Collings模型预测微液滴最大铺展直径因数研究

樊瑞瑞 肖军杰 蒋小珊 齐元胜 焦慧敏

摘要:目的—微液滴撞击平面基底承印物表面的铺展行为决定喷墨网点的大小,决定数字喷墨印刷成像的质量,研究微液滴撞击平面基底的铺展行为对印刷行业具有重要意义。方法—研究Collings等人的液滴撞击平面铺展模型,基于能量平衡方程推导Collings模型表达式,得出最大铺展直径因数与韦伯数、接触角的函数关系,而且将模型计算结果和试验数据进行对比,分析总结Collings模型公式的适用范围。结论—该模型在液滴直径较小、撞击速度较慢、液滴的韦伯数介于[15,115]、雷诺数远大于韦伯数的条件下,对液滴的最大铺展直径因数具有较好的预测能力;其它条件下,需要考虑更多的物性参数才能更准确地预测微液滴最大铺展直径因数。

关键词:Collings模型;液滴铺展;最大铺展直径因数;接触角

中图分类号:TS853+.5;TS805.3 文献标识码:A 文章编号:1400 (2022) 01-0034-08

Prediction of Maximum Spreading Diameter Factor of Micro Droplets Based on Collings Model

FAN Rui-rui1, XIAO Jun-jie1,2,3,4, JIANG Xiao-shan1,3,4, QI Yuan-sheng1,2, JIAO Hui-min1(1.School of Mechanical and Electrical engineering, Beijing Institute of Graphic Communication, Beijing 102600, China; 2.Intelligent Manufacturing Laboratory, Beijing Institute of Graphic Communication, Beijing 102600, China; 3.Beijing Key Laboratory of Digital Printing Equipment, Beijing Institute of Graphic Communication, Beijing 102600, China; 4.Engineering Research Center of Printing Equipment of Beijing Universities, Beijing Institute of Graphic Communication, Beijing 102600, China)

Abstract: The spreading behavior of the droplets against the flat substrate determines the quality of the printing image, so the study of droplet spreading behavior is beneficial to improve the quality of printed products and is of great significance to the printing industry. In this paper, the Collings model to characterize the spreading behavior of droplets impacting on a plane substrate was investigated. It is deduced from the energy balance expression of Collings model, and the relationship among the maximum spreading diameter factor , the Weber number, and the contact angle is obtained and verified. The application scope of the formula is analyzed and summarized via the comparation between calculation results and the experimental data. Under the conditions of small droplet diameters, slow impact speeds, Weber number from 15 to 115, and Reynolds number much larger than Weber number, the model has a good prediction ability for the maximum spreading diameter factor of droplets; under other conditions, more physical parameters of liquids need to be considered to predict the maximum spreading diameter factor of droplets more accurately.

Key words: Collings model; micro droplet spreading; maximum spreading diameter factor; contact angle

微液滴撞擊固体表面的铺展现象是现实生活中的常见现象,如喷墨打印、荷叶效应、农药喷洒等,涉及多种应用领域。在数字喷墨印刷领域,喷墨网点是构成印刷图像的最小结构单元,即油墨在承印物表面依据图像颜色的深浅形成大小不同或疏密程度不同的印刷墨点;网点在转移过程中的传递特性决定着印品质量,如网点形状、面积、立体形态、分布,在承印物表面的渗透、扩散等属性都会影响印品的质量[1];其深层原因是,微墨滴着陆时发生的铺展行为会引起物理网点的扩大,网点扩大一般发生在网点周边,它决定着沉积成像的质量。此外,在数码印刷中,影响印刷质量的还有其它因素,如温度、纸张性能[2]、油墨性能[3]等。印刷纸张质量的品质直接决定着印品质量的等级。E. W. Collings等人[4]研究了金属液滴撞击平面的铺展特性,进行了流体力学分析,但未推出显式的液滴铺展公式和使用条件。本文在对Colling模型详细推导的基础上,得出了(液滴最大铺展直径因数)与韦伯数、接触角的关系式,而且将计算结果和试验数据进行对比验证,分析了Colling模型的预测能力和应用范围,为精准研究微液滴的最大铺展直径因数奠定了基础,进而提高印品质量。

1 Collings理论模型

Collings模型研究的是金属液滴在平面基底自由下落的溅射淬火凝固过程[4]。金属液滴采用Nitronic 40,衬底材料分别采用铜、氧化铝和熔融石英。在实验中,直径为几毫米的液滴从静止状态下落入一根垂直安装的长管中,管子抽成真空,或者充入各种压力的惰性气体。在真空环境下,用电子束熔炼金属或合金导线的末端,产生液滴。

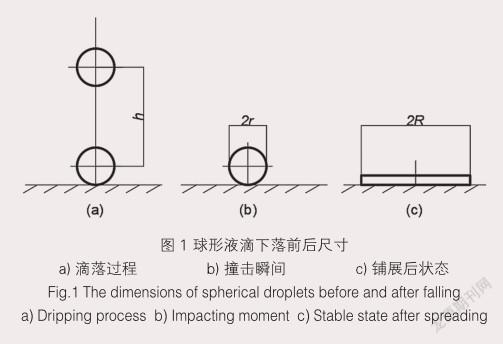

Collings实验假设球形液滴的初始密度为Q,初始半径为r,最终液滴凝固为半径为R的极薄圆柱形薄饼状样条,液滴初始下落高度为h,如图1所示。

2 接触角讨论

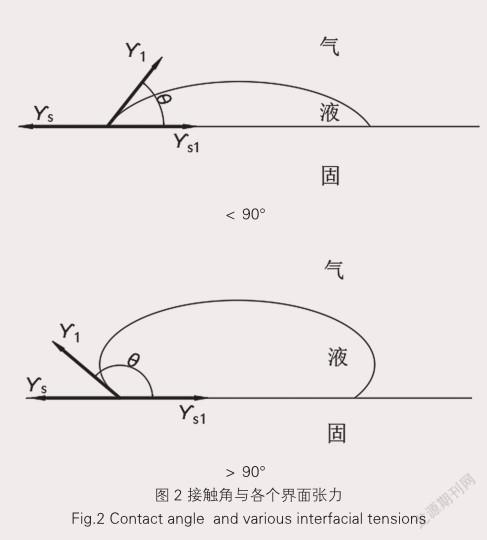

接触角是液滴撞击铺展实验中一个重要的参数,它直接影响最终公式的精确度,因此,讨论接触角的取值具有十分重要的意义[4]。

接触角基本理论描述的是接触角和三个界面张力之间的联系,是Young在1805年提出的Young方程[4]。接触角是在气液固三相交界处,γs1与γ1之间的夹角。当达到平衡时,有γs=γs1+γ1cosθ。

下图为液滴撞击到固体上达到平衡时的两种形态:

根据接触线是否移动,可将接触角分为静态接触角和动态接触角,实际上Young通过其理论定义的接触角为静态接触角。

被润湿的固体表面存在气液固同时接触的界面,称为三相接触线。当三相接触线静止时,即停止润湿时,所测得的接触角成为静态接触角。当三相接触线移动时测得的接触角称为动态接触角。动态接触角随接触线的移动速度变化而变化[5]。

接触角的选择有两种情况。当液体完全润湿基底表面时,接触角为0°;当液体没有完全润湿固体表面,也就是液体下落后撞击在固体表面形成液滴时,接触角为非零[6]。

在理想情况下,当气体层将扩散的液体与基底分离时,液滴扩散的边缘曲线满足Young方程,此时基于该方程可知,γs1与γ1之间的夹角为π,故可知接触角θ的准确值为π。Collings模型中,在真空条件下做的试验,表面干净、光滑、不易溶解,符合理想条件,故此时接触角的取值为π。

3 Collings模型的试验数据验证

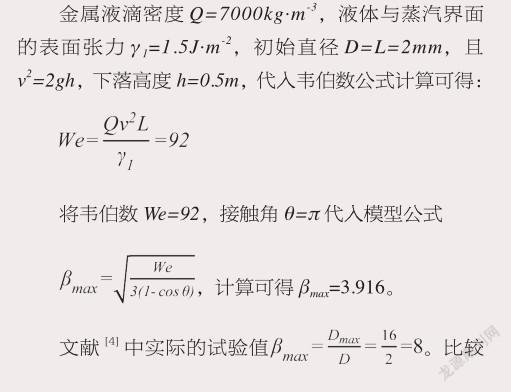

Collings模型中,由于初始球形液滴的表面能与势能项相比通常很小,故被忽略;摩擦耗散的总能量也被忽略。但如果液滴下落过程中大量能量被耗散,或者如果测量的液滴半径小于最大半径Rmax,则得到的γ1的值将大大高于实际值,这些忽略的条件可能影响模型公式的预测精确度。

3.1 Collings模型及其试验数据对比

3.2 液滴撞击水平壁面的最大铺展因数试验数据[8-21]

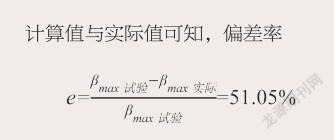

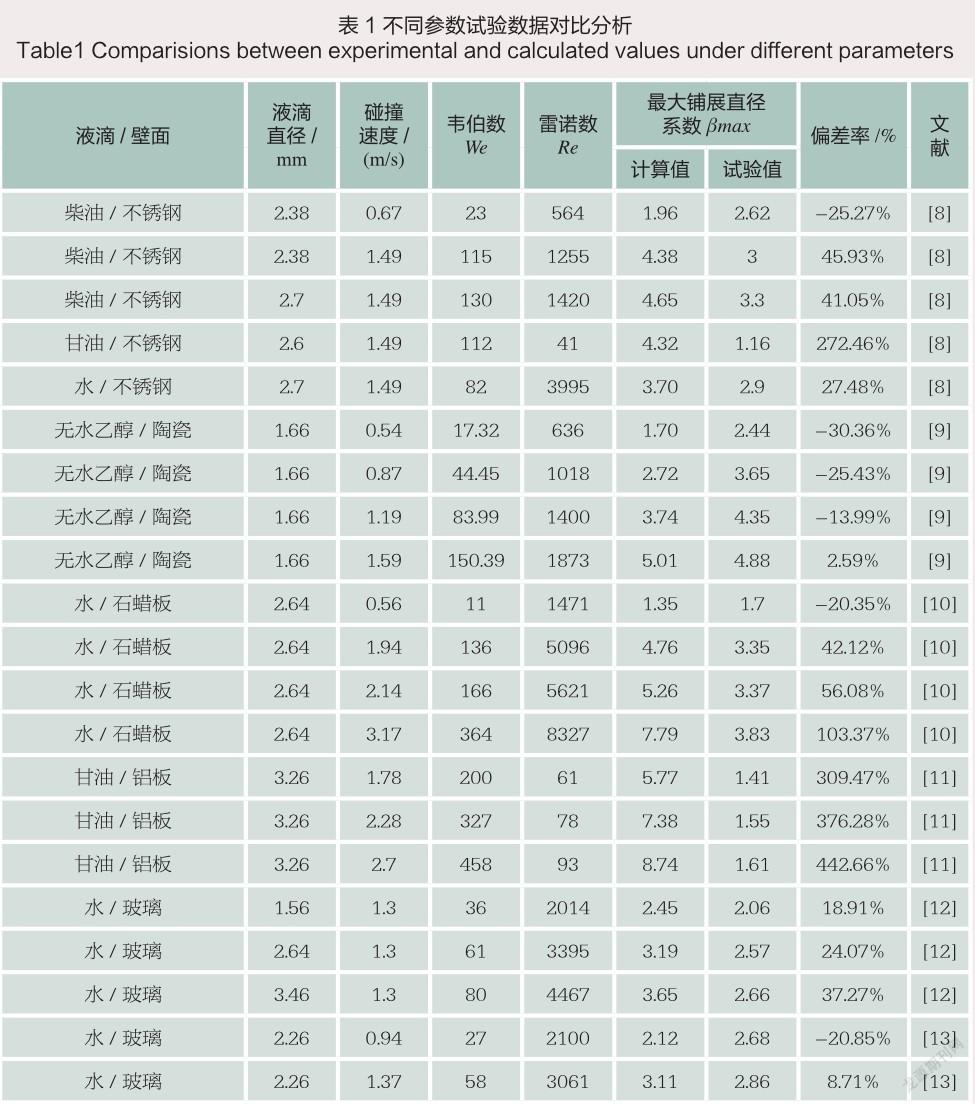

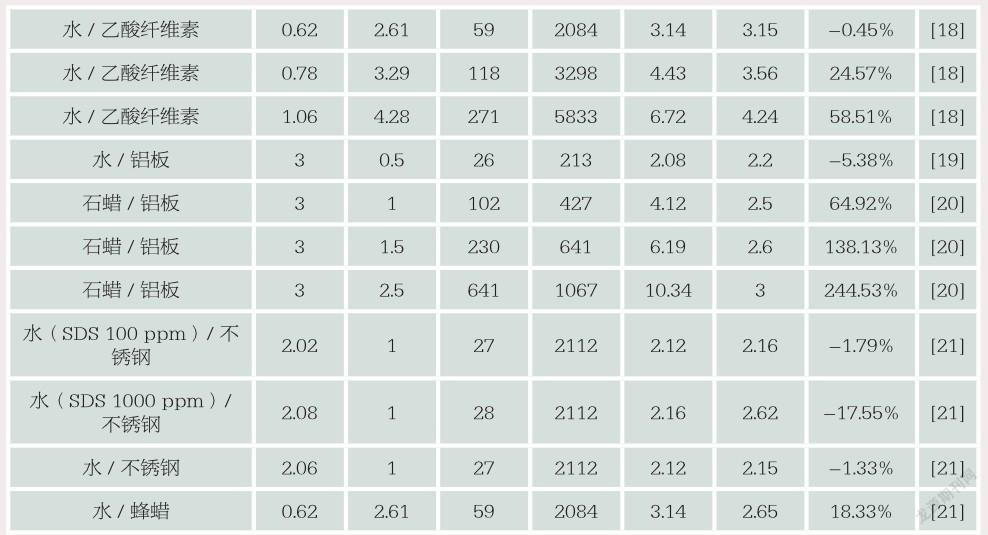

为了研究Collings模型的泛化能力,采用公式(4)对文献[7]的试验数据进行对比,模型的预测结果及偏差率见表1。

2)農药/枸杞叶[14]中农药为稀释800倍的4.5%高效氯氰菊酯乳油剂。试验中为使乳液稳定,提高药效,将4.5%高效氯氰菊酯乳油剂加水稀释800倍,故液滴表面张力降低到36mN/m,从而导致液滴的韦伯数增大,雷诺数与韦伯数的比值过小,故Collings模型公式对农药最大铺展直径因数的预测精度较低。

4 结论

基于能量平衡关系式对Collings模型公式进行了理论推导,总结出了最大铺展直径因数与韦伯数、液滴/承印物表面形成的接触角的关系式,对其代入试验数据进行验证,并总结分析出其适用范围:液滴直径较小、撞击速度较慢、液滴的韦伯数介于[15,115]、雷诺数远大于韦伯数的情况下,Collings模型预测精度较好。其它条件下,需要考虑雷诺数等更多的液体物性参数才能准确表征液滴的铺展行为;同时,对液滴撞击铺展最大直径因数的深入研究,为今后开展微液滴斜面、曲面铺展特性研究奠定了理论基础。

参考文献:

[1] 王茜,王琪.基于网点的喷墨印刷质量评价体系研究[J].包装工程,2015,36(21):115-121. WANG Qian, WANG Qi. Research on Quality Evaluation System of Inkjet Printing based on Dot[J]. Packaging Engineer ing,2015,36(21):115-121.

[2] 杨群.数码印刷纸张性能对印刷质量控制影响的研究[D].株洲:湖南工业大学,2017. YANG Qun. Study on the Effect of Digital Printing Paper Properties on Printing Quality Control[D]. Zhu Zhou: Hunan University of Technology,2017.

[3] 林定武.數码印刷电子液体油墨印刷性能的研究[D].西安:西安理工大学,2008. LIN Ding Wu. Study on the Printing Performance of Electronic Liquid Ink in Digital Printing[D]. Xi An: Xian University of Technology,2008.

[4] COLLINGS E W, MARKWORTH A J, MCCOY J K, et al. Splat-quench Solidification of Freely Falling Liquid-metal Drops by Impact on a Planar Substrate[J]. Journal of Materials Science,1990,25(8):3677-3682.

[5] 陆军军.液滴撞击过程的实验研究[D].上海:华东理工大学,2008. LU Jun Jun. Experimental Study of Droplet Impingement Process[D]. Shang Hai: East China University of Science and Technology,2008.

[6] 丁晓峰,管蓉,陈沛智.接触角测量技术的最新进展[J].理化检验(物理分册),2008(02):84-89. DING Xiao Feng, GUAN Rong, CHEN Pei Zhi. The Latest Development of Contact Angle Measurement Technology[J]. Physical and Chemical Examination (Physical Volume),2008(02):84-89.

[7] 温原,陈叶茹,唐宇航.液滴碰撞水平壁面的最大铺展系数[J].力学研究,2019,8(1):1-12. WEN Yuan, CHEN Ye Ru, TANG Yu Hang. Maximum Spreading Coefficient of Droplet Impact Horizontal Wall[J]. Mechanics Research,2019,8(1):1-12.

[8] ROISMAN, ILIA V. Inertia Dominated Drop Collisions. II. An Analytical Solution of the Navier-Stokes Equations for a Spreading Viscous Film[J]. Physics of Fluids,2009,21(5):296.

[9] 石庆杰.微墨滴撞击光滑陶瓷曲面的铺展研究[D].北京:北京印刷学院,2019. SHI Qing Jie. Study on the Spreading of a Smooth Ceramic Surface Impacted by a Microink Droplet[D]. Bei Jing: Beijing Institute of Graphic Communication,2019.

[10] 周龙玉.液滴碰撞试验与数值研究[D].哈尔滨:哈尔滨工程大学,2013. ZHOU Long Yu. Droplet Collision Test and Numerical Study[D]. Harbin: Harbin Engineering University,2013.

[11] 毕菲菲,郭亚丽,沈胜强,等.液滴撞击固体表面铺展特性的实验研究[J].物理学报,2012,61(18):295-300. BI Fei Fei, GUO Ya Li, SHEN Sheng Qiang, et al. Experimental Study on Spreading Characteristics of Liquid Droplet Impinging on Solid Surface[J]. Journal of Physics,2012,61(18):295-300.

[12] 杨宝海,朱恂,王宏,等.不同直径液滴撞击亲水壁面动态特性实验研究[J].工程热物理学报,2014,35(1):91-94. YANG Bao Hai, ZHU Xun, WANG Hong, et al. Experimental Study on Dynamic Characteristics of Droplets with Different Diameters Impinging on a Hydrophilic Wall[J]. Journal of Engineering Thermophysics,2014,35(1):91-94.

[13] 张帆,陈凤,薄涵亮.不同亲疏水表面液滴动力学行为实验研究[J].原子能科学技术,2015,49(1):288-293. ZHANG Fan, CHEN Feng, BO Han Liang. Experimental Study on Droplet Dynamics on Different Hydrophilic and Hydrophobic Surfaces[J]. Atomic Energy Science and Technology,2015,49(1):288-293.

[14] 崔洁,陆军军,陈雪莉.液滴高速撞击固体板面过程的研究[J].化学反应工程与工艺,2008,24(5):390-394. CUI Jie, LU Jun Jun, CHEN Xue Li. Study on the Process of Liquid Droplet Impinging on Solid Surface at High Speed[J]. Chemical Reaction Engineering and Process,2008,24(5):390-394.

[15] 謝亚星,慕松,陈星名.液滴撞击枸杞叶片铺展特性实验研究与仿真分析[J].中国农机化学报,2017,38(9):70-74. XIE Ya Xing, MU Song, CHEN Xing Ming. Experimental Study and Simulation Analysis on Spreading Characteristics of Lycium Barbarum Leaf Impacted by Droplet[J]. Chinese Journal of Agricultural Mechanization, 2017,38(9):70-74.

[16] 郭亚丽,陈桂影,沈胜强,等.盐水液滴撞击固体壁面接触特性实验研究[J].工程热物理学报,2015,36(7):1547-1552. GUO Ya Li, CHEN Gui Ying, SHEN Sheng Qiang, et al. Experimental Study on the Contact Characteristics of Saline Droplet Impinging on a Solid Wall [J]. Journal of Engineering Thermophysics,2015,36(7):1547-1552.

[17] 李长宁,夏振炎,李建军,等.液滴撞击有机玻璃固壁的实验和数值研究[J].工程塑料应用,2014,42(3):39-43. LI Chang Ning, XIA Zhen Yan, LI Jian Jun, et al. Experimental and Numerical Study of Droplet Impinging on the Solid Wall of Plexiglass [J]. Application of Engineering Plastics,2014,42(3):39-43.

[18] FORD R E, FURMIDGE C G L. Impact and Spreading of Spray Drops on Foliar Surfaces. Society of Chemical Industry, London,1967,417-432.

[19] CHANDRA S, AVEDISIAN C T. On the Collision of a Droplet with a Solid Surface[C]. Proceedings: Mathematical and Physical Sciences,1991,432,13-41.

[20] BHOLA R, CHANDRA S. Freezing of Droplets Colliding with a Cold Surface[J]. ASME HTD, Vol.1995,306,181.

[21] PASANDIDEH-FARD M, QIAO Y M and CHANDRA S. Capillary Effects during Droplet Impact on a Solid Surface[J]. Physics of Fluids,1996,8(3):650-659.