aged state,with ultimate tensile strength (UTS) of 346 MPa,tensile yield strength (TYS) of 217 MPa,and elongation to failure (EL) of 13.6%.The improvement of mechanical properties is mainly attributed to the existence of strong fibe texture,small rod-shaped and block-shaped phases.

Keywords: Mg alloys;Pre-aging;Extrusion;Texture;Dynamic recrystallization.

1.Introduction

Magnesium (Mg) alloys containing rare earth (RE) elements have attracted great attention due to their good mechanical properties,creep resistance,corrosion resistance and damping properties [1–4].However,industrial application of Mg-based products or components is still rather limited due to relatively lower yield strength and poor formability at room temperature.To solve the above shortcomings,micro-alloying with RE elements through microstructure refinemen and texture modificatio for Mg alloys are proved to be an effective method.In this case,second phase particles are usually introduced into the Mg alloys to control the grain size and texture evolution by stimulating the dynamic recrystallization (DRX)behavior.

Precipitation strengthening is controlled by the interparticle spacing and is thus influence by the precipitates size and number density [5].The effectiveness of precipitation strengthening against slip and twinning highly depends on the relationship between dislocations and the precipitates,which is heavily dependent upon precipitate morphology and aspect ratio [6].It will accelerate and enhance the aging process through introducing the lattice defects in Mg–Zn alloys [7].Trace alloying elements have also been used to refin the size and increase the number density of the precipitates [8-10].In terms of the formation of precipitates in Mg–Zn systems,stable rod–type and basal platelet-type precipitates is obtained when the temperature is higher than 110 °C.The maximum solubility of gadmium (Gd) in Mg matrix is 22.8 wt.% at 550 °C.The maximum solubility of erbium (Er) in Mg matrix is 32.58 wt.% at 570 °C.In this work,Gd and Er is added synchronously in Mg–6Zn (wt.%) alloys so as to form multiple phase particles.In Mg–Zn–RE ternary system(RE=Y,Gd,Tb,Dy,Ho or Er with an approximate composition Mg3Zn6RE),except the Mg4Zn7phase co-exist with Laves phase MgZn2within the precipitates,the icosahedral quasicrystalline phase (i-phase) is also formed.

The recrystallization behavior of Mg–Zn–RE alloys containing stable Mg5RE particles and meta-stable Mg3Zn6RE phase would be hardly predicted,which is highly dependent on the chemical compositions of alloys and thermal mechanical processing history.The corresponding twin nucleation,shear band nucleation and particle stimulated nucleation(PSN) effects were systematically investigated with prefabricated particle alloys during extrusion.The effects of the second phase particles on the recrystallization behavior,texture evolution and mechanical properties would be clarified

2.Experimental procedure

The Mg–6Zn–1Gd–1Er(wt.%)cylindrical ingots were prepared by semi-continuous casting with a diameter of 120 mm and 6000 mm in length.The ingots were melted at 760 °C under a mixture of SF6/CO2(1: 99) protective atmosphere.Before pouring,the molten was cooled to 700 °C in 45 min and then reheated to 720 °C for degassing and melt purifi cation.The casting speed of ingot was set to 100 mm/s and cooling water fl w was 1000 L/min,respectively.The experimental process was summarized in Table 1.The billet with 150 mm in length and 98 mm in diameter was homogenizedat 500 °C for 6 h.The homogenized billet was executed solid solution treatment at 480 °C for 20 h and cooled in water at 70 °C to prevent cracking during cooling stage.The solutionized billets were pre-aged at 200 °C for 0.5~96 h.Afterwards,the solution treatment and pre-aged billets were preheated for 1 h at 420 °C before hot extrusion.Finally,XJ-638T horizontal extrusion press was used to execute hot extrusion deformation at 420 °C,with an extrusion ratio of 10: 1 and an extrusion speed of 1 mm/s.

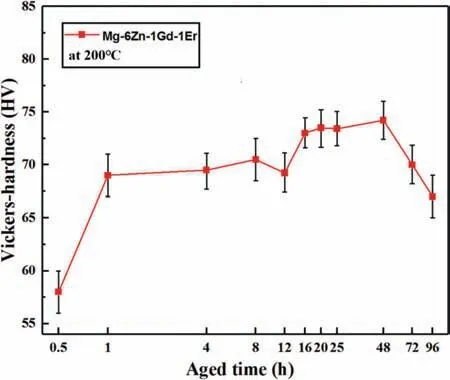

Table 1 Heat treatments implemented for the Mg–6Zn–1Gd–1Er alloys.

The thermal behavior of extruded alloy was determined by differential scanning calorimetry (DSC).DSC sample was heated to 700 °C in Ar atmosphere and then cooled to 50 °C at a rate of 10 °C/min.Microstructure of the specimens were observed in the longitudinal sections by optical microscope(OM,Leica DMIRM) after polishing and etching in picric acid and oxalic acid solution at room temperature.Prepared samples were etched for 15 s in a 5 ml acetic acid+5 g picric acid+10 ml water+100 ml ethanol solution.The sectioned surface for electron backscatter diffraction (EBSD) examination was mechanically polished and followed by electropolishing using a solution of AC2at a voltage of 20 V and a temperature of −20 °C for 50 s.Microstructural observation and microchemistry analyses of specimens were performed by optical microscopy (OM,Leica) and scanning electron microscopy (SEM,JEOL 7010) equipped with energy dispersive X-ray spectroscopy (EDS) system.A microhardness profil was obtained from cross section by microhardness tester(HXD-1000) with a load of 1 N and dwelling time of 15 s.Material fl w and microstructure evolution analyses were conducted by EBSD with the samples electrolytic polished with a AC2solution.The EBSD measurements were obtained on a Zeiss Merlin SEM with HKL package.The OIM was used as the EBSD analysis software,and data points with confidenc index values lower than 0.1 were removed.The samples for tensile tests were prepared according to the ASTM E8 standard for sheet type material (i.e.,50 mm gage length and 12.5 mm gage width) keeping the tensile axis parallel to the extruding direction (ED).Tensile tests were performed by using screw–driven machine at room temperature and at a strain rate of 10−3/s.

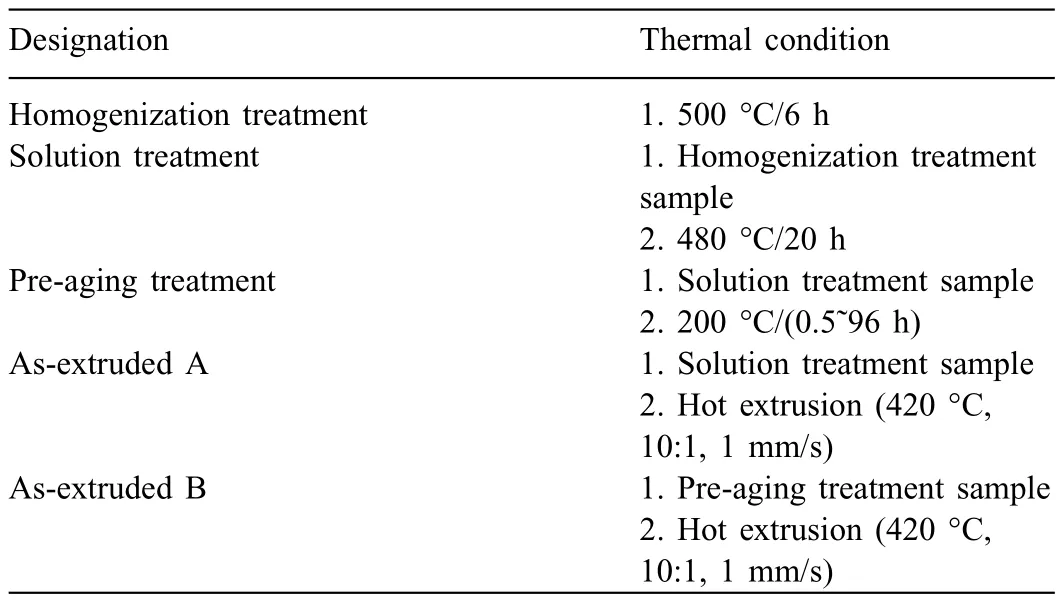

Fig.1.Optical microstructure of Mg–6Zn–1Gd–1Er alloy: (a) as-cast.(b) after homogenization treatment.

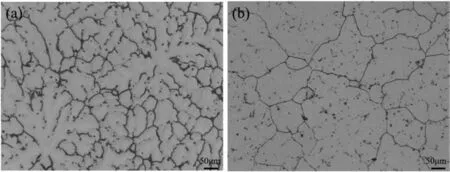

Fig.2.SEM images of Mg–6Zn–1Gd–1Er alloy under different treatment conditions: (a) solution treatment at 480 °C for 20 h.(b) After solution treatment at 480 °C for 20 h and aging treatment at 200 °C for 12 h.(c)Aging treatment at 200 °C for 48 h.(d) Aging treatment at 200 °C for 96 h.

3.Results and discussion

3.1 Microstructure.of initial conditions

Fig.1 shows OM micrographs of Mg–6Zn–1Gd–1Er alloy before and after homogenization treatment.The as-cast alloy is composed of eutectic compounds Mg5(Zn,Gd,Er)andα-Mg matrix at the grain boundary.The mean grain size is about 80 μm,as shown in Fig.1a.After homogenization treatment at 500 °C for 6 h,the segregation of alloy phase constituents has been disappeared,and more Zn-rich phases are precipitated out in the interior of the grains (Fig.1b).SEM micrographs of the alloys after pre-aging treatment are shown in Fig.2.In the solid solution treatment,Mg5(Zn,Gd,Er) phases tend to decompose with the heat treatment time,and Gd,Er and Zn elements diffuse intoα-Mg matrix.After solution treatment at 480 °C for 20 h,most of Mg5(Zn,Gd,Er) phases are dissolved intoα-Mg matrix.The atomic diffusion distance is quite limited in the solid-state phase transition process,and Mg5(Zn,Gd,Er) phase is mainly distributed at the grain boundary,so a small number of larger particles are still distributed at the grain boundary after solid solution treatment,as shown in Fig.2a.After aging treatment at 200 °C for 12 h (Fig.2b),Zn,Gd and Er elements are segregated and then G.P.zone or original cluster is formed.After aging treatment at 200 °C for 48 h (Fig.2c),it was obtained for the precipitated phase to appear in the form of dispersed small rod-shaped particles and scattered around particles.The larger particles are mainly distributed near the grain boundaries,while the fin rod-like particles are formed in the grain interior.With the prolonging of treatment (96 h),the precipitates keep growing and the distance between precipitates increases,as shown in Fig.2d.

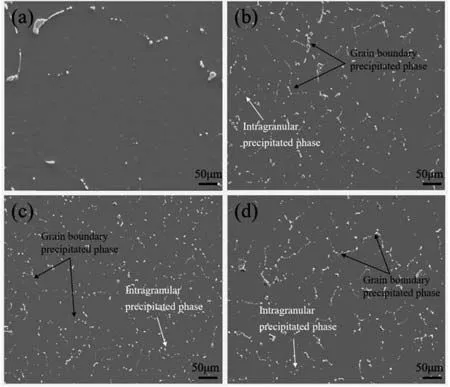

Fig.3.Age hardening response of Mg–6Zn–1Gd–1Er alloy aged at 200 °C up to 96 h.

3.2.Age hardening response

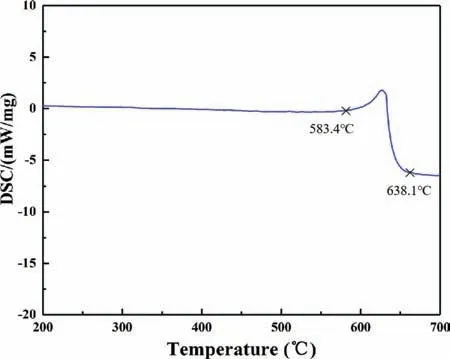

Fig.4.DSC curve of extruded sample under peak-aged condition(200 °C/48 h.).

Fig.3 shows the aging hardness curve of Mg–6Zn–1Gd–1Er alloy at 200 °C.It is observed that the hardness of the alloy increases rapidly within 1 h,and this rapid aging hardening behavior was directly related to the precipitation phase contribution.This phenomenon is also observed in Mg–4.58Zn–2.6Gd–0.18Zr (wt.%) alloy [17].Mg–6Zn–1Gd–1Er alloy reaches its peak value for hardness(74 HV)in 48 h.Relevant studies have shown that the addition of gadolinium will delay the age hardening reaction of magnesium-zinc alloys[18].In order to explore the influenc of the pre-aging precipitated phase on the properties of hot extruded Mg alloys,the factors of morphology,quantity and size was considered.The extrusion experiments were carried out under the conditions of solution and peak-aged (48 h),and the two extruded samples were studied in depth using EBSD technology.DSC result for the extruded Mg–6Zn–1Gd–1Er alloy is shown in Fig.4.The phase transition point of the extruded alloy under peak aging condition was measured at 583 °C~638 °C,indicating that the pre-aging hardening precipitates are existed stably under the extrusion condition of 420 °C.

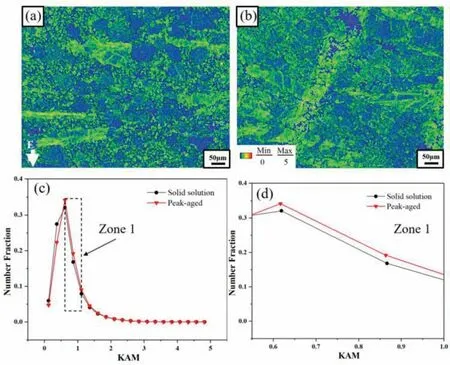

3.3.Microstructure development and texture evolution after extrusion

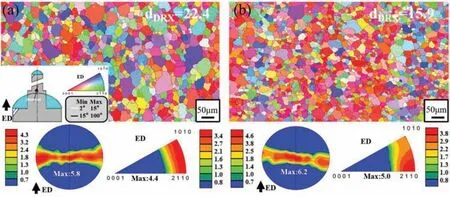

Fig.5 represents the microstructure and texture of extruded alloys under solid solution and peak-aged conditions.The microstructure of extruded samples is composed of fully recrystallized grains and exhibited typical fibe texture.The average grain size of the two aforementioned alloys is 22.4 μm and 15.9 μm,respectively.It is worth noting that the texture strength of the extruded alloy under peak aging condition is 6.2 multiples of random distribution (MRD),which is slightly larger than that under solid solution condition.This indicates that the texture strength of Mg–6Zn–1Gd–1Er alloy is affected by the second phase particles during the extrusion process,and the texture strength is relatively large after peak-aged treatment.

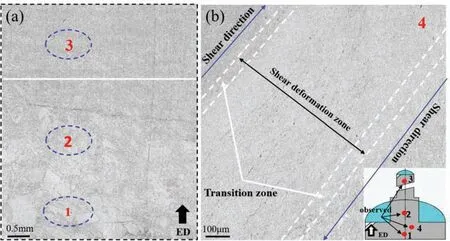

Fig.6 shows the OM images of the extruded sample in the peak-aged state during the extrusion process.It can be seen that in the initial stage of extrusion,there are lenticular twins in the original mother crystal grains,as shown in the zone 1 marked in Fig.6a.In the middle stage of extrusion,DRX and unDRX grains coexist,showing a typical bimodal microstructure distribution,as shown in Fig.6a marked zone 2.In the late stage of extrusion,the quantity and volume fractions of DRX grains increased significantl,forming a completely recrystallized structure,as shown in the zone 3 marked in Fig.6a.Therefore,it is reasonable to believe that twins have a profound effect on the DRX process.In addition,shear bands are formed in the shear deformation zone,as shown in Fig.6b.

Fig.5.Microstructure and texture of the extruded alloy under solid solution (a) and peak-aged condition (b).

Fig.6.Optical microstructures of the interrupted extruded sample at the locations marked in each schematic illustration.

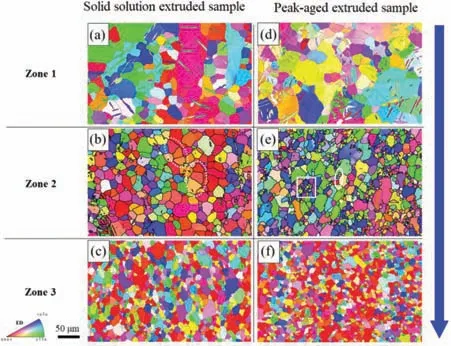

Fig.7.Microstructure evolution of the extruded Mg-6Zn-1Gd-1Er alloy in the 1,2,and 3 zones: (a),(b) and (c) solid solution extruded samples;(d)–(f) peak aged extruded samples.The extrusion direction is vertical.

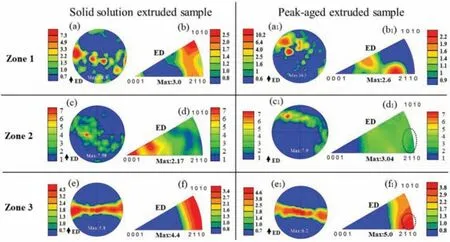

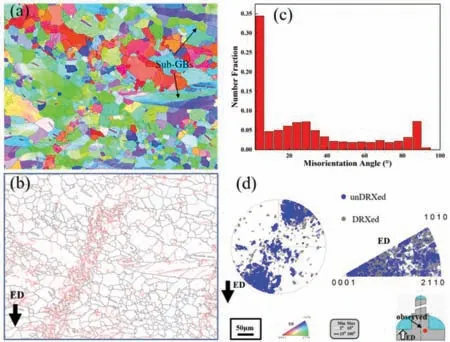

Fig.7 shows the IPF images of the extruded Mg-6Zn-1Gd-1Er alloy in the zone 1,2,and 3 in Fig.6.In the zone 1,it can be seen that the number of twins for the solid solution extruded sample is less than that in the aging state,but the size is larger.It can be explained as follows: the twins in the solid solution extruded sample suffer less resistance during the growth process and tend to grow laterally.In contrast,the twins in the peak aging extruded sample are hindered by the second phase particles during the growth process,and the lateral growth trend of the twins is restricted,so there will be stress concentration around the twins.In order to adapt the twins to the strain imposed by the external force,the stress concentration around the twins will promote the nucleation of new twins in the grains to relieve the strain imposed by the outer surface.Therefore,in the peak aging state,more twins with smaller size will be formed in the extruded sample.Generally speaking,the prefabricated second phase particles are conducive to twin nucleation,which will reduce the size of twins.The IPF graphs of extruded samples for zone 2 in the solid solution state and peak aging state is shown in Fig.7b and e.There is a big difference in the degree of recrystallization,grain size and orientation between two heat treatment states.This is mainly affected by the mechanism of twininduced nucleation and particle-induced nucleation (PSN) in the alloy with different morphologies.The size of the recrystallized grains for the solid solution extruded samples is large,and most of them show the recrystallized grains formed by twinning-induced nucleation,which is marked by the white circle in Fig.7b.However,the twin-induced recrystallization grains in the peak-aged extruded samples are fine as marked by the white circle in Fig.7e.It is ascribe to the fine twin size and large number of twins for the extruded samples in the peak-aged state.As a result,the size of the recrystallized grains induced by such twins is smaller.In addition,it can be seen from the area marked by the rectangle in the figur that the recrystallized grains of the extruded sample in the peak-aged state are also controlled by the particleinduced nucleation (PSN) mechanism.Under the influenc of the aforementioned two recrystallization mechanisms,the average grain size for recrystallization of the fina peak-aged extruded sample is smaller than that of the solid solution state,as shown in Fig.7(c,f).

Fig.8.Texture development of extruded Mg-6Zn-1Gd-1Er alloy in 1,2 and 3 zones: (a),(a1),(c),(c1),(e) and (e1) (0001) pole f gures;(b),(b1),(d),(d1),(f) and (f1) inverse pole figures

Fig.9.The stress-strain curves of the as-cast and extruded samples are tested along with ED at ambient temperature.

3.4.Mechanical properties

3.5.Discussion

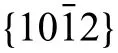

Fig.10.EBSD results of extruded sample under solid solution treatment in region 1: (a) IPF figure (b) Misorientation angle distribution.(c) Line profile of the misorientation angle along the black arrow AB.(d) Corresponding boundary misorientation map.(e) (0001) pole figur and (f) inverse pole figur and the light gray points indicate the orientations of the whole grains (For interpretation of the references to color in this figure the reader is referred to the web version of this article.).

Fig.11.EBSD results of extruded sample under peak-aged in region 1:(a)IPF map.(b)Misorientation angle distribution.(c)Line profile of the misorientation angle along the black arrow CD.(d) Corresponding boundary misorientation map.(e) (0001) pole figur and (f) inverse pole figur and the light gray points indicate the orientations of the whole grains.

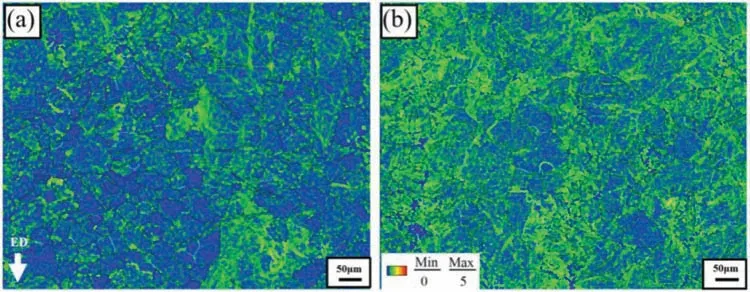

Fig.12.KAM figure of extruded samples in region 1 under solid solution (a) and peak-aged conditions (b).

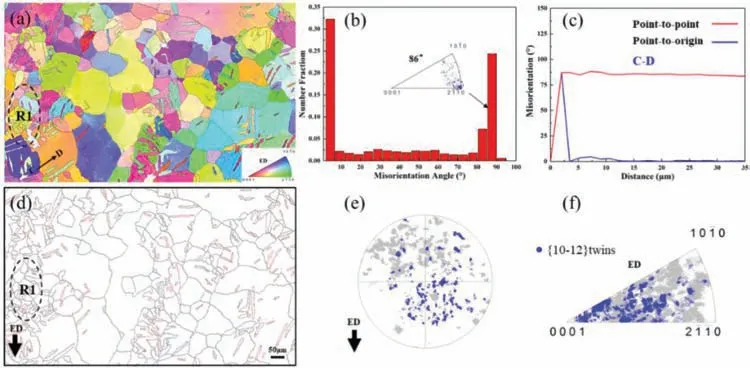

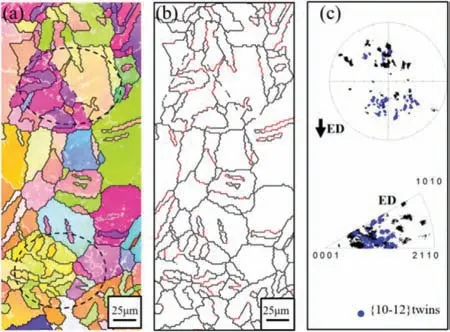

Fig.13.The R1 region selected from Fig.9c shows {10–12} twins engulfin the original grain: (a) IPF map.(b) corresponding boundary misorientation map.(c) (0001) pole figur and inverse pole figur representing the corresponding {10–12} twin orientation in blue (For interpretation of the references to color in this figur legend,the reader is referred to the web version of this article.).

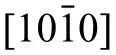

Fig.14 shows the distribution of the second phase particles in the transition region of the shear deformation zone of Mg-6Zn-1Gd-1Er alloy.It can be seen from the figur that the second phase particles are distributed "chain-like" along the shear direction.The quantity of the second phase particles in the solid solution state is significantl higher than that in the peak aged state.It is preliminarily believed that the dynamic precipitation occurred in the process of shear deformation of the solid solution sample,while the pre-aged phase dissolved in the peak aged sample.The dynamic precipitation and dissolution of precipitate will be further verifie by EBSD results.

Fig.14.Distribution of the second phase particles of Mg-6Zn-1Gd-1Er alloy in the transition region of shear deformation zone: (a) solid solution extruded sample,(b) peak aging state extrusion sample.

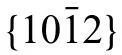

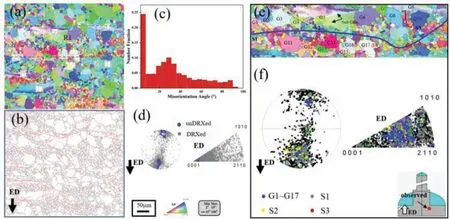

Fig.15.EBSD results of extruded samples under solid solution conditions were found in region 4: (a) IPF map.(b) Corresponding boundary misorientation map.(c) Misorientation angle distribution with axis distributions for the angles of 86°.(d) Light gray and blue dots in (d) indicate the orientation of DRX and unDRX measured grains,respectively.(e) IPF diagram containing a typical shear band is intercepted from the R1 region of Fig.15a.(f) The pole and inverse pole figur show the orientation of DRX grains in the shear band and unDRX grains in the edge region.UnDRX grains (G1~G17) are marked in blue.DRX grains in S1,S2 and S3 shear bands are highlighted in gray,yellow and red,respectively (For interpretation of the references to color in this figur legend,the reader is referred to the web version of this article.).

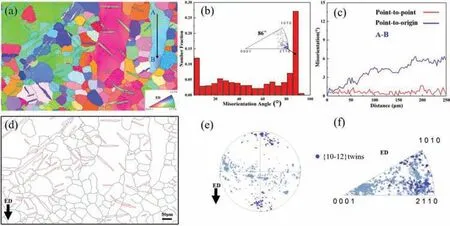

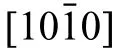

The S1,S2 and S3 shear bands are marked with blue,yellow and red curves respectively,and the elongated grains around the shear bands (G1~G17) are also marked,as shown in Fig.15e.The corresponding (0001) pole figur and inverse pole figur (Fig.15f) show that DRX and elongated grains in the shear bands exhibit random orientation.Fig.16 shows the EBSD results (region 4) of the sample under peak-aged condition.IPF figur (Fig.16a) shows that the structure is composed of elongated grains,DRX grains,and a small number of twins.Through comparative analysis of Figs.15c and 16c,it is found that the DRX grains in the extruded sample under the solid solution condition are much more than the DRX grains in the peak-aged sample.In the severe shear deformation process,the extruded samples have higher dislocation density and vacancy,and the diffusion coefficien of solute atoms increases,leading to dynamic precipitation.The precipitation phase provides a large number of heterogeneous nucleation sites,which promotes the process of DRX.A large number of literatures have reported the phenomenon of dynamic precipitation in the severe shear deformation.The PSN mechanism is dominant in the shear deformation region of the solid solution extruded sample,while the nucleation site of recrystallized grains is mainly provided by the "concaveconvex" grain boundary in the peak aging region.By comparing Figs.15d and 16d,it is found that in the transition region of shear deformation zone,no matter what nucleation mechanism is,the texture type is similar to that of the fina structure,so it will not have a significan effect on the texture type.Roven et al.[29] studied the dynamic precipitation of Al–Mg–Si alloy during severe plastic deformation,and the results showed that dynamic precipitation occurred in the severe deformation process,and there were a lot of dislocation around the precipitated phase and nucleated at the dislocation place,leading to refin the grains.Han et al.[30] proposed that the GP zone of the alloy formed during the plastic deformation was mainly affected by vacancy concentration,indicating that the vacancy existed in the solid solution sample effectively promoted the dynamic precipitation process.Yang et al.[31] studied the dynamic precipitation phenomenon in the adiabatic shear band of ZK60 Mg alloy treated with solid solution,and pointed out that in the intense shear deformation process,the increased diffusion coefficien of solute atoms can accelerate the dynamic precipitation process due to the high dislocation density and vacancy in the adiabatic shear band.In addition,the existence of fin equiaxed grains in the shear band was explained by rotating DRX mechanism.The extruded sample under the solid solution condition forms high dislocation density and vacancy concentration during the process of severe shear deformation,which leads to dynamic precipitation,resulting in provided a large number of nucleation sites for DRX.The increase in the orientation difference of the sub-grains existing in the elongated grains leads to the formation of large angular grain boundaries,and finall the formation of new grains [32].It can be seen from Fig.17 that the KAM value of the sample under the solid solution condition is much less than that under the peak-aged condition.This indicates that the energy stored in the extruded sample under the solid solution condition is less than that in the sample under the peak-aged condition,because of the energy stored in the grain is consumed by the dynamic precipitation of the extruded sample under the solid solution condition.The higher for the number of precipitated phases,the higher of the energy expenditure would occur.

Fig.16.The EBSD results of extruded samples under peak-aged were in region 4: (a) IPF map.(b) Corresponding boundary misorientation map.(c)Misorientation angle distribution with axis distributions for the angles of 86°.(d) Light gray and blue dots in (d) indicate the orientation of unDRX and DRX measured grains,respectively (For interpretation of the references to color in this figur legend,the reader is referred to the web version of this article.).

The amount of DRX grains in the extruded samples under the peak-aged condition is small,it can be inferred that there is no sufficien nucleation sites provided by the dynamic precipitation phase to promote DRX.During shear deformation,some pre-aging hardened precipitates have dissolved and cannot provide heterogeneous nucleation sites.Secondly,the dissolution of hardening precipitations and segregation of solute elements (Gd,Er and Zn) at the grain boundaries slow down recrystallization kinetics [21].This can explain the reason why the amount of DRX in the peak aging sample is small.Many studies have confirme that the pre-aging precipitates in the matrix will dissolve instantaneously in the severe shear deformation.Jiang et al.[33] studied the dissolution of the pre-aging precipitates in the adiabatic shear band of peak-aged ZK60 Mg alloy,and the results showed that the dissolution of the pre-aging precipitates was accelerated by the combined action of the free energy difference between the pre-aging precipitates and the matrix,the shortcircuit diffusion caused by dislocation and the adiabatic temperature rise.Lojkowski et al.[34] pointed out that high density dislocations and grain boundaries provided rapid diffusion channels for carbon from cementite to ferrite.In this study,a large number of dislocations (Fig.17b) and low-angle grain boundaries (Fig.16b) exist in the extruded samples under the peak-aged condition (region 4),providing a fast channel for the dissolution of pre-aging precipitates.The amount of DRX grains is small due to the lack of precipitation phase of heterogeneous nucleation sites provided for DRX grains in the sample under the peak aging condition.

It can be inferred from the following two aspects that the extruded sample under the solution condition experiences dynamic precipitation during severe shear deformation (region 4).Firstly,the number of DRX grains in the extruded sample under the solution condition is greater than that of the extruded sample under the peak-aged condition.The dislocation density and vacancy concentration in the sample under the condition of solid solution increase rapidly during the severe shear deformation,and a large number of Sub-GBs are formed in the elongated grains [29].Due to the collective effects of grain boundary,Sub-GBs,vacancy and dislocation,a large number of heterogeneous nucleation sites are provided,which promotes the dynamic precipitation of the second phase particles [29–32].The second phase particles follow the PSN mechanism to promote DRX.Secondly,the dynamic precipitation of second phase particles will consume the storage energy in the grains.It can be seen from Fig.17 that the storage energy of the extruded samples under the solid solution condition is lower than that of the extruded samples under the peak-aged condition,and the dynamic precipitation needs to consume the storage energy in the grains.In turn,the dissolution of the aging precipitates in the extruded samples under the peak-aged condition is also explained.In the severe shear deformation,the lattice of the aging precipitates and the matrix produces distortion,which leads to the increase of free energy,thus promoting the dissolution of the aging precipitates [33].In addition,the dislocation brought by short-circuits diffusion,also lead to the dissolution of aging precipitates.Because the aging precipitates have dissolved during the severe shear deformation and cannot provide heterogeneous sites,the DRX degree of the extruded samples under the peak-aged condition is relatively low in the region 4.

Fig.17.KAM extrusion sample analysis: (a) and (b) are KAM figure of extruded samples in region 4 under solid solution and peak-aged conditions,respectively.(c) The corresponding KAM value and (d) a larger view of zone 1 in Fig.17c.

The aging precipitations not only affect the dynamic recrystallization behavior,but also affect the strengthening mechanism.The extruded alloy is enhanced by the strong fibe texture,fin rod and block particles.The fin rod particles play a dispersion strengthening role in the Smith-Zener nailing effect.The smaller the spacing of small rod-shaped particles,the more effective it is in preventing dislocation movement and improving the strength of the alloy (Fig.12).The difference is that the size and spacing of the hardened precipitates are too large to directly affect the dislocation motion through the nailing effect.

4.Conclusions

To sum up,the effect of pre-aging treatment on microstructure,texture and mechanical properties of Mg–6Zn–1Gd–1Er(wt.%) alloy was discussed.The mechanism of pre-aging precipitates on twinning nucleation,shear band nucleation and texture evolution during extrusion was studied systematically.The main conclusions are as follows:

(1) Small rod-shaped and block-shaped precipitates were evenly distributed in the extruded samples after preaging treatment at 200 °C for 48 h.These precipitates partially dissolved during severe shear deformation,but most of them remained stable and affected the DRX behavior.

(3) The existence of grain boundary,Sub-GBs,vacancy and dislocation in the severe shear deformation of the extruded samples under the solid solution condition provided many heterogeneous nucleation sites for the second phase particles,and promoted the DRX process under the action of PSN mechanism.The samples under peak-aged condition during the severe shear deformation,the lattice distortion in the sediments and matrix resulted in the increase of free energy,which promoted the dissolution of the aging precipitates.Dissolution of precipitations and segregation of solute elements (Gd,Er and Zn) at grain boundaries effectively slowed down recrystallization kinetics and hindered the DRX process.

(4) The mechanical properties for the different treated samples was mainly attributed to the effect of aging precipitates on twins and DRX behavior during extrusion.Fine rod-shaped grains were refine by PSN mechanism.Therefore,it was particularly important to fully understand this problem and to control the microstructure and improve the mechanical properties of the extruded alloy by controlling the size,quantity,morphology and orientation relationship between the pre-aging phase and the matrix,which provided a way to develop new high-performance wrought Mg alloys.

Declaration of Competing InterestNone.

Acknowledgments

The authors gratefully acknowledge the financia supports from the National Natural Science Foundation of China(Grant No.51975207 &51404079),Hunan Provincial Natural Science Foundation for Excellent Young Scholars of China (Grant No.2019JJ30010),and Guangdong Provincial Department of Science and Technology (Grant No.2014B010105009,No.2015A030313902).

Journal of Magnesium and Alloys2023年1期

Journal of Magnesium and Alloys2023年1期

- Journal of Magnesium and Alloys的其它文章

- Development of high-strength magnesium alloys with excellent ignition-proof performance based on the oxidation and ignition mechanisms: A review

- Development and application of magnesium alloy parts for automotive OEMs: A review

- Recent advances in surface endothelialization of the magnesium alloy stent materials

- Recent developments in high-pressure die-cast magnesium alloys for automotive and future applications

- Exploring the contribution of oxygen reduction reaction to Mg corrosion by modeling assisted local analysis

- Microstructures,mechanical properties,corrosion,and biocompatibility of extruded Mg-Zr-Sr-Ho alloys for biodegradable implant applications