In-package cold plasma treatment of braised chicken: voltage effect

Yli Zhng, Yng Lei, Suhong Hung, Xioli Dong, Jicho Hung, Ming Hung,*

a Nanjing Innovation Center of Meat Products Processing, Jiangsu Collaborative Innovation Center of Meat Production and Processing,Quality and Safety Control, and College of Food Science and Technology, Nanjing Agricultural University, Nanjing 210095, China

b College of Engineering, Nanjing Agricultural University, Nanjing 210095, China

Keywords:

In-package cold plasma

Braised chicken

Shelf-life

Quality

A B S T R A C T

This study investigated the effect of different dielectric barrier discharge cold plasma (DBD-CP) treatment voltages on the microbiological growth and quality characteristics of braised chicken during storage at (4 ± 1) °C.Argon-packed samples were subjected to DBD-CP treatment for 3 min at voltages of 50, 60 and 70 kV. As a result, there was no significant (P > 0.05) difference in L*, a*, b* and pH of braised chicken between control and treatment groups at the same storage time. However, the development of lipid oxidation in DBD-CP treatment samples was slower than that in air-packed samples. Compared to air-packed samples, the reduction of total viable count, yeasts and molds, lactic acid bacteria and Pseudomonads spp. in 70 kV treated samples on day 15 were 3.21, 2.41, 2.44 and 1.96 lg (CFU/g), respectively. The results indicate that DBD-CP treatment could extend the shelf life of braised chicken without negative impacts on quality characteristics.

1. Introduction

Meat products are easily contaminated by spoilage microorganisms, and the quality is decreased, eventually leading to corrupt meat products [1]. Traditional sterilization technologies,especially thermal treatment, are associated with negative impacts on the texture and nutrition of food [2]. Hence, many nonthermal sterilization technologies, e.g., high pressure processing [3], high pressure carbon dioxide [4], high voltage pulsed electric field [5]and cold plasma [6], have emerged in recent decades to prevent the occurrence of food microbiological safety problems, to avoid the destruction of food nutrition, and to make up for the de ficiencies of traditional technologies.

The ionization of single or mixed gases could produce free radicals, termed cold plasma [7], which could attack the cell membrane and intracellular substances of spoilage bacteria to kill the microorganisms [8]. Cold plasma is one of widely studied nonthermal sterilization technologies that has been extensively researched in food decontamination due to its energy-efficient and chemical-free advantages [9]. Further, the mutagenic safety and the toxicological safety of food treated with cold plasma have been reported by previous research [10,11].

Braised chicken is a favored and traditional meat product that is named “the greatest chicken dish” in China. As a kind of Chinese traditional ready-to-eat meat, braised chicken enjoys high attention among consumers in China due to its attractive color, delicious taste and unique flavor [12]. In recent years, ready-to-eat braised chicken is usually packaged in a vacuum and sterilized by thermal treatment. However, thermal treatment can compromise the quality characteristics and nutrients of braised chicken. Furthermore,mutagens or carcinogens might be produced by high temperature treatment on food for a long time, causing food safety problems [13].Therefore, nonthermal sterilization is becoming the main direction of research to obtain superior quality meat products. It is now well established that cold plasma is a promising, nonthermal technology for controlling the surface pathogenic bacteria of prepackaged readyto-eat beef [14,15]and the surface spoilage bacteria of boiled chicken breast [16]and chicken patties [17].

The parameters of cold plasma treatment played a considerable role in the decontamination effect [18]. Over the past decade,a considerable amount of literature has been published on the decontamination ability of meat products after cold plasma treatment with different parameters. Rossow et al. [19]indicated that argon cold plasma treatment could be used for chicken preservation, following 120 s argon cold plasma exposure, to obtain the highestC. jejunireduction of up to 2 lg(CFU/cm2). Cold plasma treatment on one side of the meat products could achieve the optimum decontamination,as there was no significant difference in the inactivation ofE. colion raw chicken breasts after cold plasma with both sides treated or one side treated [20]. Moreover, a wide range of increases in treatment time (beyond 180 s) did not obtain further reduction of psychrophilic population on chicken breast, while an extra log-reduction could be achieved by increasing treatment time from 60 s to 180 s [21].Further, Dirks et al. [22]revealed that skinless chicken breast could obtain more log-reduction of inoculated bacteria than chicken thigh with skin following 3 min of air plasma exposure. This situation might be attributed to the influence of different surface textures and topography [23]and the effect of different lipid contents on the potential protection of lipid molecules [24]in various samples. These previous studies revealed that cold plasma with different parameters had different effects on disparate meat products. Therefore, the decontamination efficacy of different cold plasma parameters on various meat products should be researched to improve its potential commercial application value.

Up to now, what is not yet clear is the effects of different voltages of cold plasma treatment on braised chicken throughout the storage period, as the research to date has tended to focus on the decontamination ability of cold plasma rather than the influence of the quality of meat products during storage after cold plasma treatment. Therefore, this study used DBD-CP treatment on braised chicken drumsticks (as a representative of braised chicken) to meet the demand of consumers for guaranteeing microbiological safety and maintaining nutritional and quality characteristics.

2. Materials and methods

2.1 Sample preparation

Braised chicken drumsticks ((90 ± 10) g each), obtained from Nanjing Huangjiaoshou Food Science and Technology Co., Ltd.(Nanjing, China), were cooled naturally in a control room (4 °C)and readied for packaging. These samples were packaged in air with a polyethylene film and 100% argon with 25 μm low-density polyethylene/polyamide/low-density polyethylene (LDPE/PA/LDPE) barrier pouches (size: 223.3 mm × 133 mm × 59.8 mm,2 drumsticks/pouch). The volume ratio of was 2.68 (gas to meat). These samples were divided into the following 5 groups: air-packed; argonpacked without plasma treatment; argon-packed with 50 kV plasma treatment (Ar + 50 kV); argon-packed with 60 kV plasma treatment(Ar + 60 kV); and argon-packed with 70 kV plasma treatment (Ar +70 kV). The air-packed and argon-packed groups were the control groups, and the Ar + 50 kV, Ar + 60 kV and Ar + 70 kV groups were the treatment groups.

2.2 In-package plasma treatment

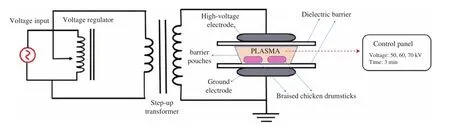

The plasma device consisted of an AC dielectric test device(BK-130, Phenix Technologies, Accident, MD, USA), an aluminum ring-shaped ring electrode (diameter 150 mm) and two dielectric barrier layers (polypropylene sheets, distance 8 mm). As shown in Fig. 1 [25], the barrier pouches with braised chicken drumsticks were placed at the center of the electrode between the two dielectric layers (direct treatment) and were approximately 1.5 mm distant from the upper dielectric layer, then treated at 50, 60 and 70 kV for 3 min [26,27], respectively. These treatments were carried out at room temperature ((25 ± 1) °C) and atmospheric pressure. Samples were immediately stored at (4 ± 1) °C (compressor cooled incubator ICP260, Memmert, Germany) and analyzed at day 0, 5, 10, 15 and 20. On different sampling days, 3 barrier pouches (6 braised chicken drumsticks) were stochastic taken for each treatment group, and then sampled randomly from the 6 braised chicken drumsticks for determination of different indicators.

Fig. 1 Schematic diagram of the cold plasma device [25].

2.3 Microbial analysis

Microbiological analysis was performed using the spread plate method described by Wang et al. [26]. The meat with skin (half each, 25 g in total) were removed from braised chicken drumsticks immediately after aseptically opening the packages, then put it into a stomacher bag (HaiBo Co., Qingdao, China) containing 225 mL sterile saline (0.85% NaCl) and patted evenly for 2 min. Decimal dilutions were prepared using sterile saline. Then draw 1 mL of the appropriate gradient dilution to the following medium: Plate count agar (PCA, Lang Bridge Co., Beijing, China) and Centrimide Fucidin-Cepha Loridine (CFC) medium (HaiBo Co., Qingdao,China) were used for total viable count (TVC) (incubated at 37 °C for(48 ± 2) h) andPseudomonasspp. (incubated at 25 °C for (44 ± 4) h),respectively. The lactic acid bacteria (LAB) were cultured on Man Rogosa Sharpe agar (HaiBo Co., Qingdao, China) in an anaerobic environment at 37 °C for (72 ± 2) h. Rose Bengal Medium (HaiBo Co., Qingdao, China) was used for mold and yeast and was incubated at 28 °C for 5 days. The results were expressed as lg (CFU/g).

2.4 Surface color evaluation

The surface color of braised chicken drumsticks was determined by the CR-400 colorimeter (Minolta, Osaka, Japan). A whiteboard was used to calibrate the instrument before measurement. Braised chicken drumsticks were tested by CR-400 colorimeter with illuminant D65,an 8-mm diameter measurement range and a 2° viewing angle at each sampling day [28]. The process of measurement was carried out under indoor lighting conditions. Three different regions with no obvious defects of each sample were selected to recordL* (lightness),a*(redness) andb* (yellowness).

2.5 pH measurement

Peeled and minced braised chicken drumsticks (5 g) were mixed with 50 mL ultrapure water [29]. Then, the mixture was homogenized at 5 000 r/min for 30 s using a homogenizer (Ultra Turrax T25,IKA, Germany), and pH was determined using a pH meter (Hanna HI9025c, Portugal).

2.6 Lipid oxidation assay

Lipid oxidation was measured using the method described by Salih et al. [30]and Utrera et al. [31]with minor modifications.Firstly, 5 g of sample was mixed with 25 mL of 7.5% (m/V)trichloroacetic acid (TCA) solution and homogenized at 9 000 r/min for 40 s (2 × 20 s with 10 s interval) using a homogenizer (Ultra Turrax T25, IKA, Germany). Then, the mixture was centrifuged at 12 000 r/min for 7 min (4 °C). The mixture consisting of 2 mL of the supernatant and 2 mL of 0.02 mol/L thiobarbituric acid (TBA)was reacted for 40 min in a boiled water bath. The mixture was cooled to room temperature, and the absorbance at 532 nm was measured. 1,1,3,3-tetraethoxypropane (TEP) solution was used for the standard curve to calculate the TBA-reactive substances content. The results were expressed as milligrams malondialdehyde(MDA) per kg of sample.

2.7 Statistical analysis

The results were expressed as the means ± S.D. (n= 3).Microbiological counts were described as the logarithms of the number of colony-forming units (CFU/g). The results were subjected to one-way analysis of variance (ANOVA) using SAS statistical software (SAS, Release 8.1; SAS Institute Inc., Cary, NC, USA).Differences among mean values were compared using the Duncan’s multiple range test. Correlation between variables was calculated using SAS statistical software. In all cases, the statistical significance level wasP< 0.05.

3. Results and discussion

3.1 Microbial analysis

3.1.1 Microbial enumeration on braised chicken drumsticks during storage

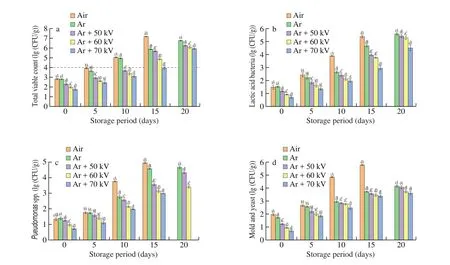

According to the International Commission on Microbiological Specifications of Food, TVC is the main restriction factor of the shelf life of poultry [32]. The effects of DBD cold plasma using argon gas on the inactivation of microorganisms on braised chicken drumsticks were studied depending on the treatment voltage (50-70 kV) (Fig. 2a).TVC in air-packed samples was 2.83 lg (CFU/g) on the initial day and increased to 3.91 lg (CFU/g) after 5 days of storage. Air-packed samples without secondary sterilization and any treatment were more prone to attract the growth of spoilage microorganisms, which might be the most important reason for the samples to exceed the microbiological limit of Chinese Cooked Meat Microbial Standard(GB 2726-2016, TVC < 4 lg (CFU/g)). TVC in argon-packed samples was also close to 4 lg (CFU/g) on day 5, and there were no significant(P> 0.05) differences between argon-packed and air-packed samples within 10 days storage. After 10 days storage, argon-packed displayed inhibition of the growth of microorganisms compared with air-packed samples. The antibacterial effect of argon-packed treatments might be attributed to the anaerobic environment created with 100% argon leading to lower TVC counts. Olatunde et al. [33]con firmed the role of Ar-MAP in retarding the growth of microorganisms, especially spoilage bacteria. Previous studies also pointed out that modifiedatmosphere package (MAP) using argon could extend the shelf life of sardine products [34]and turkey breast [35]. For the DBD-CP treatment groups, microorganisms (TVC, LAB,Pseudomonasspp.And yeasts and molds) at day zero in the different cold plasma voltage treatment samples were all significant (P< 0.05) lower than that in air-packed samples (Fig. 2), indicating that cold plasma treatment with argon packing possessed a certain bactericidal effect [36]and could lead to the death of most microorganisms, instead of injury. Mahnot et al. [25,37]observed the shrinkage, deformation and bursting ofSalmonella,E. coliandL. monocytogenesupon cold plasma treatment, resulting in the final death. However, Wan et al. [38]demonstrated that a considerable population ofS. enteritidismight only be injured instead of completely inactivated by the application of high voltage atmospheric cold plasma treatment on chicken eggs. Lim et al. [39]stated that the ionization of argon may lead to a larger production of metastable oxygen and other bactericidal active substances due to the high electron density of argon/oxygen plasma. Our investigation results also confirmed that the growth rate of microorganisms on braised chicken drumsticks decreased gradually with increasing DBD-CP treatment voltage. Previous study described that the higher voltage plasma treatment increased the surface temperature of samples and enhanced the inactivation effect by denaturation [19]. However, Kim et al. [40]found that the thermal impact of radio-frequency atmospheric pressure plasma (RF plasma)had very little contribution to the decontamination ofS. aureusafter a short duration (< 4 min). When the duration of RF plasma treatment exceeded 8 min, the thermal effect could lead to a considerable(1.2 ± 0.2) log-reduction ofS. aureus, but the RF plasma treatment still played a critical role in the inactivation ofS. aureus. In our study,the treatment time was 3 min (lower than 4 min) and the sampleswere cooled before treatment, so the population of microorganisms decreased with increasing DBD-CP treatment voltage maybe not due to the rise temperature on the surface of braised chicken drumsticks.Wan et al. [41]demonstrated that a greater antimicrobial efficacy was achieved by higher applied voltages causing an increased production of reactive oxygen and reactive nitrogen species. Therefore, the result in our study might create by the higher voltage causing the carrier gas to ionize more active substances, while it requires more extra researches to prove. Further, Fernández et al. [42]reported that higher cell density could leave the bacteria in multiple layers,and the inactivated bacteria on the top layers may form a physical barrier to prevent plasma species from inactivating bacteria beneath by entering the multilayered cells. In this study, the inactivation effects of different voltage treatments in braised chicken drumsticks were significant, indicating that bacterial density might not reach a high level in our samples or that higher voltage might make plasma species reach the underlying cells to improve the bactericidal effect.In summary, the shelf lives of braised chicken drumsticks in the control groups and cold plasma treatment groups (50 and 60 kV) were approximately 5 and 10 days, respectively. DBD-CP treatment with 70 kV was the most effective voltage to inhibit the growth of spoilage bacteria and could extend the shelf life of braised chicken drumsticks to about 13 days, according to the GB 2726-2016 (TVC < 4 lg (CFU/g)).

Fig. 2 Changes in (a) total viable count, (b) lactic acid bacteria, (c) Pseudomonas spp., (d) yeast and mold count of braised chicken drumstick under refrigerated storage for different treatment conditions.. Error bars represent standard deviations of the mean (n = 3). a-d. Values with different lowercase letters, within differentstorage times, were significantly different (P < 0.05). A-D. Values with different uppercase letters within the same sampling day were significantly different.

3.1.2 Populations of LAB on braised chicken drumsticks during storage

A comparison between control and treatment samples showed that DBD-CP possessed a significant (P< 0.05) effect on inhibiting the growth of LAB (Fig. 2b). The initial population of LAB in the airpacked sample was 1.49 lg (CFU/g), and the population increased to 5.40 lg (CFU/g) on day 15. The counts of LAB on day 15 increased to 4.68 lg (CFU/g) (argon-packed), 3.98 lg (CFU/g) (Ar + 50 kV),3.78 (lg CFU/g) (Ar + 60 kV) and 2.95 lg (CFU/g) (Ar + 70 kV). The rapidly increased population of LAB could be explained by the fact that LAB are facultative anaerobic bacteria [43]and could produce lactic and bacteriocin to inhibit the growth of other bacteria [44].Moreover, the increase in LAB counts in the DBD-CP treatment groups were significantly lower than those in the control groups. This result demonstrated that LAB could be inactivated by DBD-cold plasma treatment [45].

3.1.3 Populations of Pseudomonas spp. on braised chicken drumsticks during storage

As shown in Fig. 2c, a 70 kV cold plasma treatment was more effective in retarding the development ofPseudomonasspp. than other treatments during the refrigeration storage time. The population ofPseudomonasspp. in air-packed braised chicken drumsticks was increased by approximately 3.19 lg (CFU/g) from days 5 to day 15 of storage, which was similar to that in argon-packed samples(2.83 lg (CFU/g)). The increase in thePseudomonasspp. population in the 50, 60 and 70 kV cold plasma treatment groups from days 5 to day 15 of storage were 1.97, 1.84 and 1.88 lg (CFU/g), respectively.This increase in thePseudomonasspp. population was in consistent with the result reported by Douglas et al. [46], who found thatPseudomonasspp. expanded their population on day 7 in an anaerobic environment (80% CO2: 20% N2). Albertos et al. [47]demonstrated that cold plasma could reduce the population ofPseudomonasspp. and found that both LAB andPseudomonasspp. displayed great sensitivity to the increase in applied voltage. The inhibition of cold plasma on the growth ofPseudomonasspp. was also found in fresh chicken fillets during the storage period [26]. Moreover, Bartis et al. [48]stated that the basic component of cell walls of gram-negative bacteria(lipopolysaccharide) could be chemically modified by argon plasma treatment.

3.1.4 Populations of yeast and mold on braised chicken during storage

Yeasts and molds (YM) in the air-packed group sharply (P< 0.05)increased from 1.98 lg (CFU/g) to 5.80 lg (CFU/g) within 15 days of storage, while the growth of YM was significantly (P< 0.05)restrained in the argon-packed and DBD-CP treatment groups (Fig. 2d).Similar results addressed by previous studies showed that argonpacked cold plasma treatment could reduce the population of YM on the surface of the pork longissimus dorsi muscle [49]and cherry tomatoes [50]. By comparing control and treated groups, the results indicated that the argon modified atmosphere packaging was not conducive to the growth of YM [51]. The results also indicated that cold plasma treatment could enhance the inhibitory effect of argon packaging on YM growth. This investigation result was agreement with that of Gök et al. [52], who achieved approximately 1.66 lg (CFU/cm2) reduction in the population of YM of the beef product by argon-packed and cold plasma treatment for 180 s.

3.2 Physicochemical changes

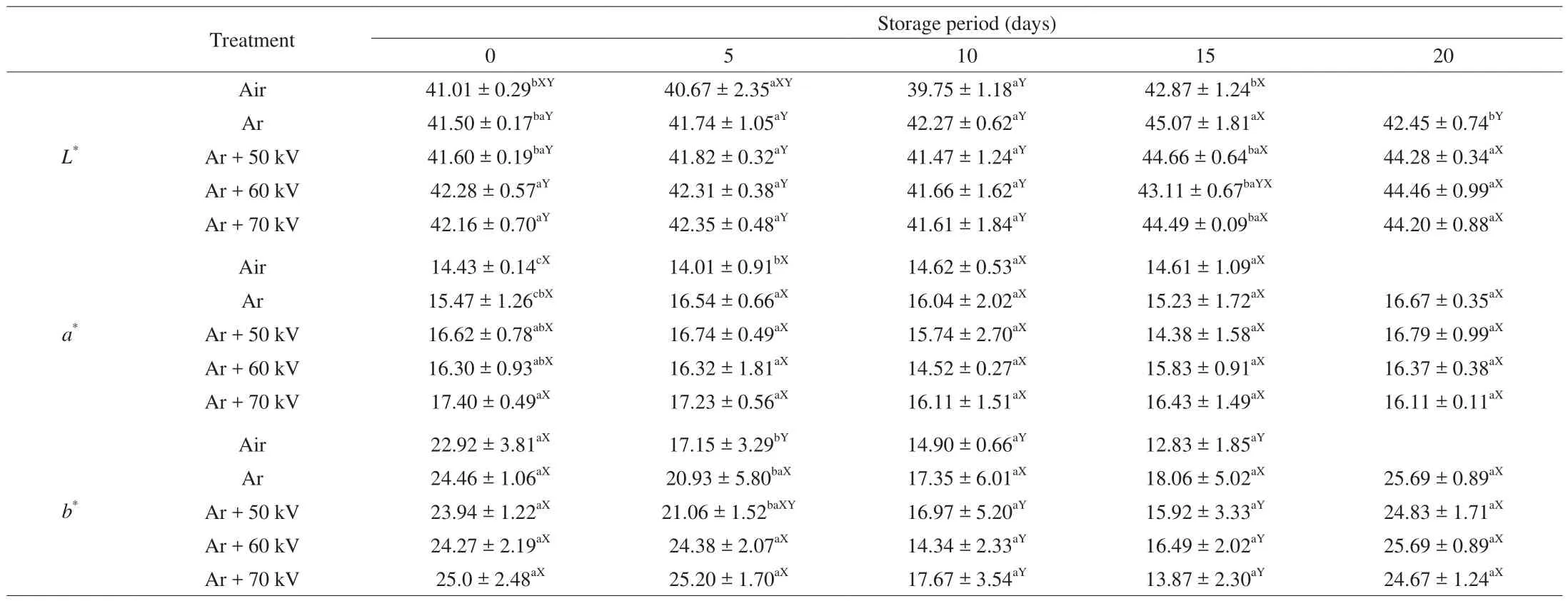

3.2.1 Surface color

The surface color of food determines the acceptance of consumers during purchase, as it is the major and intuitive indicator among several food quality attributes [53]. Hence, the determination of the color of samples after cold plasma treatment is important. As presented in Table 1, thea* value was not associated with storage time, while theb* andL* values were varied within the storage period. A difference in the color parameters of the samples between control and treated groups was observed on day 0, and the difference also existed in the subsequent storage time. The storage time [54], pH, moisture and water-holding capacity [55]affect the color of broiler skin and meat, which might be mistaken as an effect of cold plasma treatment. Hence, it could be considered that DBDCP treatment had no adverse impact on the surface color of meat products, which was consistent with previous studies [19,26,36,41].Interestingly, Bauer et al. [56]demonstrated that all of theL*,a*andb* values of noncovered beef loin increased after high power atmosphere cold plasma (ACP) treatment, while there was no significant difference in theL*,a* andb* values of packaged loins following low power ACP treatment. Likewise, Fröhling et al. [57]found that thea* values of air-packed pork increased with the application of cold plasma treatment. Their research suggested that higherb* values of fresh pork might be attributed to the production of metmyoglobin induced by the radicals formed by atmospheric pressure plasma treatment.

Table 1The effect of different voltages of cold plasma on the surface color of braised chicken drumsticks under refrigerated storage.

3.2.2 pH value

The pH slightly declined during the storage period of the first 15 days, and returned to the initial pH value of about 6.78 on day 20 (Table 2). The change of pH in meat is influenced by many factors,such as the buffering capability of the meat organized system and the metabolism of some microorganisms [58]. In this case, the increase of pH value in braised chicken drumsticks from day 15 to day 20 might be explained by the metabolism of LAB resulting in the accumulation of ammonia and basic nitrogen compounds [59,60]. Although the pH values of samples varied within the storage time, there was no significant (P< 0.05) difference between the control and treated groups in pH value. Especially after cold plasma treatment (day 0),there was no significant difference in pH between the treatment groups and the control groups, indicating that cold plasma treatment would not affect the pH value of braised chicken drumsticks. That was consistent with the study of Kim et al. [29]for bacon, which showed that cold plasma using a helium/oxygen mixture could not cause a change in pH values. The similar result in our and Kim et al. [29]studies might be attributed to the reduction of the formation of acid producing molecules by using inert gas as the carrier gas. In other circumstances, the reduction of pH in previous studies may be due to the formation of acidogenic molecules (NOx) by air cold plasma treatment [61].Hong et al. [62]also reported that in-package cold plasma (IPCP) treatment did not cause the change in pH of raw chicken breast meat, but the colors.

Table 2The effect of different voltages of cold plasma on the pH value of braised chicken drumsticks under refrigerated storage.

3.2.3 Lipid oxidation

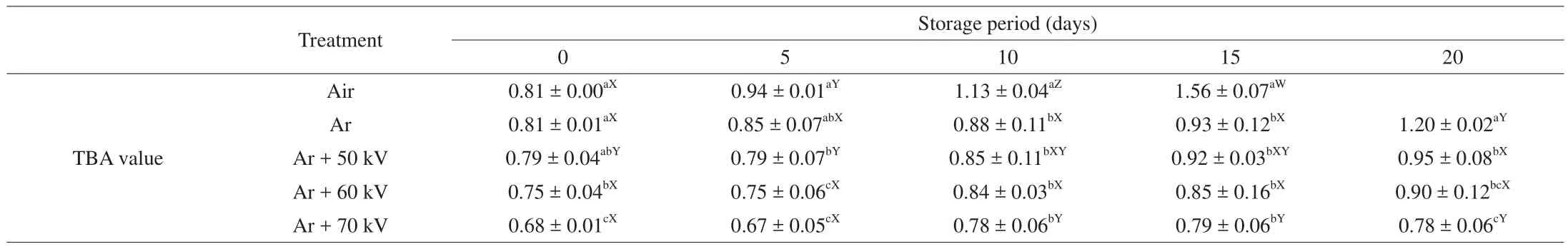

The TBA (thiobarbituric acid-a secondary lipid oxidation product)value of braised chicken drumstick increased with the extension of the storage period (Table 3). There was no significant difference(P> 0.05) in TBA values of air-packed (0.81 mg/kg), argon-packed(0.81 mg/kg) and Ar + 50 kV (0.79 mg/kg) samples on day zero,while the TBA values of 60 kV and 70 kV cold plasma treated groups were significantly lower than those of untreated samples (P< 0.05).Similarly, Kim et al. [29]also observed that TBA values of samples treated with 75 kV He-cold plasma and 125 kV He/O2-cold plasma were lower than those of untreated control group on day zero. This may be related to the type of carrier gas and treated voltage, but further research is needed to prove it. The TBA value in air-packed samples increased from 0.81 mg/kg to 1.56 mg/kg within 15 days of storage. The TBA value in air-packed samples of 15 days storage(1.56 mg/kg) was higher than that in argon-packed samples of 20 days storage (1.20 mg/kg). The lower development of lipid oxidation in argon-packed samples might be attributed to the effective replacement of oxygen by argon [33]. TBA values of cold plasma treatment samples on day 20 were 0.95 mg/kg (in Ar + 50 kV), 0.90 mg/kg (in Ar + 60 kV) and 0.78 mg/kg (in Ar + 70 kV), respectively. This result displayed that the combination of argon-packed and cold plasma treatment could significantly (P< 0.05) decelerate the development rates of lipid oxidation.

Table 3The effect of different voltages of cold plasma on the TBA value of braised chicken drumsticks under refrigerated storage.

Lee et al. [10]applied ACP on chicken breast and showed that ACP treatment did not affect lipid oxidation. Similar results were also reported by Choi et al. [63]and Moutiq et al. [64]. In contrast,Rod et al. [14]stated that lipid oxidation offlaked instant beef was aggravated with the increase in cold plasma voltage and the extension of storage time. Many researchers have also reported that cold plasma treatment could affect the lipid oxidation of meat or meat products to various degrees [29,65,66]. The degree of lipid oxidation depended on the fat content of samples, and there was a positive correlation between them [67], which might explain the different effects of cold plasma treatment on lipid oxidation. Therefore, the different results of cold plasma treatment on the effect of lipid oxidation in our and Rod et al. [14]studies might be because the total fat content of chicken breast was lower than that of beef or pork [68].

Many factors, such as various meat samples (different fat composition and content), plasma type, carrier gas and exposure time, could be used to explain the different results of lipid oxidation of meat products after cold plasma treatment [69]. Hence, more attention should be paid to the effect of cold plasma treatment on lipid oxidation and other quality characteristics of meat products.

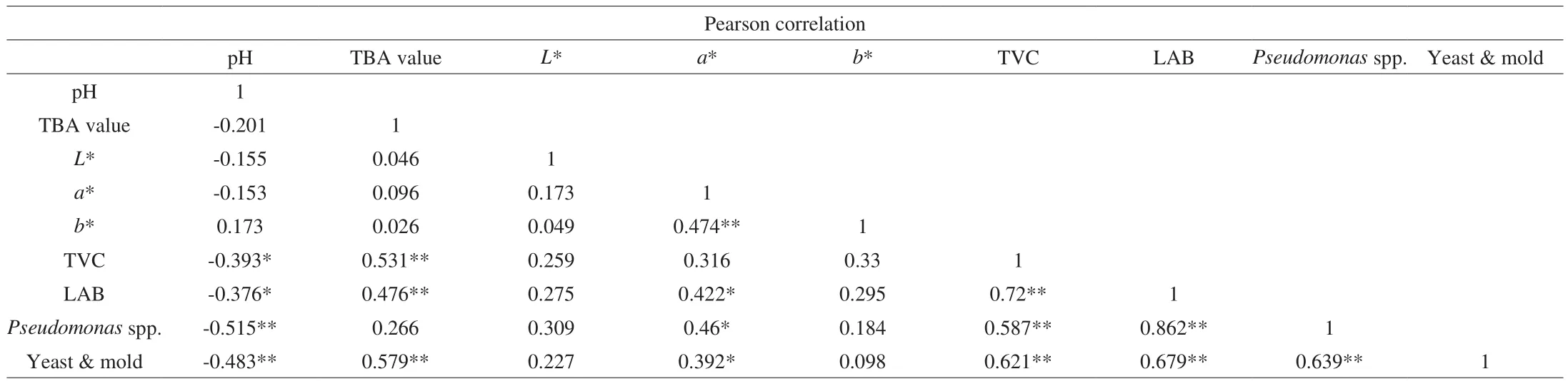

3.2.4 Pearson correlation analysis

The Pearson correlation analysis results of microbiological and physicochemical properties of braised chicken drumstick showed that pH values of samples had a significant negative correlation with TVC and LAB (P< 0.05), and an extremely significant negative correlation withPseudomonasspp. and YM (P< 0.01) (Table 4). That means microorganisms could decrease the pH values of samples in the early stages of corruption. The pH values increased significantly after 15 days of storage, which might be attributed to the production of amines by microbes using nutrients of samples. Moreover, the correlation analysis also implied that a slight positive correlation existed betweena*values and microorganisms, and a medium positive correlation was found between TBA values and microorganisms on braised chicken drumsticks(Table 4). Therefore, the physicochemical index (pH, TBA values,a* values) could be regarded as important quality indicator of braised chicken corruption. It should be mentioned that a high correlation did not mean that there was truly a causal relationship but that a relationship becomes more probable.

Table 4Correlation of microbiological and physicochemical of braised chicken drumsticks for different treatment conditions throughout the refrigerated storage ((4 ± 1) °C for 15 days).

4. Conclusions

In this study, DBD-CP treatment showed an inactivation effect against spoilage microorganisms (TVC, LAB, molds and yeasts,Pseudomonads) on the surface of braised chicken drumsticks. The differences inL*,a*,b* values and pH of braised chicken drumsticks were not significant (P> 0.05) between control and DBD-CP treatment samples at the same storage time. A storage investigation under refrigeration demonstrated that DBD-CP treatment (especially 70 kV voltage) could significantly (P< 0.05) suppress the growth of microorganisms without concomitant adverse changes in quality characteristics (surface color, pH and lipid oxidation) in braised chicken drumsticks. Therefore, our study suggests that DBDCP treatment can be used as a potential technology to prolong the shelf-life and preserve the quality characteristics of braised chicken drumsticks.

Conflict of interest

The authors declare there is no conflict of interest.

Acknowledgements

This work was financially supported by the Key R&D Program(Modern Agriculture) of Jiangsu Province (BE2019308).

- 食品科学与人类健康(英文)的其它文章

- Pomegranate peel polyphenols alleviate insulin resistance through the promotion of insulin signaling pathway in skeletal muscle of metabolic syndrome rats

- Sucrose-free hawthorn leathers formulated with fructooligosaccharides and xylooligosaccharides ameliorate high-fat diet induced inflammation,glucose and lipid metabolism in liver of mice

- Roles of Adinandra nitida (Theaceae) and camellianin A in HCl/ethanol-induced acute gastric ulcer in mice

- Polygonatum sibiricum polysaccharides protect against obesity and non-alcoholic fatty liver disease in rats fed a high-fat diet

- Trehalose ameliorates autophagy dysregulation in aged cortex and acts as an exercise mimetic to delay brain aging in elderly mice

- Deep eutectic solvents and alkaline extraction of protein from seabuckthorn seed meal: a comparison study