基于二硫化钨增敏的锥形光纤表面等离子体共振传感器

张文林,刘琨,江俊峰,徐天华,王双,张炤,井建迎,马金英,刘铁根

(天津大学精密仪器与光电子工程学院光电信息技术教育部重点实验室,天津300072)

0 Introduction

Fiber optic Surface Plasmon Resonance(SPR)sensors are rapidly becoming key devices in the fields of biological detection,environmental monitoring and food safety due to their superior performance of high sensitivity,anti-electromagnetic interference,label-free,remote monitoring etc.[1-3].Fiber optic SPR is a phenomenon in which the evanescent field at the surface of the fiber and the surface plasma wave of the metal are coupled and the energy at a certain wavelength will be strongly absorbed.When the external environment changes,the resonance wavelength will move correspondingly[4].Therefore,biomolecule detection and chemical analysis can be carried out without labels by detecting wavelength changes only.

However,traditional multimode fiber optic SPR sensors are limited by low sensitivity,which leads to their insufficient performance in the detection of low-concentration analytes and small molecular weight biomolecules[5].Different methods have been studied to overcome this limitation.Among them,it is widely used to improve the sensitivity of sensors by changing the structure of optical fibers(e.g.D-shaped fiber,Ushaped fiber,photonic crystal fiber,hollow core fiber,tapered fiber).Verma theoretically predicted the effect of the tapered fiber on the sensitivity of sensors[6-7].VIVEK S et al.[8]evaluated the effect of different tapering ratios of tapered fibers on SPR sensors experimentally.The larger the tapering ratio is,the higher the sensitivity is.

Recently,there has been increasing interests in optimizing film structures of fiber optic SPR sensors.The strong electric field excited by the local SPR of metal nanoparticles[9](e.g.Au,Ag)is used to amplify the SPR signal.The modification of one or more dielectric layers(e.g.high Refractive Index(RI)oxides,ceramic materials,two-dimensional materials)on the surface of the metal layer can also be applied to improve the sensitivity.With the discovery of unique optoelectronic properties,graphene has been widely used in the fiber optic SPR sensing due to its unique optoelectronic properties[10-12].Similar to graphene,Transition Metal Dichalcogenides(TMDCs) have also attracted much attention.Among them,WS2shows many unique optoelectronic properties such as high complex RI ratio(the ratio of the real part to the imaginary part of the RI),direct band gap and large surface-to-volume ratio.WU L M et al discussed the enhancement effect of twodimensional materials on SPR[13].OUYANG Q L et al[14]theoretically designed a gold-Si-WS2heterostructure SPR biosensor to improve the sensitivity of the sensor.A WS2nanosheet-assisted prism SPR sensor was reported,and the sensitization effect of WS2on the SPR sensor was experimentally proved[15].However,in aforementioned research works,TMDCs are usually coated by means of the physical adsorption,and they can easily fall off in long-term or repeated use.This will degrade the performance of the sensor[16].

This study aims to contribute to this growing area of SPR research by exploring the impact of WS2on tapered fiber SPR sensors.A method for enhancing the sensitivity of SPR sensors is proposed.At first,WS2and Au films are sequentially coated on the tapered fiber surface to form the fiber optic SPR sensor.In order to explore the enhancement effect of WS2,the sensitivities of tapered fiber SPR sensor and tapered fiber WS2-Au SPR sensor are compared via theoretical simulations and experimental tests.The influence of thicknesses in the WS2overlayer on the sensor is discussed.Then,the experimental sensitivity of the sensors with two different structures(Au-WS2and WS2-Au)at the optimal number of coating layers of WS2is analyzed respectively.Compared to traditional multimode fiber optic SPR sensors,the sensitivity has been improved.To the best of our knowledge,there are few reported experimental studies on WS2-assisted fiber optic SPR sensors.Our results show that the tapered fiber WS2-Au SPR sensor proposed in this paper can significantly increase the sensitivity.Moreover,this structure is simple to manufacture and can provide better reliability.

1 Sensing principles and simulation analyses

1.1 Structure of the tapered fiber WS2-Au SPR sensor

The proposed tapered fiber WS2-Au SPR sensor consists of four layers,followed by fiber core,WS2layer,metal layer and analyte.The structure of the sensor is schematically illustrated in Fig.1.The tapering ratio of fiber is defined as:ri/ro.2rois the minimum diameter of the tapered fiber and 2riis the initial diameter of the multimode fiber.The length of the sensing area is set as 1 cm[17]and the material of the metal layer is selected as gold and the thickness of the gold film is set as 50 nm,because the 50 nm gold film can provide good resonance response and gold has better stability compared to the silver film[18].

Fig.1 The schematic configuration of tapered fiber SPR sensor

1.2 Theoretical model of fiber optic SPR sensor

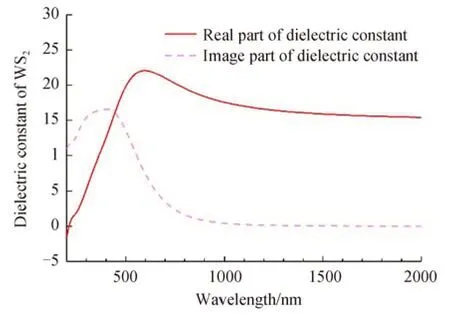

The wavelength-dependent dielectric constant of the fiber core and gold can be expressed by the Sellmeier dispersion relationship and the Drude model,respectively[19].The relationship between the dielectric constant of WS2and the wavelength is obtained by the first principles using the generalized-gradient approximation[20]as shown in Fig.2.

Fig.2 Simulation results of the dielectric constants of WS2

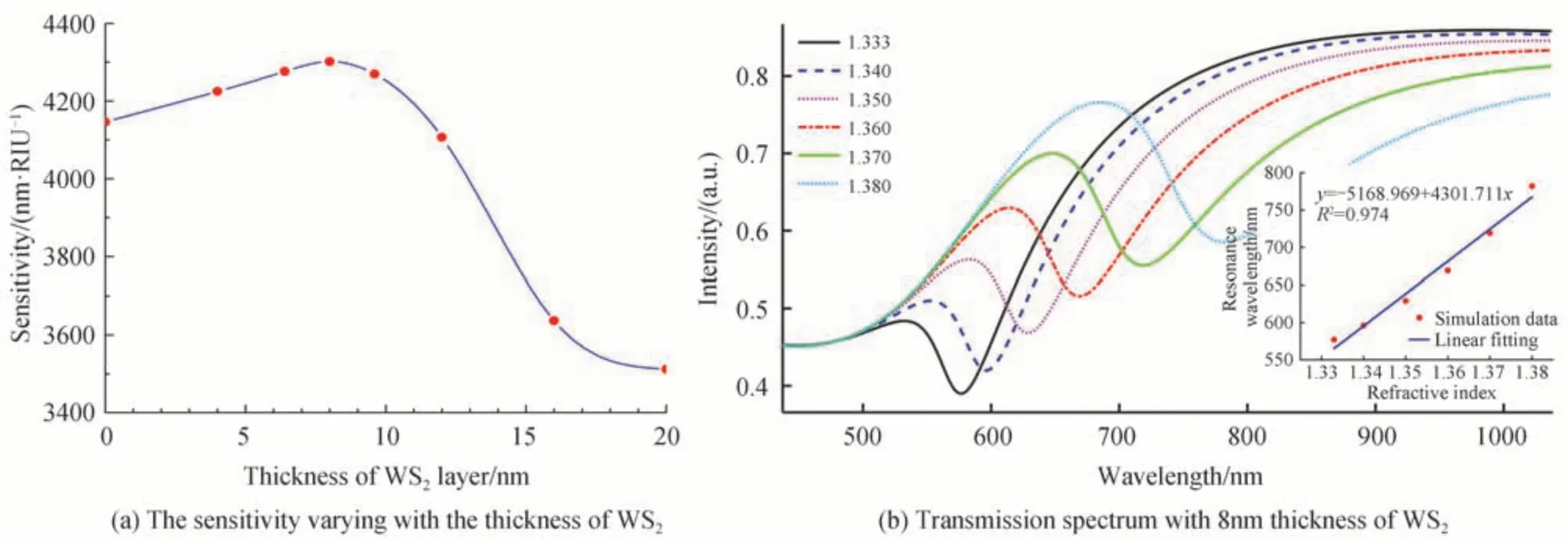

To evaluate the RI sensitivity after the tapering and after the addition of WS2,the transfer matrix method of the multi-layer model[21]is employed to simulate the characteristics of the sensor.The normalized transmission power at the output end of the fiber is given by[7]

In the formula,Rp(θ,z)is the reflectivity of p-polarized incident light and can be calculated by the N-layer matrix method.Φ1andΦ2are the angle changes caused by the fiber tapering[7].Nrefis the number of reflections experienced by the light in the tapered sensing area(the length of the tapered area isL)and is given by

whereρ(z)is the taper radius varying with distance,andΩis the taper angle[7].

1.3 Simulation and analysis of fiber optic SPR sensor

The transmission characteristics of the sensor are simulated using the above transmission matrix model.In order to better study the influence of the tapering ratio and the WS2film on the SPR phenomenon,the multimode fiber with a core diameter of 600 μm is selected as the substrate of the sensor due to its robust and large contact reaction area[20].

1.3.1Effect of taper ratio

Sensitivity is the main parameter that intuitively describes the performance of the sensor,which can be expressed as follows

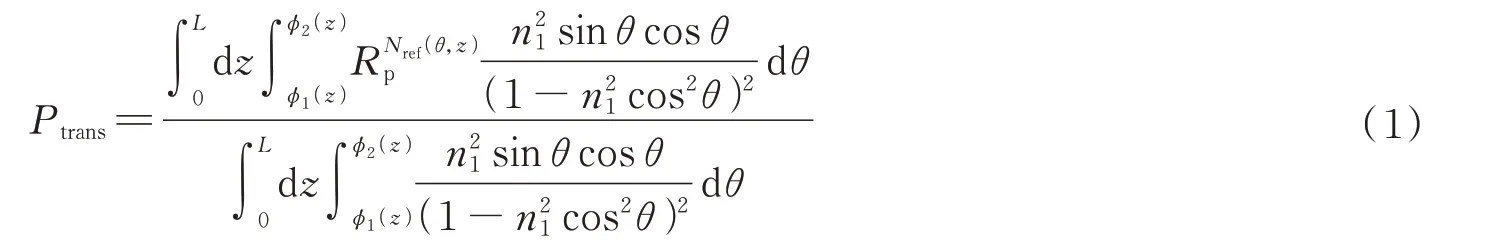

where Δλis the shift of the resonance wavelength,and Δnis the change of the sensing RI.The sensitivity under different tapering ratios is simulated in order to explore the influence of the tapering ratio on the sensor.The relationship between the sensitivity and the tapering ratio is shown in Fig.3(a).It can be seen that,as the tapering ratio increases,the sensitivity also gradually increases.However,the increase in the tapering ratio will make the diameter of the fiber smaller,which will reduce the mechanical strength and increase the complexity of subsequent experiments.Therefore,the fiber optic sensor with a tapering ratio of 2 is applied in the following discussion.Corresponding resonance spectra in different RI solutions and sensitivity fitting curves of the sensor with a tapering ratio of 2 are shown in Fig.3(b).The sensitivity of the tapered fiber SPR sensor is increased by 322.551 nm/RIU compared to that of multimode fiber SPR sensors(the tapering ratio of 1).

Fig.3 The influence of the tapering ratio on the multimode fiber SPR sensor sensitivity

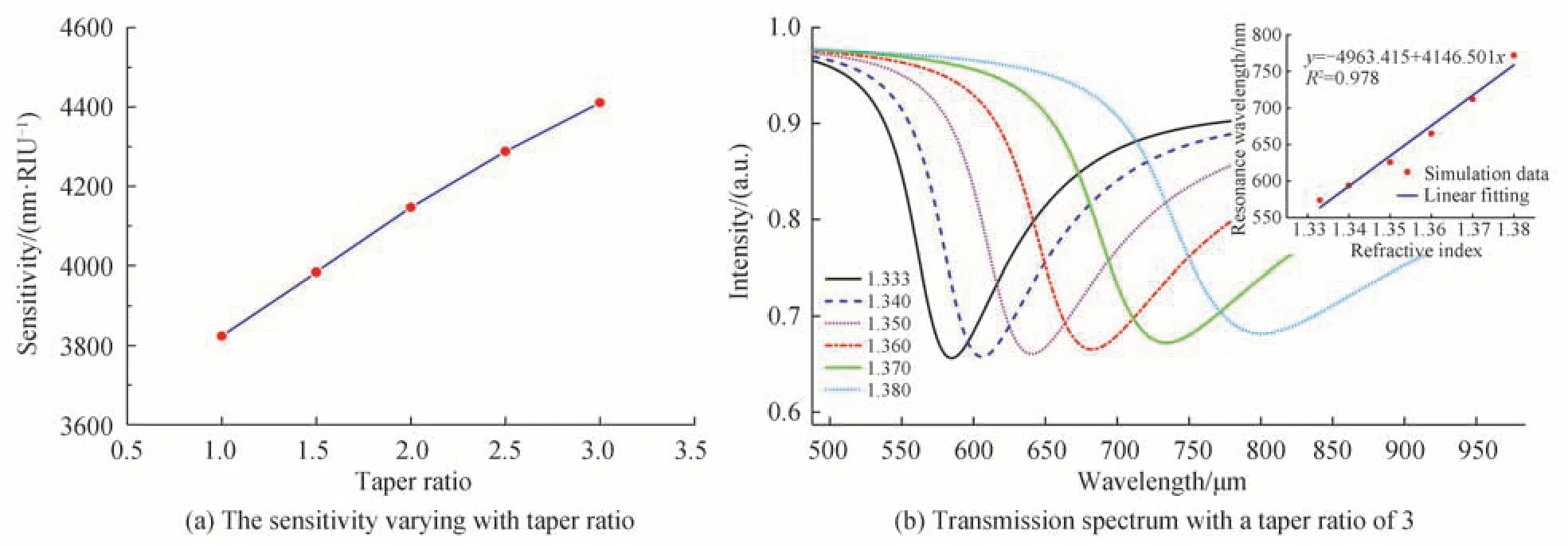

1.3.2Effect of the thickness of WS2

In the case of a taper ratio of 2,the normalized transmission spectra corresponding to different thicknesses of the WS2layer is calculated in Fig.4(a).As the thickness of the WS2layer increases,the sensitivity of the sensor will first increase and then decrease.This is mainly because WS2has a high real part in the dielectric constant and a relatively large ratio of complex refractive index[12,22]which can reduce the energy loss and enhance the evanescent field of the gold film interface.In addition,the evanescent field in the fiber has a larger penetration depth for WS2coating than other TDMC materials[21].In the case of a thinner WS2coating,the sensor has a stronger SPR phenomenon,which leads to an enhanced sensitivity.However,as the deposition thickness is further increased,the overlap between the evanescent field and the surface plasma wave of the gold film is reduced,the SPR phenomenon will become weaker,and the sensitivity will also get decreased.Therefore,the interaction between these two effects causes the sensitivity to first increase and then decrease.Fig.4(b)shows the transmission spectrum and sensitivity fitting curves of the tapered fiber WS2-Au SPR sensor with WS2thickness of 8 nm.Compared to the tapered fiber SPR sensor,the sensitivity is further increased by 155.210 nm/RIU.

Fig.4 The influence of the WS2 on the tapered fiber WS2-Au SPR sensor sensitivity

According to above simulations,the sensor with optimized tapering ratio and WS2film thickness can provide the performance improvement to some degree.This theoretically demonstrates the feasibility of the proposed sensor in RI measurement.

2 Experiments

2.1 Fabrication of sensors

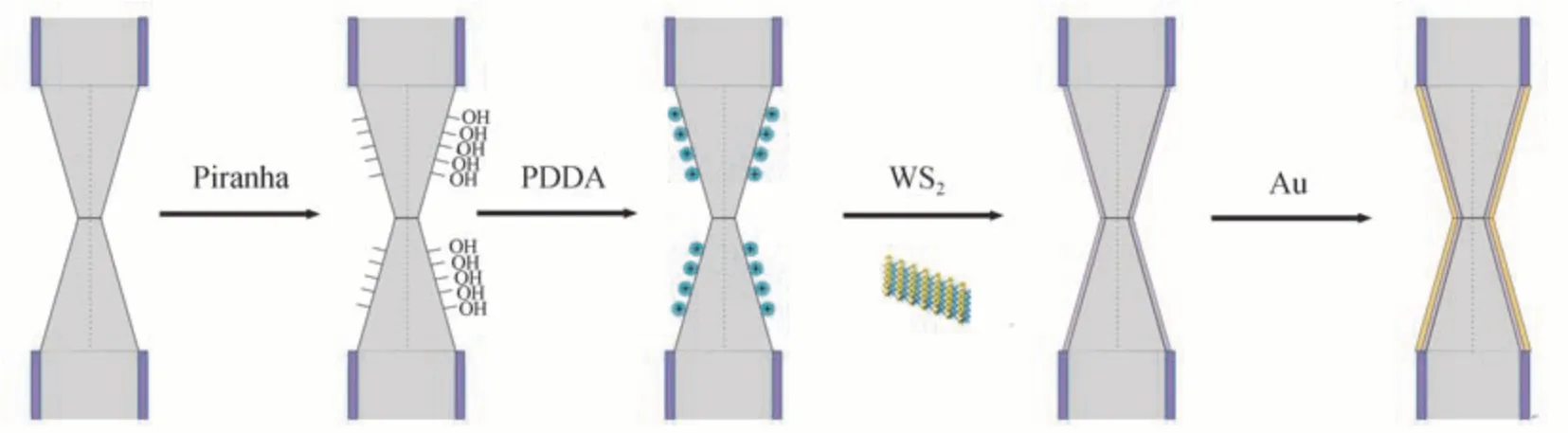

Built on numerical simulations,experiments for evaluating and comparing the sensitivities have been carried out for the multimode fiber SPR sensor,the tapered fiber SPR sensor,the tapered fiber Au-WS2SPR sensor and the tapered fiber WS2-Au SPR sensor.The schematic diagram of the manufacturing process for the tapered fiber WS2-Au SPR sensor is shown in Fig.5.

Fig.5 The manufacturing process of tapered fiber WS2-Au SPR sensor

2.1.1Fabrication of tapered fiber WS2-Au SPR sensor

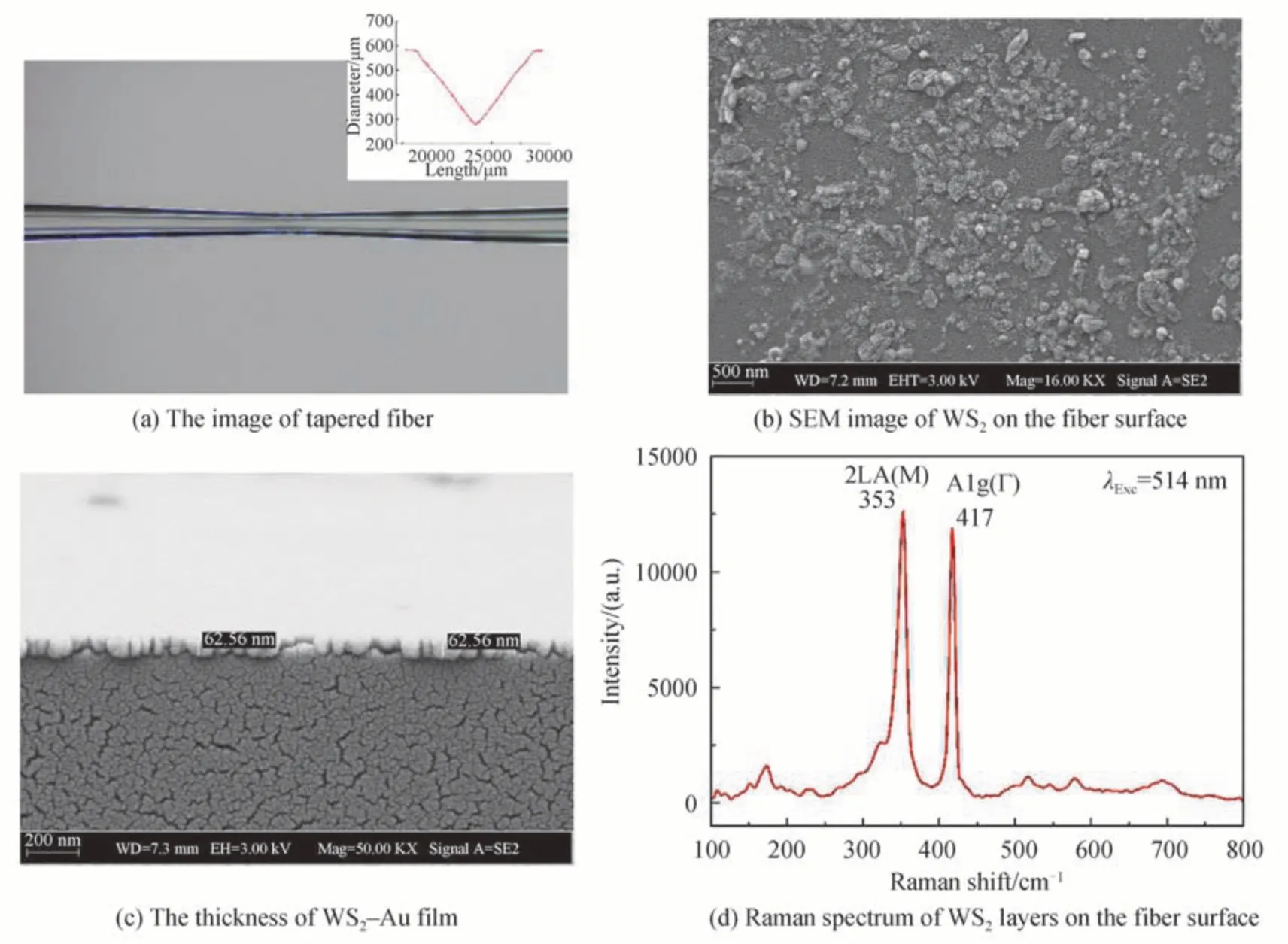

The sensor is fabricated based on a plastic cladded multimode step-index fiber.At first,the non-adiabatic taper with a tapering ratio of 2 is produced via the fusion taper method.The image of tapered fiber is shown in Fig.6(a).It can be seen that the produced taper has a very good linear transition.

Fig.6 The micrographs of the sensor

Afterwards,WS2nanosheets are modified on the surface of the fiber using the electrostatic self-assembly technique[16,23].We further place the fiber into a piranha solution to hydroxylate the surface of the fiber and to remove surface impurities.After one hour,the fiber is taken out and the excess piranha solution is cleaned with the deionized water.In the next step,the fiber is immersed in a 1 mg/mL PDDA solution for one hour to positively charge the surface of the fiber.Since the WS2nanosheet dispersion is negatively charged,it is modified on the surface of the fiber via the electrostatic adsorption.The fiber from the previous step is fixed in the reaction tube with the ultrasonically treated WS2ethanol dispersion solution(1 mg/mL,100 μL)added.The full evaporation of the dispersion solution means the completion of one deposition cycle.The repetition of this deposition process can increase the thickness of the WS2nanosheets[15].When the deposition is finished,the sensor is annealed in an environment of 60 °C for one hour to improve the stability[24].The scanning electron microscope(SEM)of WS2on the surface of fiber is shown in Fig.6(b).It can be found that the WS2nanosheets with sizes ranging from tens of nanometers to hundreds of nanometers are dispersed on the surface to increase the specific surface area of the fiber,which is beneficial to the improvement of the sensor sensitivity.Finally,a 50 nm thick gold film is sputtered on the modified WS2nanosheet fiber using the magnetron sputtering coating technique[25].The cross-sections of the tapered fiber WS2-Au SPR sensor is shown in the Fig.6(c).The thickness of WS2-Au film on the fiber surface is 62.560 nm.This is basically consistent with the simulated values.It is shown in Fig.6(d)that Raman scattering spectroscopy is used to characterize the produced sensor.The WS2overlayer modified on the surface of the fiber can be regarded as a multilayer film by comparing the intensities of the two Raman mode peaks of 2LA(M)and A1g(Γ)[26].2.1.2Fabrication of other three types of SPR sensor

The fabrication of the tapered fiber Au-WS2SPR sensor is similar to the fabrication of the tapered fiber WS2-Au SPR sensor.A gold film is sputtered on the surface of the tapered fiber,and then WS2nanosheets are coated on the gold film via the electrostatic self-assembly technique.

The tapered fiber is produced by the fusion tapering method,and the 50 nm gold film is sputtered on the tapered fiber and the multimode fiber using the magnetron sputtering coating technique to fabricate the tapered fiber SPR sensor and the 600 μm fiber SPR sensor.

2.2 Experimental setup

The measurement system of the sensor is shown in Fig.7.The light emitted from the halogen broadband light source(HL-2000,Ocean Optics,Inc.America)is transmitted to the sensor via fiber jumper,and is collected by the spectrometer (HR-4000,Ocean Optics,Inc.America).Additionally,the resonance wavelength is monitored by computer.The transmission spectrum of the sensor for different RI solutions(the solution is made up of deionized water and glycerin with different proportions,and the RI ranges from 1.333 to 1.380)is processed by the computer.100 data points every 1 s are collected to calculate the standard deviation of the resonance wavelength.The sensor needs to be cleaned three times using the deionized water before the next RI measurement to ensure the accuracy of the detection results.During the experiment,the ambient temperature is maintained at room temperature.

3 Results and discussions

3.1 Sensitization effect of tapered fiber

The transmission spectra of the tapered fiber SPR sensor and the 600 μm fiber SPR sensor under different RI solutions are shown in the Fig.8.The Empirical Mode Decomposition(EMD)technology[27]is used for noise reduction preprocessing and the polynomial fitting method[9]is used to demodulate the resonance wavelength.When the RI change is 0.047 RIU,the resonance wavelength of the tapered fiber SPR sensor is red-shifted by 101.457 nm,while the resonance wavelength of the 600 μm fiber SPR sensor is only red-shifted by 87.420 nm.Fig.9 shows the linear fitting curves of the performance for the two sensors.The sensitivity of the tapered fiber SPR sensor is 2 126.536 nm/RIU,which is 15.5% higher than the sensitivity of the 600 μm fiber SPR sensor.Compared to simulation results,the enhancement in the sensitivity is relatively small.On the one hand,it is difficult to ensure the symmetry of the tapered fiber during the fabrication process.On the other hand,the absorption medium of the sensor is only the gold film.A considerable portion of the evanescent field energy gets lost and is not coupled with surface plasma waves[28].

3.2 Sensitization effect of WS2 film

In order to evaluate the effect of WS2on the sensor,the sensitivity between the conventional coating method(first sputtering gold film,then coating WS2)and the proposed coating method(first coating WS2,then sputtering Au)is compared.

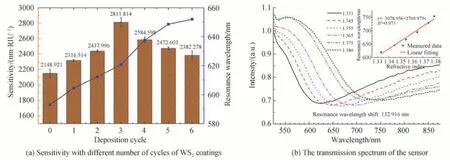

3.2.1The structure of Au-WS2

To ensure the repeatability,each group of experiments has been repeated five times.The influence of WS2on the sensitivity of the sensor is plotted in Fig.10(a).It is shown that the average RI sensitivity increases significantly from 0 to 3 cycles,and then gradually decreases.The resonance wavelength shows a significant red shift.Fig.10(b)is the transmission spectrum of a sensor after three cycles of deposition in one of the deposition experiments.It can be seen that the sensitivity of the sensor is improved to 2 769.979 nm/RIU,which is 30.3%higher than that of the tapered fiber SPR sensor without WS2coating.

Fig.10 The characteristic of the tapered fiber Au-WS2 SPR sensor

The unique photoelectric characteristic of WS2is the main reason for the enhancement in the sensitivity of the sensor.The high quantum conversion efficiency of WS2nanosheets can stimulate more electrons to be transferred from WS2to the gold film[29].and the transfer of electrons can enhance the surface electric field to improve the coupling efficiency of the SPR sensor.

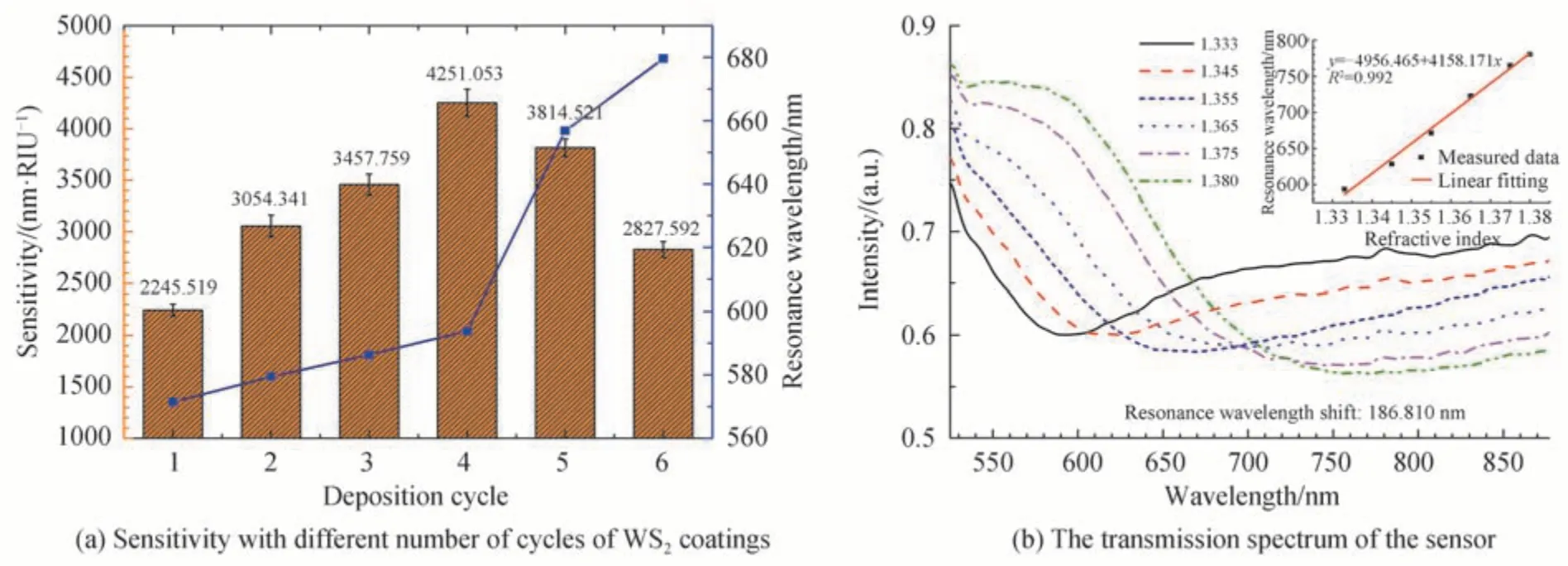

3.2.2The structure of WS2-Au

The measurement process of the RI sensitivity for the tapered fiber WS2-Au SPR sensor is similar as that of the above three sensors.The transmission spectrum of the sensor coated with 4 cycles of WS2nanosheets is shown in Fig.11(b).When the RI change is 0.047 RIU,the resonance wavelength of the sensor is red-shifted by 186.810 nm.

Fig.11 The characteristic of the tapered fiber WS2-Au SPR sensor

Similarly,the effect of different WS2deposition cycles is studied in Fig.11(a),and a similar conclusion as the Au-WS2sensor can be obtained.After coating four cycles of WS2,the sensitivity of the WS2-Au sensor can reach 4 158.171 nm/RIU,which is 50.1% higher than that of the Au-WS2sensor.It is seen that the sensor with WS2coated between the fiber and the gold film provides a better sensitivity than sensor with WS2coated on the surface of the gold film.However,the spectral broadening caused by the radiation damping of WS2is inevitable[30].

3.3 Discussions

According to the above results,coating WS2has a significant enhancement effect on the sensitivity of the tapered fiber SPR sensor in the Fig.12(a).This is mainly attributed to photoelectric properties of WS2.The fiber tapering can enhance the strength of the evanescent field,but some rays do not meet the total reflection condition,and are not coupled with the plasma wave.When only the gold film is coated,it is not enough for the sensor to stimulate a strong SPR effect.When WS2is coated between the fiber and the gold film,the good photon absorption characteristics of WS2can effectively increase the absorption of light energy,and can thereby enhance the energy coupling.In addition,high quantum efficiency and high complex RI ratio of WS2can reduce the energy loss during the electron transfer process and can enhance the electric field intensity on the surface.Therefore,good photon absorption characteristics and high quantum conversion efficiency of the WS2nanosheets between the fiber surface and the gold film can greatly improve the RI sensitivity of the sensor and can make the sensor more sensitive to changes in the external environment.The coating of WS2nanosheets on the surface of the gold film will only increase the photon utilization rate of the sensor system,and thus the tapered fiber Au-WS2SPR sensor shows a relatively small increase in the sensitivity compared to the sensor with the WS2-Au structure.It is worth mentioning that the WS2coated on the surface of the gold film is easier to fall off during the experiment than the WS2coated on the inner side.Therefore,the proposed sensor has better sensitivity and reliability.

Fig.12 The characteristic of fiber optic SPR sensors with four different structures

From above analyses,the good linear relationship between the resonance wavelength and the sensing RI demonstrates that the sensing RI change can be well detected through observing the shift in the resonance wavelength.The proposed tapered fiber WS2-Au structure sensor is compared with other reported SPR sensors in terms of structure complexity of sensors,as shown in Table 1.It is seen that the proposed sensor has a relatively simple structure to provide a significant sensitivity enhancement in the refractive index range of 1.333~1.380(corresponding to the biochemical sensing window).

Table 1 Comparison of sensors with different structures

4 Conclusion

In this paper,a tapered fiber SPR sensor with the WS2-Au structure is proposed.The influence of tapering and WS2nanomaterial on the fiber optic SPR sensing system is investigated.The theoretical feasibility of the sensor is proved using the transfer matrix method.WS2is modified on the fiber surface via the electrostatic selfassembly technique,and then the gold film is sputtered to fabricate the sensor.The experimental RI sensitivity of the proposed sensor can reach 4 158.171 nm/RIU,which is 125.8% higher than that of the 600 μm fiber SPR sensor.Experimental results show a good agreement with the numerical simulations.It is demonstrated that the introduction of the WS2layer can improve the sensitivity of the fiber optic SPR sensor and enhance the reliability of the sensor.In summary,the developed sensor can provide a high-sensitivity,low-cost,simple and environment-friendly platform for the biochemical detection.