Comparison for ecological economic performance of Chinese sea perch(Lateolabrax Maculatus) under different aquaculture systems

Zhiyi Zhang , Xiu Fang , Longqi Sun

a College of Economics and Management, Shanghai Ocean University, Shanghai, 201306, China

b Fujian Minwell Industrial Co., LTD, Fuding, 355200, China

c Yellow Sea Fisheries Research Institute, Chinese Academy of Fishery Sciences, Qingdao, 266071, China

Keywords:

Chinese sea perch (Lateolabrax maculatus)

Ecological economic performance

Pond farming

Cage culture

Data envelopment analysis

A B S T R A C T

Chinese sea perch (Lateolabrax Maculatus) is one of the main marine fish culture species in China, its green development has received increasing attention and its ecological economic study is rare.Based on field survey,this paper takes water pollution tax of China as conversion indicator for aquaculture eutrophication to simulate aquaculture waste fee for further analyzing the ecological impact of Chinese sea perch’s aquaculture.For data analysis, data envelopment analysis model has been used.The comparison for Chinese sea perch’s economic performance and ecological economic performance under its main aquaculture systems has been done.The results show that: 1.The simulated waste fee has no significant impact for the comparison.2.Ranking for ecological economic performance’s ecological economic, technical and scale efficiency is as follow: pond farming, offshore cage culture and cage culture.3.Offshore cage culture is the only system presenting positive increase for ecological economic performance, which makes its aquaculture activity more sustainable than other systems.4.The key point of green development is to maximize the ecological economic efficiency of main aquaculture systems.Thus, offshore cage culture is the most sustainable aquaculture system among China’s current marine fish culture systems, and other systems need innovation for achieving the green development of China’s aquaculture.

1.Introduction

The “Opinions of the Ten National Committees on Accelerating the Sustainable Development of Aquaculture” (Ministry of Agriculture and Rural Affairs of the People’s Republic of China, 2019; translated from Chinese) “accelerating the sustainable development of aquaculture construction using the spatial pattern, industrial structure, and production system, and promoting the transformation of China from a large aquaculture country to a strong aquaculture country” is a primary goal.As the second highest production volume species of Chinese marine fishes in 2018 (Fisheries and Fisheries Administration of Ministry of Agriculture and Rural of the People Republic of China et al.,2015-2019),providing a sustainable supply of Chinese sea perch (Lateolabrax maculatus) is significant for both the marine fish supply and high protein food supply for citizens in China, which makes its sustainable development more important than ever before.During the past 40 years, the aquaculture industry related to Chinese sea perch has developed rapidly in Zhuhai, Guangdong and in Fuding, Fujian, where provide the most appropriate natural aquaculture resource for this species.At present,Chinese sea perch is mainly cultured by pond farming as well as inshore and offshore cage culture, where pond farming contributes (71.71%)1more volume than the two other systems (28.28%).1However, because the Chinese sea perch aquaculture industry has rapidly agglomerated in Zhuhai and Fuding, related environmental issues have developed in the agglomerated areas.(Pan et al., 2019; Liao et al., 2018).Facing the aggravation of aquaculture pollutants, a renovation of sustainable development that can promote the sustainability of aquaculture activity must be performed.The benefits of this type of aquaculture for farmers have to be taken into account while discovering methods designed to provide for sustainable development of the industry and for solving environmental issues.Thus, the sustainable development not only involves environmental sustainability, but also concerns economic efficiency.Therefore, to deal with the current policies of Chinese government, it is crucial to explore the ecological economic(eco-economic) side of Chinese sea perch aquaculture industry.

Current research related to the Chinese sea perch industry mainly focused on growth performance (Hou et al., 2019), gene sequencing (Qu et al., 2018; Wang et al., 2017), toxicology (Zhou et al., 2011), and other biological fields of study.The limited research that has been conducted in the field of economics for this species has been mainly addressed brand building (Liao, 2019), value chain development (Gao et al., 2015),and economic performance (Liao et al., 2018).Most researchers were trying to come up with preliminary research results related to the biological characteristics of Chinese sea perch to promote various aquaculture techniques, while some of researchers sensed the importance of studying the economic side of the industry as well as ecological aspects needed to achieve sustainable development of the industry.Although,economic research and ecological research of Chinese sea perch is still limited and cross-field studies are rare, in the meantime, quantitative analysis is sparse in the existing research studies.into the eco-economic aspect of Chinese sea perch culture and production is still lacking; the need to measure the eco-economic performance of the main aquaculture systems for this species is pressing.The aim for this study is to evaluate the actual production data and eco-economic performance for farmers of Chinese sea perch, which cover the three main existing Chinese sea perch aquaculture systems, and to explore and reveal the optimal Chinese sea perch aquaculture system from an eco-economic aspect.Owing to its sustainability and product quality, offshore cage aquaculture has been regarded as the most advanced system in the field of marine fish culture (Jin & Zhou, 2006; Guo, 2006).With the goal of producing an eco-economic performance analysis, a field survey was questionnaire was used and the related data were collected in the selected areas.This study is organized into four parts (Ministry of Agriculture and Rural Affairs of the People Republic of China, 2019): the current aquaculture status of Chinese sea perch (Fisheries and Fisheries Administration of Ministry of Agriculture and Rural of the People Republic of China,2015), methodology and data description (Pan et al., 2019), results and discussion, and (Liao et al., 2018) conclusions and research prospects.

2.Materials and method

2.1.Method

The Data Envelopment Analysis (DEA) method, which originated in 1957, was invented for analyzing production efficiency with unsure production function cases.In 1978, A.Charnes, W.W.Cooper, and E.Rhodes established the Constant Return to Scale (CRS) model, which is based on the constant return to scale hypothesis.Banker, Charnes, and Cooper established the Variable Return to Scale (VRS) model in 1984 that is based on the variable return to scale hypothesis and can be used in cases when the output increase rate is not equal to its input increase rate.The Stochastic Frontier Approach, as another popular efficiency test method, is often used for production efficiency analysis, which needs a production function for analyzing.For this study, the aim is to evaluate and compare main aquaculture system’s production efficiency of Chinese sea perch from both economic side and eco-economic side, and each system has different production inputs that make each system’s production function differ from others.Thus, for this study, DEA is more proper for the eco-economic efficiency analysis of three different marine fish culture systems.

The DEA method has been used in many different research areas for efficiency and performance evaluation.Because the need for broad scale evaluation has increased, this method has recently been applied to the following research areas.(a) integrated DEA and life-cycle assessment were used to evaluate the technological and environmental performance of sludge-to-energy systems, which documented the overall and pure technical efficiency systems in 16 samples (Lam et al., 2020).(b)DEA-WEI was used as a base to further develop a corporate social performance index, which was able to identify the impact of company activities on its stakeholders (Lahouel et al., 2020).(c) DEA with a double bootstrapping technique was used to measure the efficiency of shrimp farming’s efficiency, which helped to determine the actual efficiency for the cost and technical side of current farming techniques; the results were more precise than a traditional DEA for aquaculture (Long et al.,2020).Thus, to provide a more accurate eco-economic performance evaluation, the traditional DEA method is inadequate.Therefore, data analysis has been designed based on using the eutrophic ingredients of aquaculture waste water as the environmental impact indicator to stimulate the environmental cost of aquaculture activities, which can be seen as an ecological cost in this study.

The mathematical programming of DEA is as follows: suppose there are n decision making units (DMUs), and each DMU has m types of“input” and s types of “output".xijis the input amount of the jth DMU to the ith input,xij>0;yrjis the output amount of the jth DMU to the rth output,yrj>0;viis the weight of the ith input;uiis the weight of the rth output, where i =1,2, …,m; r =1,2, …,s; j =1,2, …,n; for convenience,see:

Thus, CRS’s mathematical programming of DEA is:

Based on our knowledge of the marine fish culture and the results of field surveys, the Chinese sea perch market is not a perfectly competitive market, and the assumption that all inputs are in line with the constant return to scale cannot be fully confirmed.Based on the above and previous studies (Cang et al., 2018), this paper mainly used the VRS of the DEA method for data analysis, while DEAP2.1 software was employed for measurement.The following dual programming of VRS model will be used:

Wherein,yjis the output variable;xjis the input variable and θ is the result of efficiency value.With this model, multiple inputs with single output can be measured to get efficiency level.Moreover, strong DEA efficiency will be achieved when θ =1 and s- =s+=0, in which scale and technical efficiency of DMU are both reached, and DMU’s optimal combination and output are achieved.On the other hand, when θ =1 and s-∕=0 or s+∕=0, weak DEA efficiency will be achieved, in which only scale efficiency or technical efficiency is achieved.For θ ≤ 1, the DMU’s efficiency value is non-DEA efficiency, in which both scale efficiency and technical efficiency are not achieved.

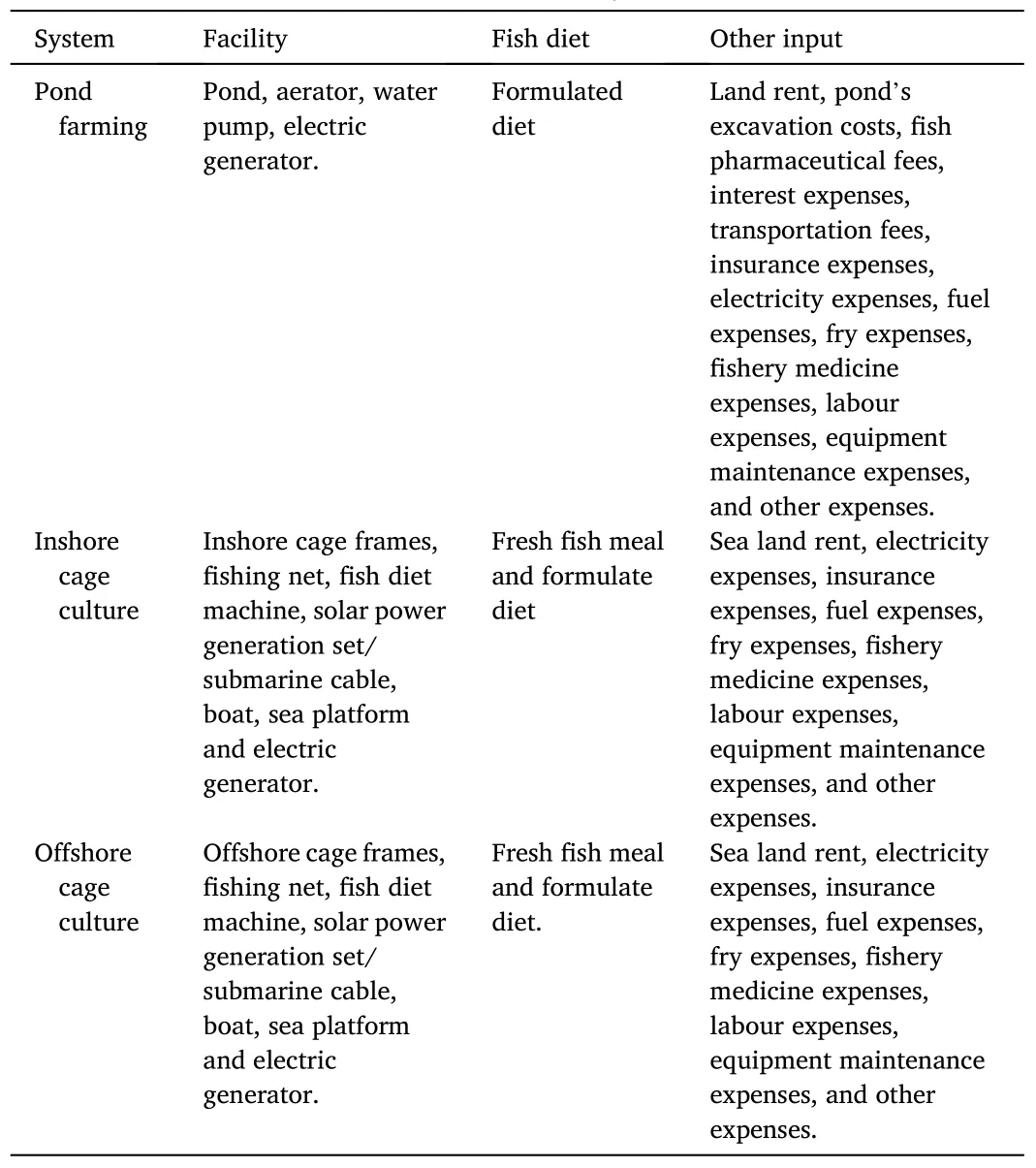

Based on the VRS model and the actual conditions of Chinese sea perch aquaculture,field surveys were conducted with a designed questionnaire for each system.Starting with total cost theory, a questionnaire was designed based on a solid foundation of preliminary research studies that were done during the past 10 years related to marine flat fish culture (Cang et al., 2018).To resolve the economic and eco-economic performance of Chinese sea perch aquaculture, the questions were all designed to solve the input and output by culture cycle.Construction is the first step in developing aquaculture activity.Land rent and pond excavation involve the major construction costs of developing a pond farming system, while cage frame building takes almost all cost of construction fees in inshore and offshore culture.Considering different characteristics of each system, the following factors were inserted(Table 1): building cost of cage frames and living area, solar power generation equipment fees, fresh and formulated diet input including unit price and feeding coefficient, fuel input, labour input, investment in boats, utilities, equipment maintenance cost, sea area use fee, and employee salaries.For pond farming, the cost of land rent, pond excavation, formulated diet input,fish pharmaceutical fees, interest expenses, transportation fees, aerators, electric generators, and fuel input,water pumps, and employee salary were inserted.For output factors,average sales price and sales volume were inserted in the questionnaire.To acquire more information, other related questions were addressed that discussed issues currently faced by farmers that were designed after finishing the initial questionnaire.With face-to-face individual in-depth interviews, the field surveys were expected to be able to provide related data.

Table 1Inputs of each Chinese sea perch aquaculture system.

2.2.Data source and indicator selection

2.2.1.Current aquaculture status of Chinese sea perch

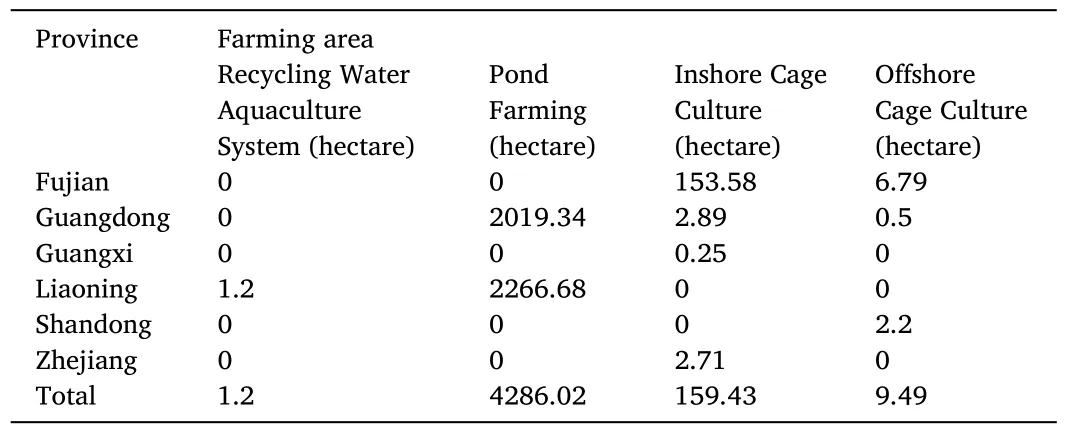

According to China Fishery Statistics Yearbook (CFSY) (Fisheries and Fisheries Administration of Ministry of Agriculture and Rural of the People Republic of China et al.,2015-2019), the total marine culture area for fishes was 75.12 ×105ha in 2018.For understanding current aquaculture status of Chinese sea perch, data have been collected in China Agriculture System Marine Fish Centre (CARSMFC) Database.This database has 19 comprehensive test stations covering more than 84 counties of ten coastal provinces in China (the main marine fish production area) (Fig.1).Data show that in 2018, 4.46 ×105ha of aquaculture area existed for Chinese sea perch in the main marine fish production area, including 4.29 ×105ha of pond farming (accounting for 96.18% of all), 0.17 ×105ha of inshore and offshore cage culture aquaculture area (accounting for 3.57% of all) and 1.2 ha of recyclingwater aquaculture systems.Pond farming systems are mainly used in Liaoning (56.82%) and Guangdong (37.86%), while inshore cage culture systems are mainly applied in Fujian (96.34%) and offshore cage culture systems have only been adopted in Fujian (71.55%) and Shandong (Table 2).

Fig.1.Comprehensive test stations of China Agriculture System Marine Fish Centre.

Table 2Chinese sea perch’s aquaculture area of each aquaculture system in the main marine fish production area in 2018.

The production volume of Chinese sea perch has been steadily increasing in the recent years with Guangdong and Fujian as the main contributors in the main marine fish production area.According to CFSY(Fisheries and Fisheries Administration of Ministry of Agriculture and Rural of the People Republic of China and China Society of Fisheries,2015-2019), from 2014 to 2018, total output of Chinese sea perch was 113.8 × 104tons, 122.54 × 105tons, 139.46 × 105tons, 156.6 × 104tons and 166.58 ×105tons, respectively.The ring growth rates were 7.68%, 13.81%, 12.28%, and 6.38%, respectively, and the average annual growth rate was 10%.As the main production areas, Guangdong and Fujian contributed 52.43% and 20.25%, respectively, to the total Chinese sea perch production in 2018.

The data for the stock of the Chinese sea perch production areas in 2018 show that the stock at the end of seasons experienced large changes.The stock at the end of the first quarter was 36.02 ×105tons,which increased by 64.87% in the second quarter, then increased again by 67.74% in the third quarter, and finally decreased by 23.63% at the end of the fourth quarter.Compared with 2017, the stock at the end of one year increased by 1.57% in 2018 (76.07 ×105tons).

In the main marine fish production area, the production area of Chinese sea perch fry was 1.76 ha in 2018, in which a running water aquaculture system is adopted.As for the contributors, Fujian contributed 42.61%, Liaoning and Shandong also contributed 37.5% and 19.89%, respectively, to the production.The fry production area of Fujian was steady in each quarter of 2018, which was 0.75 ha.Liaoning became the highest production area (0.66 ha) in the first quarter of 2018 but production decreased in the following quarters, while the production area of Shandong remained steady from the first to the third quarters (0.1 ha) and peaked in the final quarter (0.35 ha).

In 2018, the fry of Chinese sea perch were mainly sold to Fujian,Guangdong, Guangxi, Liaoning, Shandong and Zhejiang.Therefore, for the present study fry prices were collected in those areas.Despite of the large amount of production area, Liaoning only sold 2 million tails of fry and there were all sold in the second quarter.Shandong sold 1.37 million tails mainly in the first quarter.The total sales volume was 52.37 million tails and Fujian marketed 49 million tails mainly in the first quarter.The price of Chinese sea perch fry is normally set based on two different sizes divided by fry length (shorter or longer than 5 cm).The sale price of fry not longer than 5 cm ranged from 0.23 to 1.8 Yuan/tail with the lowest price reported for Guangdong.The sale price of fry longer than 5 cm was higher than smaller fry with a price ranging from 0.6 to 7 Yuan/tail.

The pond farming industry for Chinese sea perch has been developing for over 30 years, and a unique aquaculture industry has been created.To produce this species, the pond farming system uses aerators provide an abundant supply of oxygen in the ponds with a low construction cost; however, the cost of electricity and the yield are both relatively higher than those of the other two systems.The cycle of pond farming culture is normally around 10-12 months, and 600-750 g fish per tail can be produced.Furthermore, with the high accumulated temperature in Guangdong, its culture cycle can last 18 months so that over 1000 g of fish per tail can be produced.With the use of a formulated diet during the entire culture cycle, the pond farming industry often involves a high rate of debt for farmers who buy formulated fish food from the food manufacturers.The debt relationship creates a purchasing advantage for some large formulated diet manufacturers, which will be a way of compensating for the debt with fish products sold at a lower price than the general market.Because Chinese sea perch is often sold in a chilled form, the advantages for the large formulated diet manufacturers gives them the ability to manipulate the fish’s sales price by holding a large amount of chilled fish at times.Thus, even with the high yield and newly developed farming methods, the industry still faces an urgent need for reform.

Unlike pond farming, inshore and offshore cage culture techniques use a natural marine environment.However, taking advantage of nature is expensive and sometimes involves a higher level of risk related to the occurrence of fish disease and dissemination as well as the risk of extreme weather when compared with pond farming.Compared with inshore cage culture, running an offshore cage culture farm requires not only a large investment for construction, but also requires high operating expenses mainly for shipping fish meal.The production cycle for inshore and offshore cage culture systems is normally 18-24 months, in which fish with the weight of 750 g-1000 g per tail can be produced.Compared with pond farming, fresh fish meal is more commonly used in both cage culture systems; fresh fish meal is normally used for 8 months per year because of the summer moratorium prohibiting marine fishing in summer in China.For the two cage culture systems, fresh fish meal is the main bait source and suppliers require immediate payment at the time of purchase, which requires a large amount of cash and limits the operating scale of many farmers.The formulated diet for the two cage culture systems is also considered to be an alternative fish bait that has recently become popular among a relatively small scope of farmers.Thus, even if the chilled product still includes a high proportion in all products, formulated diet manufacturers do not currently have the advantage of purchasing in those two systems.

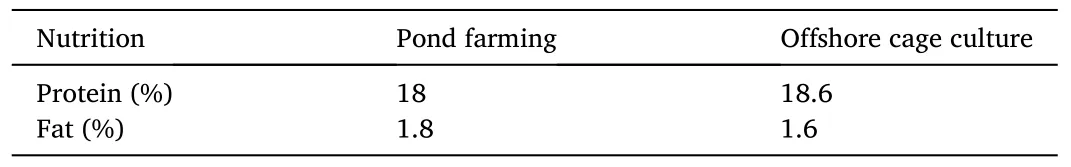

In 2018, Chinese sea perch ranked second in terms of production volume among all Chinese marine fish culture species.Chinese sea perch is mainly sold through four distribution channels and a variety of products from different aquaculture systems have various sales prices.The main distribution channels for this species are domestic commodity,high-end, e-commerce, and export markets.Chinese sea perch is normally sold by different sizes such as 600 g/tail, 750 g/tail, 1000 g/tail and over 1100 g per tail, and over 1100 g per tail the last of which accounts for the lowest overall percentage.The 600 and 750 g/tail sizes are the most common in Chinese commodity market, because they are more convenient for household use and in some restaurants.The 750 and 1000 g/tail products are often used for high-end public service meals, business dining, and all kinds of banquets.The>1100 g/tail fish are popular during festivals in Shandong based on local customs, and it is also used for export, normally to Korea.The sale price of Chinese sea perch has continued a slow but steady increasing trend.The marine environment of offshore cage culture can provide better farming conditions than pond or inshore culture providing enhanced protein content and reduced fat content.The aquaculture environment and flavour of products of the same size produced in pond farms are sold at a much lower price than the products from inshore and offshore cage culture.Offshore cage culture can create farming conditions similar to the natural habitat of Chinese sea perch and its products can normally be sold at a higher price than products of the same size under an inshore cage culture system.Moreover, products with a weight of>1100 g/tail can usually be sold at a higher price than the products of other sizes.

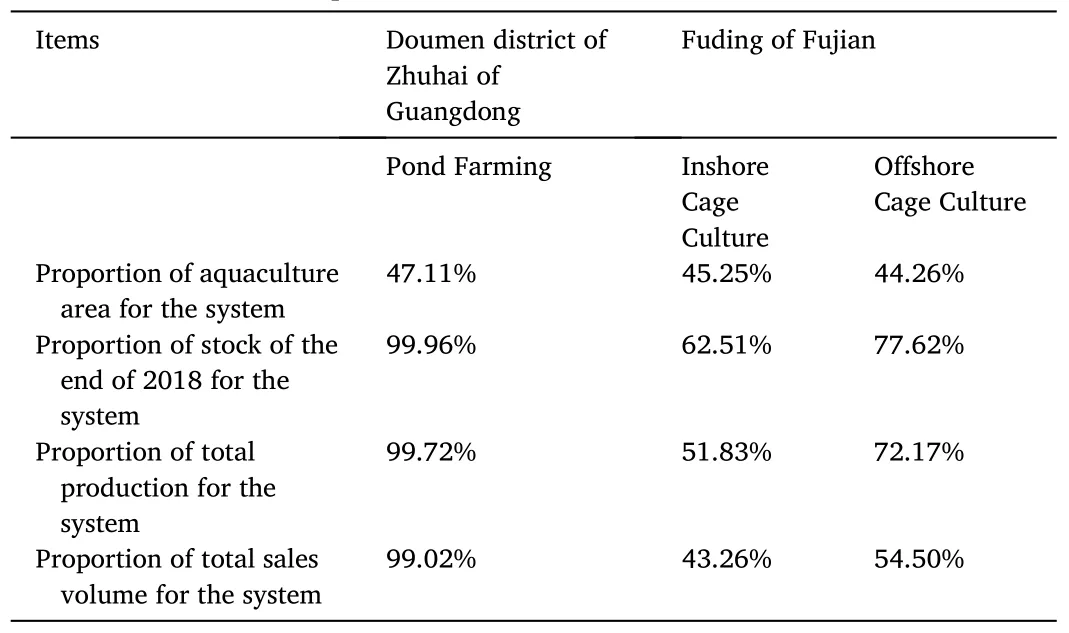

The data collection of this study was supported by the China Agriculture Research System in 2017.Based on data collected from CARSMFC Database for pond farming systems, even if the production area of the Doumen District in Zhuhai was less than 50% of the entire main production area, Chinese sea perch production in Doumen accounted for>99% of the total production under this system in the main production area in 2018.The production area for inshore and offshore cage culture in Fuding accounted for around 40% of the entire main production area and its yield exceeded 50% of the total production in 2018 (Table 3).Thus, to understand the main culture systems used in Chinese sea perch aquaculture, this study selected two locations for the collection of field survey data.The data were collected by face-to-face individual in-depth interviews from 2017 to 2019 due to limitations of field surveys as well as the need for data accuracy.A total of 74 farmers were involved who gave comprehensive information according to the provided questionnaire, of whom five used more than one system for Chinese sea perch aquaculture.Due to the uncertain input details of each aquaculture system for those five samples, they were eliminated from the analysis; this study employed the other 69 samples that applied only to farmers using a single aquaculture system for the analysis of ecoeconomic performance.

Table 3Percentage of Chinese sea perch’s different system aquaculture area by province in the main marine fish production area in 2018.

Field survey areas have long history of being used to address issues related to the Chinese sea perch aquaculture; their use in the aquaculture industry has developed comparatively well.Located near the south of Zhejiang Province, the county level city of Fuding in Fujian Province has excellent marine resources that can provide suitable aquaculture conditions for inshore and offshore cage culture for Chinese sea perch and other marine fishes (especiallyLarimichthys crocea).Fuding is developing its marine cage culture industry, which serves as one of the main marine cage culture areas in China.During the field surveys, 19 and 13 farmers were interviewed in 2017 and 2019, respectively.The interviews in Fuding included interviews and surveys of 13 offshore cage culture farmers, 14 inshore cage culture farmers and five interviews of farmers using both systems.Zhuhai is located at the southwestern end of the Pearl River Delta and has estuaries of two of Pearl River’s tributaries-Beijiang and Xijiang-in its area.The development of pond farming for Chinese sea perch in Zhuhai mainly depends on areas with a suitable and effective accumulated temperature as well as abundant water resources provided by the Pearl River system; those unique and powerful strengths result in fruitful yields.Because Weiguo Village of Doumen District is the production area with the longest history of Chinese sea perch pond farming, field survey data for this system were collected from seven villages, including Weiguo Village of Doumen, in 2018 and 2019.A total of 42 pond farming interviews were conducted(Table 4).

Table 4Collected Chinese sea perch’s field survey data from Fujian province and Guangdong province (2017-2019).

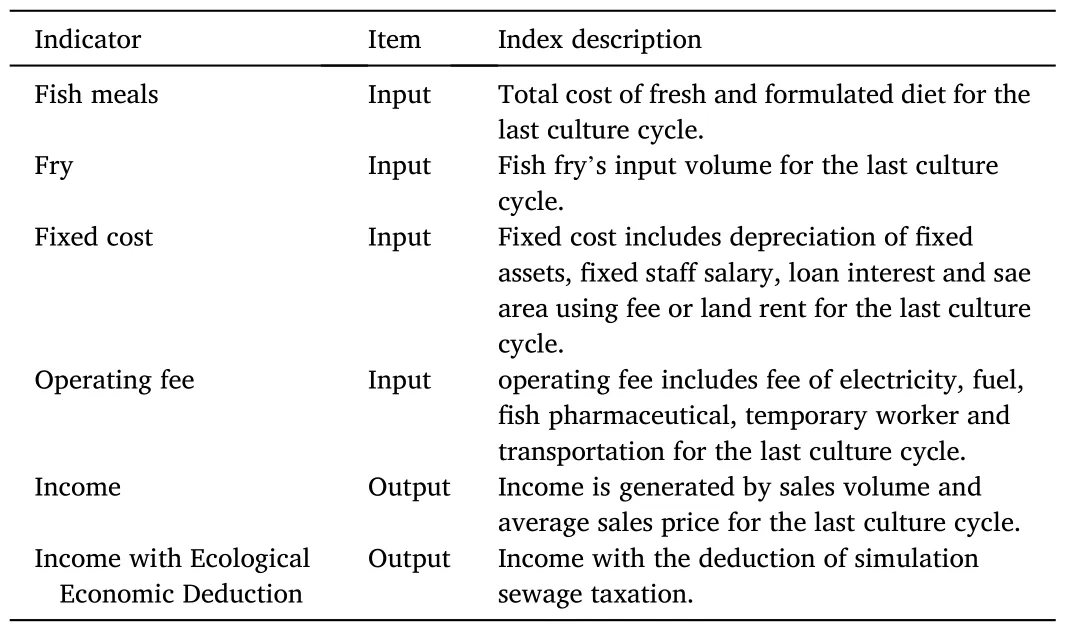

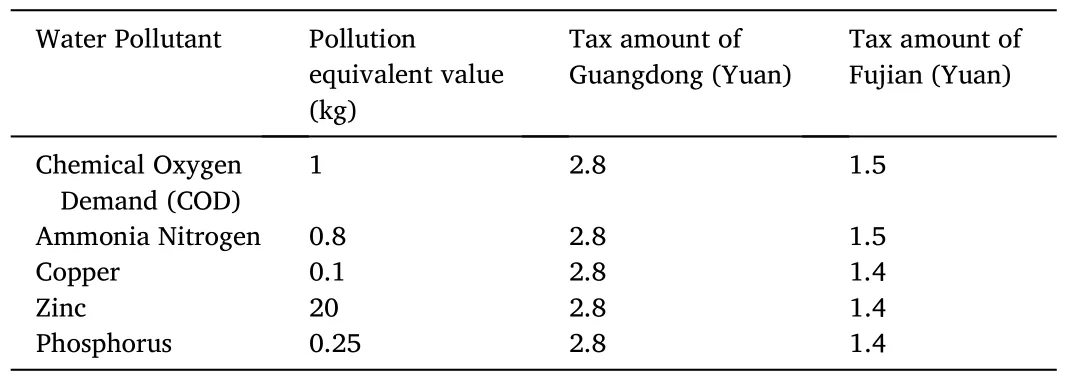

The collected questionnaire data were classified into five variables for data processing: fish meal, fry, fixed costs, operating fees, and income (Table 5).For measuring the eco-economic factor, this study took a pollution loads of Chinese sea perch aquaculture for each system from“The First National Pollution Source General Investigation of Aquaculture Pollution Source Pollution loads Manual” (The Group of Pollution Discharging Loads in the National Aquaculture Pollution Census, 2009)as the index to measure environmental effects of aquaculture.This was done by converting the production volume of each DMU to the amount of aquaculture eutrophication it caused to obtain the related simulated aquaculture waste fee.The Environmental Protection Law of People’s Republic of China (EPLC) and the implementation of the EPLC’s taxation standards for water pollutant discharges in Fujian and Guangdong were used to measure the environmental effects based on the simulated tax for aquaculture waste, which is an eco-economic deduction variable for farmer’s income.To compare the differences between economic performance and eco-economic performance of each system, the income and income without an eco-economic deduction were both employed as output variables for DEA (Tables 6 and 7).

Table 5DEA analysis’s indicator description.

Table 6Fujian and Guangdong’s implementation of taxation standards for water pollutant discharges of the Environmental Protection Law of People’s Republic of China (Per pollution equivalent).

Table 7Pollution loads and charge standards of each aquaculture system for Chinese sea perch.

It should be noted that (Ministry of Agriculture and Rural Affairs of the People Republic of China, 2019): offshore cage culture areas are normally in offshore areas, which experience stronger waves and faster seawater exchange speed.These factors shorten the pollution decay cycle; currently, the offshore cage culture system has a limited distribution of offshore cage culture areas.Previous research (Jin & Zhou,2006; Guo, 2006) has shown that the offshore cage culture system produces a negligible amount of pollution in the surrounding environment.Thus, the waste discharge from and cost of the offshore cage culture system were considered negligible in this study (Fisheries and Fisheries Administration of Ministry of Agriculture and Rural of the People Republic of China, 2015).The field survey and questionnaire data were obtained in Doumen, Zhuhai, in 2018 and 2019, and in Fuding, Fujian, in 2017 and 2019.This article adopted the China Fishery Product Production Price Index (104.95 and 102.6) to convert the cost of fish meal, fixed assets, and fees of the related sample data; the output variables were converted by the China Consumer Price Index for Aquatic Products (104.4 and 103.8) accordingly (Pan et al., 2019).The pollution loads of inshore cage culture for Zhejiang is the only accessible pollution rate found that addresses Chinese sea perch inshore cage culture; this system for this species normally uses the same fish meal method.Thus,the pollution loads of Zhejiang could be used as a reference for the inshore cage culture system in Fuding.Therefore, the pollution rates were used for analysis.

3.Results

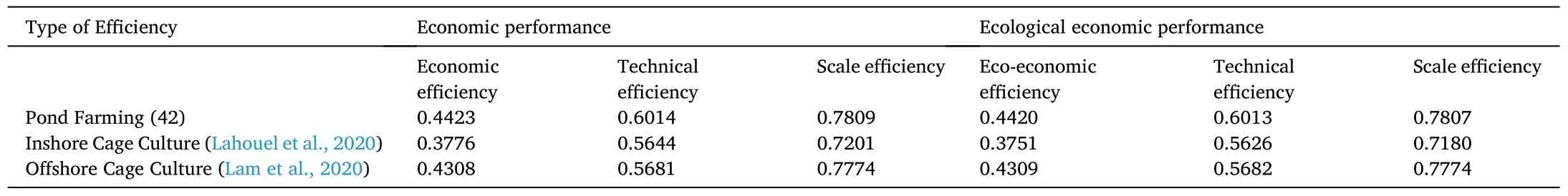

The analysis results found using DEAP2.1 software show the average economic efficiency and eco-economic efficiency of each system did not have major differences (Table 8).Under the simulated waste fee based on the implementation of taxation of EPLC in Guangdong and Fujian, the eco-economic factor is presented based on the waste fee as a deduction from income for the comparison output variable.The results show that the simulated waste fee cannot change the frontier points of economic efficiency.However, some samples’ efficiency was changed and this kind of change can also be found in the average efficiency level.

Table 8Efficiency of each aquaculture system.

When the ecological factor is not considered, the economic performance analysis shows the following results (Ministry of Agriculture and Rural Affairs of the People Republic of China, 2019): The average values of economic, technical, and scale efficiency of each system had the same ranking.Among all systems, pond farming was the most effective, while offshore cage was more efficient than inshore cage culture (Fisheries and Fisheries Administration of Ministry of Agriculture and Rural of the People Republic of China, 2015).For the average value of economic efficiency, the gap between offshore cage culture and pond farming(0.0114) was smaller than that between offshore cage culture and inshore cage culture (0.0532) (Pan et al., 2019).As for technical efficiency, the difference of pond farming and offshore cage culture was 0.0333, whereas it was only 0.0036 for offshore and inshore cage culture systems (Liao et al., 2018).For scale efficiency, the difference between pond farming and offshore cage culture was 0.0035, whereas it was 0.0573 for offshore cage culture and inshore cage culture (Hou et al.,2019).By comparing the average efficiency of the three types of aquaculture, scale efficiency was the highest and economic efficiency was the lowest.

The eco-economic performance analysis results show the same ranking existed for average values of three types of efficiency for the simulated waste fee when compared with economic performance(Table 8).However, slight changes can be found in some efficiency results of some samples that are scattered in all systems.By comparing economic performance analysis results, the eco-economic performance analysis results show (Ministry of Agriculture and Rural Affairs of the People Republic of China, 2019): the eco-economic, technical, and scale efficiency of pond farming all declined slightly by 0.0002, 0.0001, and 0.0002, respectively (Fisheries and Fisheries Administration of Ministry of Agriculture and Rural of the People Republic of China, 2015).The findings for inshore cage culture were similar with those of pond farming in that all types of efficiency declined to some extent.Eco-economic efficiency decreased the most (0.0025), while scale efficiency (0.0021) and technical efficiency (0.0018) experienced smaller changes (Pan et al., 2019).The eco-economic and technical efficiencies of offshore cage culture both increased by 0.0001, whereas scale efficiency remained unchanged.

Furthermore, major eco-economic efficiency disparities existed for collected samples.The eco-economic efficiency frontier was created by four samples that were strongly effective in DEA.Those samples were spread across each system with two of the frontier samples using the offshore cage culture system.The frontier sample ratios of pond farming,inshore cage culture, and offshore cage culture were 2.38%, 7.14%, and 15.38%, respectively.For weakly effective points in DEA, six samples reached technical efficiency and the ratios for each system were 7.14%,7.14%, and 15.38%, respectively.However, the 10 samples with the lowest eco-economic efficiencies were scattered in inshore and offshore cage culture systems, while the sample ratios were 42.86% and 30.77%,respectively.The lowest eco-economic efficiency sample applied to the offshore cage culture system and its technical efficiency was the main reason for the shortage.The lowest technical efficiency also belonged to the offshore cage culture system; but with much higher scale efficiency,the eco-economic efficiency of this sample was not the lowest of all.For scale efficiency, its lowest value was in an inshore cage culture sample that had the highest technical efficiency.As for scale status, three samples showed a decreasing trend among all 69 samples.Among them,two used the pond farming system and the other one used the inshore cage culture system.

Considering the simulated waste fee based on current legislation, the results of DEA for field surveys show a high contact ratio exists between economic and eco-economic efficiencies for Chinese sea perch aquaculture; their efficiency rankings are the same with the following order:pond farming>offshore cage culture>inshore cage culture.Although the offset of the simulated waste fee does not show a significant effect, it resolved a slight increase in the positive eco-economic performance of offshore cage culture system.Only one sample showed a positive change in both eco-economic efficiency and technical efficiency, and it also shows the effect was still weak.In contrast, eco-economic performance analysis results of samples for pond farming and inshore cage culture all show a decreasing trend, compared with the economic performance analysis for all three types of efficiency.In addition, the results show that samples of pond farming had a smaller change in efficiency than the samples of inshore cage culture in all types of efficiency.

Chinese sea perch aquaculture serves as an important part of the Chinese marine fish culture industry and the spatial extent of its aquaculture area is also a region with a high level of natural resources in southern China.Thus, its sustainable development has a significant effect on the supply of Chinese marine fish products.The following problems were found based on the field surveys and DEA: the current aquaculture systems still have disadvantages, such as a low degree of intensification, polarized development, and environmental pollution caused by the use of fish meal.Those are the main obstacles to sustainable development of Chinese sea perch aquaculture.

4.Discussion

With the longest history of Chinese sea perch aquaculture in China,inshore cage culture had the lowest economic and eco-economic efficiencies.When compared with previous studies, salmon cage culture’s eutrophication cost was directly compared with human settle (Folke et al., 1994), which proved its pollution represent a net addition to the environment and the relative impact depend on the amount of fish farmed.Moreover, compare with the human nutrient production, the release of fish farm for 1994’s Nordic countries salmon total production exceed the human nutrient production of Stockholm, Sweden.Due to the areas of inshore cage culture systems analyzed in this study have low currents, Chinese sea perch inshore cage culture showed show environmental impacts as salmon culture in Nordic countries Chile and other places (e.g.Folke et al., 1994; Buschmann et al., 1996).Moreover,because of different input methods, the technical efficiency of inshore cage culture for each sample had huge disparities.Inshore cage culture farmers have different feeding methods and different expectations for the size of the products, which results from their own experiences.Fresh fish served as the original fish meal for the inshore cage culture system,and the high percentage of waste caused by using fresh fish meal creates main environmental pollution problem for this system.To protect the environment and maintain biodiversity, the literature indicate that it is essential to increase the efficiency for fresh fish meal’s conversion,switching to formulated feeds, reduction of the incorporation of fish meal and oil in fish diets (Naylor et al., 2000) and adopting bioremediation techniques like Integrated Multitrophic Aquaculture allowing to recycle and extract nutrient loads form aquatic and marine systems(Chopin et al., 2001).However, a high percentage of farmers believe a formulated diet cannot achieve the same effect as frozen or fresh fish meal.Thus, only six samples out of 14 showed the use of a formulated diet, including four samples with seasonal use of a formulated diet; the main reason is for this was to reduce the risk of fish disease occurrence.In contrast, inshore cage culture uses wooden frame cages with foam float at a depth that is normally<10 m.The cost of wooden frames and the related operating fees are normally less expensive than those of offshore cage culture.The lower cost of building wooden frame cages means the aquaculture not only uses less space, but also employs a high cage density in ideal coastal areas.To improve the yield, the smaller space is used with the highest density limitation for Chinese sea perch,which as former study proved will slows the growth rate of the fish(Hwang et al., 2014).Thus, more resources are needed for aquaculture such as fish meal and fuel, which will create heavier burdens on the environment.Both of high density application of inshore cage culture systems in inshore aquaculture area and high density cage culture can reduce the speed of seawater flow, which will eventually accelerate the accumulation of inshore cage culture area’s organic sediments under the cage as former study shown (He, 2015).Sediment will make it extremely difficult to clean the area creating environmental pollution (Pereira et al., 2004; Aguado-Giménez et al., 2011).In addition, the occurrence of fish disease is riskier than for the offshore cage culture system (He,2015).All of these make the current inshore cage culture system an unsustainable aquaculture system.

For a pond farming system, although the Doumen District of Zhuhai has a brand certificate titled “Products of Geographical Indication of People Republic of China” and a technical advantage, farmers in this area have only achieved a medium level of consistent development in scale efficiency.Extensive production, poor market access, and a shortage of scientifically sound production planning have led to a polarization of eco-economic efficiency (Cui & Chui, 2017), which will not change naturally.In addition, as ponds age over time with ongoing aquaculture activity, sediments tend to accumulate so that the normal cleaning depth does not remove them, thus increasing environmental risks as well as the occurrence of fish diseases (Steeby et al., 2004; Riera et al., 2017).Actually, water resources are abundant, its high yield offsets some of the negative eco-economic effects such as eutrophication and land occupation (Herbeck et al., 2013; Aubin et al., 2015).Moreover, the flourishing vegetation of the river body is also able to absorb pollutants from waste discharge and limit eutrophication, which also offsets some negative eco-economic effects of the pond farming system(Gennaro et al., 2006).

As the most updated system, offshore cage culture has its pros and cons.Offshore cage culture areas experience stronger waves and faster seawater exchange, shortening the pollution decay cycle.Moreover, the expense involved in establishing this type of aquaculture and the ongoing cost of using the technique in offshore areas still creates an obstacle most farmers have difficulty overcoming, so that offshore areas have a smaller area of distribution for offshore cage areas than inshore cage culture in coastal areas.Thus, offshore cage culture is more environmentally friendly (Molina Domı́nguez et al., 2001; Jin & Zhou, 2006;Guo, 2006; Varol, 2019).Nevertheless, it should be noted that the costs of building an offshore cage system and fish meal transportation are high.Actually, the high yield of the offshore cage culture means the unit cost for this system does not differ markedly from that of an inshore cage culture system (Di Trapani et al., 2014).For small scale farmers, offshore cage culture is still too difficult to implement due to the major operating costs even with government subsidies used for cage building; subsidies canfinance about 60% of the cage cost.However, because the offshore cage culture method provides a better environment for rearing fish than other systems (Du et al., 2019), the fish can grow without fish disease and live in what is essentially a wild environment.This results in fish that are in better physical shape, are of a higher quality (Table 9), and grow at a faster rate than fish raised in other systems (Hwang et al.,2014), allowing the fish products to be sold at a higher price on domestic market or even exported to other countries.Nevertheless, former research studies have proved that offshore cage culture can provide a similar fish aggregation device, thus increasing biodiversity (Riera et al.,2017).Therefore, despite the major investment required, offshore cage culture has a positive effect from an eco-economic perspective.

Table 9Chinese sea perch’s nutrition of pond farming and offshore cage culture system.

As for the current status of Chinese aquaculture, the most important need related to the development of green aquaculture is to maximize the eco-economic efficiency of the current production systems.The main problem with pond farming is the need to treat wastes to minimize the emission of nitrogen and phosphorus while minimizing the chemical oxygen demand.In addition, for farmers with low scale and technical efficiencies, feeding more efficiently is also the main way to reduce their environmental impact (Jackson et al., 2003).The main problems for the sustainable development of inshore cage culture are the use of fresh fish meal and the high cage density in inshore areas that cause water eutrophication and a high risk of fish disease occurrence.Thus,improvement in the fish meal feeding system is needed as soon as possible.Meanwhile, scientifically sound and detailed feeding methods should be provided to farmers so that they can further improve the utilization rate of fish meal (Ballester-Moltó et al., 2017).Spatial planning and fish disease prevention should also be prioritized by stakeholders (Ferreira et al., 2014).In addition, the current inshore cage culture system mostly uses foam floats that always cause serious particle contamination because the foam breaks down over time, is difficult to control, and is harmful to the health of local residents.Note that the treatment for particle contamination is costly and difficult to achieve.Although offshore cage culture has greater eco-economic efficiency, the construction and operation costs are too high for small and medium scale farmers.Thus, the operation and generalization of this system will be another major issue in support of the sustainable development of the aquaculture industry.

At present, the provinces and cities in the study region have carried out related experiments in support of the sustainable development of Chinese sea perch aquaculture.Fuding in Fujian has renovated the production of wooden cage frames since 2019.This move aims to support the majority of farmers to replace wooden cage frames and to relocate aquaculture cages into specific planning areas so that inshore cage culture in Fuding can be more environment friendly.The goal of this relocation is to offer government subsidies that will cover about 60% of the cost of building new plastic cage frames.With the new cages,based on solid research related to the spatial planning of aquaculture,specific aquaculture areas have been identified.This type of frame is normally cube-shaped; its border is about 20-24 m long on the four sides with an 8-15 m deep net.The new type of cage will be set up in the planning area.The new material is more environmentally friendly,which can reduce particle contamination from inshore cage culture.With the above renovation, the eco-economic efficiency of inshore cage culture is expected to increase remarkably.With a view of further increasing the market price of the product and enhancing the brand advantage for sales, Doumen of Zhuhai has started to prepare for the establishment of a Chinese sea perch aquaculture association.Relevant policies for waste discharge are already in preparation in support of the sustainable development of aquaculture, with the goal of reducing water pollution caused by aquaculture to some extent.In addition, some farmers invest 30-40 tails into four major Chinese carp individuals per mu during Chinese sea perch farming to help regulate the water quality.The fish can not only be sold for a good price (100 yuan/mu), but also reduce the discharge of water pollutants.

5.Conclusions and research prospections

5.1.Conclusions

As the second highest production volume species of China marine fishes in 2018, Chinese sea perch has been steadily increasing in the recent years in terms of the yield and the main contributors for the main marine fish production area are Guangdong and Fujian.The main systems for Chinese sea perch aquaculture are pond farming, inshore and offshore cage culture.In the main marine fish production area, the most representative area of pond farming system is Doumen.For inshore and offshore cage culture, the most representative area is Fuding.

The analysis has been done to evaluate eco-economic performance of main aquaculture systems for Chinese sea perch and further explore the optimal eco-economic aquaculture system based on the existing main culture systems.It turns out that the deduction of simulated waste fee doesn’t have significant effect on eco-economic performance of major aquaculture system for Chinese sea perch, and its economic efficiency and eco-economic efficiency are highly consistent.Meanwhile, the ranking of all three types of efficiency is the same, i.e.pond farming,offshore cage culture and inshore cage culture.Although all three types of efficiency of eco-economic performance drop slightly compared to economic performance, pond farming system still maintains the highest eco-economic efficiency.The reasons for this high efficiency lie not only in its abundant water resources, great vegetation conditions and strong environmental self-purification ability, but also in the high yield and relatively small environmental pollution of formulated diet.However, it is worth noting that the polarization of technical and scale efficiencies also shows that there is a great gap between some samples and the strongly effective point in DEA for pond farming system.With stricter access conditions for inshore and offshore cage culture, it can be seen that pond farming still has lower access, less investment and lower technical requirements than the other two systems.These characteristics can be a double-edged sword for sustainable development of pond farming.

Inshore cage culture, similar with pond farming, also show a huge disparity with all three types of efficiency.But compared with pond farming, inshore cage culture cannot provide a higher level of remuneration and the main reason is the unscientific feeding method for some farmers.And compared with offshore cage culture, under the similar feeding method, inshore cage culture has higher risks of fish disease occurrence and lower product quality.Furthermore, with a slower water flow speed, the nitrogen, phosphorus and COD produced by aquaculture metabolism have aggravated eutrophication of the bay and accelerated sediment deposition.Those negative impacts can be seen from the data analysis results that eventually lower its eco-economic efficiency.

Offshore cage culture is the only system that can achieve a positive change from economic performance to eco-economic performance, but its efficiency is affected by the high cost of frame building and operation.The eco-economic efficiency of offshore cage culture is lower than that of pond farming and higher than that of inshore cage culture.The positive effect is mainly due to the assumed eutrophication discharge, the faster growth rate and higher quality of its products.However, the huge investment in cage frame building and high transportation cost for fish meal and equipment maintenance are the obstacles for small and even medium farmers to join in.Innovation for business practice is needed to accelerate the generalization for this system.But with the better living conditions, the higher quality products can be sold at a higher price,which can ultimately increase the eco-economic efficiency.

5.2.Research prospections

This study mainly focuses on the current major systems in use for Chinese sea perch aquaculture in the agglomeration areas; however, the sample size is still small.Thus, further data collection and fixed-point tracking will be conducted as a part of future research.For the conversion of the waste discharge related to Chinese sea perch aquaculture,“The First National Pollution Source General Investigation of Aquaculture Pollution Source Pollution loads Manual” was used to simulate the waste fee; individual differences among the three aquaculture systems and other reasons caused some deviation in the simulation.Furthermore, sediments generated by aquaculture metabolism and the particulate pollution of inshore cage culture were not included in the analysis indicators, which need to be investigated in further research.

The treatment for aquaculture waste is the key to the sustainable development of the pond farming system.As for inshore cage culture,the replacement of fish meal and renovation of the cage frame are the most essential issues for the industry’s future development.Offshore cage culture also needs technical innovation with the better use of fuel during the transportation of fish meal and improvement in formulated diet.This system needs a new business practice if it is going to be generally used among small- and medium-scale farmers.

CRediT authorship contribution statement

Zhiyi Zhang: Formal analysis, Methodology, Project administration,Software, Writing - review & editing.Xiu Fang: Investigation.Longqi Sun: Investigation.

Acknowledgments

During the field survey, the Industrial Economic team, Zhuhai Comprehensive Test Station and Zhangzhou Comprehensive Test Station of China Agriculture System Marine Fish Centre have contributed very considerate input, which is sincerely appreciated.The authors take sole responsibility for this paper.

Appendix A.Supplementary data

Supplementary data to this article can be found online at https://doi.org/10.1016/j.aaf.2021.02.004.

Funding

This research was funded by China Agriculture Research System(CARS-47).

Conflicts of interest

The authors declare no conflict of interest.

Aquaculture and Fisheries2022年6期

Aquaculture and Fisheries2022年6期

- Aquaculture and Fisheries的其它文章

- Impact of anthropogenic activities on changes of ichthyofauna in the middle and lower Xiang River

- Environmental variables affecting the gillnet catches and condition of Labiobarbus festivus and Osteochilus hasseltii in northern Malaysia

- Genetic diversity and relatedness inferred from microsatellite loci as a tool for broodstock management of fine flounder Paralichthys adspersus

- Retention of fin clips and fin and operculum punch marks in rainbow trout

- Preliminary data of life history traits of Mormyridae (Actinopterygii:Teleostei) in the Upper Sanaga River, Central Region of Cameroon

- Hybrids production as a potential method to control prolific breeding in tilapia and adaptation to aquaculture climate-induced drought