Clamping force of a multilayered cylindrical clamper with internal friction

Bo-Hua Sun, Xiao-Lin Guo

a School of Civil Engineering & Institute of Mechanics and Technology, Xi’an University of Architecture and Technology, Xi’an 710055, China

b School of Sciences & Institute of Mechanics and Technology, Xi’an University of Architecture and Technology, Xi’an 710055, China

Keywords:Clamping force Multilayer clamper Curvature Bending Friction Dissipation Deflection

ABSTRACT Holding an object by clamping force is a fundamental phenomena. Layered or laminated architectures with internal sliding features are essential mechanism in natural and man-made structural system. In this paper, we combine the layered architecture and clamping mechanism to form a multilayered clamper and study the clamping force with internal friction. Our investigations show that the clamping force and energy dissipation are very much depend on the number of layers, its geometry and elasticity, as well as internal friction. The central goal of studying the multilayered clamp is not only to predict the clamping force, but also as a representative case to help finding some clue on the universal behaviours of multilayered architectures with internal friction.

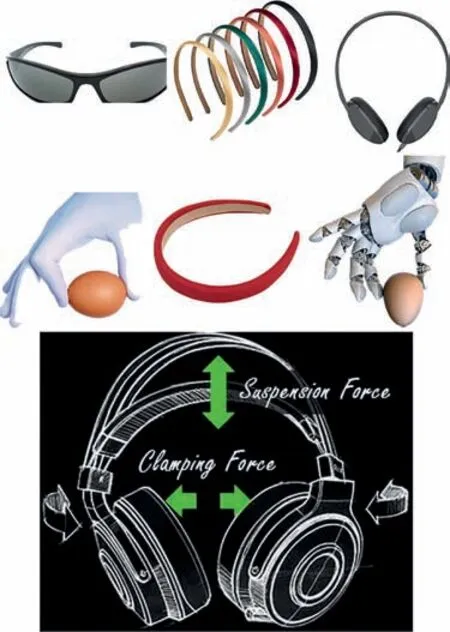

Holding an object by clamping force is a fundamental process for functional structures in natural and manmade systems. Examples encompass different applications as shown in Fig. 1, such as,medical clips, glass frame, hairband, headphone as well as robots[1–3]

Everyone may have the experience of holding an egg in their hand, and in order to prevent the egg from falling, you must apply enough clamping force, but the clamping force must also be just right, otherwise the egg will be crushed. Similarly, if you want to design a robotic hand to grasp objects that are very easy to break,the control of the clamping force is very important. Therefore, accurately predicting the clamping force is a problem worth to be studied [1–3].

To have a better strength and a good flexibility, layered or laminated architectures with internal sliding features are essential mechanism in natural and man-made structural system [4,5]. For example, scaled skins are a very common structure in both the animal kingdom and engineering applications, such as lizards, fish,leaf springs, scaled armour, pangolin and books [4–17].

In this paper, we combine the layered architecture and clamping mechanism to form a multilayered clamper and study the clamping force with internal friction. In the deformation of the layered structures/system, the interactions between layers play a central role in controlling the overall mechanical performance of the system, in particular the interlayered friction is crucial to the response of elastic system. As pointed by Poincloux et al. [4], it is a great challenging to predict how the microscopic architecture and interlayer interactions of a layered mechanical system give rise to a specific macroscopic constitutive response, especially for large deformations.

Although both Poincloux et al. [4] and Sun et al. [17] studied the multilayered book without initial curvature, namely plane book, however, we can not apply their results directly to the clamps, because the clamps are normally in curved surface rather than in plane. Therefore, seeking the clamping force is a difficulty problem.

Formulations and implicit representation of clamping force without internal friction:

For investigation of the clamp with interlayer friction, following assumptions will be adopted: (1) The Kirchhoff hypothesis is applied; (2) Each layer is inextensible; (3) No delamination; (4) Interlayers can slide with friction; (5) In cylindrical bending.

Fig. 1. Some examples of using clamping force.

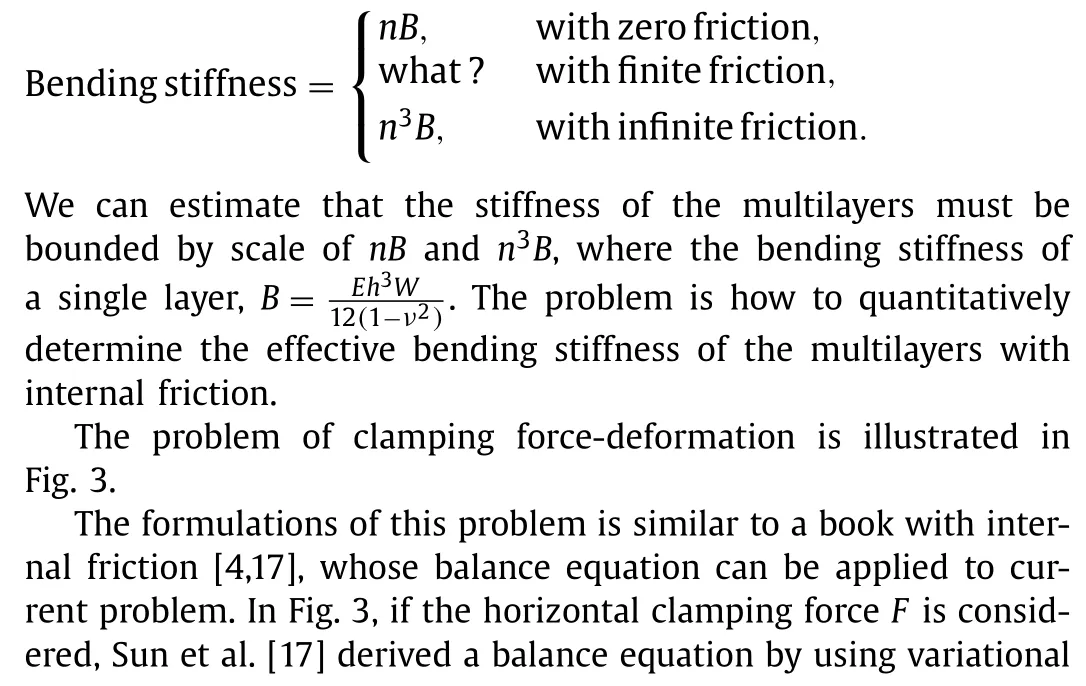

For a multilayers plate withnlayers having equal thicknessh,the total bending stiffness isnBfor zero interfacial friction, andn3Bfor infinite interfacial friction. What is the bending stiffness of a multilayers with internal friction?

Fig. 3. Deformation under horizontal clamping force F. Tangent angle θ versus arc length s. ˜x(s,y)=x(s)+n(s)y, where x(s)=x1(s)e1 +x2(s)e2 is a reference inextensible planar curve of centerline, n(s) is the unit normal vector to the centerline. The arc length ˜s on the offset curve is given by d˜s=ds1+2yκ +y2κ2 =(1+yκ)ds [4,19].

Fig. 2. Multilayers layout with layer thickness h1 =h2 =···=h, the radius of middle surface is defined as R=(R1+R2)/2=R1 +nh/2.

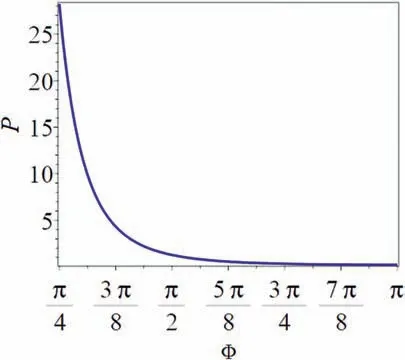

Fig. 4. P-Φ profile, where the dimensionless parameter P =[1-()2]2/[1+ μ].

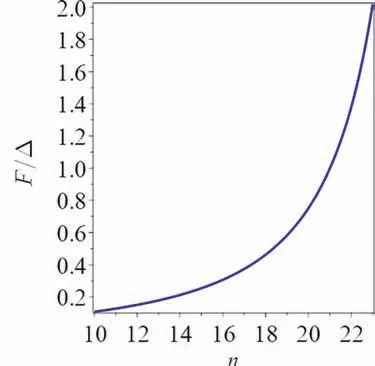

Fig. 5. F/Δ-n profile, for case of the opening angle Φ=2.3.

For given opening angleΦ, the energy dissipationDis proportional to then2, which reveals a simple mechanism where the energy dissipated per cycle can be made to vary by a large amount; this could be harnessed to design new classes of low-cost and efficient damping devices.

For numerical validation, we consider the surface of an acrylic cylinder with radiusR=10 ~23 mm with a thin oriented polypropylene sheet of thicknessh=0.00143 m to ensure uniform frictional interactions with the shell, with friction coefficientμ=0.52, lengthL=0.11 m, widthW=0.03 m, the Young modulusE=2.4×109N/m2, the Passion ratioν=0.44 and single layer bending stiffnessB=Eh3W/[12(1-ν2)]=0.021757×10-4N·m2.

If we set the opening angleΦ=2.3, the clamping forcedeformation rationF/Δis increasing with the increasing with the number of layersn, which is depicted in Fig. 5.

Fig. 6. F/Δ-μ profile, for the case of layers number n=20.

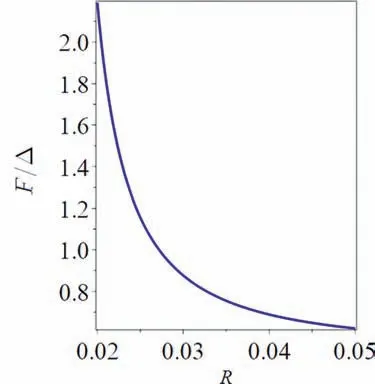

Fig. 7. F/Δ-R profile, for the case of layers number n=20.

If we set the number of layersn=20, the clamping forcedeformation rationF/Δis linear proportional to the friction coefficientμ, which is depicted in Fig. 6. TheF/Δ-μprofile is a straight line.

If we set the number of layersn=20, the clamping forcedeformation rationF/Δis deceasing with the increasing of radiusR, which is depicted in Fig. 7.

We studied the clamping force of the multilayer clamper and derived the expression of the clamping force and energy dissipation when considering friction, and the results showed that the number of layers, friction coefficient and radius all have an impact on the clamping force. When considering internal friction, the energy dissipation within per loading-unloading cycle can be made to vary by a considerable amount.

To the best of the authors’knowledge, this is the first detailed study of clamper mechanics in the context of the physics of thin structures. Our study reveals a quantitative design space for clamp and illustrates how an exquisite combination and interaction of geometry, elasticity, and friction leads to an emergent mechanical clamping devices. The study is potentially insightful to envision a future clamps design suitable for sustainable wearable human engineering.

Declaration of Competing Interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Acknowledgment

This work was supported by Xi’an University of Architecture and Technology (No. 002/2040221134).

Theoretical & Applied Mechanics Letters2022年5期

Theoretical & Applied Mechanics Letters2022年5期

- Theoretical & Applied Mechanics Letters的其它文章

- A machine learning based solver for pressure Poisson equations

- Optimization for vibro-impact nonlinear energy sink under random excitation

- Performance improvement of the stochastic-resonance-based tri-stable energy harvester under random rotational vibration

- Simulation and experimental analysis of melt pool evolution in laser engineered net shaping

- Hydrothermal analysis of hybrid nanofluid flow on a vertical plate by considering slip condition

- A structure-preserving algorithm for time-scale non-shifted Hamiltonian systems