A 61-mJ,1-kHz cryogenic Yb:YAG laser amplifier∗

Huijun He(何会军) Jun Yu(余军) Wentao Zhu(朱文涛) Qingdian Lin(林庆典)Xiaoyang Guo(郭晓杨) Cangtao Zhou(周沧涛) and Shuangchen Ruan(阮双琛)

1Shenzhen Key Laboratory of Ultraintense Laser and Advanced Material Technology,Center for Advanced Material Diagnostic Technology,and College of Engineering Physics,Shenzhen Technology University(SZTU),Shenzhen 518118,China

2College of Physics and Optoelectronic Engineering,Shenzhen University,Shenzhen 518060,China

Keywords: ytterbium laser system, Yb:YAG laser amplifier, cryogenic laser amplification, high energy laser amplification

1. Introduction

Diode-pumped solid-state (DPSS) lasers are known for their compactness, simplicity, and high conversion efficiency.[1–4]Among various laser gain media in DPSS lasers, Yb:YAG is attractive for its high damage threshold,long fluorescence time (∼1 ms), high thermal conductivity,and ease of growth, which are beneficial for high-power and high-energy laser amplification.

Yb:YAG shows quasi-three-energy-level system characteristics at room temperature, which means temperature rise in Yb:YAG could affect the system performance severely.However, under cryogenic cooling temperature, the thermal population is reduced substantially and Yb:YAG shows fourenergy-level characteristics. Meanwhile, the thermal conductivity is four times that at room temperature.[5–7]Therefore,cryogenically cooled Yb:YAG has been adopted by several research groups building high-power,high-energy laser systems with good beam quality. This kind of laser system shows great potential in scientific research[8]and industrial manufacturing,such as laser shock peening.[9]

One other competitive laser crystal is Nd:YAG,which can achieve high-power,high-energy laser pulses with good beam quality.[10]However, compared to Nd:YAG, cryogenically cooled Yb:YAG has the following advantages: (i) Yb:YAG shows a longer fluorescence time (∼1 ms) compared to that of Nd:YAG, which is around 230 µs. Thus, it is beneficial to use Yb:YAG crystal to maximize diode pump power utilization under high-energy laser amplification. (ii) The quantum defect of Yb:YAG (9.6% at 940-nm pump) is much smaller than that of Nd:YAG (20.2% at 885-nm pump); furthermore, the thermal conductivity of cryogenically cooled Yb:YAG is approximately four times that of Nd:YAG.[11]Therefore, the thermal effect is much lower in cryogenically cooled Yb:YAG laser systems. (iii)Yb:YAG has an emission bandwidth broader than Nd:YAG,even under cryogenic cooling conditions. Chirped pulse amplification method can be effectively applied such that severe Bintegral accumulation can be avoided in the laser amplification process. Wanget al.realized 1.1-J pulse generation at 1 kHz with laser pulses compressed to 4.5 ps with 90%compression efficiency.[12]

To achieve efficient crystal cooling, Yb:YAG is usually used as an active mirror with end pumping and end cooling.[13,14]The high gain stored in the disk crystal introduces parasitic amplified spontaneous emission (ASE). To overcome this problem, Cr:YAG is usually adopted to absorb the spontaneous light, whether diffusion bonded to the four lateral faces of Yb:YAG crystal[12]or used as interlayers in an Yb:YAG multislab amplifier.[15]This adds difficulty to crystal production. In contrast,rod-type Yb:YAG is more suitable for amplifiers with output power below 200 W.[16]With a low doping rate and long length,the accumulated heat can be transferred to the heat sink efficiently through the lateral surfaces of the Yb:YAG crystal.

Herein, we report a cryogenic laser amplifier based on rod-type Yb:YAG crystal. An activelyQ-switched cryogenic Yb:YAG oscillator is built that delivers 5.75-mJ pulses at 1 kHz. A collinear four-pass configuration based on polarization rotation control is adopted to achieve good beam matching. As a result, the laser pulses were amplified to 61 mJ in a single stage with an optical-to-optical efficiency of 24%andM2factor below 1.4.

2. System design

Our system is illustrated in Fig. 1. A single-frequency fiber laser works as a seed laser of the activelyQ-switched oscillator. The output laser of the oscillator is sent to a four-pass main amplifier. Liquid nitrogen cooling is adopted in both theQ-switched oscillator and the main amplifier. To avoid crystal damage,a 4f imaging system is added to monitor the beam radius variation on the Yb:YAG crystal under different pumping power in the main amplifier.

Fig. 1. Laser system design, DM: dichroic mirror, LN2: liquid nitrogen chamber,Xtal: Yb:YAG crystal,L1–L5: lens,HWP:half-wave plate,QWP:quarter-wave plate,FR:Faraday rotator,TFP:thin-film polarizer,PC:Pockels cell,OC:output coupler,PM:plane mirror,M1,M2: convex mirror.

2.1. The Q-switched oscillator

In the activelyQ-switched oscillator,the gain medium is a Yb:YAG crystal with a 3%-atom doping rate, aperture of 4 mm×4 mm,and length of 10 mm. The crystal is wrapped in indium foil and placed in a copper heat sink which is cooled down to−195◦C using liquid nitrogen in an evacuated chamber. A DKDP Pockels cell (PC) is used in theQ-switched system with quarter-wavelength voltage around 3.2 kV.

Fig. 2. Laser mode distribution in the Q-switched oscillator. DM: dichroic mirror;L1: plane-concave lens with a focal length of −150 mm;L2: planeconvex lens with a focal length of +200 mm; PC: Pockels cell; OC: output coupler.

A telescope system composed of anf=−150-mm lens(L1) andf=+200-mm lens (L2) is inserted into the oscillator. The cavity mode of the activelyQ-switched oscillator is shown in Fig. 2. A 30-W/940-nm diode laser with a fiber core diameter of 105µm is used as the oscillator’s pump source. To reduce the heat load on Yb:YAG crystal,we adopt quasi-continuous-wave (QCW) pumping with pulse duration of 700 µs at 1 kHz. A delay generator DG645 is applied in this system, which independently controls the time delay of the single-frequency fiber seeder,pump diodes,and PC.

2.2. The main amplifier

The main amplifier is a Yb:YAG four-pass amplifier. The crystal is also placed in a cryogenically cooled copper heat sink in an evacuated chamber. The diameter of the crystal is 8 mm and the length is 20 mm with 1%-atom doping rate.To reduce the severe heat load on the surface of the Yb:YAG crystal under high-power pumping, the crystal was diffusion bonded with 2-mm undoped YAG caps on the two ends. One end of the crystal has a 1.5◦wedge to suppress ASE.The absorption ratio of the crystal on the 938-nm pump laser is measured to be 85%.

To make the system compact, a collinear four-pass amplifier based on laser polarization rotation is built. This also ensures good beam overlap between the amplified laser beam and pump laser. The fiber-coupled 938-nm pump laser used in the main amplifier has a core diameter of 330µm and power up to 1100 W. We focused the pump laser to a diameter of 3.3 mm by adopting a 30-mm focal-length collimating lens and a 300-mm focal-length focusing lens,and the output laser beam delivered by theQ-switched oscillator is collimated to 3 mm by L3 and L4 (in Fig. 1). In high energy laser amplification, components damage should be avoided. As can be seen in the main amplifier in Fig. 1, an additional dichroic mirror(DM)is used to protect the pump laser in case that the laser pulses introduce damage to the other DM and subsequent damage to the pump laser.

A 4f imaging system is added to this system to monitor the amplified beam radius on the Yb:YAG crystal in the four-pass amplification. As shown in Fig.1,two plane-convex lenses with a focal length of 500 mm are used in the imaging system. By slightly moving the position of the CCD,the beam profile at the given position of the Yb:YAG can be monitored.To avoid laser pulse induced damage on the Yb:YAG crystal,the laser pulse fluence is controlled to below 1 J/cm2.

3. Experimental results

InQ-switched oscillator, laser is built from spontaneous emission. Therefore, the build-up time and pulse energy vary from pulse to pulse and the output pulse train of theQ-switched oscillator is not stable. Pulse energy fluctuation could lead to component damage in the main amplifier.Therefore, we added a single-frequency laser as a seeder. Its central wavelength is 1029.36 nm with a bandwidth of 8.3 kHz and the average power is approximately 50 mW.The seeder is modulated by an electronic–optic modulator with output pulse duration of 4 ns at a repetition rate of 1 kHz,synchronized to the whole system. By finely tuning the seed-in time relative to the high-voltage time applied to the PC,the laser build-up time is greatly reduced and a stable pulse train is obtained, which means the seeder pulse is captured and amplified by the cavity.The output pulse train and pulse duration are shown in Fig.3.

Fig. 3. (a) Output pulse train and (b) output pulse duration, monitored by oscilloscope.

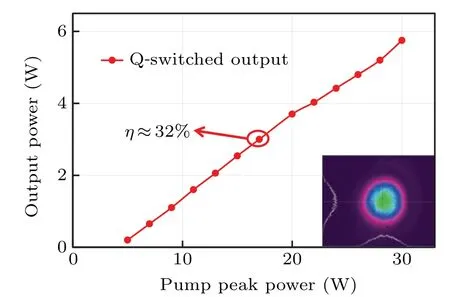

TheQ-switched oscillator delivers 5.75-mJ pulses at 1 kHz with a pulse duration approximately 40 ns under a pumping peak power of 30 W (QCW, 1 kHz, 700 µs). The output power underQ-switched mode is shown in Fig.4.

Fig.4. Output power of the actively Q-switched oscillator; inset: near-field beam profile.

To make the system compact,we used two convex reflective mirror(M1:R=−4 m,M2:R=−2 m)to maintain good beam mode matching in the main amplifier. The footprint area of the whole laser system is 0.5 m×1 m. To minimize laser depolarization, a Faraday rotator is placed between M1 and DM in the main amplifier at first,as shown in Fig.1. As laser depolarization in laser amplification is not observed, we replaced the Faraday rotator with a quarter-wave plate. Figure 5 shows the output power, which varies with the pump average power applied to the main amplifier with different pump pulse durations. Under the same average pumping power(same absorbed pump energy),more of the stored energy is converted to spontaneous emission with a longer pump pulse duration. The final output laser energy reaches 61 mJ at 1 kHz with pump duration of 300µs.

Fig.5.Output power versus pump average power under different pump pulse durations(τp).

As it benefits from good beam overlap in the main amplifier, theM2factor of the output beam is<1.4 (measured by Dataray S-WCD-LCM-C,Dataray,America),as shown in Fig. 6. At a pulse energy of 61 mJ, the laser beam diameter on the Yb:YAG crystal is approximately 2.8 mm,corresponding to a pulse fluence of 0.99 J/cm2. To avoid laser-induced damage to the Yb:YAG crystal,the pump peak power is set to 900 W with a pump pulse duration of 300µs(average power of 270 W).Based on the absorption efficiency of the Yb:YAG of around 85%, the optical-to-optical efficiency in the main amplifier is around 24%.

Fig.6. The M2 factor of the output laser beam(inset: near-field and far-field beam profile).

4. Conclusion and perspectives

A compact cryogenic Yb:YAG laser amplifier is presented in this work,wherein an activelyQ-switched cryogenic Yb:YAG oscillator seeded by a single-frequency laser delivers 5.75-mJ pulses. The pulses were amplified to 61 mJ at 1 kHz under QCW pumping in a four-pass amplifier with an opticalto-optical efficiency of 24% in the main amplifier. TheM2factor of the final output laser is<1.4.

In our experiment,the temperature of the cooper heat sink increases gradually with an average pumping power of over 300 W,which indicates that the heat load surpasses the cooling power of our liquid nitrogen Dewar. In the future,we will upgrade the oscillator to 20 mJ and add an additional amplification stage. Laser pulses that are amplified beyond 200 mJ can be expected.

- Chinese Physics B的其它文章

- Modeling the dynamics of firms’technological impact∗

- Sensitivity to external optical feedback of circular-side hexagonal resonator microcavity laser∗

- Controlling chaos and supressing chimeras in a fractional-order discrete phase-locked loop using impulse control∗

- Proton loss of inner radiation belt during geomagnetic storm of 2018 based on CSES satellite observation∗

- Embedding any desired number of coexisting attractors in memristive system∗

- Thermal and mechanical properties and micro-mechanism of SiO2/epoxy nanodielectrics∗