Effect of Freeze-Thaw Treatment on Structural, Thermal, Mechanical and Physical Properties of Starch-Based Films

GAO Shan, YU Li, DENG Yun, WANG Danfeng, ZHONG Yu

(SJTU-OSU Innovation Center for Environmental Sustainability and Food Control, Key Laboratory of Urban Agriculture, Ministry of Agriculture and Rural Affairs, School of Agriculture and Biology, Shanghai Jiao Tong University, Shanghai 200240, China)

Abstract: A series of edible films were obtained using native potato starch (PS) or modified potato starches, including hydroxypropyl distarch phosphate (HDP), acetate starch (AS) and oxidized starch (OS) by the casting method. The effects of freeze-thaw (F-T) treatment on the physical, mechanical and barrier properties, microstructure and thermal stability of the films were studied. X-ray diffraction (XRD) indicated that potato starch granules displayed a typical B-type crystalline structure, the crystallinity was damaged during the film-forming process, and the peak intensity was decreased obviously after F-T treatment. F-T treatment damaged the microstructure of starch-based films as observed by scanning electron microscopy (SEM), and there appeared obvious cracks on PS film, and honeycomb-like and lamellar structures on AS film, while OS and HDP films maintained a more complete morphology. In the thermogravimetric curves of starch-based films, four stages of mass loss appeared as temperature increased, corresponding to water loss, volatilization of glycerol,and depolymerization and decomposition of starch, respectively. Nevertheless, F-T treatment had little effects on the thermostability. At room temperature, PS film had the best mechanical property with tensile strength (TS) of 2.29 MPa and elongation at break (EB) of 68.82%. After three F-T cycles, film TS increased at least twice and EB generally declined,while solubility and WVP changed only a little. HDP film displayed much better F-T stability considering the microstructure,mechanical property, water vapor permeability and water solubility collectively, indicating its potential applications in frozen low-moisture foods.

Keywords: starch-based edible film; freeze-thaw stability; modified starch; physical property; structural characterization

Nowadays, extensive attention has been paid to the edible film made from biopolymers due to the essential role in replacing plastic packaging on food products[1]. Edible films have been utilized extensively to prolong the shelf life and improve the quality of food including fresh produce, meat,dairy or seafood[2]. Especially, edible films are good alternatives for preserving frozen food as they can reduce water transfer between the food and the surrounding atmosphere, and may enhance structural integrity of food after thawing[3].

The biopolymers for producing edible films can be derived from different origins, including polysaccharides,proteins or lipids[4]. Among them, the starches are of the most widely usage because of its biodegradability, renewability,abundance and low cost[5]. However, the application of native starch films is limited because of its low water barrier ability, high water solubility and poor mechanical properties[6-7]. Chemical modification has been commonly practiced to overcome the adverse properties of native starches. Previous studies showed that carboxyl groups of the oxidized starch were more hydrophobic and could reduce the sensitivity to the bonded and external water of the resulted films[8]. Meanwhile, Baruk et al.[9]reported that water vapor permeability of banana starch films increased with the increase in oxidation level, and oxidation enhanced the tensile strength while decreased the elongation at break of the films.Yildirim-Yalcin et al.[10]indicated that the values of oxygen permeability, water vapor permeability and solubility of the edible films made from corn starches that cross-linked with sodium trimetaphosphate were lower than those of native starch films.

When stored in different environmental conditions,starch films undergo physical or chemical changes which affect their retrogradation kinetics and result in property variations[11]. Especially, storage temperature can influence the structural characteristics of starch films and change the barrier and mechanical properties. It was reported that tensile strength (TS), elastic modulus and water vapor permeability(WVP) values of cassava starch-based film increased with the increase in temperature (10-40 ℃)[12]. Besides,freezing storage (-20 ℃) could slow down color-change but increase WVP of kudzu starch-based film[13]. During freezing, ice crystal growth induces physical stress, causes phase separation of starch system, and results in rapid starch retrogradation during storage. Upon thawing, the meltwater can be easily released, known as syneresis[14]. Retrogradation and syneresis can be accelerated by repeated freezing and thawing (F-T), which is detrimental to the starch pastes and gels[15]. And chemical modification is commonly practiced to overcome retrogradation and syneresis of native starch[16]. It was reported that after a F-T cycle, an increase in the stiffness and syneresis was found in the native corn starch paste, while the negative change did not appear in the hydroxypropyl distarch phosphate paste[17]. Zhang Faling et al.[18]found that the freeze-thaw stability of acetate starch was superior to that of native starch and less water was exuded from acetate starch gel. In addition, the carboxyl and carbonyl groups introduced by oxidation might prevent the starch from rearranging and reuniting and lead to reduced retrogradation or syneresis[19].However, the influence degree of repeated F-T treatment on the performance of starch film is less known, and whether chemical modification can reduce the negative influence of F-T is unclear, which is important for the application in coating or packaging frozen food.

The major purpose of this study was to investigate the effects of F-T treatment on the properties of starch films including native potato starch (PS), hydroxypropyl distarch phosphate (HDP), acetate starch (AS), oxidized starch (OS).The property parameters included microstructure, mechanical property, water sensitivity, and thermostability.

1 Materials and Methods

1.1 Materials and reagents

PS, HDP (hydroxypropyl content of 3.0%) and AS(acetyl content of 1.4%) were provided by Gansu GLDARK potato modified starch company. OS (carboxyl content of 1.0%) was provided by Hangzhou STARPRO starch company. Glycerol, of analytical grade, was purchased from Aladdin Reagent Co., Ltd..

1.2 Instrument and equipment

D8 ADVANCE DA Vinci X-ray diffractometer Bruker AXS company, Germany; Sirion 200 field-emission scanning electron microscope FEI company, USA; TA.XT PLUS texture analyzer Stable Micro Systems company,UK; TGA8000 thermogravimetric analyzer PerkinElmer company, USA.

1.3 Methods

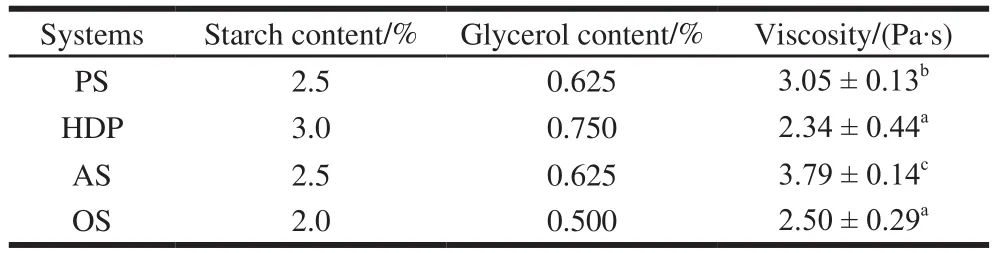

1.3.1 Preparation of edible films

Edible films were processed by casting method as previously reported with some modifications[20]. Four different systems were used to prepare film-forming solutions and the components were listed in Table 1. The aqueous suspensions were stirred at 80 ℃ for 30 min. The resulted solutions were degassed with a vacuum pump for 30 min, casted on glass plates(25 cm × 25 cm) with commercial release agent and dried at constant temperature and humidity (25 ℃, relative humidity(RH) 50%) for 72 h to obtain films with thickness ca. 0.1 mm.

Table 1 Composition and viscosity of film-forming solutions of native and modified potato starch

1.3.2 F-T treatment of edible films

The prepared films along with the glass plates were frozen at -20 ℃ for 24 h, and then thawed at 25 ℃ for 6 h[21]. The F-T cycle was repeated three times before peeling off the films[22].

1.3.3 X-ray diffraction analysis

X-ray diffraction (XRD) was used to observe crystalline structures of starch powder and film (3 cm × 3 cm) with Cu-Kα radiation operating at 40 kV and 30 mA. XRD patterns were obtained in an angular range of 5°-50° (2θ)with scanning rate of 5 (°)/min.

1.3.4 Scanning electron microscope observation

The film was conditioned in desiccator containing P2O5for 7 days and surface morphology of the film after F-T treatment was observed using a field emission scanning electron microscope (SEM) at 10 kV. The magnification times was 80 000.

1.3.5 Mechanical characterization measurement

The mechanical properties of the edible films were evaluated by determining tensile strength (TS) and elongation at break (EB) using a TA-XT2i texture analyzer, and the experiment was repeated eight times for each sample[20].

Film samples were cut into 15 mm × 100 mm strips and clamped using tensile grips probe (A/TG). The initial grip separation was set as 50 mm and tensile speed was 0.8 mm/s. TS and EB of the films were calculated as formula (1) and (2), respectively.

WhereFmis the measured maximum tensile strength at break/N;Lis the thickness of the sample/mm;Wis the width of the sample/mm.

Wherelmis the measured maximum length at break/mm;l0is the original length of the sample/mm.

1.3.6 Water content measurement

Testing samples (0.5 g in mass) were dried in an oven at 105 ℃ for 24 h. Water content (WC) was calculated as percentage mass loss. Three replicate measurements were carried out for each sample.

1.3.7 Water solubility measurement

The samples were first dried overnight and weighted,then conditioned at room temperature in beakers containing 30 mL of distilled water for 24 h, and finally dried to constant weight. Water solubility (WS) of the testing samples was calculated as the percentage of mass loss, and the test was repeated three times for each sample.

1.3.8 Water vapor permeability measurement

Film samples were cut into rectangular pieces of 80 mm ×80 mm, and sealed over circular acrylic cells (Φ57 mm ×15 mm) containing distilled water of 11 mL. The cells were placed at RH of 70% and weighted every hour. WVP was calculated as formula (3)[20], and each test was repeated three times.

Wheremis the mass of water permeated through the film/g;Lis the thickness of the sample/mm;Ais the permeable area/m2;tis the penetration time/d; ΔPis water vapor pressure difference/kPa.

1.3.9 Thermogravimetry analysis (TGA)

Thermal characterization of edible film was measured by Pyris 1 thermo gravimetric analyzer. The testing samples (ca.5 mg) were crushed, placed in alumina cells, and heated from 30 to 500 ℃ at the speed of 10 ℃/min under the protection of nitrogen with flow rate of 60 mL/min.

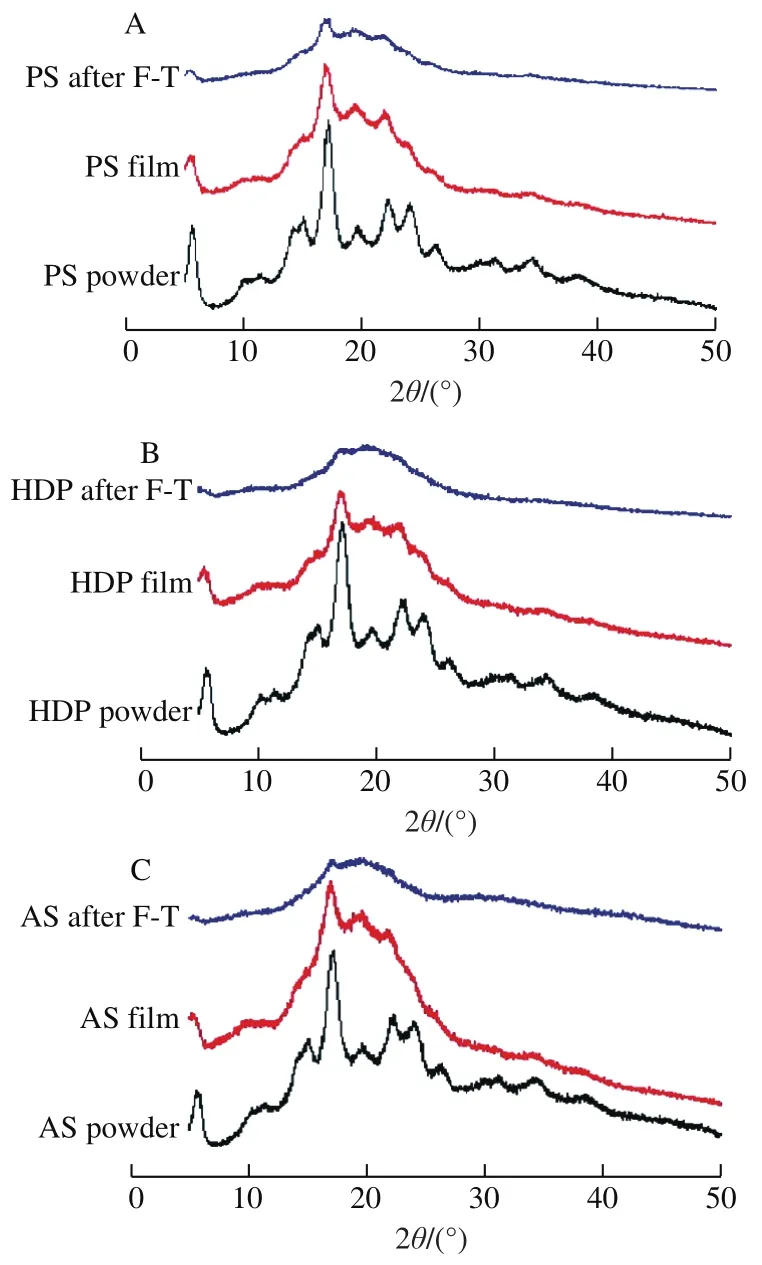

1.3.10 Evaluation criteria

Fuzzy comprehensive evaluation method was used to judge the performance of starch film with multiple experimental factors considered[23]. Subordinating degree function was introduced as formula (4) and (5).

WhereX(u) is the function value of a parameter;Xiis the data value of the point to be analyzed;Xmaxis the maximum value in the data column of a parameter; andXminis the minimum value in the data column of a parameter.

After fuzzy transformation, the performance indexes were turned into cumulative weighted membership value∑X(u)Y. The larger it was, the better the performance of the film would be. The experimental factors includedWVP(negative effect),TS(positive effect),EB(positive effect), andWS(positive effect). The weight subsetYof the comprehensive evaluation was {0.40, 0.20, 0.20, 0.20}.

1.4 Statistical analysis

Experimental data were analyzed by analysis of variance(ANOVA) with SPSS Statistics 19 (version 13.0) and expressed as mean values ± standard deviation. The minimum significant difference (LSD) analysis was performed with the level of significance set atP< 0.05.

2 Results and Analysis

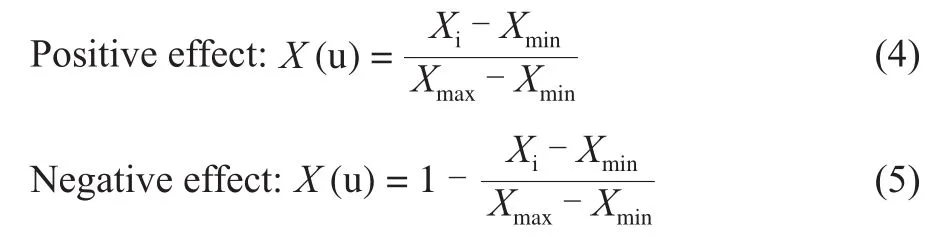

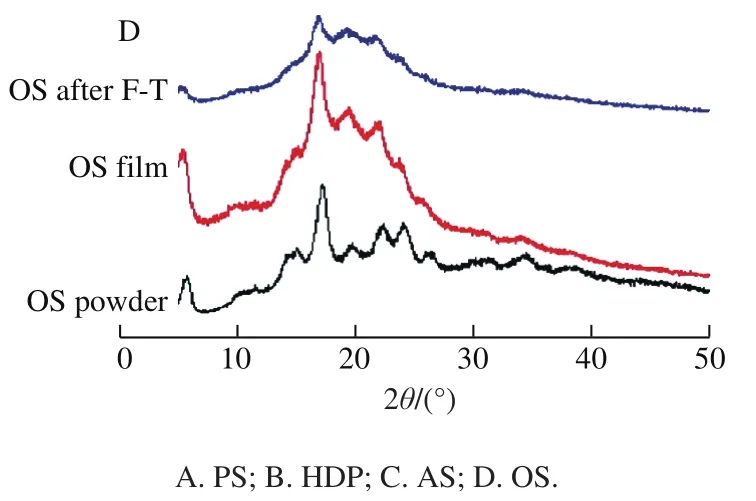

2.1 Results of X-ray diffraction

The X-ray diffractograms of starch powders, and starch films before and after F-T treatment were illustrated in Fig. 1. The diffraction curves of PS powder consisted of peak diffraction and dispersive diffraction, indicating that the PS powder was composed of both crystalline and amorphous regions. PS powder showed a typical B-type pattern with reflection peaks at 2θvales of 5.6°, 15°, 17°,22° and 24°[24]. The peak positions of modified starches (MS)were consistent with the positions in native PS, while the relative intensities decreased. The reason might be that the molecular chains of the crystallized starch were damaged during chemical modification[25]. In present study, the XRD patterns of all starch films exhibited B-type as well, but the intensities declined as compared with starch powders. After the film-forming process, the crystallinity loss was to be expected due to the disruption of H-bonding between the starch molecules[26]. After F-T treatment, the diffraction-peak intensities of starch films reduced significantly compared with original film curves. The diffraction peaks of HDP film even disappeared at 2θ> 17.2°. It was reported that the relative crystallinity of wheat starch increased after multiple F-T cycles, as F-T accelerated organization of double helices or crystal perfection[27]. However, starch suspension was used for F-T treatment in their study, while the mobility of starch chain was greatly restrained in film form at low WC in our research. The repeated F-T might weaken the doublehelix structures of starches, and the molecular arrangements became more disordered[28]. It was also reported that F-T disrupted the crystalline structure within starch granules or damaged the short-range molecular order of double helices in the starch granules[28].

Fig. 1 X-ray diffractograms of native and modified potato starch as well as starch films

2.2 Results of scanning electron microscope

Starch films before F-T presented homogeneous and smooth surfaces without pores or cracks[29]. After three F-T cycles, the surface topography of the films changed (Fig. 2).There appeared obvious cracks on PS film, and the surfaces of HDP and OS films became rougher with many small protuberances. In addition, there exhibited honeycomb and lamellar structures on AS films. During frozen stage, ice crystals formed in the films and caused micro-mechanical stresses. After thawing process, the melting ice crystals led to the relaxation[29]. It could be observed from Fig. 2 that the structural integrality of PS film was easier to be destroyed,while OS and HDP films were more stable. It might be deduced that HDP or OS film could better resist the damage of F-T treatment compared with PS film.

Fig. 2 Surface morphology of native and modified potato starch films after freeze-thaw treatment

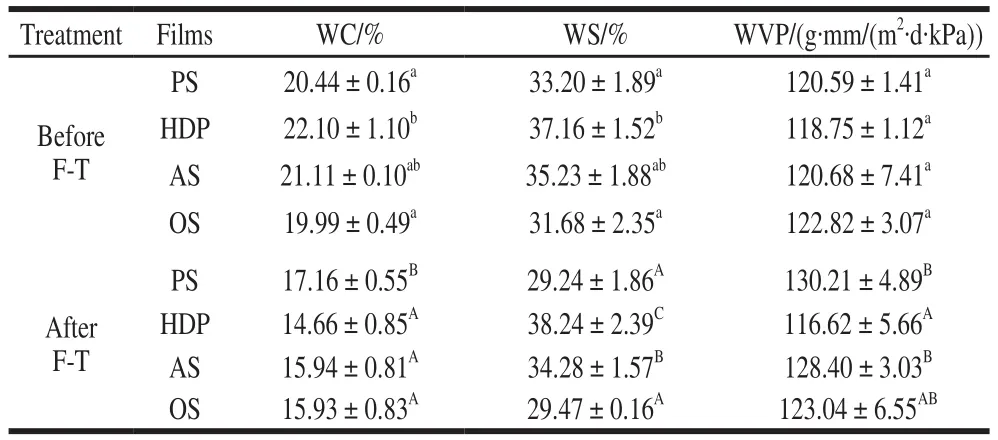

2.3 Results of water content, water solubility and water vapor permeability of starch films

As shown in Table 2, the WC of starch films were all around 20% before F-T, and the values went down after F-T. The reduce might be caused by water evaporation and contributed partly to the changes of water barrier and mechanical properties of the films[12-13].

Table 2 Water content, water solubility, and water vapor permeability of native and modified potato starch films before and after freeze-thaw treatment

Film solubility in water is a parameter depending on application. Films used for high moisture foods should have low WS, while edible films should have high WS[29]. WS of starch films before F-T ranged from ca. 32% to 37%, similar with the reported data[30]. And there were no differences in WS after F-T, which indicated less influence of F-T on WS.It was also reported low temperature did not show obvious influence on WS of kudzu starch-based films[13].

Preventing water transfer between environment and food product was one of the most important functions for food packaging[31]. And for this purpose, smaller WVP was preferred. The WVP values of all the films were similar before F-T, at around 120 g·mm/(m2·d·kPa). However, the values increased significantly for PS and AS films after F-T.As shown in Fig. 2, there existed obvious damages in PS and AS films after F-T, and when cracking or fracture occurred,the WVP elevation was sure to be anticipated[3]. However,the WVP values of starch-based films were lower than those of pea starch, rice starch, methylcellulose and hydroxypropyl methylcellulose films[32].

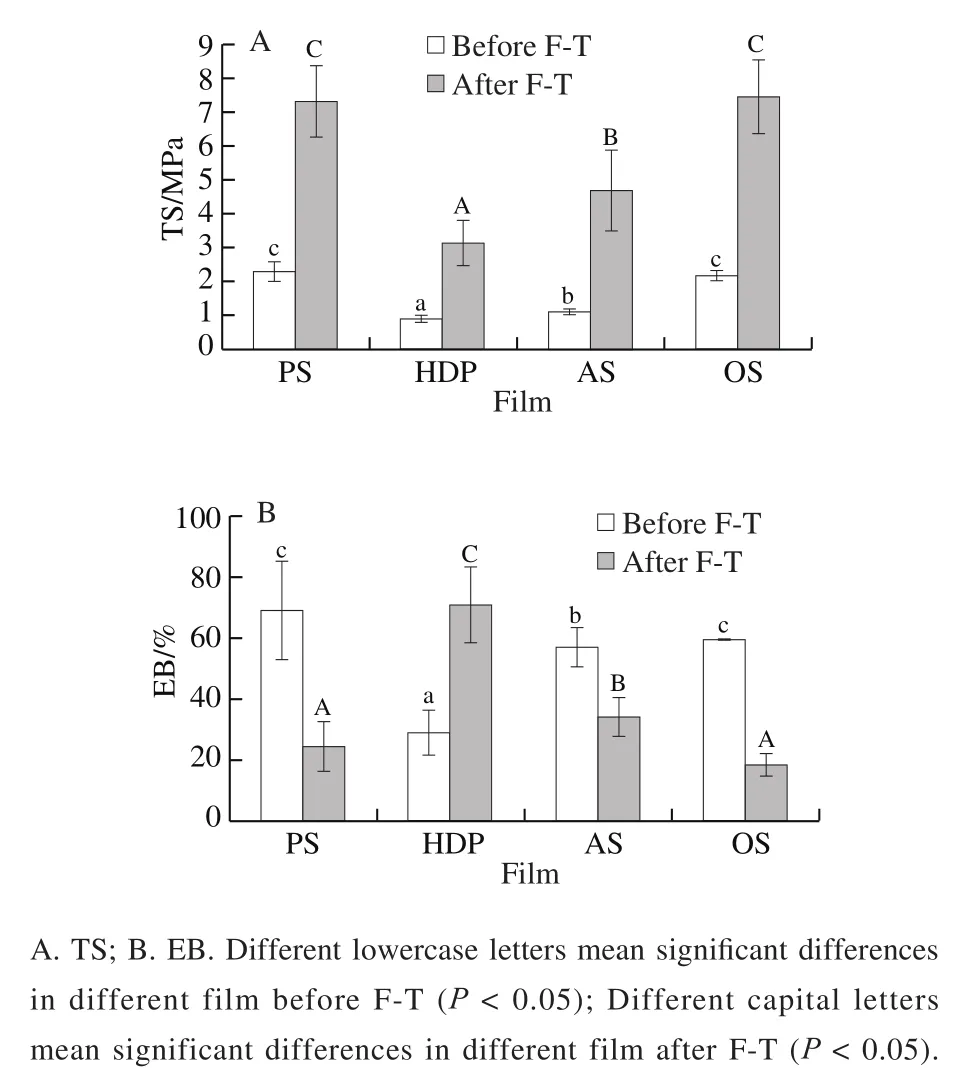

2.4 Mechanical characterization

The mechanical property of edible film is required for retaining the integrity and resisting against external stress[33]. As observed in Fig. 3, TS of PS film before F-T was 2.29 MPa and the EB was 68.82%, which were similar with the data of cassava and corn starch-based films[34].

Fig. 3 Mechanical properties of native and modified potato starch films before and after freeze-thaw treatment

Generally, crosslinking, esterification and oxidation modifications have positive effects on mechanical properties and water sensibilities of films[9-10]. However, TS and EB values of MS films decreased as compared with those of PS film in present study, with data of OS film were the nearest(2.18 MPa, 59.33%). Biduski et al.[29]reported higher TS but lower EB values for acid and oxidation modified starch films,and the different trends with our study might be attributed to the differences of modification degrees and the amounts of active groups[35]. Higher modification degree induced greater heterogeneity in the spacing between action sites.And heterogeneity brought about stress on the chains and then transferred the stress to other chains, which led to the decreased internal resistance[36]. Moreover, higher densities of covalent bonds during modification process did not allow required flexibility of chains to be close enough for physical stabilization by hydrogen bounds, generating low degree of crystallinity[36], which was also found in present study.

After F-T, TS of all films increased to 3-4 times of original values before F-T. Although the molecular ordering was declined (Fig. 1) and micro-integrity was damaged(Fig. 2), the loss of water (Table 2) was more related to the enhancement of macro-strength[12]. In addition, low temperature decreased the molecular mobility and caused cryo-concentrated effects on films, and resulted in the relatively higher TS as well[13]. EB generally showed the opposite trend with TS, while it was worth noting that the EB of HDP film increased to 70.76% after F-T. This phenomenon might be attribute to the inherent properties of HDP, as it was resistant to excessive granular swelling and possessed desired short texture property after F-T[37].

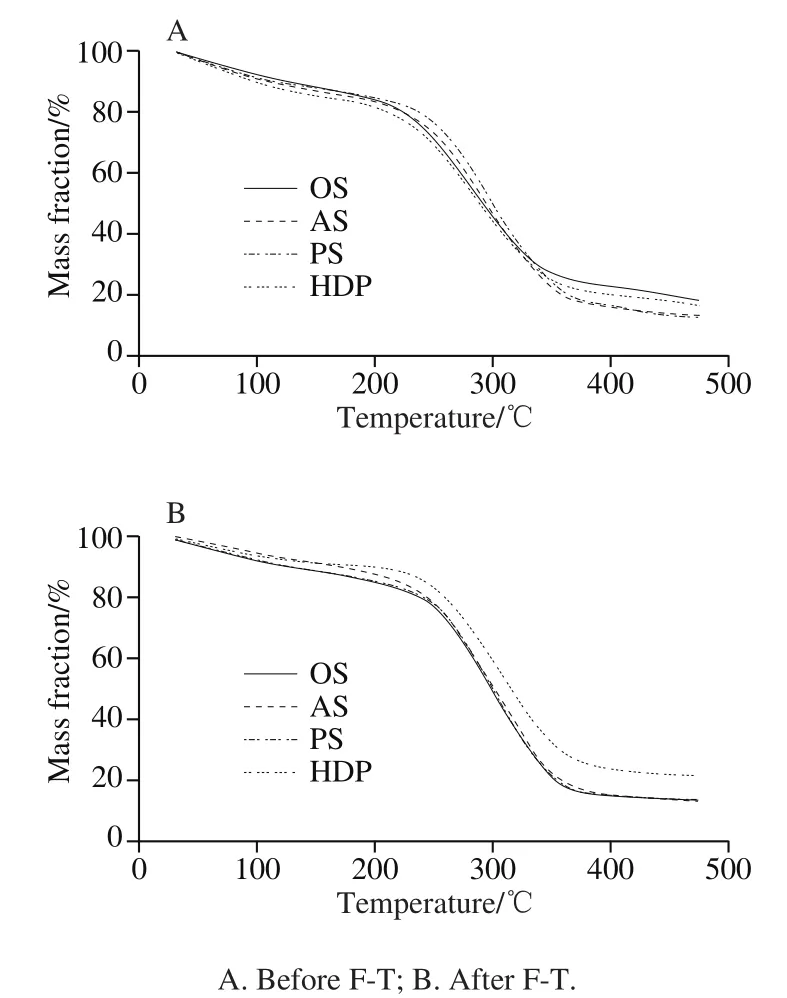

2.5 Results of thermogravimetry analysis

TGA could reflect thermal stability of film by measuring mass loss with temperature increase. It could be seen from Fig. 4Athat TG curves of starch films before F-T presented four stages of thermal decomposition.

Fig. 4 Thermogravimetric analysis of native and modified potato starch films before and after freeze-thaw treatment

The first degradation stage occurred under 30-150 ℃could be attributed to water loss. According to literature[38],mass loss at the first decomposition stage related to bound WC, which reflected starch retrogradation. The second degradation stage ranged from 150 to 250 ℃, and corresponded to volatilization and degradation of glycerol.The third stage of mass loss at about 305 ℃ was probably due to the depolymerization of starch and conversion to smaller molecules[8]. The fourth degradation could be resulted from the decomposition of the carbon components coming from the starch and the glycerol[8]. The thermal degradation behaviors of starch films after F-T were similar to those of untreated films (Fig. 4B), and less mass loss of HDP film at first stage indicated less retrogradation degree[38], which was consistent with the result of XRD.

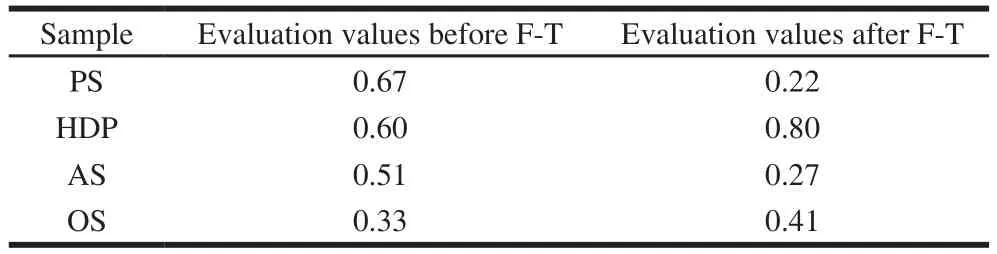

2.6 Comprehensive evaluation

As seen from Table 3, PS film presented the best performance before F-T (0.67), indicating that chemical modifications had negative effects on mechanical properties and water sensibilities in present study. However, repeated F-T cycles brought about more damages on PS film, while HDP film possessed much better F-T stabilities (0.80),which might be due to that double esterification crosslinking reaction of HDP starch could better resist the damage of freeze-thaw treatment.

Table 3 Comprehensive evaluation scores of native and modified potato starch films before and after freeze-thaw treatment

3 Conclusion

At room temperature, native PS film had the best mechanical property as compared with MS films. F-T treatments led to damages of starch films, decreased the intensities of crystallization peaks and obviously changed the mechanical property, while had little influence on WS and WVP. HDP film possessed the best overall performance after F-T, indicating it was more suitable for use in frozen low-moisture foods such as frozen dough. The practical significance of HDP film should be further verified considering the storage quality and microstructures of the coated products. However, the performance of starch film should be further enhanced by mixing with other biopolymers or addition of nanoparticles.

- 食品科学的其它文章

- 天然抗氧化剂对鱼糜及鱼糜制品抗氧化能力及品质影响的研究进展

- 茶多酚对小麦淀粉理化特性和面包品质的影响及机理

- 运动对苏尼特羊脂肪代谢和肉品质的影响

- 升温方式对鲢鱼肌球蛋白结构和理化性质的影响

- Thermal Unfolding and Aggregation Process of Recombinant Staphylococcal Enterotoxin M (rSEM) Associated with Potential Toxin Responsible for Staphylococcal Food Poisoning

- 小米麸皮水溶性膳食纤维-Cr(III)配合物的合成、表征及其体外抗氧化活性