农药雾滴沉积特性研究进展与展望

康 峰,吴潇逸,王亚雄,郑永军,李守根,陈冲冲

·农业装备工程与机械化·

农药雾滴沉积特性研究进展与展望

康 峰1,吴潇逸1,王亚雄1,郑永军2,李守根1,陈冲冲1

(1. 北京林业大学工学院,北京 100083;2. 中国农业大学工学院,北京 100083)

农药雾滴在喷施过程中因无法有效润湿靶标而出现反弹、飞溅、聚并滚落等现象,致使周边环境受侵害,严重威胁生态稳定及安全。由于雾滴沉积过程较为复杂,且相关机理尚不成熟,因此雾滴沉积特性研究是实现药液有效沉积,推动病虫害防治技术快速发展的关键。该文从单液滴微观动力学和雾滴群沉积飘移特性两个方面对目前研究进行总结,主要阐述了单液滴撞壁行为研究方法、影响单液滴界面行为的主要因素及单液滴撞壁理论建模研究;雾滴群分布特性研究方法、沉积量收集及检测方法以及雾滴群建模研究;并探讨了以上两种主流研究思路对最终沉积量评估的贡献及目前存在的瓶颈问题,且基于此提出了未来发展建议,以期为农药沉积特性研究及病虫害防治技术提供参考。

农药雾滴;沉积;飘移;单液滴;雾滴群;界面行为

0 引 言

农药作为全球重要农业生产资料,是实现农业增产丰收的重要保障。数据显示,截至2020年底,中国水稻、小麦、玉米三大粮食作物农药利用率为40.6%。现阶段,化学农药是病虫害防治的重要手段,但中国仍采用大面积、大流量的施药方法,大量药液在喷施过程中产生飘移,作物得不到有效化学防治,不仅造成了资源浪费,更严重威胁了生态稳定及安全[1-2]。近年来,随着中国农业机械化的快速发展,高效植保机械化技术获得较好的推广应用。但总体来说,植保机械性能和施药技术水平还比较落后,无法满足当今农业生产和环境保护的要求[3-6]。2021年中央一号文件强调,十四五期间应“持续推进化肥农药减量增效,推广农作物病虫害绿色防控产品和技术”,发展绿色防控科技、大幅降低化学农药用量是当前科研的核心任务[7]。

农药主要通过茎叶喷雾方式施用,因无法有效润湿靶标表面会出现反弹、飞溅、聚并滚落等现象[8]。基于此,大量学者开展了液滴微观动力学研究,通过建立单液滴撞壁模型对液滴界面行为进行预测。但在实际施药环节,液滴间相互作用及冠层结构等因素均对沉积行为产生影响,故从单液滴出发对沉积量进行预测是远远不够的[9-10]。另一方面,研究人员以雾滴群为研究对象,通过实地田间试验来获取沉积量与初始可控变量的简单函数关系,在理论建模方面则试图引入单液滴撞壁模型来进一步模拟喷施过程,但由于其中关键参数难以准确获取,模型效果尚不理想[11-13]。本文综述了单液滴微观动力学和雾滴群沉积飘移特性两种主要研究思路的研究进展,介绍了单液滴撞壁动态行为研究方法、影响单液滴撞壁动态行为的主要因素及单液滴撞壁理论建模研究;雾滴群分布特性研究方法、沉积量收集及检测方法以及雾滴群建模研究。明确了目前研究中存在的瓶颈问题,并基于此提出了未来发展建议,为农药沉积特性研究及病虫害防治技术提供参考。

1 单液滴微观动力学研究

农药喷施过程中,喷雾雾滴以单液滴形式作用于靶标叶片,由于单液滴运动及撞击过程构成雾滴群动态行为,因此建立单液滴撞壁行为模型对群体雾滴撞击规律的探究及最终沉积量的评估至关重要。雾滴撞壁行为在自然界和工业领域中经常出现,相关研究也较早起步于工业领域,例如涂层、清洁、冷却,燃烧中喷雾与壁面的相互作用、喷墨打印以及电子产品的焊接和生物技术中的微阵列[14-16]。

1.1 单液滴撞壁行为研究方法

单液滴撞击靶标的微观动力学研究从Worthingdon利用电火花设备观察牛奶及汞在烟熏前后玻璃板的反弹现象就已开始,尽管有140多年的研究,但其动力学直到近20多年高速摄影技术出现后才逐渐开始得到解释[17-18]。1947年,Bowden等[19]首先利用胶片相机记录了硝酸甘油撞击壁面的全过程,研究了撞击时间和爆炸引发时间的关系。Pederson[20]则将胶片相机与远距显微镜结合,对单液滴撞击加热壁面的运动特性和传热特性进行了研究,该系统的线性放大倍数可达15.5倍。到20世纪90年代,数码相机开始在工业研究领域投入使用,CCD作为灵敏度高、噪声小的感光元件广泛应用于研究中[18,21]。Mao等[22]使用快门速度达到1s的CCD相机对室温下雾滴撞击平面的反弹和铺展现象进行了拍摄,并建立了反弹模型。Kim等[23]使用30 fps CCD相机拍摄了100m粒径雾滴撞击固体表面的过程,并使用撞击前雾滴运动参数估计雾滴铺展的时间。随着现代高速数码技术的发展,研究中相机的拍摄速度越来越快,观测界面的分辨率和清晰度也得到了进一步提升。高速摄像头结合等幅波激光仪等其他相关设备亦可实现对喷雾撞壁气液相形态的精确捕捉[24-25]。相较于其他领域,高速摄影技术在农业喷雾领域研究中的应用起步较晚,研究初期使用的相机拍摄速度和分辨率也较低。1998年,Reichard等[26]利用VC-81D黑白摄像机对液滴撞击空心菜叶片、小麦叶片、黄豆叶片、狐尾草叶片进行了观测,并发现雾滴在小麦叶片、空心菜叶片上会发生反弹现象。贾卫东等[27]利用幻影V310s型高速数码摄像机,并配合两组长焦微距镜头(焦距分别为222 mm和418 mm),对雾滴撞击大豆叶片表面过程进行拍摄,拍摄速度为11 700 fps,并计算了液滴发生沉积和回缩现象的临界值。崔迎涛等[28]使用CP-2200型注射泵产生大小均匀的液滴,利用拍摄速度5 000 fps的GC-PX100BAC型高速摄像机对单液滴撞击大豆叶片过程进行拍摄,测量了液滴在大豆叶片表面的接触角并对其表面黏附性进行了测试。图1为高速摄影下蒸馏水液滴撞击大豆叶片的照片。

随着计算机技术的飞速发展,虚拟仿真技术受到越来越多学者的青睐。研究人员基于二维或三维模型,通过计算流体力学(Computational Fluid Dynamics,CFD)来模拟单液滴撞击靶标表面后的行为过程。虚拟仿真技术通过获取丰富的界面信息提高了液滴微观形态变化的可视性,是研究液滴界面行为的有效手段。1981 年,Hirt和Nichols首先提出VOF(Volume of Fluid)方法[29]。VOF模型是一种固定在欧拉网格下的表面跟踪方法,其通过定义流场每个网格中目标流体体积与网格体积的比值获得流体体积函数,并将体积函数引入流体控制方程组中进行求解,实现对多相流运动界面的追踪。董祥[30]采用VOF方法对单滴蒸馏水和非离子表面活性剂溶液撞击竹蕉、一品红、天竺葵和玉米植物叶片表面后的动态铺展过程进行了数值计算和仿真分析,初步获得了沉积和反弹过程中雾滴内部流场和压力场的变化情况。Delele等[31]同样通过VOF方法对水滴撞击不同植物叶片(苹果、梨、韭菜和卷心菜)的动态冲击行为进行了研究。谢亚星等[32]采用Fluent中多相流计算模型VOF对单液滴碰撞枸杞叶片的过程进行了数值模拟,结果表明仿真结果与试验结果的一致性较高。2018年,Zhu等[33]使用CLSVOF(Couple Level Set & Volume of Fluids)界面追踪法,评估了3种常用农药(百菌清、乐果和马拉硫磷)雾滴在茶树叶片表面的沉积差异。此外,作者还分别研究了农药雾滴在叶片表面横向和纵向的液相形态、表面润湿性、压力和速度分布,发现界面追踪模型计算的预测结果与实际结果具有一致性。这也证明了CLSVOF界面追踪法在深入研究农药雾滴撞击叶面动力学行为方面具有极大的应用潜力。但在目前的仿真模拟中,靶标叶片的模型构建及特征描述尚有欠缺,还需进一步完善靶标以提高模型准确性。

1.2 影响单液滴撞壁动态行为的因素

随着观测技术的提升,研究人员开始探究液滴撞壁行为的运动机理,试图对该动态过程进行理论推导。研究发现,液滴的界面动态变化过程与喷头雾化特性、药液性质及靶标特性密切相关[34-37]。

1.2.1 雾化特性对液滴撞壁动态行为的影响

雾化特性参数包括雾滴粒径、雾滴速度和雾锥角,其中,雾滴粒径和速度是影响雾滴沉积和飘移的主要因素[38-39]。在喷施过程中,较大雾滴易沉降,不易随风飘移,但高速时易飞溅,低速时易出现反弹和聚并滚落现象;较小雾滴则易飘散,靶标有效覆盖率较差。研究中人们经常使用雷诺数()和韦伯数()对其进行描述。Levin等[40]对液滴撞击干燥与湿润表面的飞溅现象进行观察后发现,当冲击速度足够大时,液滴在碰撞点附近将溅射出皇冠形液膜,作者因此将其命名为“冠状结构”并提出了破碎机制。Yang等[41]在雾滴撞击草莓表面的试验中,用微型计量泵和滴管分别从25、50、75、100、125和150 cm的高度释放出直径为0.5至4 mm的液滴,结果表明雾滴直径和喷雾高度对发生溅射雾滴的数量、流量、速度、溅射角和能量影响显著。其中单液滴运动的初始速度和撞击后的飞溅角度显著相关,且雾滴直径、运动距离、初始速度和动能呈现威布尔累积分布函数关系。Usawa等[42]研究了不同半径液滴撞击光滑且部分润湿壁面的飞溅临界值,发现半径越小,飞溅所需的撞击速度就越大,但当≥5时,飞溅将被抑制。张瑜等[43]探究了不同初始速度及不同初始直径对液滴铺展的影响,结果显示:低速时表面张力阻碍铺展,液滴回缩反弹,高速时动能克服势能,液滴发生破碎;大直径有利于铺展破碎,小直径有利于铺展反弹。张帆等[44]定性分析了初始液滴直径()、液滴撞击速度、湿壁面及倾斜角度对飞溅现象的影响,并对不同角度湿壁面的撞击情况进行了水平拍摄。结果显示:高初速度及小直径易导致飞溅产生。另外,临界速度和临界直径的大小随倾角增大而增加。图2为倾斜角度为10°,液滴撞击速度为2.90 m/s,液滴直径分别为2.17、2.44、3.27 mm时的飞溅情况。李玉杰等[45]基于相场的混合格子Boltzmann有限差分法,模拟液滴在不同初始状态下撞击不同大小圆柱内表面的形态变化,并分析了液滴密度、黏性等自身物理性质对撞击现象的影响,其发现高韦伯数下液滴会产生分裂现象。以上有关雾化特性的研究可为喷头选型提供理论基础,研究人员还可通过不同喷头与植物的适用性试验选择最优喷头以改善沉积效果。

1.2.2 药液性质对液滴撞壁动态行为的影响

药液性质对单液滴撞壁行为影响较为显著,有关生化领域的研究也集中在该层面。雾滴的物理化学性质包括表面张力、黏度及密度等。不同表面张力的雾滴在作物叶片的接触角不同,从而影响了雾滴的粘附性能。以往研究表明,在农药制剂中添加适宜表面活性剂是提高药液对靶润湿沉积的有效方法[46-48]。1991年,Trapag和Szekely发现表面张力对雾滴形态变化起到非常重要的作用[49]。1994年,Holloway[50]通过大量试验证实在农药助剂中加入适宜表面活性剂可提高雾滴在植物靶标的粘附性。后期研究表明,表面活性剂分子通过非共价键相互作用(洛伦兹-范德华力、疏水相互作用及静电相互作用等)吸附于气-液和固-液界面,从而改变靶标界面性质,实现液滴有效润湿沉积[51-53]。Bergeron等[54]发现在药液中加入稀释的聚合体溶液可有效抑制反弹发生,且高黏度溶液可以减少液滴反弹。顾中言等[55]研究发现农药药液本身均含有表面活性剂,但由于大多数药剂推荐浓度的表面张力值大于靶标临界表面张力值,即药液中的表面活性剂浓度未达到临界胶束浓度,导致大多数药剂难以在植物表面实现有效润湿。2007年,顾中言等[56]又对甘蓝叶片表面的铺展特性进行了研究,发现向水中添加表面活性剂TX-10后,液滴能够很好地在甘蓝叶表面润湿铺展。这是因为TX-10可降低水的表面张力,使得溶液的表面张力小于甘蓝叶片的临界表面张力,同时又使溶液中表面活性剂浓度达到或超过临界胶束浓度。

表面活性剂的分子成分可分为阳离子、阴离子、非离子和两性基团。其中,阳离子表面活性剂对植物具有消泡性和毒性,因此单一阳离子成分表面活性剂不推荐使用。还有研究发现,在相同浓度和结构下,离子表面活性剂在带电介质中具有较高的表面张力,因此在对表面活性剂进行选择前可先对叶片的电荷特性进行评估[46,57]。此外,表面活性剂研究中也经常涉及到有机硅化合物[58-59]。Wang等[60]探讨了不同表面活性剂对缓释微球阿维菌素-苯甲酸酯(Emamectin-Benzoate,EMB)粒径和分散性的影响。缓释制剂允许农药活性成分在较长时间内持续和有效释放,以减少农药在非目标环境挥发、降解和损失。该方法是目前提高农药使用率最有效的方法之一。试验结果表明,样品在聚合物稳定剂聚乙烯醇(Polyvinyl Alcohol,PVA)和复合非离子表面活性剂聚氧乙烯蓖麻油(EL-40)的最佳配方混合液中具有良好的分散性,且优选的EMB农药缓释微球具有优异的抗光解性能和稳定性,可在叶片均匀分布[47, 61]。Ma等[62-63]基于植物叶片表面化学成分中含有三萜烯类化合物的特性,选择具有刚性三萜疏水骨架、亲水葡萄糖醛以及具有较好表面活性的天然产物甘草酸,制备了新型丁硫克百威乳油制剂,实验发现游离在溶液中的甘草酸在一定浓度下可抑制液滴在靶标表面弹跳。Zhao等[58]制备了含有三硅氧烷表面活性剂和阿维菌素农药的纳米颗粒,发现随着三硅氧烷表面活性剂含量的增加,可有效降低该粒子在叶面的接触角。另外,Song等[51,64]观察到水稻、小麦、花椰菜、甘蓝等超疏水叶片上有较多条纹和弯曲结构,研究发现该结构可诱发液滴的各向异性铺展和反弹,极大增加了农药液滴沉积的难度。针对该问题,其团队将具有显著拉伸黏度的柔性聚合物PEO与表面活性剂ATO相结合,通过提高液体黏度使单液滴在撞击后的反冲阶段有较高的拉伸长度,耗散了液滴大部分能量从而抑制破碎现象,同时该过程又确保了液滴内表面活性剂分子有足够的时间移动到接触界面,以实现较好的润湿性。图3及图4可见该囊泡型表面活性剂抑制液滴在超疏水叶片表面飞溅的优势所在。

1.2.3 靶标特性对液滴撞壁动态行为的影响

植物叶片特性作为固有特性一般只能通过提高认识水平来推动后续研究。植物叶片表面主要为蜡质层,其作为靶标作物界面最外层结构,决定着植物叶片的亲/疏水性,使作物免受周围环境的影响[65-66]。外蜡质层的界面特性包括表面化学成分、表面拓扑形貌及表面自由能,其共同决定着植物靶标的润湿特性。该润湿特性通常被划分为疏水性、超疏水性,亲水性和超亲水性,其被浸润的难易程度直接决定了叶片药液持有量的多少[67]。植物叶片表面蜡质层主要由长链烷烃、伯醇、醛、酮、脂肪酸及三萜烯类化合物组成,通常利用气相色谱质谱联用仪(GC-MS)及液相色谱质谱联用仪(LC-MS)等方法进行定性及定量研究[68]。1974年,Hall和Burke对叶片表面显微结构进行了观察,认为蜡质层的厚度和绒毛会影响叶片润湿性[69]。1993年,Stevens等[70]发现植物叶片蜡质含量的多少对液滴在叶片表面的动态行为有一定影响,且液滴在蜡质含量多的叶片表面容易出现弹跳和滚落现象。Mao等[71]通过研究水稻蜡质层的化学成分认为叶片亲疏水性与碳链长度具有相关性。水稻叶片外蜡质层主要由34.3%的脂肪酸(碳链长度集中于C24~C32)、31.2%脂肪醛(碳链长度集中于C30~C34)、23.9%伯醇(碳链长度集中于C30)以及6.9%的长链烷烃等组成,显示出疏水性。总体来说,亲水性靶标叶片中伯醇含量占比较高,碳链长度集中于C26~C28之间;疏水性靶标叶片中烷烃及其衍生物含量占比较高,且碳链长度集中于C32~C34之间[36]。蜡质层厚度和碳链长度通常会随生长期和湿度的变化而变化[72-75]。Koch等[74]通过试验发现,与40%~75%的相对湿度条件相比,98%的相对湿度条件下甘蓝、刚尼桉及金莲花植物叶片的总蜡质含量和密度均会下降,叶片表面润湿性则会显著提高;而在20%~30%相对湿度条件下,三种植物叶片的总蜡质含量增加,润湿性降低。说明在干旱胁迫下植物叶片为了减少水分蒸发会自主增加蜡质层厚度。

植物叶片表面拓扑形貌(表面粗糙度)包括叶片表面的微观结构、气孔和不规则附着物(毛、刺等)等[64,76-77]。研究人员通常利用扫描电镜(SEM)和透射电镜(TEM)进行观测[78-79]。国外学者Barthlott和Neinhuis最早开始关注荷叶非光滑表面特性,通过观察荷叶表面微观形态结构发现,荷叶表面具有微米级的乳突结构和蜡质物,其共同导致了荷叶的超疏水和自清洁功能[80-83]。同样具有微米级乳突结构的还有水稻叶片,水稻叶片表面定向排布着亚毫米级的沟槽结构,且布满乳头状突起,这种突起包被着蜡质,水稻叶片因此表现为超疏水性。另外,乳突的排列形式还导致液滴在水稻叶片表面滚动呈各向异性[64,84]。Koch等[85]从不同尺度对植物表面结构进行了观测,其发现宏观层面上观测到的外观形貌与扫描电镜下的微结构差异很大,功能也有所不同。此外,扫描电镜结果显示,黄瓜叶片表面光滑,存在具有亲水性的长绒毛,表现为亲水性表面;棉花叶片表面粗糙度略高于黄瓜,表现为中等亲水性表面[61,77]。图5和图6分别为荷叶及水稻叶片表面的电镜扫描图。表面自由能则是物体表面分子间作用力的体现,其由靶标表面化学成分和表面拓扑形貌共同影响,通常采用的计算方法包括Owens二液法、Zisman法、OWRK法等[86-88]。

式中,w,c分别代表Young方程中的本征接触角以及Wenzle方程和Cassie-Baxter方程中的表观接触角,(°);s和v分别代表表面活性剂液滴在固体和气体表面的接触角,(°);代表粗糙度,表示表观固体接触面积与本征固体接触面积之间的比值,≥ 1;s、v分别代表固体接触面积和气体接触面积占总面积的比值,s+v= 1;SV为固-气界面张力,N⋅m-1;SL为固-液界面张力,N⋅m-1;LV为气-液界面张力,N⋅m-1。

另外,润湿状态由低黏附性的Cassie-Baxter状态转变为高黏附性的Wenzel状态是实现药液有效润湿的关键,如图8所示。在具体试验中可通过调整相关参数以实现对接触角的调控[91]。

1.3 单液滴撞壁动力学模型

单液滴撞击固体壁面的动力学形态变化较为复杂。为了明确不同撞击结果,2001年Rioboo等[92]将撞击结果分为六类(图9)。研究发现,液滴在撞击固体干表面时,动能由法线方向转为切向方向,液滴迅速向外扩散。当撞击产生的惯性力大于将液滴凝聚在一起的毛细管力,液滴就会发生破碎,否则其将继续扩散,直到动能耗尽。在扩散过程中,一部分动能发生粘性耗散,另一部分转化为表面能。此时,液滴的几何形状通常呈现为扁平的圆盘,且周围有一个较厚的自由圈层边缘。当液滴扩散到最大程度时,此时的直径被称为最大扩展直径(max)[22]。如果此时液滴的表面能仍然很大,液滴将经历反冲阶段,即出现飞溅或反弹现象[14,93-95]。

对于液滴撞击后的扩散阶段,研究人员通常使用基于能量平衡的简单半经验分析模型来预测最大扩散因子[96]。相关试验表明,的计算值与若干组实验数据相当吻合,但该模型假设了液滴初始动能和表面能除部分耗散外,其余能量均转化为沉积壁面表面能,当该假设不成立时此模型适用性不强[22,97]。Roisman等[98]发现,当单液滴扩散后出现后撤现象时,壁面上的扩散液层因表面张力效应而会被自由边缘包围,该过程由自由边缘与内部液层的相互作用以及壁面对边缘施加的力所决定。因此其从自由边缘的质量和动量平衡方程出发,结合惯性力、黏性力、表面张力以及润湿性效应对该过程进行了建模研究,该模型能够较准确的预测自由边缘的直径变化。

有关反弹和破碎阶段的建模多采用传统的能量平衡原则,即在撞击过程的关键阶段强制能量和质量守恒,这种能量平衡模型已广泛用于描述液滴撞击的简单计算[22,94,99-100]。目前研究中的撞击模型多为代数形式的理想化模型,并最大限度地减少经验拟合,其优点在于计算简便,易于应用在新的喷雾场景中[99-100]。也有研究人员通过试验拟合产生一种预测附着、反弹和飞溅的概率法[101-103]。对于反冲阶段,Xu等采用弹簧-质量-阻尼方程来描述该过程,并试图用实际物理参数半经验地确定其系数[104]。Okumura等[105]则通过尺度论证明了液滴在小变形的极限下可表现为弹簧质量系统。Kim和Chun[100]在其基础上补充了能量平衡公式,并将水滴形状近似为圆柱体,结果表明其能较好地描述铺展和液滴后撤行为。

反弹的标准最早由Mao等提出,即判断撞击后剩余能量能否使液滴发生反弹,其通过一系列能量平衡对反弹行为进行了预测。但是,Mao只考虑了液滴从正上方撞击水平表面的情况[22]。2015年,Dorr等[106]对此模型进行了扩展,其补充了多角度的撞击情况,通过计算“剩余能量”(ERE,Excess Rebound Energy)来预测反弹的发生,当ERE> 0时,反弹发生。在破碎阶段建模中,为了判定液滴动能能否克服毛细管效应而导致液滴破碎,Mundo等[107]提出了判定依据:

式中=/()0.5,=2/,=/,值用于描述与液滴性质相关的因素,crit用于表征撞击壁面的表面特性,包括粗糙度及润湿性。当满足>crit时,破碎发生。当≤crit时,液滴将出现粘附或反弹现象,具体行为可结合Dorr模型中剩余能量公式进行进一步判别。临界值crit的取值可根据以下公式进行计算[108]:

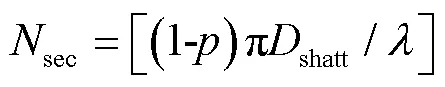

式中CA20%acetone和CA50%acetone是浓度为20%的丙酮和50%的丙酮液滴分别在叶片表面产生的静态接触角,临界值通常取两者计算得出的平均值[11]。但破碎判别方程只预测了破碎是否发生,并未对破碎产生的子液滴进行进一步分析。子液滴对液量的保留具有显著影响,因此对该阶段进行建模也是目前的研究重点。子液滴出现的形式较多,但“快速溅射”和“冠状溅射”在液滴撞击干燥壁面中最为常见[92,109]。快速溅射在液滴撞击壁面后迅速发生,冠状溅射则在扩散铺展后期发生。考虑到破碎时间的差异性,Dorr等引入飞溅扩散因子(0<≤1)对破碎时间点进行度量。以shatt=max作为破碎时液滴的直径,max为最大扩展直径[22,106,110]。=1时表示液滴在最大扩展直径时发生破碎,越小不仅可表明破碎出现的时间较早,也表明在扩散过程中液滴消耗动能较少,剩余动能可能导致子液滴产生远距离飞溅。另外,液滴发生飞溅时,通常只有部分子液滴飞离靶标表面,剩余部分仍粘附在壁面上,因此还需引入钉扎比例参数(0 ≤< 1),= 0时表示液滴完全飞溅,> 0时表示部分飞溅。飞溅出去的液体体积为Volsec=(1-)π3/6[11],子液滴(sec)的数量为[111-112]:

该过程中,子液滴数量会随溅出液体体积的减小而减少。由此可见,和同时影响飞溅产生的子液滴数,且子液滴数与成反比,与成正比。单个子液滴的动能同样可通过撞击前、破碎期间和破碎后的能量守恒方式来计算,但其较依赖于和的参数设置[11,94]。到目前为止,尚未找到理论推导的方法来确定和的参数值,这也将是未来研究的重要方向。

除分析建模外,还可采用数值模拟对撞击过程进行描述。Fukai等[113]基于有限元求解了Navier-Stokes方程,并在运动接触线处添加无滑移条件以缓解应力奇异性。1995年,Fukai通过添加接触线上前进接触角adv和后退接触角rec来完善模型,这使预测结果准确地描述了液滴扩散和后撤过程动力学演化过程[114]。Pasandideh-Fard等[97]使用VOF方法描述了黏性液滴在干燥表面和部分可湿表面的扩散过程,且对动态接触角进行了表征,动态接触角的应用可提高对液滴扩散半径预测的准确性。Tanaka等[115]采用格子Boltzmann法(Lattice Boltzmann Method,LBM)模拟了液滴在固体表面上的动力学变化过程,研究了不同韦伯数下动态接触角、接触线速度和润湿长度的变化,其结果与实际实验数据吻合较好。张莹等[116]基于界面追踪法和广义滑移边界构建了接触角模型以探究非均质壁面对液滴的俘获能力,结果表明液滴沉积于湿润壁面的能力和数与数的大小相关。韩丁丁等[117]以Oldroyd-B模型对高分子溶液黏弹性抑制液滴反弹现象进行数值模拟,发现高分子液滴接触壁面后液体内部会产生向下的作用力,该力可减小回缩速度,抑制液滴反弹。

单液滴撞壁的理论建模研究目前仍存在许多问题,如无法针对具有自由界面的撞击液滴流体动力学进行精确求解,因为其包含了复杂的固液相互作用、作为边界条件之一的动态接触角表达式、边界不稳定性出现的临界条件、三相线处不可积分的应力奇异点等问题。因此还需以基础理论研究为出发点,对其进行进一步探讨。

2 雾滴群沉积飘移研究

农药喷施过程中,液体以雾滴群的形式弥散在空气介质中,相比单液滴撞击植物靶标研究,对雾滴群的研究需考虑液滴间的相互作用,以及实际雾形和冠层结构对植物体最终沉积量的影响。目前通过群体雾滴研究雾滴沉积和飘移的方法包括两类:一是通过观测或仿真技术对喷雾场中雾滴运动信息进行捕捉并描述雾场特征,以此寻找其与沉积量间的关系[118-120]。二是通过实际试验或仿真技术计算最终沉积量,其中包括对叶片表面沉积的直接测量和通过空中及地面飘移量来侧面反映的间接测量[121-125]。

2.1 雾滴群分布特性研究方法

实际喷施过程中压力变化及不同药液性质等均会导致雾滴粒径产生变化,这削弱了喷头厂家提供的原始粒径数据的参考价值,不利于从理论层面对雾化特性与沉积效应间的关系进行阐释。1976年,相位测量球形粒子特性的理论问世,并于1984年运用到实验室中[126]。相位多普勒技术利用运动微粒的散射光与照射光之间的频差获得速度信息,通过分析穿越激光测量体的球形粒子反射或折射的散射光产生的相位移动来确定粒径大小。1991年,Hardalupas等[127]利用激光多普勒技术测量了群体雾滴在碰撞表面附近的粒径和速度,试验表明雾滴撞击壁面的角度直接影响溅射产生的粒径大小。Kalantari等[128]使用相位多普勒粒子分析仪(PDPA)对雾滴群撞击刚性壁面进行了研究,通过二次雾滴的速度和轨迹以及二次雾滴的质量和数量对喷雾与壁面的相互作用进行了表征。Lee等[129]利用相位多普勒粒子分析仪分析了多孔喷嘴的雾化特性,并与单孔喷嘴的雾化特性进行了比较。雾滴粒径信息也可通过激光粒度仪进行测量。张慧春等[119,130]利用激光成像系统和激光粒度仪测定了喷雾角和雾滴粒径,并研究了不同喷嘴的雾化机理。2020年,其团队利用开路式风洞和激光粒度仪对农药助剂在空中和地面防治时不同风速、喷头类型、喷头孔径、喷施压力、喷雾介质等情况下的雾滴粒径、分布跨度进行研究。分析了农药助剂配比、喷头结构参数、施药技术因素对雾滴粒径分布的影响。结果表明农药助剂与体积中径、分布跨度显著相关,图10为其试验测试系统。以上基于光散射原理的相关仪器可较好地实现对雾滴群的运动速度和粒径的测量,为雾滴间相互作用及多喷嘴重叠区域雾滴特征研究提供了技术支撑。

除试验观测外,也有学者通过仿真分析的方法对雾滴群运动展开研究。Dekeyser等[131]通过CFD模拟技术对几种常用喷头的羽流分布和附带空气流进行研究,证明液体分布与产生的空气流动直接相关。张宋超等[132]基于CFD方法采用SST-湍流模型对N-3型农用无人直升机作业过程中旋翼风场和农药喷洒的两相流进行了模拟,分析了喷施过程中药液的飘移情况。试验结果表明,该方法可较为准确且定性地实现对雾滴群飘移情况的模拟。张豪等[133]则在CFD中选择RNG-湍流模型、多孔介质模型和滑移网格技术构建了虚拟果园和自然风速下6旋翼植保无人机悬停条件下的复合旋翼风场模型,分析了无人机悬停高度、果树生长阶段和自然风速等因素对无人机悬停条件下的旋翼风场分布的影响,结果表明试验值和模拟值具有较好的一致性。Zhai等[134]通过Fluent软件对新型双流体扇形喷嘴的雾化机理进行了仿真研究,其采用欧拉-拉格朗日法进行建模,并在模型中使用离散相模型(Discrete Phase Model,DPM)跟踪农药雾滴的轨迹。雾滴群建模研究中,液膜破碎时间计算和粒子轨迹追踪模型的选择至关重要。另外,建模内容也可进一步扩展,使其涵盖从喷施到沉积的整个过程,该部分内容将在2.3节中进行详细介绍。

2.2 沉积量收集及检测

群体雾滴的沉积量及飘移预测试验在国外较为盛行,研究人员通常将环境因子、雾化特性、冠层结构等纳入考虑之中,通过回收喷雾液滴来对沉积量进行评估。试验一般可分为靶标沉积收集和非靶标沉积收集。在该过程中,取样阶段至关重要,其目的是最大限度地获取具有代表性的样品,因此在选取取样器时需要将其量化程度、收集效率、处理难易程度和成本问题综合考虑[135]。

水敏纸(Water Sensitive Paper,WSP)、聚酯薄膜卡片和滤纸在靶标和非靶标沉积检测中均有较多应用,特别在靶标沉积研究中,以上三种取样材料可直接固定在植物叶片表面以获取沉积信息[13,123-124,136-138]。水敏纸呈黄色,表面涂有溴酚蓝指示剂,与水滴接触后呈现深蓝色,pH值显色范围为3.0~4.6,通常用于进行覆盖率分析试验[139]。Zwertvaegher等[123]在试验中利用水敏纸对喷雾的均匀性进行了分析。Matsukawa等[137]为了评估水稻杀虫剂的杀虫效率,将水敏纸分别放置在水稻植株不同高度(底部、中部和顶部),试验发现雾滴沉积等级与褐飞虱死亡率呈正相关。但由于空气中水蒸气和露水的存在,水敏纸检测可能出现偏差。为解决该问题,Menger等[124]采取另外一种研究思路,即将加入荧光染料的药液喷施于滤纸(FP)上,喷施结束后进行拍照再通过图像处理进行药液覆盖率分析。Bueno等[122]对四种类型喷嘴进行了实际试验,建立了巴西气象条件下适用于大豆喷雾的地面沉积飘移曲线,并与欧洲气象条件下产生的模型系数进行了比较。图11为现场试验示意图,滤纸安置于下风向处,其通过荧光分析法对喷施到滤纸上的荧光剂进行了量化处理。同样,Bolat等[13]在对三种不同喷嘴类型进行喷施性能测试时,也选用了滤纸以进行沉积量定量分析,并结合水敏纸进行覆盖率测试。研究发现纸质取样器具有良好的吸收吸能,可有效地捕获液滴避免反弹现象,但量化处理较为困难。因此在进行沉积量量化试验时常选取便于清洗的聚酯薄膜卡片作为收集器。Sinha等[136]对葡萄园中两种常用喷雾系统的农药飘移情况进行了测试,其将聚酯薄膜卡片和水敏纸置于树冠上方和藤行之间的地面,并喷施带有示踪剂的溶液,后通过洗涤聚酯薄膜卡片获取沉积量化信息。

另外,在非靶标沉积试验中还经常使用不锈钢制品、尼龙绳、聚乙烯线或玻璃制品作为取样器[140-144]。Torrent等[140]对几类不同结构喷嘴在柑橘园的喷施情况进行了测试和评估,其利用尼龙绳对飘移液滴进行了收集。喷施结束后将尼龙绳干燥5 min,后在避光环境下转移到实验室进行定量分析。Brain等[142]在田间进行农药飘移测试时,分别采用不锈钢圆盘和不锈钢棒作为地面沉积和空中飘移收集器。国内张慧春等[143]以苦苣菜、棉花和稗草作为靶标植物,对农药通过空气运输并沉积到靶标植物表面(叶片或其他部位)、地面(土壤表层)以及大气(随风飘移)等不同部分的沉积进行了研究。其在开路式风洞喷施加有荧光示踪剂的喷雾,通过清洗植物叶片、地面上放置的聚酯薄膜卡和风洞中悬挂的聚乙烯线测定荧光剂含量,分析了不同体积中径、喷雾角、雾滴速度、流量、喷头高度、风速、植物类型、生长阶段等因素下农药雾化后的分配过程,定量测试了不同参数对农药在植物、地面和大气中沉积比例分配的影响。Qin等[141]在对示踪剂进行评估的试验中分别利用圆形玻璃器皿、聚酯薄膜卡和滤纸进行取样。试验表明在光稳定的条件下,示踪剂从玻璃器皿和聚酯薄膜卡的回收效果较好。在样品提取分析阶段,可通过洗脱法将化合物从取样器上提取出来,继而选用分光光度法、气相色谱法或液相色谱法等含量测定方法对提取物进行测定。另外,示踪剂回收率等特性对试验结果的准确性至关重要,为此,Qin和Nairn通过试验对几类示踪剂的优缺点及适用性进行了评估[141,145]。

2.3 雾滴群沉积飘移建模研究

群体雾滴模型通常基于田间实际试验。雾滴群撞击壁面建模阶段对沉积量影响至关重要,研究人员则试图将单液滴撞壁理论引入整体喷施模型以建立单液滴模型与群体雾滴模型间的关系。但由于液滴撞击靶标过程较为复杂,且已有雾滴群模型中对液滴间相互作用等因素考虑不足,因此模型预测效果一般[11,146]。美国农业部(USDA)林业局开发了AGDISP™及其修改版本AgDRIFT®模型,其可对喷雾飘移情况进行评估[147-148]。Zhu等[149]基于CFD和拉格朗日方法开发了DRIFTSIM,其拥有CFD模拟数据库以实现对地面飘移的预测,用户可通过操作界面来获取飘移相关数据。Kruckeberg等[150]在2012对DRIFTSIM进行了评估,发现其对近场飘移的预测更为准确,原因可能是DRIFTSIM将农药假设为水滴,因此在远场飘移时部分水滴因蒸发而影响了预测结果。2018年,Hong等[151]构建了一个综合计算流体力学模型,以预测苹果园中不同生长期冠层下农药喷雾的沉积与飘移。其利用拉格朗日粒子输运模型对农药喷施液滴进行了跟踪,并应用沉积模型表征进入多孔冠层区的液滴。在验证阶段,作者对同一果园的液滴沉积和飘移进行了测量,结果表明,在三个生长阶段下,树冠层内地面沉积和飘移量的预测与实际情况的总体相对误差分别为22.1%和40.6%。这是由于CFD模型基于农药液滴的质量平衡进行预测,但实际试验很难测得绝对理想值。同年,Hong等[34]开发了一款用于预测果园喷雾器喷雾效率及喷洒飘移的软件。该软件由CFD模拟生成的农药喷雾模型、数据分析库和人机交互界面构成,旨在初步预测特定条件下的喷雾效率和飘移程度。该特定条件包括作物类型、生长阶段、拖拉机速度、喷嘴类型、环境风速、空气温度和相对湿度,系统可结合以上条件为农药喷施提供决策。Dorr等[11]基于L-studio开发了整株植物的喷雾沉积模型,该模型综合考虑了植物叶片润湿性、撞击角度、液滴破碎及反弹行为以及产生子液滴的数量等因素,通过实际试验验证发现,其对棉花、小麦、白花藜的轨迹与沉积量预测结果较为准确。但作者指出,在数学模型的参数设置中,(飞溅扩散因子)和(钉扎比例)显著影响沉积量的预测值,因此以上参数计算还需有足够的理论支撑。2020年,Zabkiewicz等[12]在该模型的基础上使用了更新版本的软件,开发了全新的用户界面,完善了液滴破碎模型,通过试验方法表征了和参数。完善后的模型可实现对单叶、单株和多株植物的喷雾场景模拟及沉积量预测,实际试验与预测结果也呈现出较好的一致性。

3 结论与展望

农药雾滴在靶标作物叶面的沉积特性是影响农药有效利用的关键,也是关系生态环境安全的重要因素。从上述文献分析中可以看出,目前有关单液滴及雾滴群的观测技术水平较高,已可实现对喷雾液滴的精确捕捉。但单液滴撞壁模型与雾滴群沉积模型的具体关系尚不明晰。未来研究还需以基础理论研究为出发点,探明雾滴群运动机理,进而实现对沉积特性的精确描述。未来主要研究方向如下:

1)单液滴撞壁建模研究中,除了持续推进对关键参数,例如飞溅扩散因子和钉扎比例的理论推导,也可选取具体作物进行等效喷施试验,利用拟合的方式对参数进行表征。另外,可通过建立三维雾化场将目前较为成熟的单液滴撞壁模型引入雾滴群建模研究中,并以此为基础继续深入研究液滴间的相互作用机理。

2)目前存在的单液滴飞溅阈值等判别公式仅对相应撞壁行为发生与否进行了判断,并未对靶标实际沉积量进行计算。该部分可引入图像处理技术通过识别单液滴撞壁后的液滴轮廓来进行液量估算,建立行为判别与实际沉积量之间的关联。

3)在实际喷施过程中,由于农药雾滴在叶片表面累积,叶片表面特性发生改变,撞击行为也随之改变。后期需重点关注雾滴撞击液膜的动力学变化过程,探究雾滴在液膜表面接触角的变化趋势以明确液膜对沉积行为的具体影响。

4)冠层结构对沉积量的影响极其显著,目前在沉积研究中对植株结构建模较少。未来可选取叶密度、植株高度等参数对不同生长期或冠层高度的植株进行表征,通过等效喷施试验观察不同参数下的农药沉积差异,使喷施方案更具现实意义。

[1] 农业农村部科技教育司. 我国三大粮食作物化肥农药利用率双双超40%[EB/OL]. (2021-01-19)[2021-04-07]. http:// www. kjs. moa. gov. cn/gzdt/202101/t20210119_ 6360102. htm.

[2] 何雄奎. 中国植保机械与施药技术研究进展[J]. 农药学学报,2019,21(Z1):921-930.

He Xiongkui. Research and development of crop protection machinery and chemical application technology in China[J]. Chinese Journal of Pesticide Science, 2019, 21(Z1): 921-930. (in Chinese with English abstract)

[3] 郑加强,徐幼林. 环境友好型农药喷施机械研究进展与展望[J]. 农业机械学报,2021,52(3):1-16.

Zheng Jiaqiang, Xu Youlin. Development and prospect in Environment-Friendly pesticide sprayers[J]. Transactions of the Chinese Society for Agricultural Machinery, 2021, 52(3): 1-16. (in Chinese with English abstract)

[4] 何勇,肖舒裴,方慧,等. 植保无人机施药喷嘴的发展现状及其施药决策[J]. 农业工程学报,2018,34(13):113-124.

He Yong, Xiao Shupei, Fang Hui, et al. Development situation and spraying decision of spray nozzle for plant protection UAV[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2018, 34(13): 113-124. (in Chinese with English abstract)

[5] 周良富,薛新宇,周立新,等. 果园变量喷雾技术研究现状与前景分析[J]. 农业工程学报,2017,33(23):80-92.

Zhou Liangfu, Xue Xinyu, Zhou Lixin, et al. Research situation and progress analysis on orchard variable rate spraying technology[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2017, 33(23): 80-92. (in Chinese with English abstract)

[6] 郑永军,陈炳太,吕昊暾,等. 中国果园植保机械化技术与装备研究进展[J]. 农业工程学报,2020,36(20):110-124.

Zheng Yongjun, Chen Bingtai, Lyu Haotun, et al. Research progress of orchard plant protection mechanization technology and equipment in China[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2020, 36(20): 110-124. (in Chinese with English abstract)

[7] 中华人民共和国国务院新闻办公室. 中共中央国务院关于全面推进乡村振兴加快农业农村现代化的意见[R]. (2021-01-04)[2021-04-07]. 2021. http: //wwngw. gov. cn/zhengce/2021-02/21/content_5588098. htm.

[8] Xu M, Li X, Riseman A, et al. Quantifying the effect of extensional rheology on the retention of agricultural sprays[J]. Physics of Fluids, 2021, 33(3): 032107.

[9] C G, Fonte A, R S, et al. Dose expression for pesticide application in citrus: Influence of canopy size and sprayer[J]. Agronomy, 2020, 10(12): 1887.

[10] Liu X, Liu X, Li Y, et al. Estimation model of canopy stratification porosity based on morphological characteristics: A case study of cotton[J]. Biosystems Engineering, 2020, 193: 174-186.

[11] Dorr G J, Forster W A, Mayo L C, et al. Spray retention on whole plants: Modelling, simulations and experiments[J]. Crop Protection, 2016, 88: 118-130.

[12] Zabkiewicz J A, Pethiyagoda R, Forster W A, et al. Simulating spray droplet impaction outcomes: Comparison with experimental data[J]. Pest Management Science, 2020, 76(10): 3469-3476.

[13] Bolat A, Özlüoymak Ö B. Evaluation of performances of different types of spray nozzles in site-specific pesticide spraying[J]. Semina Ciências Agrárias, 2020, 41(4): 1199-1212.

[14] Josserand C, Thoroddsen S T. Drop impact on a solid surface[J]. Annual Review of Fluid Mechanics, 2016, 48(1): 365-391.

[15] Madden L V, Bucker Moraes W, Hughes G, et al. A meta-analytical assessment of the aggregation parameter of the binary power law for characterizing spatial heterogeneity of plant disease incidence[J]. Phytopathology, 2021. doi: 10.1094/PHYTO-02-21-0056-R.

[16] Chen H, Liu W, Zheng Z, et al. Impact dynamics of wet agglomerates onto rigid surfaces[J]. Powder Technology, 2021, 379: 296-306.

[17] Worthington A M. A second paper on the forms assumed by drops of liquids falling vertically on a horizontal plate[J]. Proceedings of the Royal Society of London, 1876, 25: 498-503.

[18] Thoroddsen S T, Etoh T G, Takehara K. High-speed imaging of drops and bubbles[J]. Annual Review of Fluid Mechanics, 2008, 40(1): 257-285.

[19] Bowden F P, Mulcahy M F R, Vines R G, et al. The period of impact, the time of initiation and the rate of growth of the explosion of nitroglycerine[J]. Proceedings of the Royal Society of London. Series A, Mathematical and Physical Sciences, 1947, 188(1014): 311-329.

[20] Pedersen C O. An experimental study of the dynamic behavior and heat transfer characteristics of water droplets impinging upon a heated surface[J]. International Journal of Heat & Mass Transfer, 1970, 13(2): 369-381.

[21] Yarin A L, Weiss D A. Impact of drops on solid surfaces: Self-similar capillary waves, and splashing as a new type of kinematic discontinuity[J]. Journal of Fluid Mechanics, 1995, 283: 141-173.

[22] Mao T, Kuhn D C S, Tran H. Spread and rebound of liquid droplets upon impact on flat surfaces[J]. Aiche Journal, 1997, 43(9): 2169-2179.

[23] Kim H Y, Park S Y, Min K. Imaging the high-speed impact of microdrop on solid surface[J]. Review of Scientific Instruments, 2003, 74(11): 4930-4937.

[24] Safavi M, Nourazar S. Droplet capture with a wetted fiber[J]. Theoretical and Computational Fluid Dynamics, 2021. doi: https: //doi. org/10. 1007/s00162-021-00561-3.

[25] Si Z, Shimasaki N, Nishida K, et al. Experimental study on impingement spray and near-field spray characteristics under high-pressure cross-flow conditions[J]. Fuel, 2018, 218: 12-22.

[26] Reichard D L, Cooper J A, Bukovac M J, et al. Using a videographic system to assess spray droplet impaction and reflection from leaf and artificial surfaces[J]. Pesticide Science, 1998, 53(4): 291-299.

[27] 贾卫东,朱和平,董祥,等. 喷雾液滴撞击大豆叶片表面研究[J]. 农业机械学报,2013,44(12):87-93.

Jia Weidong, Zhu Heping, Dong Xiang, et al. Impact of spray droplet on soybean leaf surface[J]. Transactions of the Chinese Society for Agricultural Machinery, 2013, 44(12): 87-93. (in Chinese with English abstract)

[28] 崔迎涛,秦超彬,张志,等. 液滴撞击大豆叶片表面研究[J]. 大豆科学,2018,37(6):961-968.

Cui Yingtao, Qin Chaobin, Zhang Zhi, et al. Experimental study on the impact of droplets on the surface of soybean leaves[J]. Soybean Science, 2018, 37(6): 961-968. (in Chinese with English abstract)

[29] Hirt C W, Nichols B D. A computational method for free surface hydrodynamics[J]. Journal of Pressure Vessel Technology, 1981, 103(2): 136-141.

[30] 董祥. 植保机械喷头雾滴撞击植物叶面过程试验测试及仿真研究[D]. 北京:中国农业机械化科学研究院,2013.

Dong Xiang. Systematic Investigation of 3-dimentional Spray Droplet Impaction on Leaf Surfaces[D]. Beijing: China Academy of Agricultural Mechanization, 2013. (in Chinese with English abstract)

[31] Delele M A, Nuyttens D, Duga A T, et al. Predicting the dynamic impact behaviour of spray droplets on flat plant surfaces[J]. Soft Matter, 2016, 12(34): 7195-7211.

[32] 谢亚星,慕松,陈星名,等. 液滴撞击枸杞叶片铺展特性实验研究与仿真分析[J]. 中国农机化学报,2017,38(9):70-74.

Xie Yaxing, Mu Song, Chen Xingming, et al. Experiment research and simulated analysison spreading characteristics of droplet impacting wolfberry leaf[J]. Journal of Chinese Agricultural Mechanization, 2017, 38(9): 70-74. (in Chinese with English abstract)

[33] Zhu L, Ge J, Qi Y, et al. Droplet impingement behavior analysis on the leaf surface of Shu-ChaZao under different pesticide formulations[J]. Computers and Electronics in Agriculture, 2018, 144: 16-25.

[34] Hong S W, Zhao L, Zhu H. SAAS, a computer program for estimating pesticide spray efficiency and drift of air-assisted pesticide applications[J]. Computers and Electronics in Agriculture, 2018, 155: 58-68.

[35] Tang C, Qin M, Weng X, et al. Dynamics of droplet impact on solid surface with different roughness[J]. International Journal of Multiphase Flow, 2017, 96: 56-69.

[36] 张晨辉,马悦,杜凤沛. 表面活性剂调控农药药液对靶润湿沉积研究进展[J]. 农药学学报,2019,21(Z1):883-894.

Zhang Chenhui, Ma Yue, Du Fengpei. Research progress on the wetting and deposition behaviors of pesticide droplet on target surfaces with the addition of surfactants[J]. Chinese Journal of Pesticide Science, 2019, 21(Z1): 883-894. (in Chinese with English abstract)

[37] 丁素明,薛新宇,董祥,等. 喷雾参数对雾滴沉积性能影响研究[J]. 农业机械学报,2020,51(S2):308-315.

Ding Suming, Xue Xinyu, Dong Xiang, et al. Effects of spraying parameters on droplet deposition performance[J]. Transactions of the Chinese Society for Agricultural Machinery, 2020, 51(S2): 308-315. (in Chinese with English abstract)

[38] 张瑞瑞,李龙龙,付旺,等. 脉宽调制变量控制喷头雾化性能及风洞环境雾滴沉积特性[J]. 农业工程学报,2019,35(3):42-51.

Zhang Ruirui, Li Longlong, Fu Wang, et al. Spraying atomization performance by pulse width modulated variable and droplet deposition characteristics in wind tunnel[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2019, 35(3): 42-51. (in Chinese with English abstract)

[39] 周晴晴,薛新宇,周良富,等. 施药喷嘴分级可行性及方法研究[J]. 农业工程学报,2019,35(9):66-72.

Zhou Qingqing, Xue Xinyu, Zhou Liangfu, et al. Feasibility and method of classification of spraying nozzle[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2019, 35(9): 66-72. (in Chinese with English abstract)

[40] Levin Z, Hobbs P V. Splashing of water drops on solid and wetted surfaces: Hydrodynamics and charge separation[J]. Philosophical Transactions of the Royal Society of London, 1971, 269(1200): 555-585.

[41] Yang X, Madden L V, Reichard D L, et al. Motion analysis of drop impaction on a strawberry surface[J]. Agricultural and Forest Meteorology, 1991, 56(1-2): 67-92.

[42] Usawa M, Fujita Y, Tagawa Y, et al. Large impact velocities suppress the splashing of micron-sized droplets[J]. Physical Review Fluids, 2021, 6(2): 23605.

[43] 张瑜,宁智,吕明,等. 液滴撞击高温壁面的运动特性[J]. 燃烧科学与技术,2017,23(5):451-457.

Zhang Yu, Ning Zhi, Lü Ming, et al. Dynamics of droplet impacting onto heated surface[J]. Journal of Combustion Science and Technology, 2017, 23(5): 451-457. (in Chinese with English abstract)

[44] 张帆,李建新,刘潜峰,等. 液滴撞击湿壁面实验研究[J]. 原子能科学技术,2018,52(9):1582-1589.

Zhang Fan, Li Jianxin, Liu Qianfeng, et al. Experiment study of droplet impacting on wetted surface[J]. Atomic Energy Science and Technology, 2018, 52(9): 1582-1589. (in Chinese with English abstract)

[45] 李玉杰,黄军杰,肖旭斌. 液滴撞击圆柱内表面的数值研究[J]. 物理学报,2018,67(18):186-199.

Li Yujie, Huang Junjie, Xiao Xubin. Numerical study of droplet impact on the inner surface of a cylinder[J]. Acta Physica Sinica, 2018, 67(18): 186-199. (in Chinese with English abstract)

[46] Appah S, Jia W, Ou M, et al. Analysis of potential impaction and phytotoxicity of surfactant-plant surface interaction in pesticide application[J]. Crop Protection, 2020, 127: 104961.

[47] Zhang Y, Liu B, Huang K, et al. Eco-friendly castor oil-based delivery system with sustained pesticide release and enhanced retention[J]. ACS Applied Materials & Interfaces, 2020, 12(33): 37607-37618.

[48] Huet O D, Massinon M, De Cock N, et al. Image analysis of shatter and pinning events on hard-to-wet leaf surfaces by drops containing surfactant[J]. Pest Management Science, 2020, 76(10): 3477-3486.

[49] Trapaga G, Szekely J. Mathematical modeling of the isothermal impingement of liquid droplets in spraying processes[J]. Metallurgical Transactions B, 1991, 22(6): 901-914.

[50] Holloway P J. Physicochemical Factors Influencing the Adjuvant-enhanced Spray Deposition and Coverage of Foliage-applied Agrochemicals[M]. Berlin: Springer, 1994: 83-106.

[51] Song M, Ju J, Luo S, et al. Controlling liquid splash on superhydrophobic surfaces by a vesicle surfactant[J]. Science Advances, 2017, 3(3): e1602188.

[52] Li Z, Ma Y, Zhao K, et al. Regulating droplet impact and wetting behaviors on hydrophobic weed leaves by a double-chain cationic surfactant[J]. ACS Sustainable Chemistry & Engineering, 2021, 9(7): 2891-2901.

[53] Ma Y, Gao Y, Zhao K, et al. Simple, effective, and ecofriendly strategy to inhibit droplet bouncing on hydrophobic weed leaves[J]. ACS Applied Materials & Interfaces, 2020, 12(44): 50126-50134.

[54] Bergeron V, Bonn D, Martin J Y, et al. Controlling droplet deposition with polymer additives[J]. Nature, 2000, 405(6788): 772.

[55] 顾中言,许小龙,韩丽娟. 一些药液难在水稻、小麦和甘蓝表面润湿展布的原因分析[J]. 农药学学报,2002(2):75-80.

Gu Zhongyan, Xu Xiaolong, Han Lijuan. The cause of the difficulty in wet-spreading of some insecticides on rice, wheat and wild cabbage Leaves[J]. Chinese Journal of Pesticide Science, 2002(2): 75-80. (in Chinese with English abstract)

[56] 顾中言,陈明亮,许小龙,等. 液体在结球甘蓝叶面上的行为趋势分析[J]. 江苏农业学报,2007(6):568-572.

Gu Zhongyan, Chen Mingliang, Xu Xiaolong, et al. Analysis of liquid action on cabbage leaf[J]. Jiangsu Journal of Agricultural Sciences, 2007(6): 568-572. (in Chinese with English abstract)

[57] Castro M J L, Ojeda C, Cirelli A F. Advances in surfactants for agrochemicals[J]. Environmental Chemistry Letters, 2014, 12(1): 85-95.

[58] Zhao M, Zhou H, Chen L, et al. Carboxymethyl chitosan grafted trisiloxane surfactant nanoparticles with pH sensitivity for sustained release of pesticide[J]. Carbohydrate Polymers, 2020, 243: 116433.

[59] Jibrin M O, Liu Q, Jones J B, et al. Surfactants in plant disease management: A brief review and case studies[J]. Plant Pathology, 2020, 70(3): 495-510.

[60] Wang Y, Wang A, Wang C, et al. Synthesis and characterization of emamectin-benzoate slow-release microspheres with different surfactants[J]. Scientific Reports, 2017, 7(1): 12761.

[61] Cao L, Zhang H, Cao C, et al. Quaternized chitosan-capped mesoporous silica nanoparticles as nanocarriers for controlled pesticide release[J]. Nanomaterials, 2016, 6(7): 126.

[62] Ma Y, Gao Y, Zhao X, et al. A natural triterpene saponin-based pickering emulsion[J]. Chemistry-A European Journal, 2018, 24(45): 11703-11710.

[63] Ma Y, Hao J, Zhao K, et al. Biobased polymeric surfactant: Natural glycyrrhizic acid-appended homopolymer with multiple pH-responsiveness[J]. Journal of Colloid and Interface Science, 2019, 541: 93-100.

[64] Song M, Hu D, Zheng X, et al. Enhancing droplet deposition on wired and curved superhydrophobic leaves[J]. ACS Nano, 2019, 13(7): 7966-7974.

[65] Da Silva B O, Victório C P, Arruda R D C D. Anatomical and micromorphological traits in leaf blade of halophytes from a brazilian sandy coastal plain[M]//Grigore M. Handbook of Halophytes: From Molecules to Ecosystems towards Biosaline Agriculture. Cham: Springer International Publishing, 2021: 933-962.

[66] Tian L, Yin S, Ma Y, et al. Impact factor assessment of the uptake and accumulation of polycyclic aromatic hydrocarbons by plant leaves: Morphological characteristics have the greatest impact[J]. Science of the Total Environment, 2019, 652: 1149-1155.

[67] Li Xuemei, Reinhoudt D, Crego-Calama M. What do we need for a superhydrophobic surface? A review on the recent progress in the preparation of superhydrophobic surfaces[J]. Chemical Society Reviews, 2007, 36(8): 1350-1368.

[68] Klein B, Thewes F R, Rogério De Oliveira A, et al. Development of dispersive solvent extraction method to determine the chemical composition of apple peel wax[J]. Food Research International, 2019, 116: 611-619.

[69] Hall D M, Burke W. Wettability of leaves of a selection of New Zealand plants[J]. New Zealand Journal of Botany, 1974, 12(3): 283-298.

[70] Stevens P J G, Kimberley M O, Murphy D S, et al. Adhesion of spray droplets to foliage: The role of dynamic surface tension and advantages of organosilicone surfactants[J]. Pesticide Science, 1993, 38(2/3): 237-245.

[71] Mao B, Cheng Z, Lei C, et al. Wax crystal-sparse leaf2, a rice homologue of WAX2/GL1, is involved in synthesis of leaf cuticular wax[J]. Planta, 2012, 235(1): 39-52.

[72] Kim K S, Park S H, Jenks M A. Changes in leaf cuticular waxes of sesame (.) plants exposed to water deficit[J]. Journal of Plant Physiology, 2007, 164(9): 1134-1143.

[73] Wang Y, Wang J, Chai G, et al. Developmental changes in composition and morphology of cuticular waxes on leaves and spikes of glossy and glaucous wheat () [J]. Plos One, 2015, 10(10): e141239.

[74] Koch K, Hartmann K D, Schreiber L, et al. Influences of air humidity during the cultivation of plants on wax chemical composition, morphology and leaf surface wettability[J]. Environmental and Experimental Botany, 2006, 56(1): 1-9.

[75] Jenks M A, Gaston C H, Goodwin M S, et al. Seasonal variation in cuticular waxes on Hosta genotypes differing in leaf surface glaucousness[J]. HortScience, 2002, 37(4): 673-677.

[76] Shao F, Wang L, Sun F, et al. Study on different particulate matter retention capacities of the leaf surfaces of eight common garden plants in Hangzhou, China[J]. Science of the Total Environment, 2019, 652: 939-951.

[77] Devi M J, Reddy V R. Transpiration response of cotton to vapor pressure deficit and its relationship with stomatal traits[J]. Frontiers in Plant Science, 2018, 9: 1572.

[78] Sajeevan R S, Nataraja K N, Shivashankara K S, et al. Expression of arabidopsis SHN1 in indian mulberry (.) increases leaf surface wax content and reduces post-harvest water loss[J]. Frontiers in Plant Science, 2017, 8: 418.

[79] Bi H, Shi J, Kovalchuk N, et al. Overexpression of the TaSHN1 transcription factor in bread wheat leads to leaf surface modifications, improved drought tolerance, and no yield penalty under controlled growth conditions[J]. Plant, Cell & Environment, 2018, 41(11): 2549-2566.

[80] Feng X, Guan H, Wang Z, et al. Biomimetic slippery PDMS film with papillae-like microstructures for antifogging and self-cleaning[J]. Coatings, 2021, 11(2): 238.

[81] Neinhuis C, Barthlott W. Characterization and distribution of water-repellent, self-cleaning plant surfaces[J]. Annals of Botany, 1997, 79(6): 667-677.

[82] Barthlott W, Neinhuis C. Purity of the sacred lotus, or escape from contamination in biological surfaces[J]. Planta, 1997, 202(1): 1-8.

[83] Zorba V, Stratakis E, Barberoglou M, et al. Biomimetic artificial surfaces quantitatively reproduce the water repellency of a lotus leaf[J]. Advanced Materials, 2008, 20: 4049-4054.

[84] 徐广春,顾中言,徐德进,等. 稻叶表面特性及雾滴在倾角稻叶上的沉积行为[J]. 中国农业科学,2014,47(21):4280-4290.

Xu Guangchun, Gu Zhongyan, Xu Dejin, et al. Characteristics of rice leaf surface and droplets deposition behavior on rice leaf surface with different inclination angles[J]. Scientia Agricultura Sinica, 2014, 47(21): 4280-4290. (in Chinese with English abstract)

[85] Koch K, Bhushan B, Barthlott W. Multifunctional surface structures of plants: An inspiration for biomimetics[J]. Progress in Materials Science, 2009, 54(2): 137-178.

[86] Owens D K, Wendt R C. Estimation of the surface free energy of polymers[J]. Journal of Applied Polymer Science, 1969, 13(8): 1741-1747.

[87] Feng X, Liu T, Wang L, et al. Investigation on JKR surface energy of high-humidity maize grains[J]. Powder Technology, 2021, 382: 406-419.

[88] Shen Q. New insight on critical Hamaker constant of solid materials[J]. Materials Research Bulletin, 2021, 133: 111082.

[89] Young T. III. An essay on the cohesion of fluids[J]. Philosophical Transactions of the Royal Society of London, 1805, 95: 65-87.

[90] 马学虎,兰忠,王凯,等. 舞动的液滴:界面现象与过程调控[J]. 化工学报,2018,69(1):9-43.

Ma Xuehu, Lan Zhong, Wang Kai, et al. Dancing droplet: Interface phenomena and process regulation[J]. CIESC J, 2018, 69(1): 9-43. (in Chinese with English abstract)

[91] Boukhalfa H H, Massinon M, Belhamra M, et al. Contribution of spray droplet pinning fragmentation to canopy retention[J]. Crop Protection, 2014, 56: 91-97.

[92] Rioboo R, Marengo M, Tropea C. Outcomes from a drop impact on solid surfaces[J]. Atomization and Sprays, 2001, 11(2): 155-166.

[93] Marengo M, Antonini C, Roisman I V, et al. Drop collisions with simple and complex surfaces[J]. Current Opinion in Colloid & Interface Science, 2011, 16(4): 292-302.

[94] Yoon S S, DesJardin P E. Modelling spray impingement using linear stability theories for droplet shattering[J]. International Journal for Numerical Methods in Fluids, 2006, 50(4): 469-489.

[95] Rein M. Phenomena of liquid drop impact on solid and liquid surfaces[J]. Fluid Dynamics Research, 1993, 12(2): 61-93.

[96] Chandra S, Avedisian C T. On the collision of a droplet with a solid surface[J]. Proceedings of the Royal Society of London. Series A: Mathematical and Physical Sciences, 1991, 432(1884): 13-41.

[97] Pasandideh-Fard M, Qiao Y M, Chandra S, et al. Capillary effects during droplet impact on a solid surface[J]. Physics of Fluids, 1996, 8(3): 650-659.

[98] Roisman I V, Rioboo R, Tropea C. Normal impact of a liquid drop on a dry surface: Model for spreading and receding[J]. Proceedings of the Royal Society of London. Series A: Mathematical, Physical and Engineering Sciences, 2002, 458(2022): 1411-1430.

[99] Attane P, Girard F, Morin V. An energy balance approach of the dynamics of drop impact on a solid surface[J]. Physics of Fluids, 2007, 19(1): 61.

[100] Kim H Y, Chun J H. The recoiling of liquid droplets upon collision with solid surfaces[J]. Physics of Fluids, 2001, 13(3): 643-659.

[101] Massinon M, Frédéric L. Experimental method for the assessment of agricultural spray retention based on high-speed imaging of drop impact on a synthetic superhydrophobic surface[J]. Biosystems Engineering, 2012, 112(1): 56-64.

[102] Massinon M, Boukhalfa H, Lebeau F. The effect of surface orientation on spray retention[J]. Precision Agriculture, 2014, 15(3): 241-254.

[103] Zwertvaegher I K, Verhaeghe M, Brusselman E, et al. The impact and retention of spray droplets on a horizontal hydrophobic surface[J]. Biosystems Engineering, 2014, 126: 82-91.

[104] Xu H, Liu Y, He P, et al. The TAR model for calculation of droplet/wall impingement[J]. Journal of Fluids Engineering, 1998, 120(3): 593-597.

[105] Okumura K, Chevy F, Richard D, et al. Water spring: A model for bouncing drops[J]. Europhysics Letters, 2003, 62(2): 237-243.

[106] Dorr G J, Wang S, Mayo L C, et al. Impaction of spray droplets on leaves: Influence of formulation and leaf character on shatter, bounce and adhesion[J]. Experiments in Fluids, 2015, 56(7): 1-17.

[107] Mundo C, Sommerfeld M, Tropea C. Droplet-wall collisions-experimental studies of the deformation and break-up process[J]. International Journal of Multiphase Flow, 1995, 21(2): 151-173.

[108] Forster W A, Mercer G N, Schou W C. Process-driven models for spray droplet shatter, adhesion or bounce[C]//Proceedings of the 9th International Symposium on Adjuvants for Agrochemicals. Freising, Germany: Technical University of Munich, 2010, 16: 20.

[109] Xu L. Liquid drop splashing on smooth, rough, and textured surfaces[J]. Physical Review E, 2007, 75(5): 56316.

[110] Dorr G J, Kempthorne D M, Mayo L C, et al. Towards a model of spray-canopy interactions: Interception, shatter, bounce and retention of droplets on horizontal leaves[J]. Ecological Modelling, 2014, 290: 94-101.

[111] Aziz S D, Chandra S. Impact, recoil and splashing of molten metal droplets[J]. International Journal of Heat and Mass Transfer, 2000, 43(16): 2841-2857.

[112] Allen R F. The role of surface tension in splashing[J]. Journal of Colloid & Interface Science, 1975, 51(2): 350-351.

[113] Fukai J, Zhao Z, Poulikakos D, et al. Modeling of the deformation of a liquid droplet impinging upon a flat surface[J]. Physics of Fluids A: Fluid Dynamics, 1993, 5(11): 2588-2599.

[114] Fukai J, Shiiba Y, Yamamoto T, et al. Wetting effects on the spreading of a liquid droplet colliding with a flat surface: Experiment and modeling[J]. Physics of Fluids, 1995, 7(2): 236-247.

[115] Tanaka Y, Washio Y, Yoshino M, et al. Numerical simulation of dynamic behavior of droplet on solid surface by the two-phase lattice Boltzmann method[J]. Computers & Fluids, 2011, 40(1): 68-78.

[116] 张莹,卢敏,李培生,等. 非均质壁面对液滴俘获能力的数值模拟研究[J]. 北京航空航天大学学报,2018,44(10):2021-2027.

Zhang Ying, Lu Min, Li Peisheng, et al. Numerical simulation of drop capturing capabilities on heterogeneous walls[J]. Journal of Beijing University of Aeronautics and Astronautics, 2018, 44(10): 2021-2027. (in Chinese with English abstract)

[117] 韩丁丁,刘浩然,刘难生,等. 黏弹性液滴撞击疏水壁面的动力学研究[J]. 中国科学:物理学力学天文学,2018,48(9):250-257.

Han Dingding, Liu Haoran, Liu Nansheng, et al. Dynamics of viscoelastic drops impacting onto a hydrophobic solid substrate[J]. Scientia Sinica Physica, Mechanica & Astronomica, 2018, 48(9): 250-257. (in Chinese with English abstract)

[118] Bhise D K, Patil B T, Shaikh V A. Air assisted atomization characterization of biodegradable fluid using microlubrication technique[J]. Materials Science Forum, 2021, 1019: 211-217.

[119] 张慧春,周宏平,郑加强,等. 喷头雾化性能及雾滴沉积可视化模型研究[J]. 林业工程学报,2016,1(3):91-96.

Zhang Huichun, Zhou Hongping, Zheng Jiaqiang, et al. A study of spray nozzle atomization performance and droplet deposition visual model[J]. Journal of Forestry Engineering, 2016, 1(3): 91-96. (in Chinese with English abstract)

[120] 王志翀,何雄奎,李天,等. 基于激光成像技术的农药雾滴飘移评价方法研究[J]. 农业工程学报,2019,35(9):73-79. Wang Zhichong, He Xiongkui, Li Tian, et al. Evaluation method of pesticide droplet drift based on laser imaging[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2019, 35(9): 73-79. (in Chinese with English abstract)

[121] 王昌陵,何雄奎,曾爱军,等. 基于仿真果园试验台的植保无人机施药雾滴飘移测试方法与试验[J]. 农业工程学报,2020,36(13):56-66. Wang Changling, He Xiongkui, Zeng Aijun, et al. Measuring method and experiment on spray drift of chemicals applied by UAV sprayer based on an artificial orchard test bench[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2020, 36(13): 56-66. (in Chinese with English abstract)

[122] Bueno M R, Cunha J P A R, de Santana D G. Assessment of spray drift from pesticide applications in soybean crops[J]. Biosystems Engineering, 2017, 154: 35-45.

[123] Zwertvaegher I K, Van Daele I, Verheesen P, et al. Development and implementation of a laboratory spray device and rainfall simulator for retention research using small amounts of agroformulations[J]. Pest Management Science, 2017, 73(1): 123-129.

[124] Menger R F, Bontha M, Beveridge J R, et al. Fluorescent dye paper-based method for assessment of pesticide coverage on leaves and trees: A citrus grove case study[J]. Journal of Agricultural and Food Chemistry, 2020, 68(47): 14009-14014.

[125] 田志伟,薛新宇,崔龙飞,等. 植保无人机昼夜作业的雾滴沉积特性及棉蚜防效对比[J]. 农业工程学报,2020,36(5):69-77.

Tian Zhiwei, Xue Xinyu, Cui Longfei, et al. Comparison of droplet deposition characteristics and cotton aphid control effect of plant protection UAV working during the day and night[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2020, 36(5): 69-77. (in Chinese with English abstract)

[126] W. D B, M. J H. Phase/doppler spray analyzer for simultaneous measurements of drop size and velocity distributions[J]. Optical Engineering, 1984, 23(5): 583-590.

[127] Hardalupas Y, Okamoto S, et al. Application of a phase Doppler anemometer to a spray impinging on a disc[C]//Proceedings of the 6th International Symposium on the Applications of laser techniques to fluid mechanics, Lisbon, Portugal. 1992: 490-506.

[128] Kalantari D, Tropea C. Spray impact onto flat and rigid walls: Empirical characterization and modelling[J]. International Journal of Multiphase Flow, 2007, 33(5): 525-544.

[129] Lee S, Park S. Spray atomization characteristics of a GDI injector equipped with a group-hole nozzle[J]. Fuel, 2014, 137: 50-59.

[130] 张慧春,周宏平,郑加强,等. 农药助剂对空中和地面防控林业有害生物的雾滴粒径影响[J]. 林业科学,2020,56(5):118-129.

Zhang Huichun, Zhou Hongping, Zheng Jiaqiang, et al. Adjuvant’ s influence to droplet size based on forestry pests’ prevention with ground and air chemical application[J]. Scientia Silvae Sinicae, 2020, 56(5): 118-129. (in Chinese with English abstract)

[131] Dekeyser D, Duga A T, Verboven P, et al. Assessment of orchard sprayers using laboratory experiments and computational fluid dynamics modelling[J]. Biosystems Engineering, 2013, 114(2): 157-169.

[132] 张宋超,薛新宇,秦维彩,等. N-3型农用无人直升机航空施药飘移模拟与试验[J]. 农业工程学报,2015,31(3):87-93.

Zhang Songchao, Xue Xinyu, Qin Weicai, et al. Simulation and experimental verification of aerial spraying drift on N-3 unmanned spraying helicopter[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2015, 31(3): 87-93. (in Chinese with English abstract)

[133] 张豪,祁力钧,吴亚垒,等. 无人机果树施药旋翼下洗气流场分布特征研究[J]. 农业工程学报,2019,35(18):44-54.

Zhang Hao, Qi Lijun, Wu Yalei, et al. Distribution characteristics of rotor downwash airflow field under spraying on orchard using unmanned aerial vehicle[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2019, 35(18): 44-54. (in Chinese with English abstract)

[134] Zhai E, Zheng J, Ru Y, et al. Atomization mechanism and numerical simulation of external mixing two-fluid fan nozzle[J]. Ekoloji, 2019, 28(107): 4277-4288.

[135] Munjanja B K, Naudé Y, Forbes P. A review of sampling approaches to off-target pesticide deposition[J]. Trends in Environmental Analytical Chemistry, 2020, 25: e00075.

[136] Sinha R, Ranjan R, Khot L R, et al. Drift potential from a solid set canopy delivery system and an axial-fan air-assisted sprayer during applications in grapevines[J]. Biosystems Engineering, 2019, 188: 207-216.

[137] Matsukawa-Nakata M, Nguyen H T, Bui T T B, et al. Spatial evaluation of the pesticide application method by farmers in a paddy field in the northern part of Vietnam[J]. Applied Entomology and Zoology, 2019, 54(4): 451-457.

[138] Xiao L, Zhu H, Wallhead M, et al. Characterization of biological pesticide deliveries through hydraulic nozzles[J]. Transactions of the ASABE, 2018, 61(3): 897-908.

[139] Turner C R, Huntington K A. The use of a water sensitive dye for the detection and assessment of small spray droplets[J]. Journal of Agricultural Engineering Research, 1970, 15(4): 385-387.

[140] Torrent X, Garcerá C, Moltó E, et al. Comparison between standard and drift reducing nozzles for pesticide application in citrus: Part I. Effects on wind tunnel and field spray drift[J]. Crop Protection, 2017, 96: 130-143.

[141] Qin W, Xue X, Zhou Q, et al. Use of RhB and BSF as fluorescent tracers for determining pesticide spray distribution[J]. Analytical Methods, 2018, 10(33): 4073-4078.

[142] Brain R, Goodwin G, Abi-Akar F, et al. Winds of change, developing a non-target plant bioassay employing field-based pesticide drift exposure: A case study with atrazine[J]. Science of the Total Environment, 2019, 678: 239-252.

[143] 张慧春,郑加强,周宏平,等. 农药喷施过程中雾滴沉积分布与脱靶飘移研究[J]. 农业机械学报,2017,48(8):114-122.

Zhang Huichun, Zheng Jiaqiang, Zhou Hongping, et al. Droplet deposition distribution and off-target drift during pesticide spraying operation[J]. Transactions of the Chinese Society for Agricultural Machinery, 2017, 48(8): 114-122. (in Chinese with English abstract)

[144] Córdoba Gamboa L, Solano Diaz K, Ruepert C, et al. Passive monitoring techniques to evaluate environmental pesticide exposure: Results from the infant's environmental health study (ISA)[J]. Environmental Research, 2020, 184: 109243.

[145] Nairn J J, Forster W A. Due diligence required to quantify and visualise agrichemical spray deposits using dye tracers[J]. Crop Protection, 2019, 115: 92-98.

[146] 张海艳,兰玉彬,文晟,等. 植保无人机旋翼风场模型与雾滴运动机理研究进展[J]. 农业工程学报,2020,36(22):1-12.

Zhang Haiyan, Lan Yubin, Wen Sheng, et al. Research progress in rotor airflow model of plant protection UAV and

droplet motion mechanism[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2020, 36(22): 1-12. (in Chinese with English abstract)

[147] Bilanin A J, Teske M E, Barry J W, et al. AGDISP: The aircraft spray dispersion model, code development and experimental validation[J]. Transactions of the ASAE, 1989, 32(1): 327-334.

[148] Teske M E, Bird S L, Esterly D M, et al. AgDrift®: A model for estimating near-field spray drift from aerial applications[J]. Environmental Toxicology and Chemistry: An International Journal, 2002, 21(3): 659-671.

[149] Zhu H, Reichard D L, Fox R D, et al. DRIFTSIM, A program to estimate drift distances of spray droplets[J]. Applied Engineering in Agriculture, 1995, 11(3): 365-369.

[150] Kruckeberg J P, Hanna H M, Steward B L, et al. The relative accuracy of DRIFTSIM when used as a real-time spray drift predictor[J]. Transactions of the Asabe, 2012, 55(4): 1159-1165.

[151] Hong S, Zhao L, Zhu H. CFD simulation of pesticide spray from air-assisted sprayers in an apple orchard: Tree deposition and off-target losses[J]. Atmospheric Environment, 2018, 175: 109-119.

Research progress and prospect of pesticide droplet deposition characteristics

Kang Feng1, Wu Xiaoyi1, Wang Yaxiong1, Zheng Yongjun2, Li Shougen1, Chen Chongchong1

(1.,,100083,; 2.,,100083,)

Pesticide droplets can rebound, splash, and roll off the target surface during spraying, due mainly to insufficient wettability. The resulting environmental pollution has seriously threatened ecological stability and safety. However, the correlative mechanism of droplet deposition is still under exploration at present. It is necessary to explore the characteristics of effective droplet deposition for pest control. This study aims to review current researches on droplet deposition ranging from microdynamics of a single droplet and drift characteristics of the droplet group. The final deposition assessment and the bottleneck were also addressed, in order to clarify the research perspective of pesticide deposition. A single droplet model was essential to the impact mechanism of the droplet group because the pesticide droplets hit the target surface in the form of a single droplet during spraying. The previous reports on the deposition of the single droplet mainly contributed to the observation technologies, the influencing factors at the interface behavior of the single droplet, and the modeling of the single droplet hitting the target surface. However, the deposition behavior in the actual work depended mainly on the droplet distribution and canopy structure. There were two approaches to explore the deposition and drift characteristics in the spray field through the droplet group at present. One approach was that the observation and simulation were utilized to determine the movement of droplets in the spray field, thereby establishing the relationship between deposition behavior and amount. Another was to calculate the final deposition through actual experiments or simulation techniques, including the direct measurement of deposition on the surface of leaves, and the indirect measurement represented by the amount of drift in the air or on the ground. The research of droplet group was introduced to the distribution characteristics, deposition collection, and detection, as well as droplet group modeling. More importantly, a further combined modeling was necessary to accurately estimate the deposition behavior and the volume of deposited pesticides. The following suggestions can be drawn: 1) To establish the relationship between the single droplet and the droplet group modeling through the three-dimensional atomization field; 2) To estimate the amount of adhesion liquid after a single droplet hits the wall through image processing; 3) To explore the influence of wetted surfaces on deposition behavior; 4) To establish plant models in different growth periods. The finding can be widely expected to provide a strong reference for the research of pesticide deposition and pest control technologies.

pesticide droplets; deposition; drift; single droplet; droplet group; interface behavior

康峰,吴潇逸,王亚雄,等. 农药雾滴沉积特性研究进展与展望[J]. 农业工程学报,2021,37(20):1-14.doi:10.11975/j.issn.1002-6819.2021.20.001 http://www.tcsae.org

Kang Feng, Wu Xiaoyi, Wang Yaxiong, et al. Research progress and prospect of pesticide droplet deposition characteristics[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2021, 37(20): 1-14. (in Chinese with English abstract) doi:10.11975/j.issn.1002-6819.2021.20.001 http://www.tcsae.org

2021-06-16

2021-09-15

国家重点研发计划项目(2018YFD0700603)

康峰,教授,博士生导师,研究方向为经济林果园装备自动化。Email:kangfeng98@bjfu.edu.cn

10.11975/j.issn.1002-6819.2021.20.001

S-1

A

1002-6819(2021)-20-0001-14