The Development of Memory Alloy Satellite-Rocket Separation Device for Commercial Small Satellites

YANG Haoliang ,WANG Yuning ,SUN Zhichao ,YANG Yiqiang

1 Beijing Zhongke Aerospace Exploration Technology Co.Ltd,Beijing 100176

2 Institute of Mechanics,China Academy of Science,Beijing 100190

Abstract: Non-pyrotechnic separation devices have been fully recognized for their high performance and high reliability.The focus of this paper is mainly around the development of memory alloy satellite and rocket separation devices.Due to the increasing demand for small-sized rockets and satellites,some suggestions and experiments for developing this new type of non-pyrotechnic device are proposed and conducted.

Key words: non-pyrotechnic separation,memory alloy,satellite-rocket separation device

1 INTRODUCTION

In recent years,with the gradual improvement of launch vehicle capabilities and the continuous miniaturization of commercial satellites,the launch mode of a single rocket with multiple satellites has developed its own trend.On January 24,2021,a SpaceX’s Falcon 9 rocket was launched successfully with 143 satellites from Cape Canaveral,Florida,USA.On February 27,2022,a Long March 8 carrier rocket took off from China’s Wenchang Spacecraft Launch Site,and launched 22 satellites into a sun-synchronous orbit about 500 km high,the launch was a complete success.

With these advances,separation technology has gradually become a very important topic in recent research in space field.Historically,most of the domestic satellite-rocket separation techniques use relatively mature and reliable pyrotechnic separation technology.However,Europe and the United States have conducted batch launch applications of separation devices without pyrotechnics.China is still in the preliminary development stage for the mature application of non-pyrotechnic separation devices.In view of this situation,the paper focuses on the development of satellite-rocket separation devices based on memory alloy technology.The main purpose of this research and development is to explore the direction of non-pyrotechnic technology.In addition,the search for alternative technologies for pyrotechnic separation devices was carried out along with identifying the requirements for high-reliability connection and separation with small satellites and rockets.

2 ADVANTAGES OF NON-PYROTECHNIC SEPARATING DEVICES

Pyrotechnic separation devices,such as explosive bolts,pyrotechnic nuts,steel ball projectile locks,and wedge projectile locks,mainly rely on energy generated by gunpowder combustion or explosion.The pyrotechnic separation device uses the explosion or combustion of gunpowder to drive the functional mechanism to fully complete its task.Key defects include poor safety,high impact load during operation,and an inability to enable functional inspection when adopted.Not only that,a point-type unlocking device often needs to be used at the same time in practical engineering applications.Here it has the disadvantage of a lack of synchronization.Hence,it also reduces the reliability of the satellite and rocket separation.More and more researchers have gradually moved to non-pyrotechnical release devices with the characteristics of small release impact,re-usability and good synchronization.The main advantages of non-pyrotechnic separation devices compared to conventional pyrotechnics are as follows.

The impact is significantly reduced when the satellite and rocket are separated.The impact can be reduced from 5,000 —20,000 g to 300 — 2,000 g.It can be seen that this fully reduces the environmental impact on satellites.

There is no impact from electromagnetic interference,static electricity and other influences from say the pyrotechnic initiator and electrical load from ignition.

We can effectively eliminate the safety protection problem.This means avoiding the safety measures that exist in a series of processes such as manufacture,transportation and storage of pyrotechnics.

There is no harmful gas or debris generated when pyrotechnics burn or explode in the process,and hence no harm to the environment.

They can be used under any condition,which is convenient for test verification.Plus it is easy to ensure the reliability of the separation mechanism.

In addition,the non-pyrotechnic separation device includes the following types of components:motor-driven separation devices,electromagnetic separation devices,pneumatic separation devices and a memory alloy based satellite-rocket separation device.In the above-mentioned novel non-pyrotechnic separation devices,the memory alloy based satellite-rocket separation device has excellent performance.In recent years,a large number of researchers have developed several kinds of memory alloy actuators which are reusable and have a fast response time,which have been utilized in the satellite separation process.

3 DESIGN OF NON-PYROTECHNIC SEPARATING DEVICES

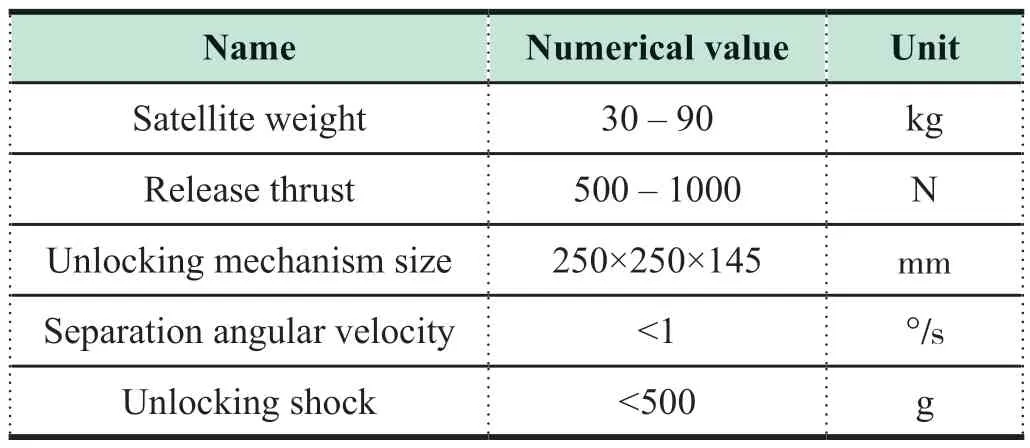

At present,research has identified that SpaceX plans to launch 42,000 small satellites within 5 years.OneWeb plans to build 900 satellites.China’s commercial small satellite market shows a geometric growth in the next 5 years that it is conservatively estimated that there will be more than 4,000 satellites at present.Satellites with a weight of 30 — 90 kg have a large launch demand.It is necessary to understand the requirements of separation angular velocity,size,unlocking shock,etc.involved in the required satellites.The main design parameters of the non-pyrotechnic separation devices are proposed in Table 1.

Table 1 Design requirement parameters

The main operating states of a satellite-rocket separation and unlocking device include locking and unlocking.When locking,it needs to be firm and reliable,and can fully resist the changing environmental state due to vibration,shock,overload,and high temperatures that the rocket is subjected to during flight.When the rocket reaches a predetermined position,the unlocking action is then performed.It requires a reliable unlocking action,its multiple locking points need to be unlocked synchronously enabling a smooth deployment after unlocking.The devices should gradually provide the satellite with the required launch inertia.

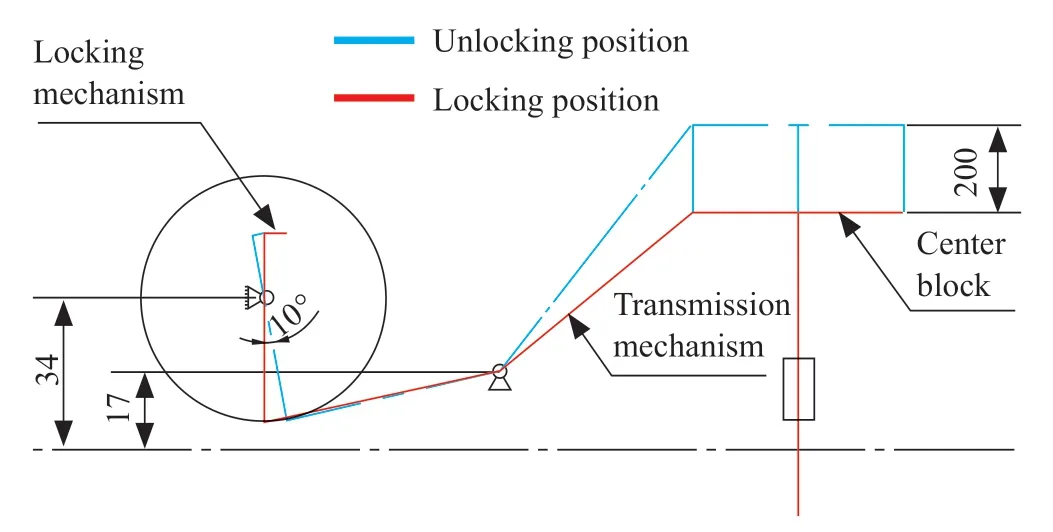

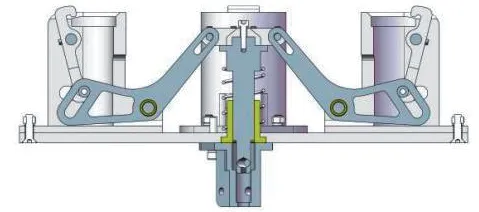

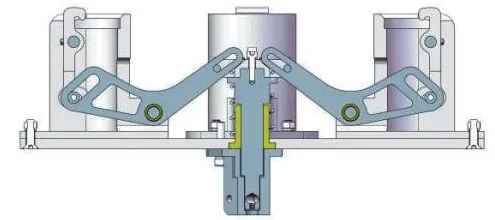

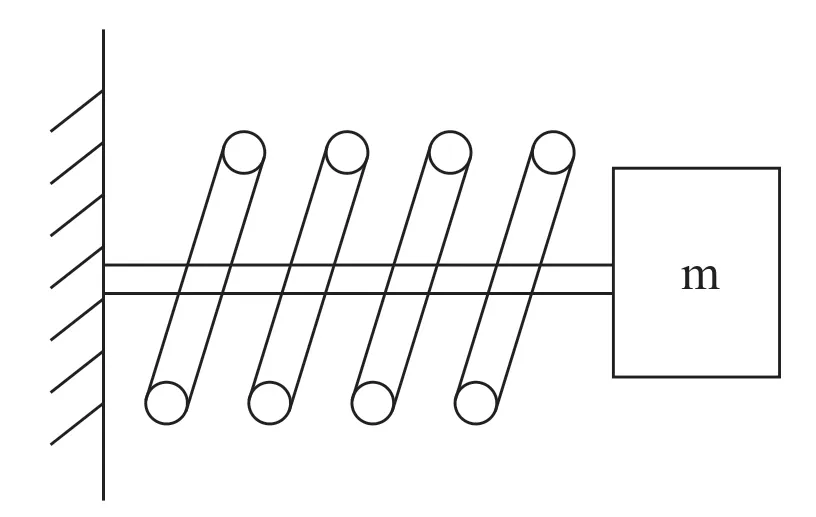

The concepts of this project lay in the unlocking trigger point position including side unlocking and center unlocking.The unlocking force of the center unlocking is mainly in the middle of the device.It is transmitted to the locking point via a connecting rod.Then the transmission power route is more controllable,so that it can fully facilitate the simultaneous unlocking of the four locking points.In addition,it is necessary to further select a rotary locking claw with a relatively simple structure where the main transmission method needs to be directly transmitted by a single transmission link.The main operational principle diagram is shown in Figure 1.

Figure 1 Schematic diagram of the satellite and rocket unlocking device

Combined with the design parameters,the pin puller is designed to generate a maximum pin pull force of 220 N.Hence,the respective force can be seen as follows:

The pin head and pin hole are made of stainless steel,and the friction coefficient=0.15 ;

Center block maximum upward force

According to the torque balance of the power transmission link,it is obtained:

The measurement schematic is obtained:

According to the locking pawl torque balance:

The measurement schematic can be obtained:

It can be seen from the above calculation results that the mechanism can theoretically generate a locking force above 1,000 kg.

At the same time,the thrust generating mechanism during unlocking is further decoupled.We can treat it as a separate action.In addition,in order to fully maintain stability,it can also be set in 4 groups.

Hence,a multi-point locking technical solution is designed.The number of locking points will change as required by the task change.This further increases design flexibility.On this basis,the polygon closed link rotation synchronous unlocking method was adopted.

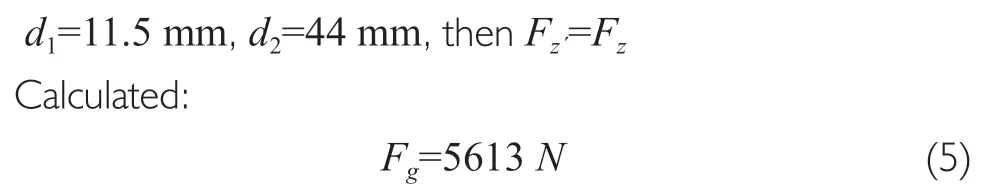

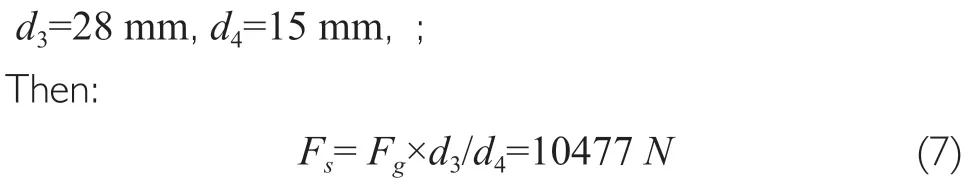

Therefore,the separation thrust offset problem of an asynchronous unlocking scheme can be fully avoided.In addition,the unlocking driving force is perpendicular to the direction of the connection and locking force,and hence are not coupled to each other.The locking force is provided by the rigid structure.Hence,the disadvantage of the small carrying capacity of the non-pyrotechnic separation mechanism can be sufficiently overcome.This makes it possible to refine the design of the structure according to the schematic diagram shown in Figures 2 and 3.Further,the rotating parts mainly use industrial grade oil-free bearings.Lubrication is provided by the carbon powder that comes with the oil-free bearing.

Figure 2 Before unlocking

Figure 3 After unlocking

The prototype of the separation and unlocking device of the non-pyrotechnic rocket is manufactured and assembled according to the design diagram and engineering two-dimensional drawings,as shown in Figure 4.The driving energy for unlocking is mainly through the memory alloy pin puller.

Figure 4 Prototype of the unlocking device for the separation of the non-pyrotechnic rockets.

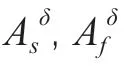

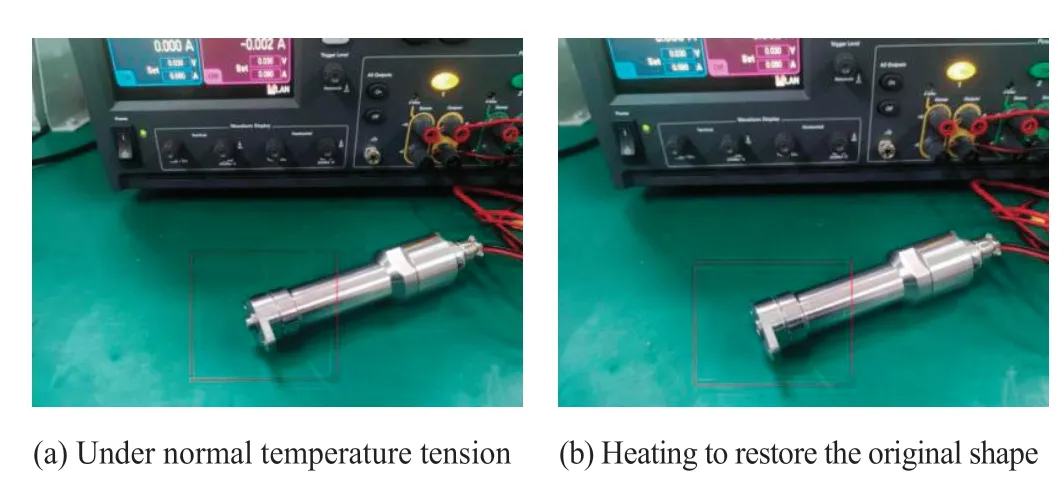

4 DESIGN OF MEMORY ALLOY PIN PULLER

Memory alloy is mainly used as the driving material,and is widely used in the separation technology of space industry.Moreover,the working principle of shape memory alloy (SMA)refers to the plastic deformation which easily occurs at low temperatures.However,when heated to a certain temperature,it can quickly return to its original shape.This is because in the process of heating and cooling,the thermo-elastic martensite undergoes phase transformation and reverse transformation.The separation device uses this memory function,so that a larger force or torque can be easily realized,thus it can be used as a drive to fully realize the unlocking and separation.Not only that,shape memory alloys also have good wear resistance and corrosion resistance,and can better adapt to harsh aviation environments.Its working state is relatively stable,has a long fatigue life,and can be reused many times.Figure 5 shows a memory alloy-based pin puller.When it is heated to a certain temperature,it can also quickly return to its original shape.

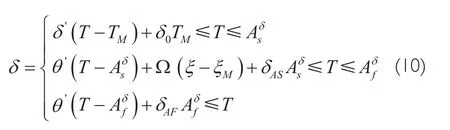

Combining the memory alloy principles and the parameter requirements of the non-pyrotechnical satellite and rocket separation and unlocking device,a more stable solution is established.Continuous development of the pin puller has been carried out.It is necessary to establish a constitutive model of the memory alloy in the design process.Based on this,the prediction of the restoring force of the memory alloy was carried out.On this basis,the relatively simple and accurate Liang model was adopted.The established model is shown in Figure 6.

Figure 5 A memory alloy-based pin puller

Figure 6 SMA driver model

whererepresents stress,represents initial stress,represents temperature,represents initial temperature,represents martensite mass fraction,represents martensite initial value,represents elastic modulus;represents thermoelastic coefficient,Ω represents phase transformation coefficient.

There is a certain relationship between the high temperature recovery stress of SMA wire and the spring stiffness k.During the heating process of memory alloy,the relationship between its stress and temperature can be expressed as:

The SMA trigger has the following advantages,including:fast response,simple reset,small impact,and can be reused.By estimation,the release time is less than 75 ms,and the pin pulling force is 220 N.

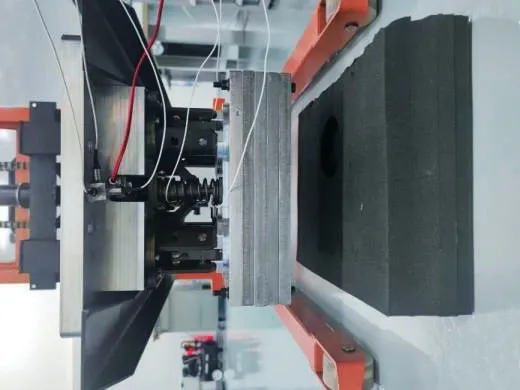

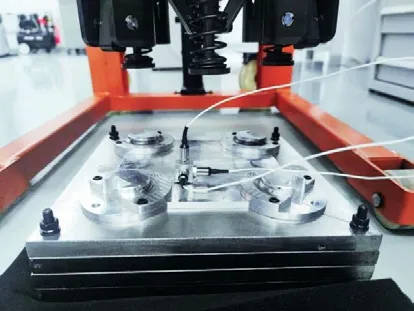

Based on the general power supply and distribution and unlocking bidirectional requirements of the launch vehicle avionics system it can be seen that when the voltage is 25-32 V,the current is 2.5-5 A,the unlocking time is 50 ms,and the pin pull-out force is 220 N.Among them,Figure 7 below shows the power-on test of the pull-out pin.Figure 8 refers to the pin pull-out force test with a test value of 220 N.

Figure 7 Memory alloy pin puller test

Figure 8 Pull-out force test

5 TESTS OF MEMORY ALLOY SATELLITE-ROCKET SEPARATION DEVICE

The memory alloy satellite-rocket separation device was subjected to random vibration tests in three directions of X,Y and Z,in accordance with the aerospace development program.In addition,shock tests and reliability tests were carried out.

Swept frequency vibration and random vibration were applied respectively for the memory alloy satellite-rocket separation device with a 100 kg counterweight in X,Y,and Z directions.

During the tests,the device experienced no negative impact.All configurations of the device remain locked.In addition,there was no loosening and slipping,and no abnormal noise witnessed during the process.Figure 9 show the test process in X direction (Rocket flight direction with random vibration condition).

Figure 9 Random vibration test (X direction—random vibration)

Figure 10 Before unlocking

Figure 11 After unlocking

Figure 12 Test results

After the vibration test,the principle prototype was subject to the separation and unlocking test.A three-way impact sensor was arranged 100 mm away,the unlocking position to measure the impact capacity.The test process and test results are shown in the following figures.The whole unlocking process was smooth,and the unlocking time was about 50 ms.Moreover,the impact on the satellite simulation part was less than 400 g,hence its impact on the satellite product is relatively small.

Based on the development of the prototype,the reliable connection and separation of the system was fully realized,adopting a more flexible structure design.This process resolved two potential technical difficulties.One being the structural design of non-pyrotechnical installations.The second being the problem of synchronization of multiple non-pyrotechnical devices.Through the reliability tests,the ability of such devices in terms of pre-tightening force,connection force,separation impact,separation time,size and quality could be evaluated,and the inspection period determined to meet the requirements.A total of 420 tests were carried out on the same product,and no failure results were recorded.Combined with the system test standard,the confidence level is 0.7.

At a confidence level of 0.7,the reliability of the system is currently 0.997.

6 CONCLUSION

The working principle and performance characteristics of non-pyrotechnic separation devices are fully analyzed.Testing was carried out under the governance of aerospace quality system.In addition,the approach tries to provide a paradigm of R&D for the future of new high-reliability non-pyrotechnic separation devices.At present,it is aimed at the upcoming high-density small satellite launch market.Such devices have great advantages in terms of driving energy,synchronization,separation time,low shock,detectability and reliability.It can be seen that this will be an important development direction in the field of satellite-rocket separation.

- Aerospace China的其它文章

- Shenzhou 12 Under Development

- The Development Status and Main Application Progress of China’s Ocean Satellites

- A Brief Introduction to China Manned Space Program Missions

- The Propulsion System of Shenzhou 13 Manned Spaceship

- Development of Solid Rocket Motor for Manned Launch Vehicle Escape System

- High Reliability LM-2F Launch Vehicle for Space Station Mission