Textile-Based Capacitive Pressure Distribution Measurement System for Human Sitting Posture Monitoring

SHI YulongZHENG YuanyuanZHANG Kun

1 Key Laboratory of Textile Science & Technology of Ministry of Education, Donghua University, Shanghai 201620, China2 College of Textiles, Donghua University, Shanghai 201620, China

Abstract: Flexible pressure monitoring device can help correct the sitting posture and prevent health problems(e.g., deformity of spinal column and musculoskeletal disease). Currently, most measurement systems hinder their wide applications owing to the high cost or low accuracy. In this study, a flexible sitting pressure measurement system was proposed based on a textile-based capacitive pressure sensor array in order to measure sitting pressure distribution simply and conveniently. The capacitive pressure sensor array is sandwich structure composed of a high-density sponge layer and two electrode array fabrics,which possesses high resolution(2.26 sensors/cm2), high sensitivity(0.701 kPa-1) and fast response(≤35 ms). It is worth noting that the raw materials of the sensing fabric include commercialized copper sheets and polyester yarns. The as-prepared pressure measurement system can accurately measure the pressure distribution nephogram for sitting posture analysis. The sitting pressure of 10 volunteers was measured and six types of posture were distinguished clearly.

Key words: smart textile; capacitive pressure sensor; pressure distribution; sitting posture

Introduction

Smart clothing for health monitoring, mobile communication and human-machine interaction,etc. has been widely designed and developed in recent years. Especially, the health-monitoring smart clothing is focused on people who spend more than 10 h every day on working and studying, during which sitting is the most commonly used posture[1]. Sedentary lifestyle has emerged as a potential risk factor for many chronic conditions and mortality including musculoskeletal disease, type 2 diabetes mellitus, cardiovascular disease, pressure ulcer, and sudden death[2-4]. In addition, unbalanced sitting pressure and back pressure distribution caused by prolonged incorrect sitting postures, such as resting one's chin on a hand or sitting with crossed legs, will lead to deformity of spinal column[5-7]. Many families are troubled by the huge cost of treating kyphosis and spinal injuries every year. Therefore, it is of great significance to measure and study the relationship between sitting pressure distribution and the occurrence of lumbar spine diseases.

The measurement of sitting pressure distribution requires human body pressure distribution testing system and technology, of which the pressure sensor is the core component. Hitherto, common pressure sensors can be classified into three categories according to the mechanisms, namely, capacitive pressure sensors[8-9], piezoelectric pressure sensors[10-11], and piezoresistive pressure sensors[12-14]. Among them, capacitive pressure sensors have the advantages of high sensitivity, well stability, rapid response, low energy consumption, multi-touch function, and simple structure[15-16], thus being investigated intensively. Yangetal.[17]reported an ultrahigh sensitive capacitive pressure sensor based on a porous pyramid dielectric layer(44.5 kPa-1within 100 Pa). However, the microstructural treatment of the elastomer dielectric layer was not suitable for large area measurement due to the complicated and expensive photolithography and chemical etching. Kimetal.[18]demonstrated a real-time sitting posture correction system made of conductive Ni-Ti alloy fiber and pressure-sensitive polyurethane elastomer with a sensitivity of 2.39 kPa-1(10-180 kPa). Although this 18-unit system could judge four kinds of sitting postures based on pressure, it could not draw pressure distribution nephograms. Seoetal.[19]proposed a posture measurement system which was unable to obtain a complete pressure distribution nephogram due to the low measurement resolution. According to Ref.[20], Tactilus is a real-time surface pressure mapping system, which is suitable for testing the pressure distribution between soft surfaces. The properties of the system are excellent, but the expensive price(120 000-200 000 RMB) limits its wide application. Therefore, the simple-structured sitting pressure testing device with high sensitivity in a large measurement range, high resolution, large area and low cost still needs to be further designed and studied.

Firstly, utilizing a simple and low-cost method, we report a highly sensitive textile-based capacitive pressure sensor array with a high resolution. Using this method, the electrode array fabric with a certain electrode width is made of copper sheets and ordinary polyester yarns. Secondly, a high-density sponge is used as an elastic dielectric layer between the two layers of fabric to obtain a textile-based pressure sensor array. The sensor array shows high sensitivity(0.701 kPa-1), fast response time under loading(≤35 ms), unloading conditions(≤176 ms), high resolution(2.26 sensors/cm2), and large area(1 705 sensing units, 36 cm×21 cm). Specifically, combining the computer with the textile-based pressure sensor array, we form a sitting pressure measurement system to classify the sitting types of users. More importantly, the system is designed in the form of thin cushion, which is easy to be used in daily life. Finally, the practical application is demonstrated and analyzed by catching six postures of users based on sitting pressure information.

1 Experiments

1.1 Fabrication of electrode array fabric

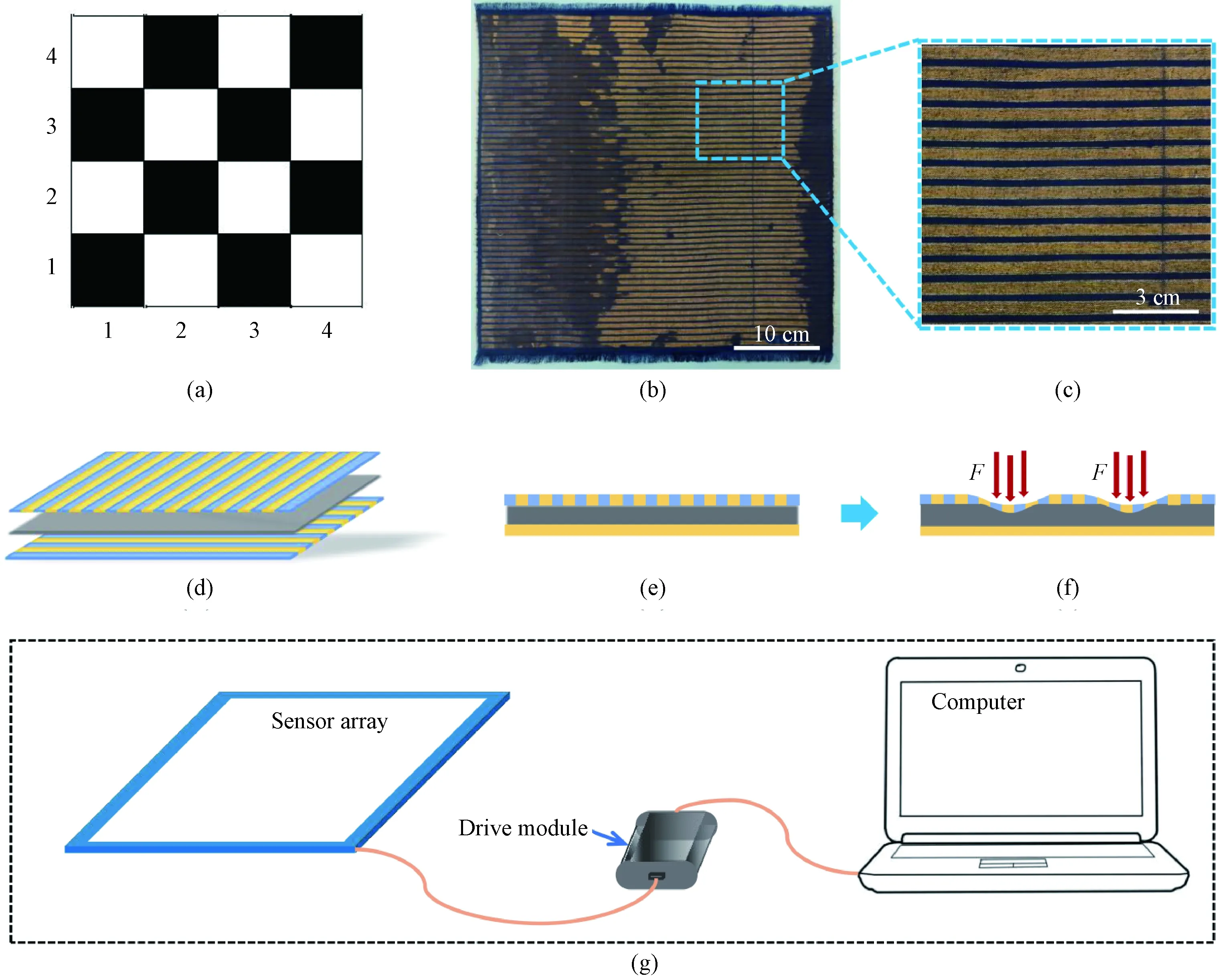

In this work, the electrode array fabric was fabricated from copper sheets and ordinary polyester yarns by utilizing the traditional shuttle weaving machine that can produce fabrics in a large scale. The electrode array fabric was woven according to the texture structure shown in Fig. 1(a). The black squares in Fig. 1(a) are the warp intersection points and the white squares are the weft intersection points. The specific fabricating procedure was as follows: the ordinary polyester yarns were first arranged in the warp direction as the skeleton of electrode array fabric; then, one group of copper sheets and another group of ordinary polyester yarns were arranged in the weft direction by the shuttle to form a strip electrode with a certain width, and there was a certain interval between adjacent electrodes. Figures 1(b) and 1(c) show the photographs of the electrode array fabric, in which the yellow parts are copper sheets and the black parts are ordinary polyester yarns. The electrode array fabric with different electrode widths can be obtained by reasonably arranging the proportion of copper sheets and ordinary polyester yarns in the weaving process.

Fig. 1 Structure and composition of sitting pressure measurement system:(a) texture structure;(b)-(c) electrode array fabric;(d) capacitive pressure sensor array;(e) cross-sectional view;(f) deformation;(g) sitting pressure measurement system

1.2 Assembly of capacitive pressure sensor array and pressure measurement system

The structure of the capacitive pressure sensor array is shown in Fig. 1(d). Two electrode array fabrics were placed orthogonally along the electrode direction, and a thick sponge 2 mm was sandwiched between them. The high density of sponge is 32 kg/m3. Then, the two fabric layers were sewn together with non-conductive threads to prevent any slippage of the layers, which might occur due to the sitting pressure. Figures 1(e) and 1(f) show the cross-sectional view and working mechanism of the capacitive pressure sensor array. When the pressure sensor array was subjected to pressureF[as shown in Fig. 1(f)], the stress point would be deformed, resulting in the increase of capacitance in the corresponding location. Subsequently, each electrode of the capacitive pressure sensor array was arranged and welded on a flexible printed circuit board in order to obtain a user-friendly pressure sensor array. Afterwards, the flexible printed circuit board was connected to computer through driving module, and the sitting pressure distribution test could be performed after running the test software, as shown in Fig. 1(g). And the signal change and corresponding pressure distribution nephogram could be obtained from the test software.

2 Results and Discussion

2.1 Characteristics and working mechanism of capacitive pressure sensor array

Essentially, the capacitive pressure sensor array is composed of multiple parallel-plate capacitors, and the capacitanceCcalculation formula can be described as

whereεis the permittivity of the dielectric layer,Ais the relative area of electrode plate, anddis the distance between electrode plates. It can be seen from the formula that capacitance is inversely proportional to the distance between plates, and proportional to the relative area and dielectric constant. In this work, the main reason for the sensor capacitance change is that the pressure changes the distance between the plates.

The capacitance of each parallel plate capacitor is very small, which is easily affected by the external coupling capacitance. When a conductor approaches or contacts the parallel-plate capacitor, the produced coupling capacitance reduces the initial capacitance. Figure 2(a) shows the influence of the coupling capacitance on capacitance signal. When a finger or a metal conductor approaches and contacts the capacitive pressure sensor array, the capacitance signal decreases from 1.07 pF to 0.67 pF or 0.64 pF. In addition, the capacitance signal drops to 0.18 pF when the capacitive pressure sensor array is clamped by the electromechanical testing machine(ZQ-990A, Dongguan, China) without loading pressure. Therefore, it is necessary to eliminate the influence of human body coupling capacitance on the testing results. The capacitance signal after subtracting the coupling capacitance is used as the initial capacitance for data processing.

The sensitivity and response properties of pressure sensors are also important parameters for determining the practical applications of sensors. As shown in Fig. 2(b), the capacitance response properties of capacitance pressure sensor array under different pressures(0.3-4.0 kPa) are measured. A significant change in capacitance can be detected when the pressure is 0.3 kPa, so the minimum resolution of the sensor is defined to be about 0.3 kPa.

Figure 2(c) shows the relationship between capacitance and pressure obtained by fitting five groups of experimental data. The function between capacitance increment and loading pressure is

y=abx,

wherea= 1.934 ± 0.057,b= 12.674 ± 0.229,xrepresents the capacitance increment, andyrepresents the loading pressure. According to the function, the loading pressure can be calculated by the measured capacitance increment, and the error is shown in the error bar in Fig. 2(c). Therefore, the system can measure the actual pressure, which is helpful for in-depth analysis of sitting pressure.

Figures 2(d) and 2(e) show the relative capacitance change of the capacitive pressure sensor array in a certain pressure range(0-200 kPa), and Fig. 2(d) is obtained by extracting a certain part(0-4 kPa) of Fig. 2(e). The pressure sensitivitySof the pressure sensor can be defined as the slope of the relative capacitance change-pressure curve and it can be calculated by

whereCandC0represent the capacitance with pressure and without pressure, respectively, andPrepresents the loading pressure. Since the hardness of the fabric itself will resist deformation,the capacitance changes slightly when the pressure is less than 0.3 kPa. The capacitance changes slightly and the sensitivity is 0.235 kPa-1in the pressure range(0.3-1.2 kPa). When the pressure increases further, the capacitance changes obviously due to the large deformation of sponge, and the sensor shows a high sensitivity of 0.701 kPa-1in the pressure range(1.2-4.0 kPa). Then, the sensitivity of the sensor decreases with the increase of deformation because of the decrease of pore density and elasticity of sponge. Therefore, the sensor shows the sensitivity of 0.273 kPa-1in the low pressure region(4-20 kPa), 0.048 kPa-1in the medium pressure region(20-60 kPa) and 0.017 kPa-1in the high pressure region(60-200 kPa). The high sensitivity can ensure the accuracy and continuity of the sitting pressure measurement.

The sensor showed good stability in repeated tests in the pressure range of 0-100 kPa [shown in Fig. 2(f)]. Figures 2(g)-2(i) show the single response and recovery processes of the capacitive pressure sensor array under a pressure of 5 kPa. Figure 2(g) shows the fast response time(≤35 ms) under the loading condition, and Fig. 2(i) shows the fast recovery time(≤176 ms) under the unloading condition.

Fig. 2 Pressure sensing characteristics of capacitive pressure sensor array:(a) coupling capacitance;(b) capacitance response signal; (c) capacitance variation and pressure curve;(d)-(e) sensitivity;(f) stability;(g)-(i) response and recovery curves

2.2 Function of sitting pressure measurement system

In this work, the sensing part of the sitting pressure measurement system is a capacitive pressure sensor array composed of multiple longitudinal strip electrodes and lateral strip electrodes. The intersection of each longitudinal strip electrode and lateral strip electrode is a capacitive pressure sensor, and there are 1 705 sensors in the whole capacitive pressure sensor array. While the sensor array works, the lateral strip electrodes send out excitation signals and the longitudinal strip electrodes sequentially receive the excitation signals. Each scan requires 1 705 signal receptions to obtain the capacitance values of all sensors, and processing the data can draw the sitting pressure distribution nephogram. The rapid scanning of the sensor array can realize the real-time display of the sitting pressure distribution nephogram.

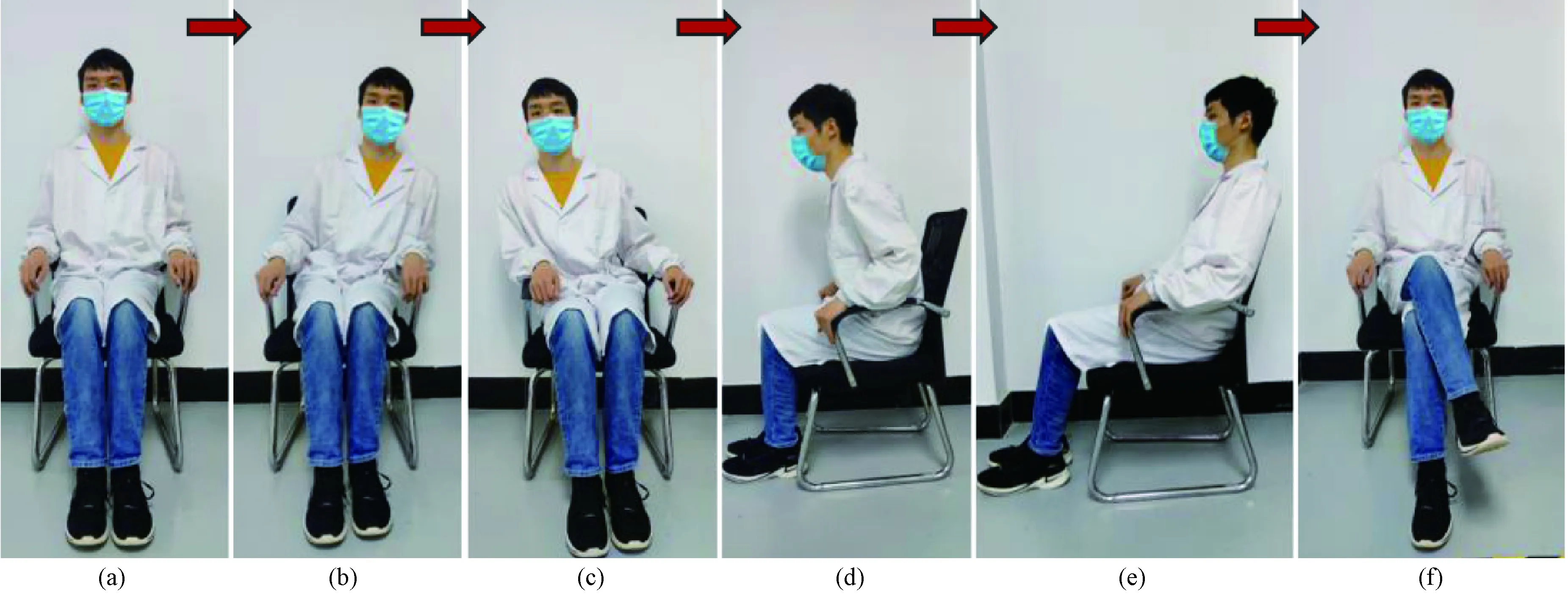

To evaluate the sitting pressure measurement system, we get 10 sets of data by measuring the sitting pressure of 10 volunteers. Six identifiable postures(correct sitting posture, tilted left, tilted right, tilted front, tilted back, and crossed legs) can be obtained by analyzing the measured data, as shown in Figs. 3(a)-3(f).

As shown in Fig. 4, there is a clear distinction among the pressure distribution nephograms in different postures [shown in Figs. 4(a)-4(f) corresponding to Figs. 3(a)-3(f)]. Different colors correspond to different capacitance increments, and the corresponding pressure can be calculated according to the capacitance increment. When sitting correctly [shown in Fig. 3(a) and Fig. 4(a)], the postmedian areas(ischium areas) of the left and right hips are often high-pressure areas, which are changed obviously by posture changing. When the body is tilted to one side [shown in Figs. 3(b) and 3(c) and Figs. 4(b) and 4(c)], the center of gravity shifting results in pressure increase on the corresponding side and decrease on the other side. When the body is tilted forward [shown in Fig. 3(d) and Fig. 4(d)], the pressure in the ischium areas decreases, and the force is uniform without any significant prominent points. When the body is tilted backward [shown in Fig. 3(e) and Fig. 4(e)], the center of gravity moves backward and the pressure in the ischium areas increases. When the two legs crossed [shown in Fig. 3(f) and Fig. 4(f)], the pressure on one side increases and the other only showed small pressure around the ischium. By analyzing and remembering the pressure distribution data, we can judge whether the sitting posture of the human body is correct, so as to monitor the sitting posture of the human body. The as-prepared pressure measurement system with high resolution and good performance, which can provide accurate and stable sitting posture monitoring in real-time.

Fig. 3 Photographs of six different postures:(a) correct sitting posture;(b) tilted left;(c) tilted right;(d) tilted front;(e) tilted back;(f) crossed legs

Fig. 4 Pressure distribution nephograms of six different postures:(a) correct sitting posture;(b) tilted left;(c) tilted right;(d) tilted front;(e) tilted back;(f) crossed legs

3 Conclusions

In this research, a textile-based capacitive pressure sensor array was designed and developed in order to measure sitting pressure distribution simply and conveniently. The system can be used to monitor the user's sitting posture and analyze six types of postures according to pressure distribution. To obtain an accurate and complete pressure distribution nephogram, a large-area high-density pressure sensor array(36 cm × 21 cm, 1 705 sensing units, 2.26 sensors/cm2) was produced. The pressure sensor array shows high sensitivity(0.701 kPa-1), fast response times under loading(≤35 ms), and unloading conditions(≤176 ms). In order to analyze and identify different sitting postures, we measured the pressure distribution of 10 volunteers under different sitting postures, and obtained six clearly distinguishable types of sitting postures. According to the capacitance increment corresponding to different colors of the pressure distribution nephogram, we can also calculate the pressure of each part. In the future, we will implement a complete sitting pressure measurement system that adds various posture types and image processing methods to distinguish different sitting postures, which can monitor the user's sitting posture and pressure distribution more accurately and effectively.

Journal of Donghua University(English Edition)2021年6期

Journal of Donghua University(English Edition)2021年6期

- Journal of Donghua University(English Edition)的其它文章

- Effect of Surface Energy of Electrospun Fibrous Mat on Dynamic Filtration Performance for Oil Particles

- Seam Damage Control and Image Analysis for Cuprammonium Fabrics

- Robust Waterborne Polyurethane/Wool Keratin/Silk Sericin Freeze-Drying Composite Membrane for Heavy Metal Ions Adsorption

- Enhancing Accuracy of Flexible Piezoresistive Pressure Sensors by Suppressing Seebeck Effect

- Reduced Switching-Frequency State of Charge Balancing Strategy for Battery Integrated Modular Multilevel Converter

- Data Augmentation Based Event Detection