Structure and Properties of Pure Cotton Low-Twist Single Yarn Based on Addition of Long-Staple Cotton

WEN Run(温 润), TAN Min(谈 敏), XU Nuo(许 诺), ZHANG Ruiyin(张瑞寅)

College of Textiles, Donghua University, Shanghai 201620, China

Abstract: Pure cotton low-twist single yarn has good softness, bulkiness, and wearing comfort, but its lower strength makes the yarn break easily during the spinning process, which seriously affects the spinning effect and progress. The addition of long-staple cotton helps to increase the average length and uniformity of the raw fiber, thereby improving the breaking load and spinnability of pure cotton low-twist single yarn. In this study, the addition of long-staple cotton, the twist factor, and the twist direction were used as variables to spin 22 kinds of combed 14.6 tex pure cotton low-twist single yarn with spinnability, and the breaking load, the hairiness, and the unevenness of the yarn were tested. The result shows that the spinnability of pure cotton low-twist single yarn is mainly related to the breaking load, and with the increase of the twist factor, the breaking load of low-twist single yarn shows an obvious upward trend. When the proportion of long-staple cotton is 70%, the breaking load of low-twist single yarn is the largest, and the harmful hairiness index and unevenness of the yarn are significantly improved.

Key words: low twist; single yarn; long-staple cotton; structure; property

Introduction

With the development of society, people have higher requirements for the comfort and safety of textiles[1]. As a natural and environmentally friendly bulk fabric, woven cotton fabric has good moisture absorption, heat resistance and alkali resistance. Woven cotton fabric is the mainstream fabric in apparel fabrics, and its output ranks first among global fabrics[2]. At present, the methods of increasing the softness of woven fabric on the market mainly include adding softeners such as silicone, napping, and reducing yarn twist[3-5]. However, the producted fabric treated by two methods of adding softener and napping is not good for human health. Reducing yarn twist is an important way to improve textile comfort[6].

Generally speaking, the twist of low-twist yarn should be at least 20% lower than that of normal yarn[7]. And the low-twist yarn has the advantages of softness, bulkiness, and comfortable wearing. However, as the twist factor of low-twist yarn decreases, some properties of the low-twist yarn will also deteriorate, such as the decrease of yarn strength and the increase of spinning breakage[8-10]. Therefore, on the basis of maintaining high comfort of low-twist yarn, it is particularly important to improve the strength of low-twist yarn.

At present, the academic research on increasing the spinnability of low-twist yarn mainly focuses on two directions. One is to add new equipment on the basis of the original machine to improve the spinnability of low-twist yarn, but this method requires high equipment cost and is easy to cause power waste[11]. The other is to add corresponding fibers to increase the strength of low-twist single yarn and expand the spinning range, such as adding long-staple cotton to increase the strength of pure cotton low-twist yarn. The increased cost of this method is relatively low, and the addition of long-staple cotton will not cause resource pollution and waste, but a reasonable addition ratio and standard for long-staple cotton have not yet been formed[12-13].

Based on the traditional Siro spinning process, this study selects two raw materials, namely long-staple cotton and fine-staple cotton, sets up experimental samples, and spins them into yarn by adjusting the addition ratio of long-staple cotton, twist factor and twist direction. The structure of pure cotton low-twist single yarn is analyzed, and the breaking load, unevenness and hairiness of the single yarn are explored.

1 Experiments

1.1 Materials

In this study, two raw materials of long-staple cotton and fine-staple cotton are selected. The long-staple cotton is Xinjiang cotton with moisture regain of 8.87%, modal staple length of 33.36 mm, and yarn breaking load of 2.79 cN. The fine-staple cotton used in the experiment is a blend of various cotton (shown in Table 1), so as to save costs and give full play to the characteristics of different raw cottons.

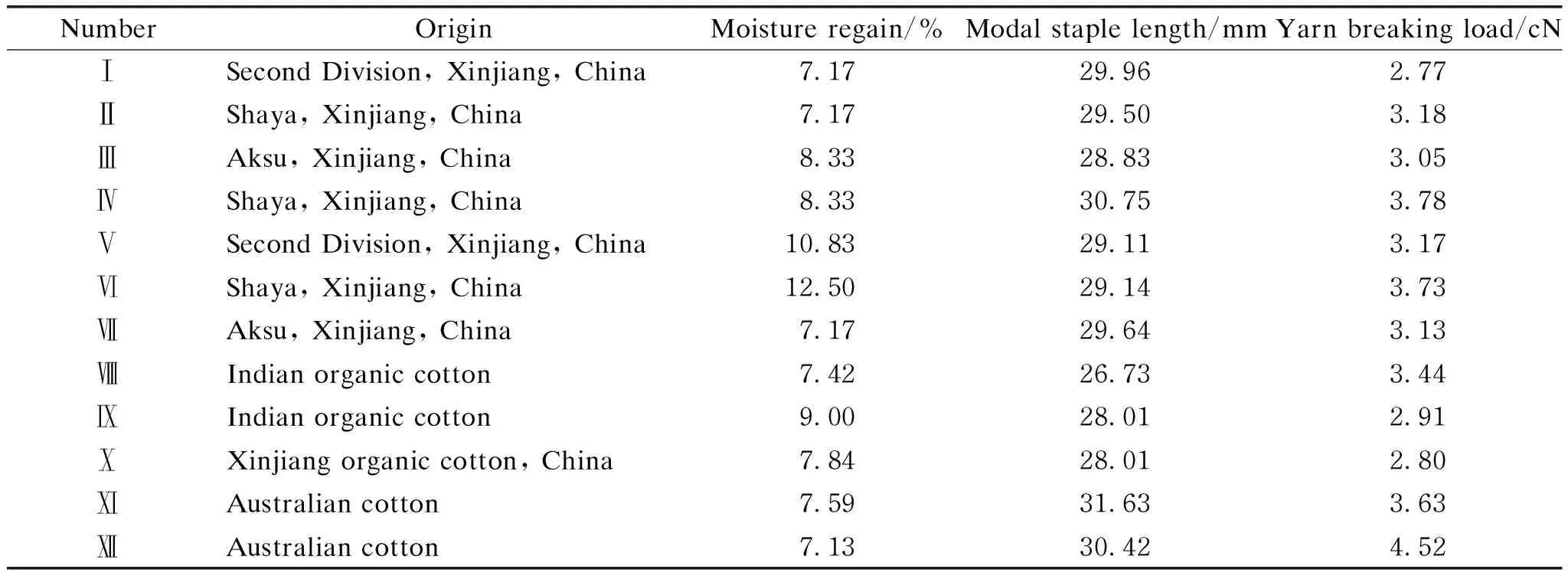

Table 1 Type of fine-staple cotton used in this experiment

In this study, three groups of samples were set up with 30% long-staple cotton in sample 1 (1#), 50% long-staple cotton in sample 2 (2#) and 70% long-staple cotton in sample 3 (3#). In each group of samples, there are two twist directions for single yarn, namely Z twist and S twist. The twist factor of conventional combed single yarn(14.6 tex) ranges from 350 to 380 [ the twist is 92-100 twisting/(10 cm) ], and the twist factor of low-twist yarn explored in this subject is not higher than 250 [ the twist is not higher than 65 twisting/(10 cm) ]. Taking 20 twist factors as a gradient, the low-twist single yarn with the twist factor less than 250 is analyzed.

1.2 Samples

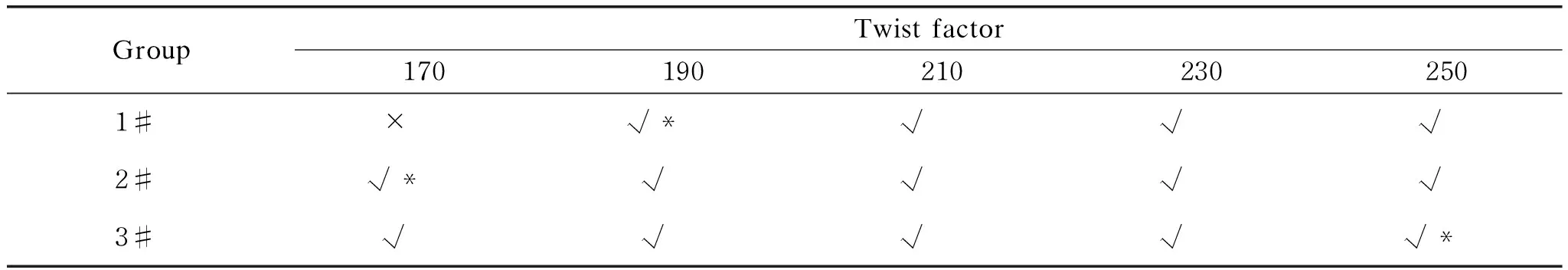

Due to the large angle between the single yarn and the bobbin in the initial and final stages of spinning, the single yarn has to bear greater tension.Therefore spinning breakage is likely to occur. Through many preliminary experiments[14], the yarn breakage in the spinning process was observed and recorded (45 min at the beginning of spinning and 45 min at the end of spinning, respectively). Taking twist factor and twist direction (Z twist and S twist) as variables, the spinnability and weaveability of different low-twist single yarns in three samples is explored. The results are shown in Table 2.

Table 2 Analysis of spinnability and weaveability of pure cotton low-twist single yarn

When the twist factor of 1# is 170, the yarn is not spinnable. When the twist factor of 1# is 190 and the twist factor of 2# is 170, the breaking load of single yarn is lower than 160 cN. The low-twist single yarn under this condition has a large number of yarn breakages during the winding, doubling, and twisting processes. And taking into account the cost of the yarn, the single yarn with a twist factor of 250 in 3# is less cost-effective. Therefore, these four kinds of single yarns of little research significance are removed, and there are 22 types of low-twist single yarns that need to be spun in this study.

1.3 Spinning process of low-twist single yarn

The specific spinning process is as follows. (1) The BLENDOMAT type straight reciprocating automatic cotton grabber, the CL-C1 type single-hand opener, the CL-P type double-axis flow cotton-cleaner and the MX-1 type multi-mixer are used to loosen the fibers[15]and complete the blending of fine-staple cotton. (2) The impurities and foreign matter in the semi-finished products are removed through the SP-FPV type foreign fiber cleaner and the SP-DX type powerful dust remover, and the TC5 carding machine for combing is used. (3) The long-staple cotton and fine-staple cotton are mixed in the pre-drawing stage through the FA302 type drawing frame. (4) The roving is spun through the JHF1618 type roving frame. (5) The low-twist single yarn required for the experiment is spun on the FA503 type spinning frame.

2 Results and Discussion

2.1 Structure analysis of low-twist single yarn

Figure 1 shows the single yarn surface morphology taken by the TM-3000 desktop scanning electron microscope (Hitachi, Japan). Three samples in Fig.1 are all combed pure cotton single yarn (14.6 tex) spun by Siro spinning. The low-twist single yarn with a twist factor of 230 is shown in Figs. 1 (a) and 1(b). The ratio of long-staple cotton to fine-staple cotton in the yarn is 1∶1. The fiber arrangement on the surface of the single yarn is relatively loose, but the fibers are arranged in the same direction. Figure 1(c) is the control sample, showing the Z-twisted combed cotton single yarn with a twist factor of 290, which is often used in factories. The fibers in the single yarn are arranged closely, and some fibers are intertwined.

Fig. 1 Surface morphologies of yarn under scanning electron microscope: (a) Z-twisted single yarn; (b) S-twisted single yarn; (c) Z-twisted combed cotton single yarn

With the increase of the single yarn twist, the fibers are arranged more closely. When subjected to external force, the fibers in the low-twist yarn can move in a large space, so the yarn is more fluffy and softer.

2.2 Performance test of low-twist single yarn

The breaking load, harmful hairiness and unevenness of 22 kinds of pure cotton low-twist single yarn were tested and analyzed to further understand the characteristics of the yarn. The test sample is pre-equilibrated for 24 h in an environment with an ambient temperature of 20 ℃ and a relative humidity of 65%, and then the test is performed.

Breaking load is the most important index in the physical and mechanical performance of single yarn. Due to the low twist and low strength of the low-twist single yarn, the breaking load directly affects the spinnability of the single yarn[16]. The relationship between twist factors and breaking load of low-twist single yarn is shown in Fig. 2.

Fig. 2 Breaking load of low-twist single yarn with different twist factors

In general, the breaking load of six kinds of low-twist single yarn all increases with the increase of the twist factor. The low-twist single yarn of 3# has the highest long-staple cotton content (70%), and its breaking load has the most obvious increase. When the twist factor is constant, the breaking load of single yarn increases with the increase of the long-staple cotton content.

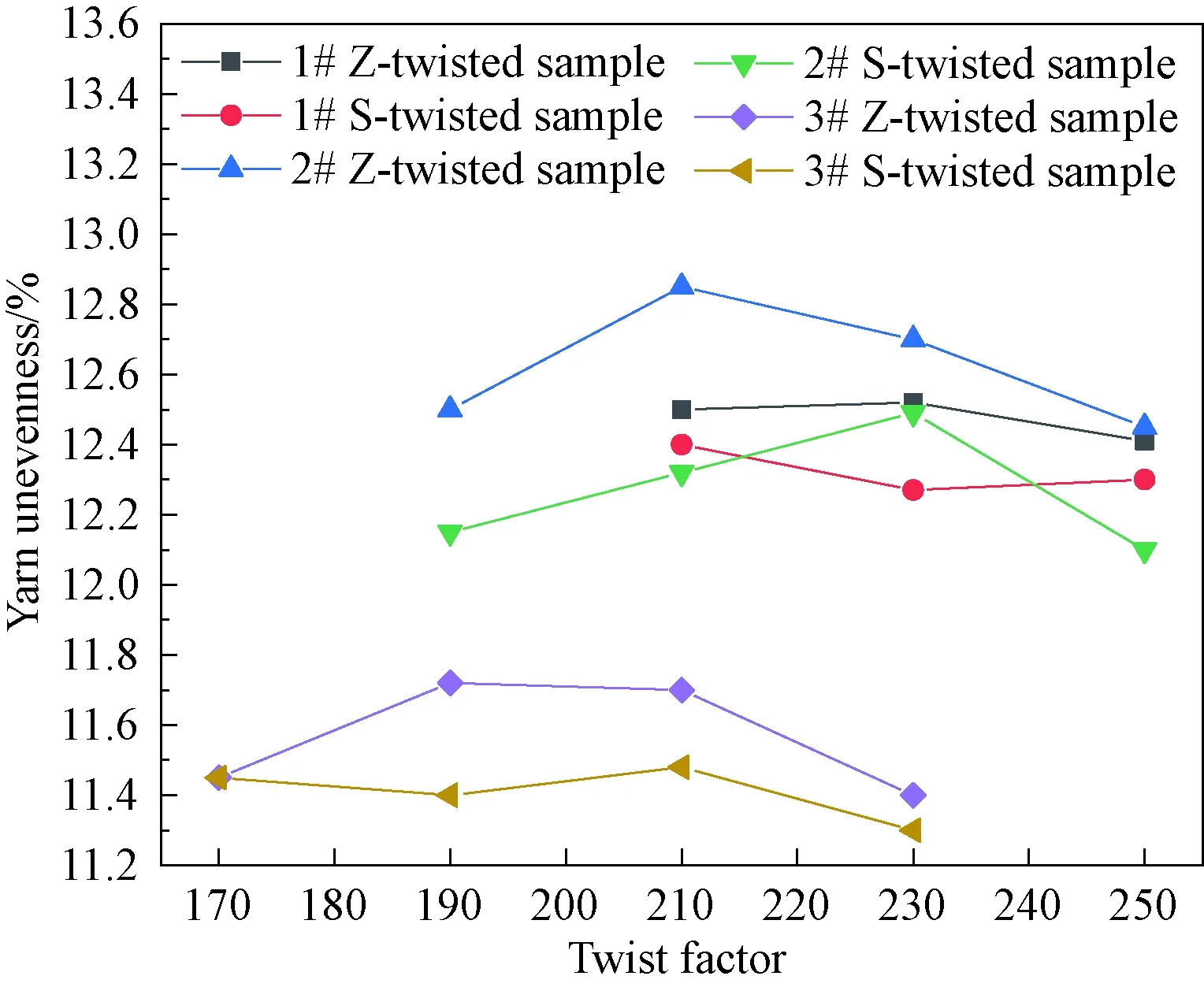

The relationship between twist factors and yarn unevenness of low-twist single yarn is shown in Fig. 3. It can be seen that the overall trend of all folding line segments is relatively gentle, and there is no obvious correlation between the twist factor and the unevenness of the low-twist single yarn, indicating that the twist factor has no effect on the unevenness. However, the unevenness of low-twist single yarn of 3# is significantly lower than that of the other two samples, indicating that the proportion of long-staple cotton has an effect on the unevenness. And the unevenness of the S-twisted samples is lower than that of the Z-twisted samples.

Fig. 3 Unevenness of low-twist single yarn with different twist factors

It shows that when the proportion of long-staple cotton is 70%, the unevenness of the low-twist single yarn is significantly improved. And considering the evenness of the yarn only, the S-twisted samples are better than the Z-twisted samples.

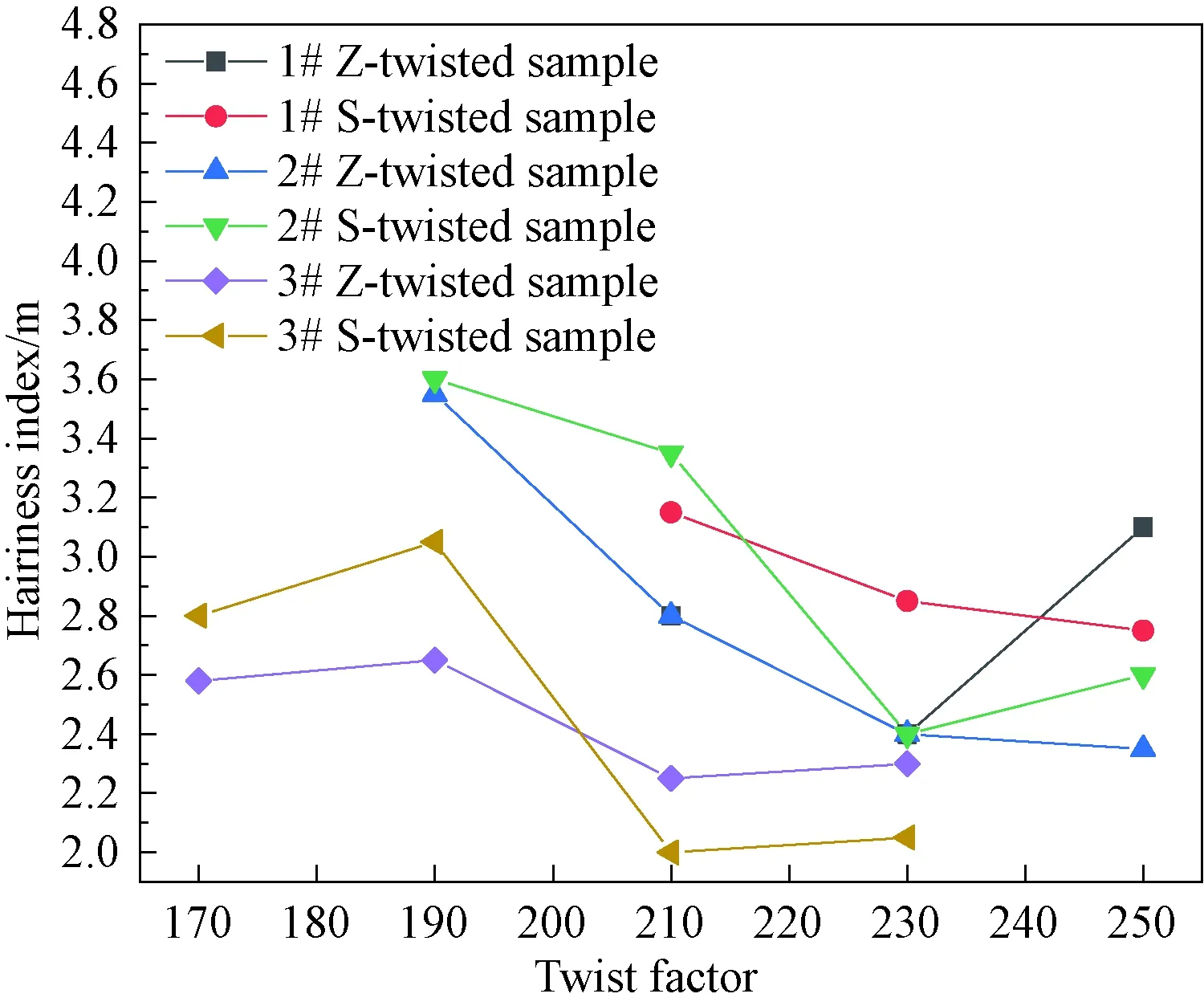

The relationship between twist factors and hairiness indices of low-twist single yarn is shown in Fig. 4. It can be seen that there is no significant correlation between the twist factor and the hairiness index of the low-twist single yarn as a whole, but the increase in the twist factor helps to reduce the hairiness. The hairiness indices of samples 1# and 2# are relatively close, and the hairiness index of sample 3# is significantly lower. It shows that when the proportion of long-staple cotton is 70%, the harmful hairiness in the low-twist single yarn is significantly improved. Harmful hairiness has a greater impact on the mechanical properties of yarn. When designing low-twist yarn, the scheme of more harmful hairiness should be avoided.

Fig. 4 Hairiness index of low-twist single yarn with different twist factors

3 Conclusions

In this study, three types of combed cotton with different proportions of long-staple cotton were used as raw materials to spin 22 types of 14.6 tex low-twist single yarn, and their breaking load, unevenness and hairiness were tested and analyzed. The results show that the spinnability of low-twist single yarn is mainly related to breaking load, but not to harmful hairiness and unevenness. The conclusions are as follows.

(1) When the proportion of long-staple cotton is 70%, the breaking load of low-twist single yarn is the largest, and the twist direction has no obvious effect on the strength of low-twist single yarn. When the proportion of long-staple cotton is 30% or 50%, the proper twist direction should be selected according to the twist factor of low-twist single yarn. And with the increase of the twist factor, the breaking load of low-twist single yarn increases obviously.

(2) When the proportion of long-staple cotton is 70%, the unevenness of low-twist single yarn is significantly improved. In the three groups of samples, the evenness of low-twist single yarn in S-twisted samples is better than that of the Z-twisted samples. And there is no significant correlation between the twist factor and unevenness of low-twist single yarn.

(3) When the proportion of long-staple cotton is 70%, the hairiness in the low-twist single yarn is significantly improved. In the three groups of samples, there is no significant correlation among twist factor, twist direction and hairiness index.

This research explores the effects of different long-staple cotton addition ratios, twist factors, and twist directions on the performance of pure cotton low-twist single yarn without adding new equipment and devices. It helps to provide customers with more choices according to their needs, and provides a reference for the actual production of pure cotton low-twist yarn in the factory.

Journal of Donghua University(English Edition)2022年2期

Journal of Donghua University(English Edition)2022年2期

- Journal of Donghua University(English Edition)的其它文章

- Specific Enthalpy Based Heat Stress Index for Indoor Environments without Radiation Effect

- Maximum Group Perceived Utility Consensus Models Considering Regret Aversion

- Dual Variational Generation Based ResNeSt for Near Infrared-Visible Face Recognition

- Crop Leaf Disease Recognition Network Based on Brain Parallel Interaction Mechanism

- Temperature-Dependent Growth of Ordered ZnO Nanorod Arrays

- Hydrothermal Synthesis of Ordered ZnO Nanorod Arrays by Nanosphere Lithography Method