大模场Er3+/Yb3+共掺锥形微结构光纤1.5 μm激光特性

王玲玲, 许鹏飞, 周德春*

(1. 山西能源学院 能源与动力工程系, 山西 晋中 030600; 2. 长春理工大学 材料科学与工程学院, 吉林 长春 130022)

1 Introduction

The near-infrared 1.5 μm laser has become a research hotspot owing to the wide range of applications in many fields such as biomedicine, environmental detection, space communications, infrared countermeasures, and guidance[1-4]. Er3+single-doped or Er3+/Yb3+co-doped microstructured optical fiber(hereinafter referred to as MOF) is an important way to generate high-power laser output in the 1.5 μm band[5-6]. This paper uses bismuth germanate glass as the host glass to prepare rare-earth-doped optical fiber. Bismuth germanate glass is expected to combine the advantages of bismuth glass and germanate glass, such as lower phonon energy, high refractive index, wider infrared transmission range, and good rare-earth ion solubility, which provides low laser pumping threshold and high pump absorption efficient. Compared with traditional optical fibers, MOF can achieve large-mode-field area, high-power single-mode laser output by effectively controlling the duty cycle and core[7-8]. Meanwhile, MOF has the advantages of a large numerical aperture and high coupling efficiency[9-11]. Fiber cone is drawn based on fiber through secondary processing technology. Its internal microstructure and cone shape make it have a large-mode-field area, adjustable dispersion, high nonlinear effect, non-cut-off single model, low transmission loss, and good beam quality[12-18]. Fiber cone has new applications in many fields. In 2017, Petersenetal.demonstrated the ability of tapered large-mode-area Ge10As22Se68PCFs to generate broadband MIR SC with record high output power above 4.5 μm[19]. In 2018, Maoetal. realized all-fiber flexible cylindrical vector lasers at 1 550 nm using fiber cones[20]. Previous studies have shown that the nonlinear effect of optical fiber can be reduced by shortening the length of optical fiber and increasing the core diameter[21-22]. However, with the increase in core diameter, the fiber laser no longer works in the single-mode state, and the quality of the output laser beam becomes poor. As the power continues to rise, there will be some scientific issues such as nonlinear effects, heat dissipation, laser damage,etc[23-26]. The design of a large-mode-field double-cladding Er3+/Yb3+co-doped MOF cone can avoid these problems and is an effective way to increase the output power further[27-30]. The excellent characteristics of rare earth doped MOF provide a new technical approach for high-power and high brightness fiber lasers.

In this paper, a waveguide structure of large-mode-field double-cladding MOF was designed based on Er3+/Yb3+co-doped 45Bi2O3-29GeO2-15Ga2O3-10Na2O-1CeO2(hereinafter referred to as BGGN) glass. The full vector finite element method and the numerical analysis methods were used to study the optimal structural parameters of the MOF during single-mode operation. Furthermore, the main structural parameters such as the lattice constant(hole spacing) and the duty cycle of the MOF were determined. The large-mode-field Er3+/Yb3+co-doped MOF and its cone were prepared using the cluster drawing method and the fused biconical taper technology. The spectral and laser characteristics were studied. Finally, a self-designed linear cavity-structured fiber laser achieved a single-mode laser output of 1 546.9 nm in the fiber cone, and its beam quality factorM2reached 1.16±0.01.

2 Experiments

2.1 Structural Design of MOF and Analytical Method

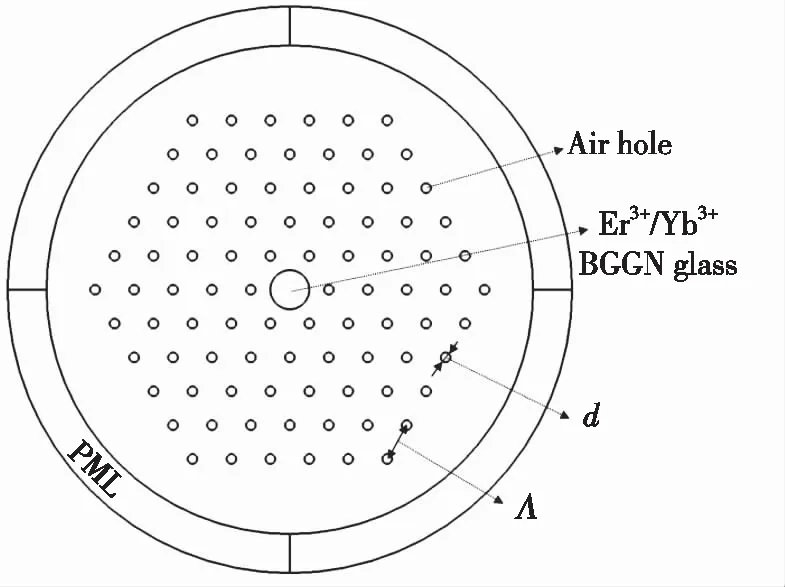

The MOF is an optical waveguide with triangular air pores in the cladding in this study. The guided mode propagates in the lattice defects in a process analogous to total internal reflection, that is, the flaws create the MOF core. Fig.1 shows the cross-section of bismuthate glass microstructure fiber. The number of microporous lattice layers in the inner cladding is 5, the core diameter is 70 μm, and the outside cladding is 488 μm. Before and after taper drawing, the fiber cone keeps the effective duty ratio at 0.25, the inner cladding air hole diameter at 10 μm, and the lattice constant at 40 μm.

Fig.1 Cross-section of bismuthate glass microstructure fiber

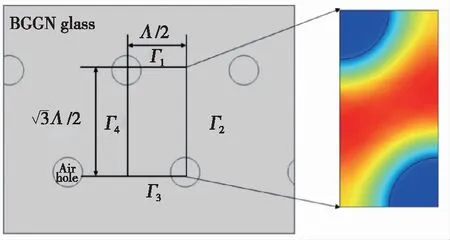

The full vector finite element method(FEM) uses matrix analysis to solve related algebraic equations.The discrete Maxwell equation is used to express the fluctuation of each cell in the transverse diffusion section of the optical fiber. The waveguide equation is solved for an approximate solution in the full fiber mode field[31]. For example, the two sides of a MOF cladding cell are ideal magnetic conductors(Fig.2). The fundamental mode HE11ypolarized in they-direction and HE11xof the fundamental mode polarized in thex-direction. The effective refractive index of the fundamental space-filling mode can be calculated by using complete vector finite element analysis(Fundamental space-filling mode, FSM).

Fig.2 The cell calculation unit of MOF cladding

The wave optics model of the MOF is developed through using FEM in this study, and the theoretical simulation calculation of the wave optics model of the MOF is performed using the absorption boundary condition of the perfectly matched layer.

As with regular step-index fibers, Birks and Knightetal. reported in 1997[32]that the comparable normalized frequencyVeffis:

(1)

wherencoreis the refractive index of the core material at the MOF’s working wavelength,nFSMis the effective refractive index of the FSM, andReffis the MOF’s equivalent core radius. The single-mode operation can be maintained whenVeffis less than 2.405.

For triangular microstructure fiber, Parketal. gave a functional relationship of equivalent core radius based on hole spacing and duty cycle in 2005[33]:

(2)

the values ofc1,c2andc3in the formula are 0.686 064, 0.265 366 and 1.291 080, respectively. Based on the fundamental mode effective refractive indexneffand the cladding effective refractive indexnFSM, the theoretical numerical aperture(NA) of the inner cladding can be computed:

(3)

The following equation can be used to calculate the effective mode field area of the MOF[34]:

(4)

whereAeffis the effective mode field area of the MOF,E(x,y) is the electric field distribution of the cross section of the fiber, and the integral region is the section of the whole fiber.

2.2 Sample Preparation

The cladding glass is composed of 45Bi2O3-29GeO2-15Ga2O3-10Na2O-1CeO2.The core glass samples with molar compositions of 45Bi2O3-29GeO2-15Ga2O3-10Na2O-1CeO2-0.5Er2O3-xYb2O3(wherex=0, 1, 2, 2.5, named as B1to B4) were prepared by melt-quenching method. The sample was weighed accurately and melted in an alumina oxide crucible at 1 200 ℃ for about 50 min under a dry O2/N2atmosphere to reduce the OH-content. Then it was quenched in preheated stainless steel blocks and annealed at the glass transition temperature for 3 h. Finally, the annealed glass sample was cut and polished to the size of 10 mm×10 mm×2 mm with two parallel sides for optical and spectroscopic measurements.

The core glass rod was prepared by the melt-quenching method, and was drawn into a core rod with a diameter of 4.2 mm and a cutting length of 280 mm by a fiber drawing machine. The bundled drawing method was used to draw it into an Er3+/Yb3+co-doped MOF with a diameter of 488 μm, the core diameter was 70 μm, the inner cladding air hole diameterdwas 10 μm, the lattice constantΛis 40 μm, and the duty ratiod/Λ=0.25. The MOF was drawn into a fiber cone with a diameter of 122 μm, a core diameter of 17.5 μm, a length of the taper region of 30 mm, and a taper angle of 0.7° using the fused biconical taper technology.

2.3 Measurements

The absorption spectra were measured with a Perkin Elmer Lambda 950-type spectrophotometer. The measurement of infrared fluorescence spectrometry employs the Horiba Jobin Yvon’s Fluorolog-3 fluorescence spectrometer. In addition, the output quality of the fiber laser before and after the taper was measured by knife-edge method. AQ6370D spectrum analyzer manufactured by Yokogawa was used to detect the optical signal. The output power at the output end of the optical fiber was recorded by using a Newport 2936-R optical power meter. All the tests were performed at room temperature.

3 Results and Discussion

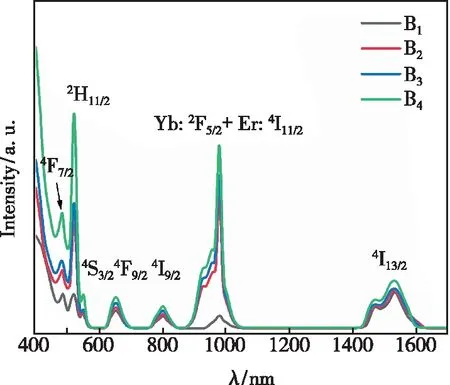

3.1 Spectral Analysis of Er3+/Yb3+ Co-doped BGGN Core Glass

The absorption spectra of B1-B4glass are shown in Fig.3. The absorption peaks at 1 530, 980, 800, 650, 543, 520, 487 nm correspond to the Er3+ion from the ground state4I15/2to the excited state4I13/2,4I11/2,4I9/2,4F9/2,4S3/2,2H11/2and4F7/2, respectively. Obviously, the absorption peak near 980 nm is very strong which is caused by the spectral overlap of Yb3+ion energy level2F7/2→2F5/2and the Er3+ion energy level4I15/2→4I11/2. Therefore, the pump efficiency of 980 nm LD can be improved by the energy transfer between the energy level2F5/2of Yb3+and the energy level4I11/2of Er3+. Owing to the absorption cross section of Yb3+being larger than that of Er3+, and the concentration of Yb3+is several times that of Er3+, the absorption peak increases with the increase of Yb3+ion concentration.

Fig.3 Absorption spectra of BGGN glass samples

Fig.4 shows the 1.53 μm fluorescence spectra in Er3+/Yb3+co-doped BGGN glass. It can be seen from the figure that the fluorescence intensity of about 1.53 μm is significantly enhanced after Yb3+ions are doped. The highest emission intensity around 1.5 μm is achieved at around 2% Yb2O3concentration. This is because the sensitization of Yb3+ions improves the pump efficiency of 980 nm LD. However, due to the concentration quenching effect and anti-cross relaxation effect of Yb3+ions, when the doping concentration of Yb3+ions reach 2.5% or more, the energy cannot be effectively forwarded Er3+ions, which makes the 1.53 μm fluorescence intensity in the B4glass decrease significantly. Hence, the optimum doping ratio of Er3+∶Yb3+is 0.5%∶2%.

Fig.4 Fluorescence spectra of the BGGN glass samples

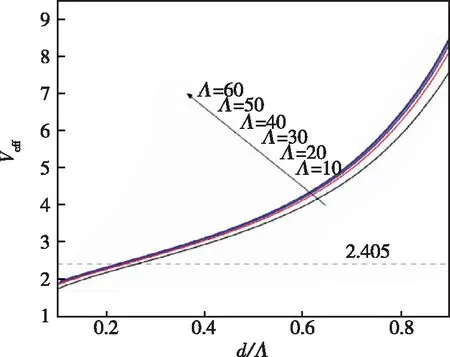

3.2 Cut-off Characteristic Analysis

The finite element method was used to study the relationship between different duty cycles and the normalized final frequency of the fiber. In this paper, the lattice constantΛof inner cladding layer is 10-60 μm(Λis 10, 20, 30, 40, 50, 60 μm in order, and the working wavelength is 1.55 μm). According to formula (1), under different conditions ofd/Λ, the relationship curve between theVeffandd/Λwas obtained in Fig.5. It can be seen that, withd/Λ=0.25 andΛ=10, theVeffof MOF is less than 2.405, and the laser can achieve single-mode operation. At this time, the air hole diameterdof the inner cladding capillary glass should be 2.5 μm, and the duty cycle should be 0.25.

Fig.5 Relationship between normalized cut-off frequency Veff and inner cladding duty cycle

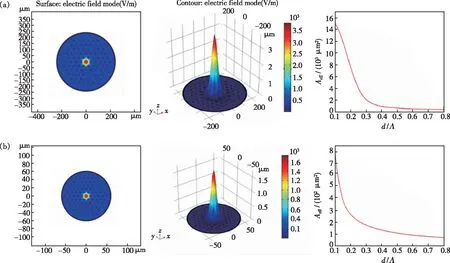

3.3 Mode Field and Numerical Aperture

The structural parameters of fiber and fiber cone were verified and calculated by using the full vector finite element method. Fig.6 shows the structure and mode-field energy distribution. It should be emphasized that the optical field of this MOF is approximately hexagonal, and the core has the strongest optical field. The mode field diameters and effective mode field areas of fiber and fiber cone are 65.661 μm, 3 014.8 μm2, 17.603 μm and 206.47 μm2, respectively. The results show the parameters of the fiber cone can meet the single-mode operation of large-mode-field lasers[35-36].

Fig.6 Structure and mode field energy distribution with effective duty ratio d/Λ=0.25. (a)Fiber. (b)Fiber cone.

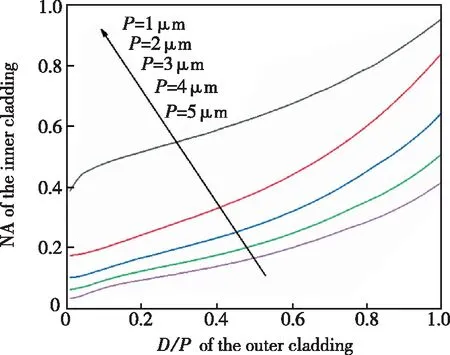

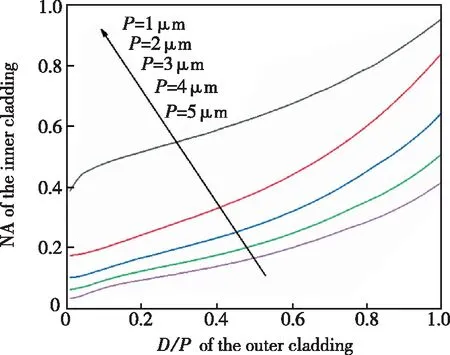

The inner cladding numerical aperture(NA) represents the ability of optical fiber collecting incident pump light, which is directly related to the coupling efficiency of the pump light[37]. Therefore, increasing the NA is important for improving the coupling efficiency of pump light. In this paper, the outer cladding air holes were selected as the cell calculation unit, the hole spacingPand the diameterDof the outer cladding air holes were used as the key variables. When the hole spacingPis 1, 2, 3, 4, 5 μm in order, the relationship curve between the NA of the inner cladding and the duty cycleD/Pof the outer cladding is shown in Fig.7. Obviously, the NA increases with theD/Pincreasing. Under the same duty cycle condition, the smallerPis, the larger NA is. WhenPis less than 2 μm, the theoretical maximum value of NA can reach above 0.8. Therefore, this work determine the hole spacingPafter taper is 2 mm,D/Pis 0.98, andDis 1.96 mm.At the same time, the optimal NA of the inner cladding could reach 0.75, which is larger than the tapered MOF (0.6) reported by Duan in 2020[38].

Fig.7 The relationship curve between NA and D/P

3.4 Laser Characteristics Analysis

Fig.8 is the schematic diagram of a laser measuring apparatus for Er3+/Yb3+co-doped BGGN MOF. The laser uses 980 nm LD as the pump source and a self-made Er3+/Yb3+co-doped BGGN fiber with a length of 30 cm as the gain medium. Fig.9 is a cross section microscopic image of self-made optical fiber. The pump source pigtail is coupled into the inner cladding of the double-clad Er3+/Yb3+co-doped fiber through a collimating lens and a focusing lens. The laser cavity consists of a front cavity mirror which is a dichroic mirror(980 nm high transmission 98%, 1 530 nm high reflection greater than 99%) closing to the input end of the fiber, and a rear cavity mirror which is Fresnel reflection putting at the output end of the fiber.

Fig.8 Structure of Er3+/Yb3+ co-doped microstructure fiber laser

Fig.9 MOF cross section microscopic image

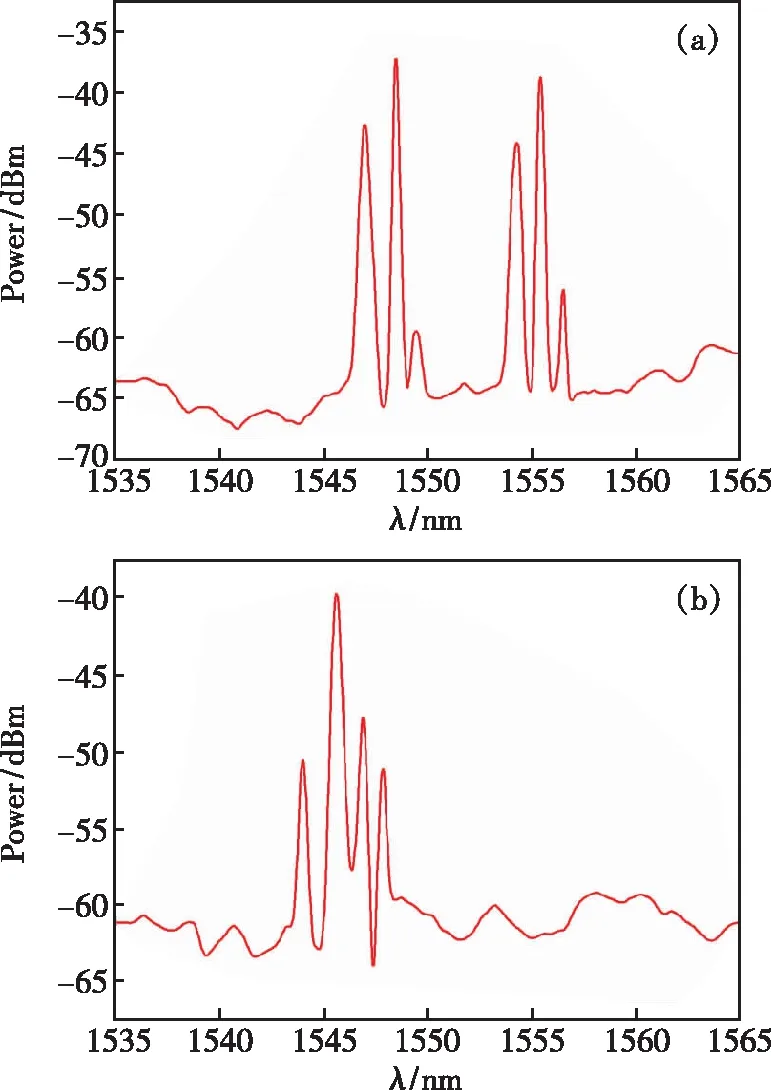

Fig.10 shows the laser output spectrum of the fiber and fiber cone. The center wavelength of the excitation spectrum of the MOF laser is 1 550.2 nm and 1 546.9 nm, respectively. The taper causes the excitation center wavelength of the laser shifting to short waves. The reason for this phenomenon is that the lasing wavelength of a fiber laser is related to the fiber length and the excitation threshold. The fiber length has less change after tapering, but the intracavity loss of the excitation light in the fiber core increases, which increases the laser’s excitation threshold. Meanwhile, an increase in the excitation threshold corresponds to a short wavelength lasing wavelength. Therefore, the fiber taper technology moves the laser’s lasing wavelength toward the short-wave direction.

Fig.10 Laser spectra of fiber(a) and fiber cone(b)

The Er3+/Yb3+co-doped MOF and its cone with a length of 30 cm were pumped with 980 nm LD. Fig.11 is the relationship curve between output power and pump power. The laser output of fiber can be observed when the pumping power of the fiber is 239 mW. When the pumping power reaches 581 mW, the maximum laser output power is 55.7 mW. According to the measured data, a linear fit was performed in the above threshold range, and the slope efficiency of the fiber was 10.29%. The maximum output power of fiber cone under the same conditions is 50.12 mW, the slope efficiency is 9.70%, and the maximum output power is reduced by about 10%. This is because after taper drawing, the hole spacing becomes smaller, and the confinement loss of all modes increases. The disappearance of high-order modes and the rise in the confinement loss of the base mode are the main reasons for reducing laser output power.

Fig.11 Laser output power characteristic curve of fiber and fiber cone

At the output end of the Er3+/Yb3+co-doped MOF, the knife-edge method was used to measure the laser output beam quality of fiber and fiber cone. The results are shown in Fig.12. The quality factorM2of the fiber and fiber cone is 3.45 ± 0.03 and 1.16 ± 0.01. Taper makes the output beam quality factorM2of the laser smaller than before, and the laser output has a good single-mode.

Fig.12 Laser output beam quality M2 of fiber(a) and fiber cone(b)

4 Conclusion

The waveguide structures of a large-mode-field double-cladding MOF and its cone were designed by the full vector finite element method. The Er3+/Yb3+co-doped optical fiber and fiber cone with composition 45Bi2O3-29GeO2-15Ga2O3-10Na2O-1CeO2were prepared by using the cluster drawing method and the fused biconical taper technology. The core diameters of fiber and its cone were 70 μm and 17.5 μm. The mode field areas were about 3 014.8 μm2and 206.47 μm2, the inner cladding duty cycled/Λof fiber and fiber cone were both 0.25. The optimal numerical aperture of the inner cladding of the MOF cone is 0.75, which can significantly improve the coupling efficiency of the pump light. The laser characteristics of fiber and its cone were studied under 980 nm LD. Results show that the taper makes the center wavelength of the excitation spectrum of the MOF laser drift from 1 550.2 nm to 1 546.9 nm. The slope efficiency of fiber and fiber cone can reach 10.29% and 9.70%, respectively. The output laser beam quality factorM2is significantly reduced from 3.45 ± 0.03 to 1.16 ± 0.01. This research provides a new approach for preparing large-mode-field, high-power laser fiber materials.

Response Letter is available for this paper at:http://cjl.lightpublishing.cn/thesisDetails#10.37188/CJL. 20220010.