Smart Manufacturing and Intelligent Manufacturing: A Comparative Review

Baiun Wang, Fei Tao, Xuong Fang*, Chao Liu, Yuei Liu, Theoor Freiheit

a State Key Laboratory of Fluid Power and Mechatronic Systems, School of Mechanical Engineering, Zhejiang University, Hangzhou 310027, China

b Department of Mechanical Engineering, University of Michigan, Ann Arbor, MI 48109, USA

c Chinese Academy of Engineering, Beijing 100088, China

d School of Automation Science and Electrical Engineering, Beihang University, Beijing 100191, China

e School of Mechanical Engineering, Xi’an Jiaotong University, Xi’an 710049, China

f School of Engineering, Cardiff University, Cardiff CF24 3AA, UK

Keywords:

ABSTRACT The application of intelligence to manufacturing has emerged as a compelling topic for researchers and industries around the world. However, different terminologies, namely smart manufacturing (SM) and intelligent manufacturing (IM), have been applied to what may be broadly characterized as a similar paradigm by some researchers and practitioners. While SM and IM are similar, they are not identical.From an evolutionary perspective,there has been little consideration on whether the definition,thought,connotation, and technical development of the concepts of SM or IM are consistent in the literature. To address this gap, the work performs a qualitative and quantitative investigation of research literature to systematically compare inherent differences of SM and IM and clarify the relationship between SM and IM. A bibliometric analysis of publication sources, annual publication numbers, keyword frequency, and top regions of research and development establishes the scope and trends of the currently presented research. Critical topics discussed include origin, definitions, evolutionary path, and key technologies of SM and IM. The implementation architecture, standards,and national focus are also discussed. In this work,a basis to understand SM and IM is provided,which is increasingly important because the trend to merge both terminologies rises in Industry 4.0 as intelligence is being rapidly applied to modern manufacturing and human–cyber–physical systems.

1. Introduction

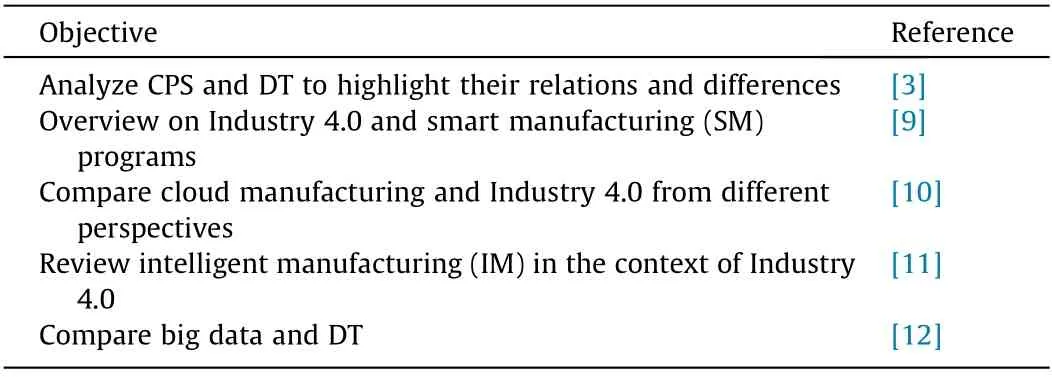

Information and communication technology plays a significant role in manufacturing systems.The ongoing development of cyber systems and related intelligent and smart technologies [1–4] has given rise to big data, Industry 4.0, the Internet of Things (IoT),cloud computing, cyber–physical systems (CPSs), digital twin(DT), and next-generation artificial intelligence (AI) [5–8]. Various advanced manufacturing paradigms have been proposed, using these concepts to enhance manufacturing processes and systems with a degree of ‘‘intelligence” or ‘‘smartness.” Table 1 [3,9–12]lists several survey papers linking or comparing these concepts and technologies.

In recent years, major countries have been addressing the importance of the transformation and upgrade of their manufacturing sectors, arousing attention by society toward digitalization,networking, and smartness/intelligence in manufacturing. Academic and industry researchers have developed two paradigms to describe the deep integration of manufacturing and advanced information/cyber technologies: smart manufacturing (SM) and intelligent manufacturing (IM) [4,13–15].

Preliminary examinations of the relationship between SM and IM have been made by scholars. Zhou et al. [4] divided the evolution of IM into three stages. The first stage, before 2000, is digital manufacturing—using computers in support of machine and system level operations with some use of decision-tree expert systems. The second stage, after 2000, is SM, where digital manufacturing leverages networking to adapt to dynamic environments and customer needs, enabled by improved digital models.The third stage, after 2020, is next-generation IM (NGIM), whichuses machine learning (ML), big data, and IoT to better integrate systems of humans and machines. Thoben et al. [9] stated that SM and IM are sometimes used synonymously, but IM focuses on technologies more than organizational concepts,while SM focuses more on analytics and control.Yao et al.[16]and Zhang et al.[17]regarded SM as an emerging version of IM,with smart technologies(IoT, CPS, cloud computing, and big data) enabling Industry 4.0.

Table 1 Papers linking or comparing emerging concepts/technologies toward Industry 4.0.

These studies reflect several early views of the SM–IM relationship. However, they do not determine if there are true differences between SM and IM, or if it is merely a difference in terminology used by researchers who lack of communication and consensus with each other. Moreover, during the evolution of SM and IM,there is a lack of careful consideration on whether the definition,thought, connotation, and technical development of SM and IM concepts in the literature are consistent. ‘‘Smart” and ‘‘intelligent”are two similar adjectives that are often used to describe clever and bright people [18,19], while the dictionary definition of‘‘intelligence” infers a higher degree of capability compared with‘‘smartness” [20]. In non-English speaking countries, SM and IM have been translated into the same phrase, which could cause confusion if they are truly different paradigms. For example, in China, SM and IM are usually translated to the same Chinese phrase ‘‘智能制造.”

Other questions arising about the relationship between SM and IM include:

• What are origins and academic definitions of SM and IM?

• What is their relation to other manufacturing paradigms,including flexible and cloud manufacturing?

•Does their current development status differ,especially in key technologies, frameworks, and architectures?

• Is the direction of development of SM and IM merging or diverging?

To clarify the differences in terminology and dispel the notion that modern applications of intelligence to manufacturing represents two paradigms, this review systematically compares SM and IM research areas, representative technologies, and architectures,in order to highlight their features.Future research pathway to further harmonize and merge SM and IM is also suggested.

2. Methodology

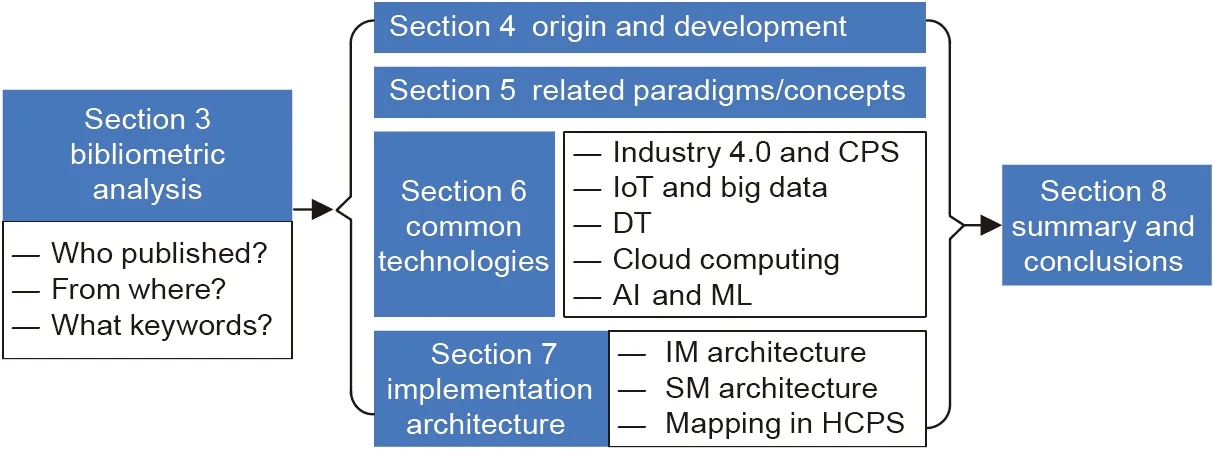

The scope of this work comprises an overview and comparison of concepts and definitions related with SM and IM, and a discussion of research issues and architectures. The paper’s outline(Fig. 1) follows the following methodological steps:

(1) Conduct a bibliometric analysis by identifying papers through title,abstracts,and keywords found in the Web of Science(WoS) Core Collection and Scopus databases, and then quantitatively analyze the top keywords with network analysis;

(2)From the top keywords,review the state-of-the-art from the literature and identify key topics on the origin, development, key technologies, and implementation architectures of SM and IM.Identify the chronology and qualitatively examine similarities among common definitions and characterization principles;

(3) Evaluate the relationship among SM, IM, and other paradigms, and quantify co-occurrence of key concepts between SM and IM;

(4)Enumerate key word frequency to evaluate shared common key technologies and review examples for understanding;

(5) Review implementation architectures and national focus of SM and IM, and examine factors typically included.

3. Bibliometric analysis on SM/IM

Bibliometric analysis evaluates current trends in the research literature, providing an overall outline and structure of the area,and guidelines and motivations for future research[18,19]. Bibliometric data was gathered from WoS and Scopus using ‘‘intelligent manufactur*”and‘‘smart manufactur*”as the search query within publication titles, abstracts, and keywords to the end of 2019. In this section, we compare research publication growth, country/region analysis and cooperation, top journals or conferences, and keyword co-occurrence frequency in SM and IM.

3.1. Annual publication volume

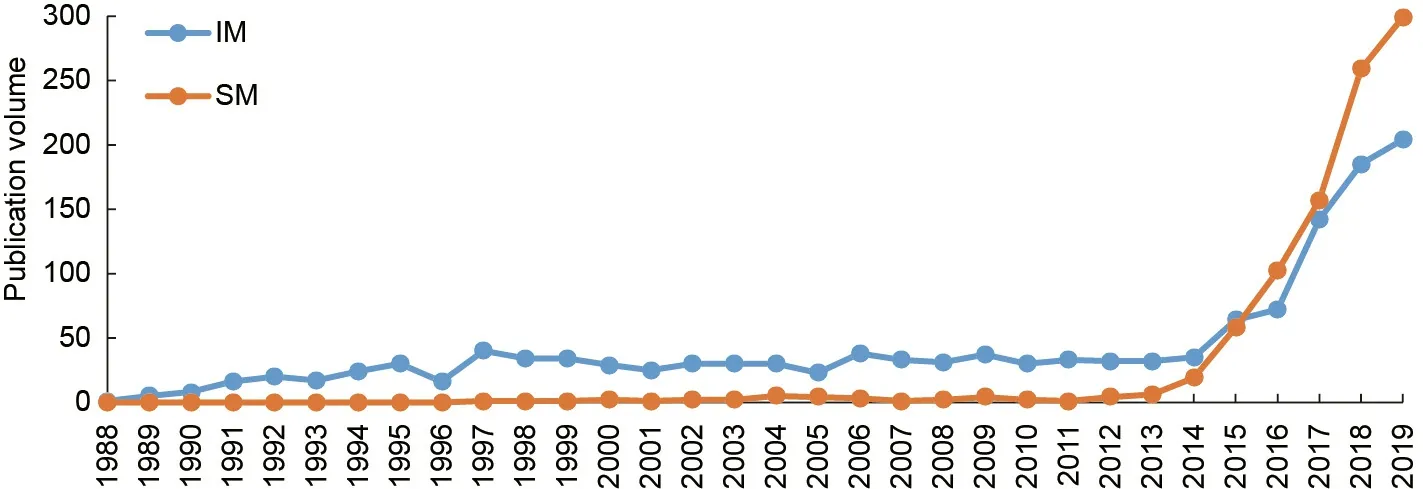

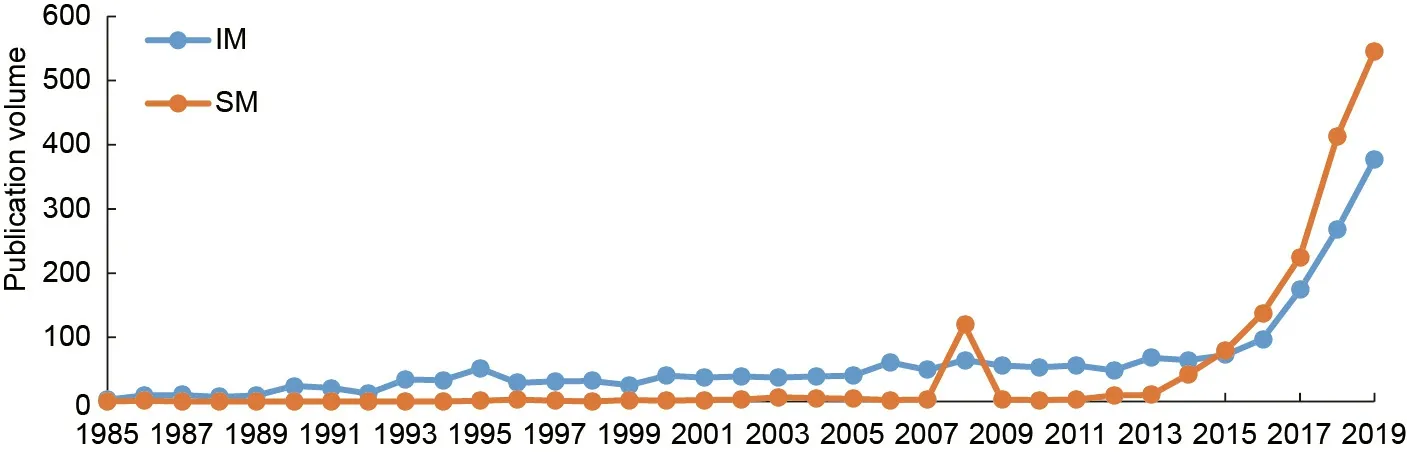

The annual publication volume indicates the interest by scholars in SM and IM research from WoS(Fig.2)and Scopus databases(Fig.3).The first publication on SM found in database was by Schaffer[20]—‘‘Artificial intelligence:a tool for smart manufacturing” in 1986. From 1985 to 2008, publications on IM grew slowly,with the WoS and Scopus databases showing annual publications from 1991 to 2012 numbering about 20–60 per year. A jump in 2008, when more than 100 papers were indexed in Scopus, can be attributed to the International Conference on Smart Manufacturing Application (ICSMA) 2008, even though only a few of these papers actually talked about SM. Figs. 2 and 3 show that more attention was paid to both SM and IM starting around 2013, by scholars who used SM-related terminologies,gaining the lead since 2015.

Fig. 1. Scope and sections of this paper. HCPS: human–cyber–physical system.

Fig. 2. Annual publication volume on SM and IM during 1988–2019 from WoS database. Total records are 1069 for SM, 1467 for IM.

Fig. 3. Annual publication volume on SM and IM during 1985–2019 from Scopus database. Total records are 1968 for SM, 2297 for IM.

3.2. Country/region and institution analysis

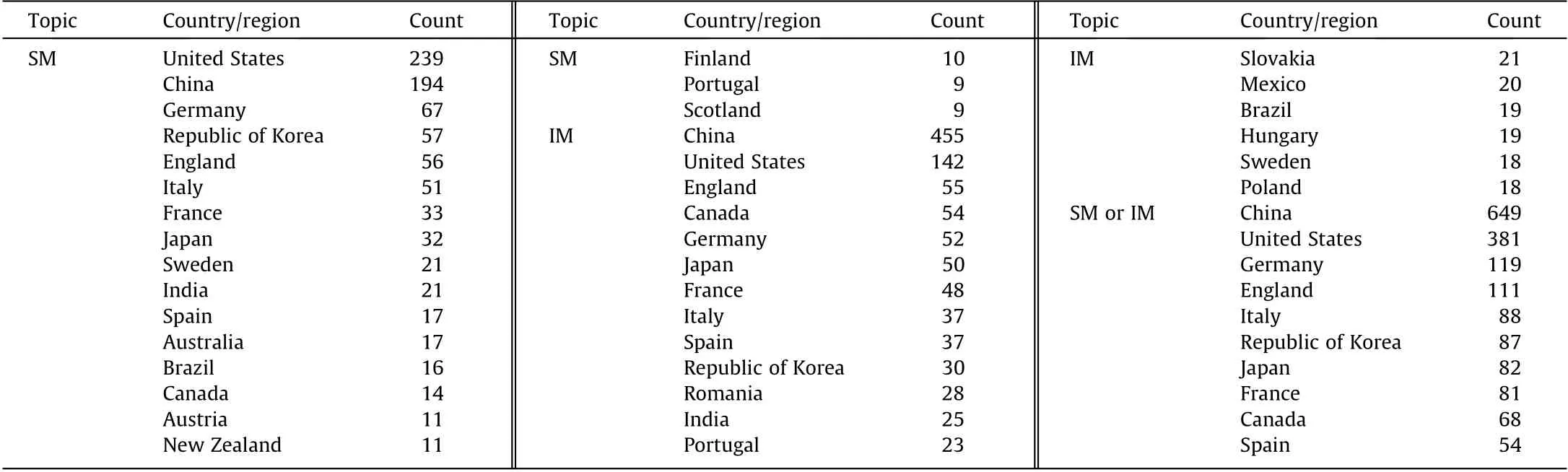

The number of publications on a regional basis is shown in Table 2 from WoS database. The country dominating SM publications is United States, followed by China, Germany, the Republic of Korea, and England. China leads the number of publications on IM,followed by United States,England,Canada,and Germany.Collectively, United States, China, and Germany represent 53% of all SM and IM publications. Moreover, these three countries have made SM or IM the focus of their national manufacturing plans or initiatives [21–23]. Other countries/regions appear to prefer one terminology over the other. For example, Japan, France,Canada, Spain, and Portugal, have collectively 1–2 publications in favor of IM, while Romania, Slovakia, Mexico, and Hungary are exclusively IM.In contrast,Italy and Republic of Korea have collectively 1–1.6 publications in favor of SM, while Australia, Austria,New Zealand, and Finland are exclusively SM. England, India,Sweden, and Brazil have relatively equal publications under these two terminologies, deviating by no more than 15%.

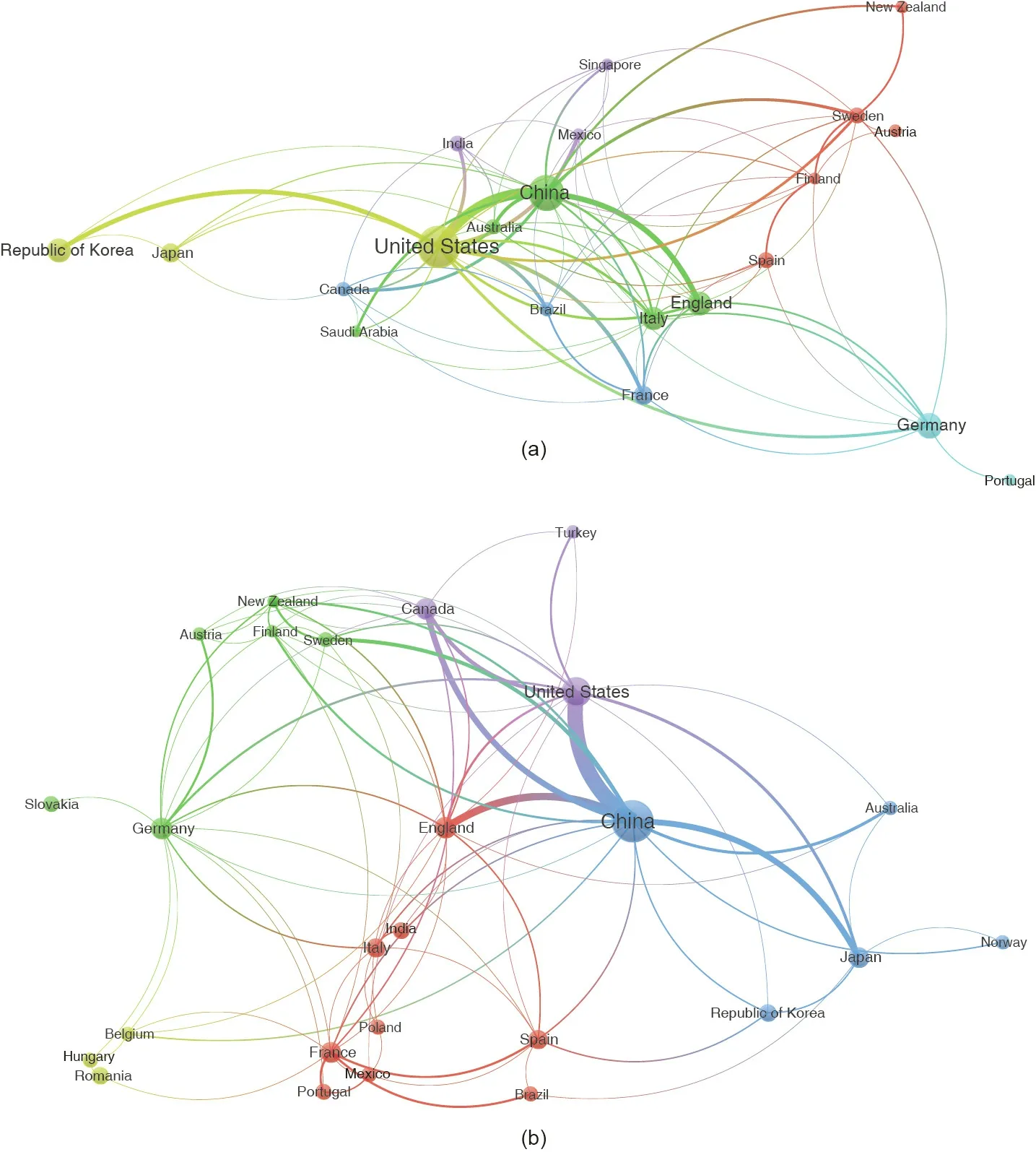

Fig. 4 shows the cooperation among the publication countries/regions. The size of the nodes represents the total linking strength, while the link thickness represents cooperation frequency between any two countries/regions. Only countries/regions that published more than ten papers were considered to ensure network clarity. As seen in Fig. 4(a), United States, China,England, Sweden, and Italy cooperate most on SM. Meanwhile,cooperation frequency is also strong in countries with fewer publications (e.g., Australia, Brazil, and Canada). As seen in Fig. 4(b),China, United States, England, Canada, and Germany cooperate most on IM. For IM, the frequency of cooperation is also strong in countries with fewer publications (e.g., New Zealand and Finland).

Table 2 Top countries/regions publishing work on SM/IM in WoS database.

Fig. 4. International cooperative research network on (a) SM and (b) IM.

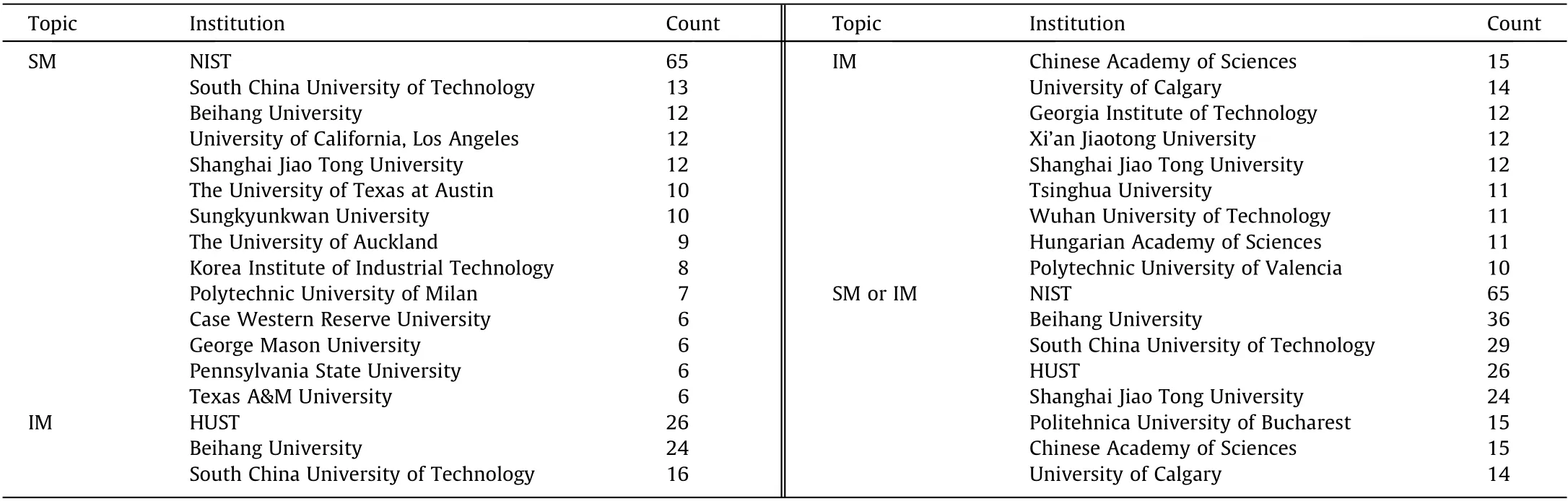

The number of institutions that published papers on SM and IM is compiled in Table 3 from WoS database. The US government agency National Institute of Standards and Technology (NIST) has published the most of SM papers, at 6–7 times more than each of the following top five universities’ publications. For IM, the top publishers are all universities, with the Huazhong University of Science and Technology (HUST) and Beihang University at 1.6–1.8 times more prolific than each of the following top five universities. North America, Asia, and Europe are all represented in top publishing universities on both SM and IM.

3.3. Top journal sources

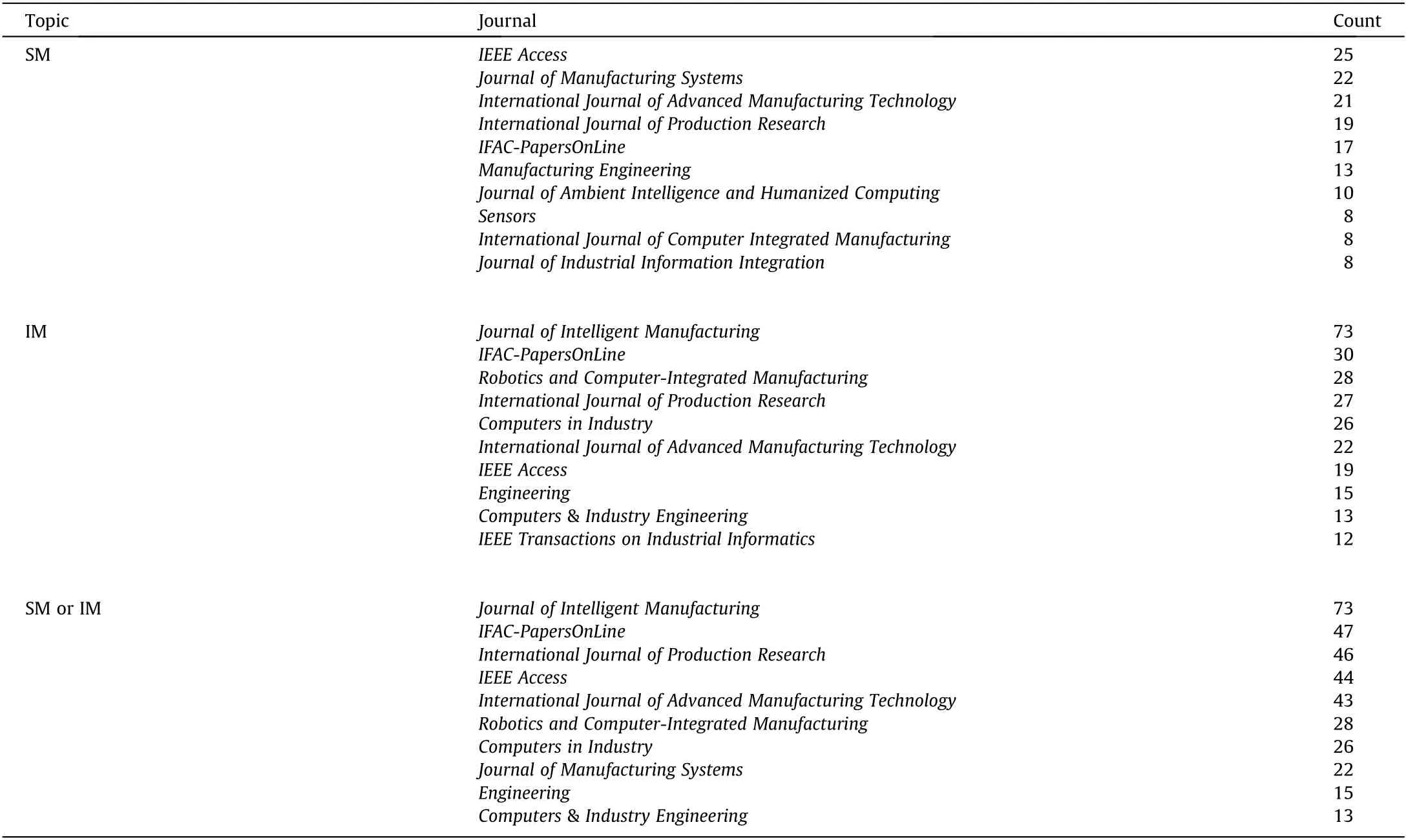

The top sources for SM and IM publications are compiled in Table 4 from WoS database.The IEEE Access has the highest number of SM publications, closely followed by Journal of Manufacturing Systems and International Journal of Advanced Manufacturing Technology. Each of the top seven journals has more than ten SM publications. For IM, the Journal of Intelligent Manufacturing has the highest number of publications, over double its closest rival,IFAC-PapersOnLine. The top ten journals all have more than ten IM publications.Among these top journals,the IEEE Access,International Journal of Advanced Manufacturing Technology, International Journal of Production Research, and IFAC-PapersOnLine have both SM and IM publications.

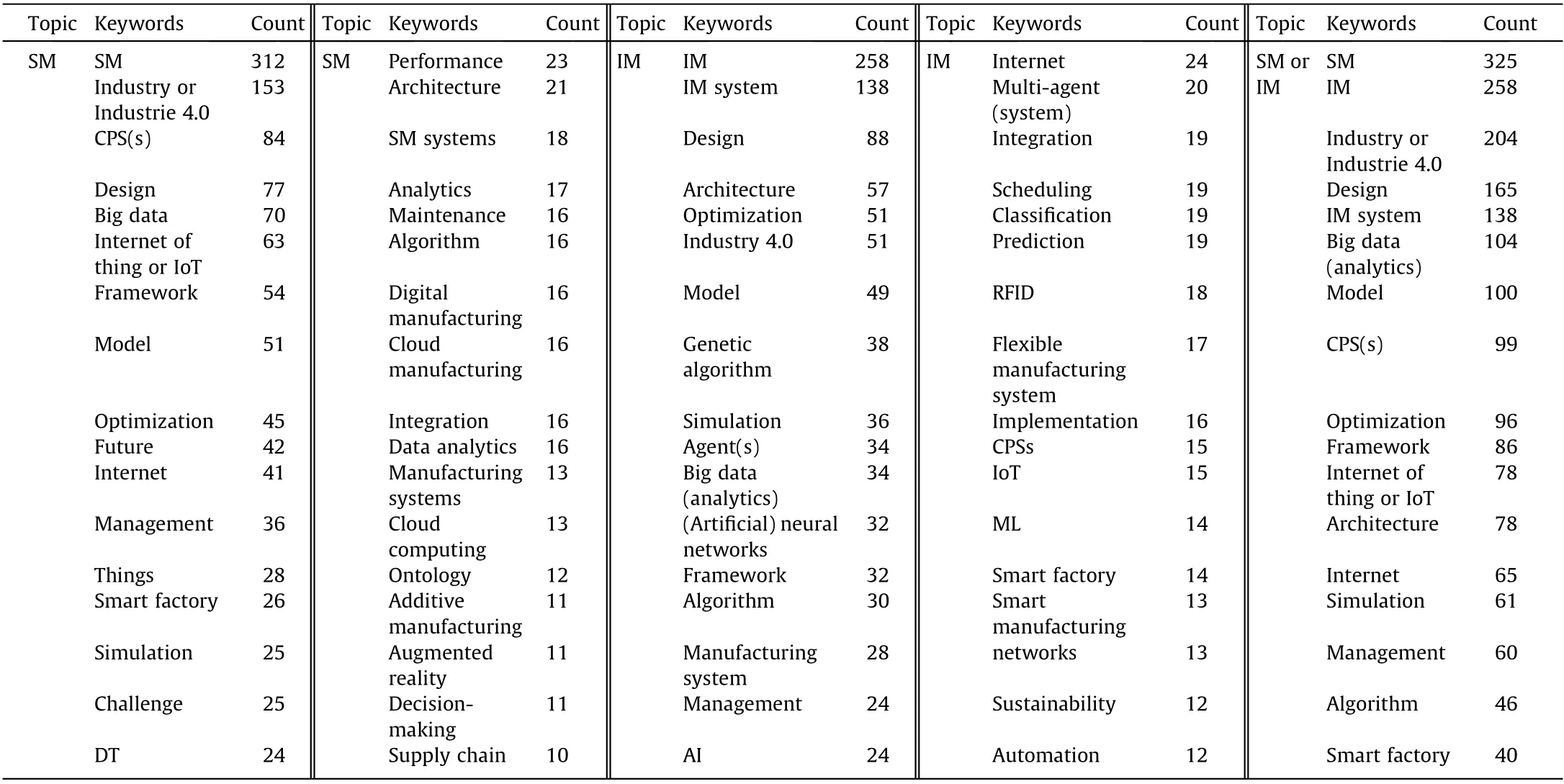

3.4. Keyword co-occurrence frequency

A keyword co-occurrence frequency analysis was conducted using VOSviewer (Centre for Science and Technology Studies(CWTS) of Leiden University, the Netherlands) [24], a widely used information visualization tool.The word count(Table 5)finds that Industry 4.0, CPS, design, big data, IoT, framework, and model make up 50% of the top keyword co-occurring with SM in the research literature. Other top concepts include optimization,internet,management,and smart factory.The top 50% of keyword co-occurring with IM include (IM) system, design, architecture,optimization, Industry 4.0, model, genetic algorithm, and simulation. Other top concepts include agent(s), big data (analytics),and (artificial) neural networks.

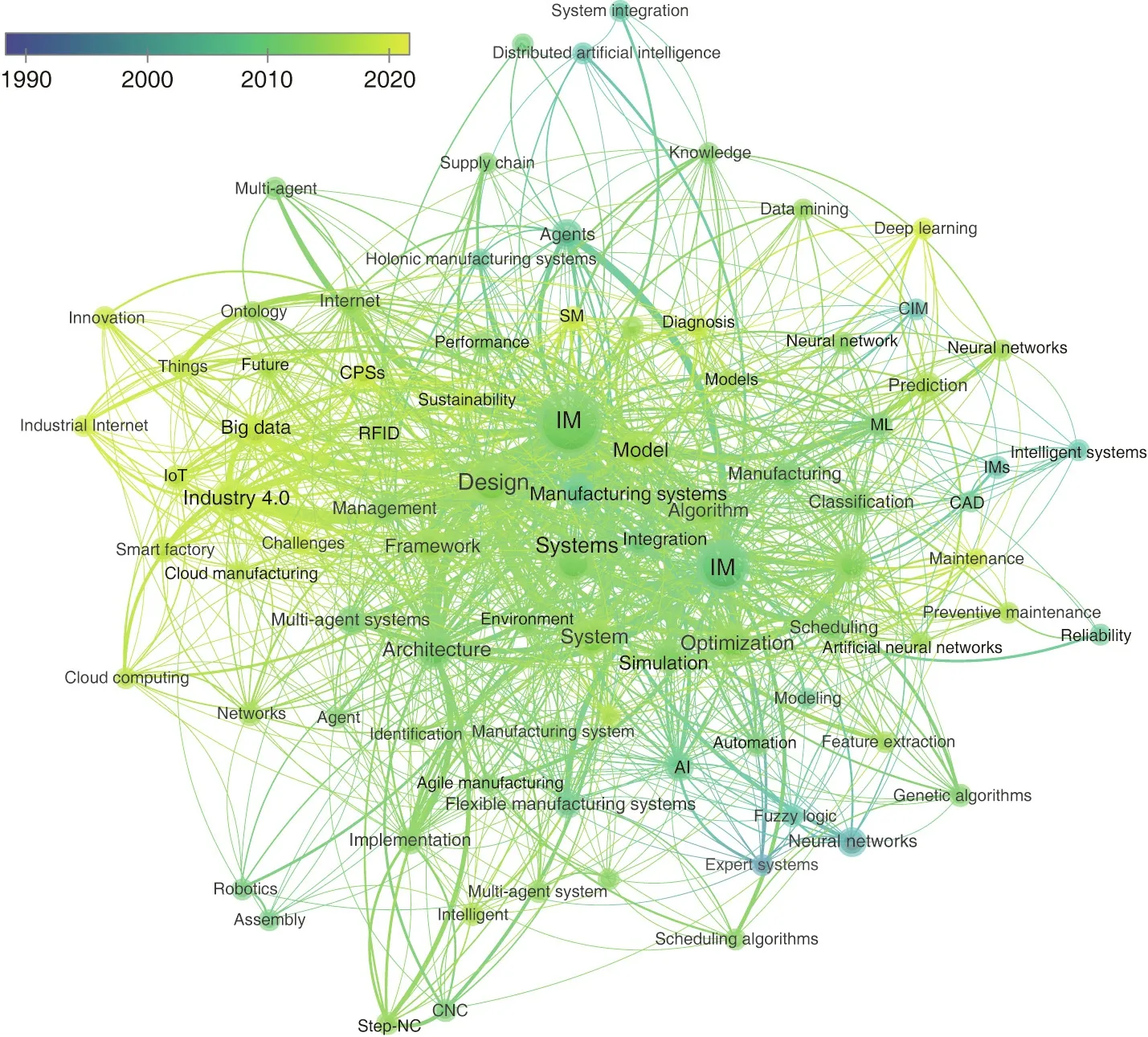

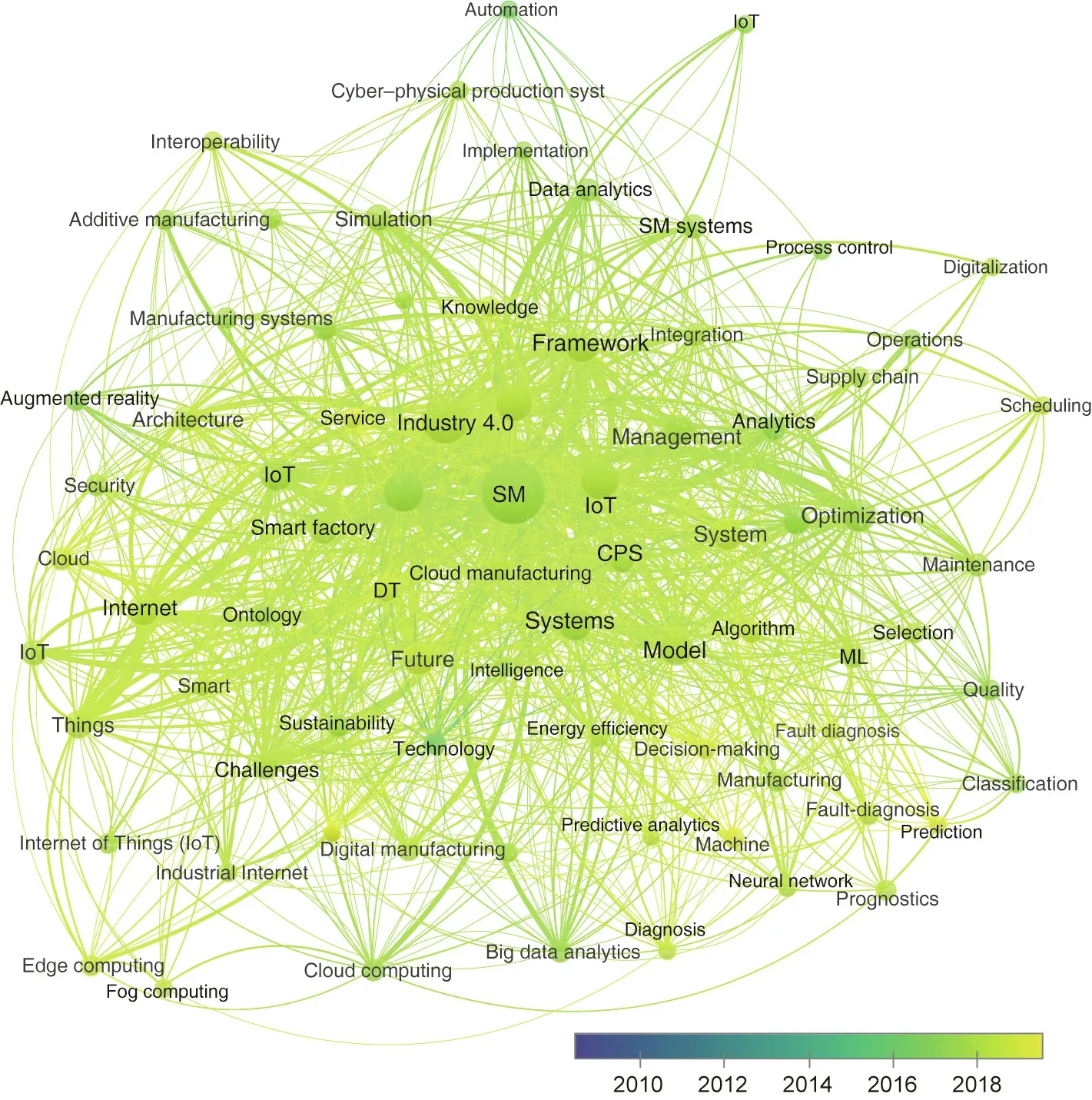

The temporal occurrence of keywords on SM and IM was also analyzed to observe usage trends and research area tendencies,as illustrated in Figs. 5 and 6. Only terms that co-appeared more than eight times were considered to ensure network clarity. In the network,the color gradient from yellow to blue represents earlier to later average publication year,respectively.Among the early phrases of IM are expert systems, fuzzy logic, neural networks,agent, flexible manufacturing system, computer-integrated manufacturing (CIM), and computer-aided desgin (CAD) (around 2000),while the early phases of modern SM are Industry 4.0 and automation (around 2010), which may reveal the focus during eachparadigm’s origin.A more detailed analysis of the origin and development of SM and IM will be addressed in Section 4. The most recent keywords for IM are Industrial Internet,smart factory,cloud computing, and CPSs (Fig. 5). Similarly, the most recent keywords for SM are CPSs, smart factory, cloud computing, big data, and IoT (Fig. 6). The expanding application of Industry 4.0 concepts and practices is likely driving keyword usage in both SM and IM.

Table 3 Top institutions publishing works on SM/IM.

Keyword usage frequency indicates that common concepts or technologies in SM and IM include Industry 4.0,CPSs,IoT,big data,DT, cloud computing, and AI. These technologies will be reviewed and discussed in Section 6. Framework and architecture are also common keywords for both SM and IM, with these concepts reviewed and discussed in Section 7.

4. The origin and development of SM/IM

Based on the bibliometric analysis, the origin, definition, capabilities, and principles of SM and IM are reviewed and discussed in this section.

Table 4 Top journals publishing works on SM/IM.

Table 5 Top frequency keywords related to SM/IM.

4.1. Origins of SM/IM

It appears that the idea of SM emerged in the late 1980s,as evidenced by ‘‘Artificial intelligence: a tool for smart manufacturing”[20], which to the best of our knowledge is the first publication where expert system AI was associated with SM. This was closely followed in 1987 by Smart Manufacturing with Artificial Intelligence[25], which addressed how AI can improve productivity and profitability in manufacturing operations. This book includes topics ranging from AI,expert systems,and computer aided process planning to robots and vision, flexible manufacturing systems, inspection, and process control. After nearly two decades of limited activity, the modern concept of SM re-emerged, in many cases in close association with the development of Industry 4.0. The core concept of today’s SM is based on definitions from NIST [26,27]and the Smart Manufacturing Leadership Coalition(SMLC)[28,29].

Scholars believe the concept of IM originally came from the field of artificial and manufacturing intelligence [30]. Early IM publications were in 1988 [30], 1990 [31], and 1995 [32]. In the 1990s, Japan pioneered research on IM that led to the establishment of the Intelligent Manufacturing System (IMS) Program[33]. Also in 1990s, United States and the European Union established research in IM [34,35], in cooperation in Japan’s IMS Program. More recently, effort in IM and IMS has focused on higher level intelligence.

4.2. Definitions of SM/IM

Different definitions have been proposed for SM in past years.

• From the engineering view [29], SM is the application of advanced intelligent/smart technologies that enable rapid and stable manufacturing of new products,dynamic response to personalized product demands,and real-time optimization of production and supply chain networks. SM platforms can integrate design, products, operations, and business systems that span shop floor,centers,factories,enterprises,and entire supply chains.

• From the networking view [36], SM is the application of CPS,IoT,and Industrial IoT(IIoT),enabled by sensors and communication technologies that capture data at all levels and stages of manufacturing. SM gets smarter over time as productivity increases with reduced errors and production waste.

•From the decision-making view[37],SM uses the accessibility and ubiquity of domain data to aid manufacturing enterprises to better predict and maintain production process and systems, and then improve productivity. Based on big data analytics (BDA), SM optimizes control processes of manufacturing operations,including schedule planning, diagnosis, predictive supply, and assessment.

Different views have also informed definitions of IM in past decades.

• From a view of replacing human intelligence, IM automation performs manufacturing functions as if skilled humans are doing the task [38,39]. IM systems utilize AI techniques to minimize human involvement and intervention into manufacturing activities and systems.

• From a system integration view, IM combines manufacturing processes and systems with different degrees of machine intelligence, including AI-supported systems, AI-integrated systems, and totally IMSs [39].

• From an intelligence science view [2], the aim of IM is to establish adaptive manufacturing operations and systems locally or globally by integrating advanced information technology,computing capacity,and AI.From a data-driven intelligence perspective, IM depends on the timely acquisition,distribution, analysis, and utilization of real-time data from humans, machines, and processes on shop floors, factories,and across product life-cycles.

• From a human–cyber–physical system (HCPS) view[1,4,40,41], IM is a composite system optimally integrating human-, physical-, and cyber-systems that cooperate to achieve set manufacturing goals. IM is the organizing principle for design, construction, and application of HCPS within manufacturing at different system levels. Advanced information technology has enabled IM to evolve through digital manufacturing to networked manufacturing, and is heading toward its next generation.

Fig. 5. Overlay visualization of the keyword occurrence on IM from WoS database. CNC: computer numerical control; NC: numerical control.

4.3. Capabilities and principles of SM/IM

Scholars have proposed several characteristics,capabilities,and principles for SM [13,28,42,43], but its key capabilities are best summarized by NIST as agility,quality,productivity,and sustainability [44].

•Agility can be defined as‘‘the capability of surviving and prospering in a competitive and dynamically changing environment by reacting effectively, driven by customer-designed products and services.” Enabling technologies are critical to the success of agility, including modelling and simulation,supply chain integration, and distributed intelligence.

•Quality reflects how well finished products meet design specifications. In the context of SM, quality also means measures of product innovation and customization.

• Productivity is traditionally defined as the ratio of output to inputs within production, using manufacturing time, cost,labor, materials, and energy efficiency. For SM, productivity measures also include responsiveness to customer demands so that the importance of customization can be better shown.

• Sustainability is defined as manufacturing’s impact on the environment, society, and its employee well-being, as well as its economic viability. Sustainability has taken on more importance compared to the traditional productivity drivers of time and cost. However, sustainability measurements are not yet mature and are an active research area.

IM systems should have the following characteristics according to Kusiak [38], Oztemel [39], and Rzevski [45]:

• Adaptation, one of the most important features, is the ability to adapt to dynamic environment without compromising objectives.

• Automated maintenance is the ability to identify errors/failures and take corrective actions without human intervention.In this context, IM systems can be reconfigurable.

• Learning and self-progress, a critical feature of IM system, is the capability to improve the system based on a continuously updated knowledge base.This can also be triggered by experimenting with existing knowledge and evaluating its performance.

• Autonomy is a level of independence without which intelligent capacity is limited.

• Communication allows the sub-system or components to cooperate by producing reports, directing orders, and initiating activities.

• Prediction capability is the ability to forecast changes and their related effect on system performance.

• Goal seeking is the capability to create, refine, and update goals in accordance with the mission and current state of the system.

• Creativity is the expectation that IM systems will create new theories, principles, forecasts, and so on. This capability requires interaction with system components, as well as a high degree of autonomy. This is currently an aspiration for IM systems.

Fig. 6. Overlay visualization of the keyword occurrence on SM from WoS database. MEs: medium-sized enterprises.

The roles human operators playing in the early stages of the IM system design is also important, and a humancentered approach to handle emerging and unpredicted behaviors should be adopted. There is a lack of attention to human–machine cooperation principles so that human can retain the control of manufacturing process [40,41]. Distinct from IM of the 1990s, Zhou et al. [1,4] and Wang et al. [46]described a version of digital–networked-IM as the NGIM with the concept of HCPSs. NGIM reflects an in-depth fusion of the latest AI technologies with advanced manufacturing technology,inspired by AI 2.0 [8,47–51]. The most fundamental feature of NGIM systems is adding powerful cognitive and learning capabilities to cyber systems to improve its learning ability and generate knowledge.

4.4. Evolutionary comparison of SM/IM

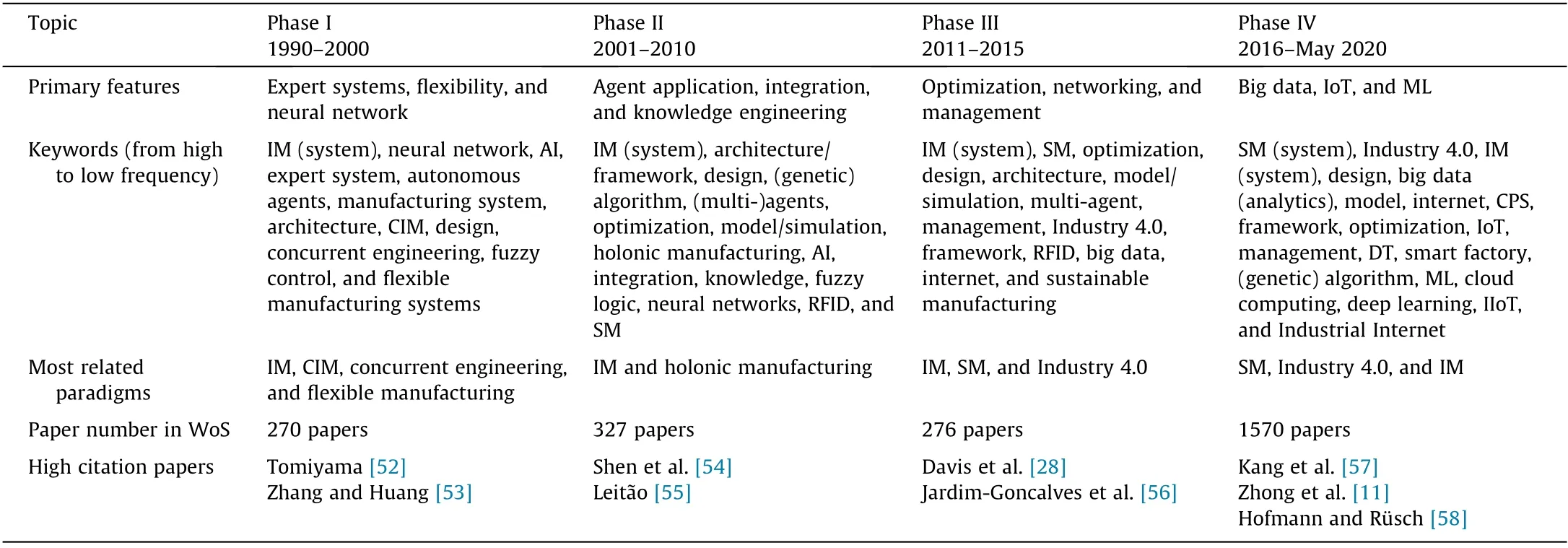

The bibliometric data summarized in Section 3 was used to analyze and compare the evolution of SM and IM.Examining their evolutionary path can provide a better understanding of its consistency. From the growth in annual publications shown in Fig.2,the evolutionary phases of SM/IM research are hypothesized to occur in four phases:Phase I(1990–2000),Phase II(2001–2010),Phase III(2011–2015),and Phase IV(2016–May 2020),as shown in Table 6 [11,28,52–58]. Even though other divisions may be possible, we believe these divisions help clarify the evolutionary trend of SM and IM related research.

Phase I(1990–2000):About 270 papers were published during this period. The keywords most used in these papers include, in order of their frequency, IM (system), neural network/AI, expert system, autonomous agents, CIM, concurrent engineering, fuzzy control, and flexible manufacturing systems. The primary features of SM/IM in Phase I include the application of expert systems,flexibility,and neural networks.In this phase,the most mentioned paradigms are IM, CIM, concurrent engineering, and flexible manufacturing.

Phase II(2001–2010):About 327 papers were published during this period. The keywords most used in these papers include IM(system), (genetic) algorithm, (multi-)agents, optimization,model/simulation, holonic manufacturing, AI, integration, knowledge, fuzzy logic, neural networks, radio frequency identification(RFID), SM, and so on. The primary features of SM/IM in Phase II include agent application,integration,and knowledge engineering.In this phase, the most mentioned paradigms are, in order of frequency, IM, holonic manufacturing, and a few papers referring to SM.

Phase III (2011–2015): About 276 papers were published during this period. The keywords most used in these papers include IM (system), SM, optimization, model/simulation, multi-agent,management, Industry 4.0, framework, RFID, big data, internet,and sustainable manufacturing. The primary features of SM/IM in Phase III include optimization, networking, and management. In this phase, the most mentioned paradigms are, in order of frequency, IM, SM, and Industry 4.0.

Phase IV(2016–May 2020):About 1570 papers were published during this period, showing a vast increase in SM/IM interest. The keywords most used in these papers include SM(system),Industry 4.0, IM (system), big data (analytics), internet, CPS, optimization,IoT, DT, smart factory, (genetic) algorithm, ML, cloud computing,deep learning,IIoT,and Industrial Internet.The primary features of SM/IM in this phase include IoT, big data, cloud computing, and ML. The most mentioned paradigms are, in order of frequency,SM, Industry 4.0, and IM.

The bibliometric comparison of the SM/IM evolutionary path shows that keywords have changed as research into enabling technologies and research hotpots changed. The change in paradigms may have arisen from an evolution in national level technology development strategies and plans.The most recent research trends are for information connectivity [59], the human role [1,60],manufacturing data [61], intelligence science [2], learning algorithms [62], and maturity index [63] in the context of SM/IM.A practical insight from this evolutionary analysis is that enterprises or regions at a relatively low SM/IM level of development can find guidance on transformation paradigms, making development strategies, selecting suitable technologies, and evaluating phased maturity within the literature.

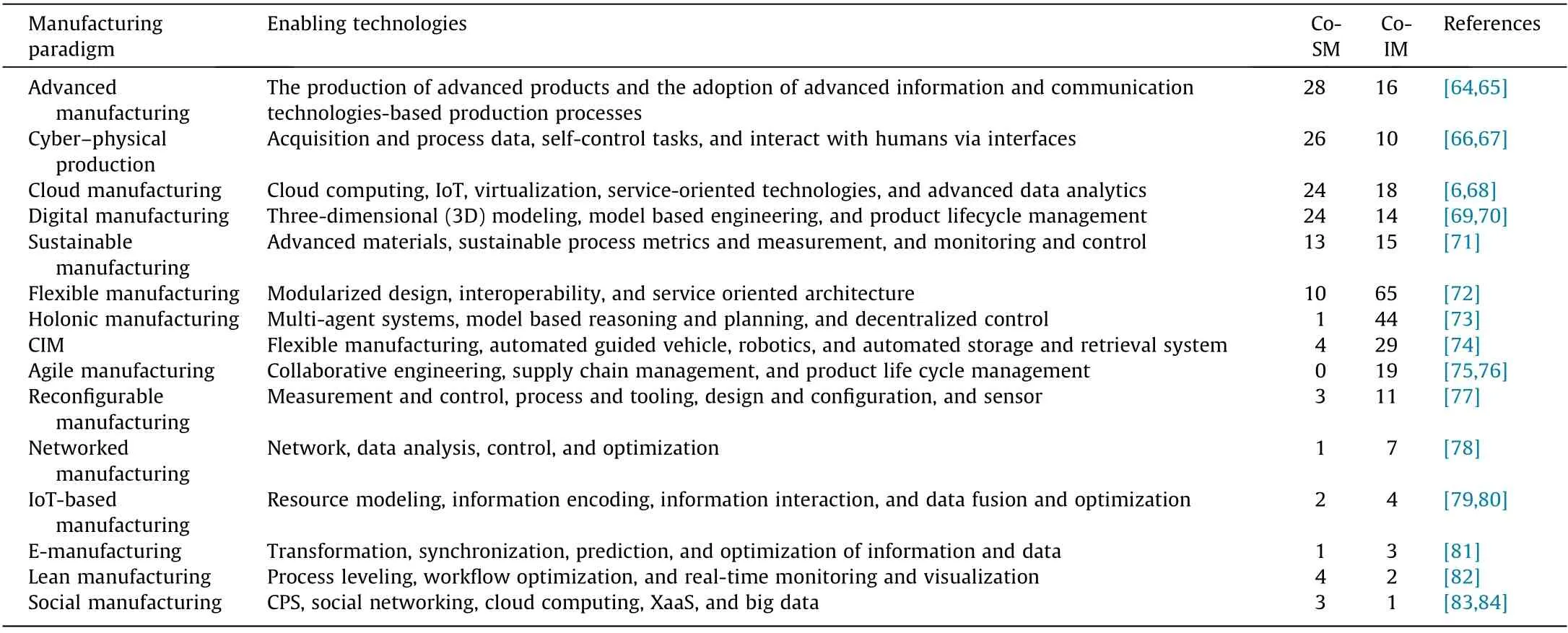

5. Relationship of SM/IM with other manufacturing paradigms

Many manufacturing paradigms have emerged during the development of SM and IM, including CIM, digital manufacturing,cloud manufacturing, networked manufacturing, cyber–physical production, and social manufacturing. Table 7 [6,64–84] summarizes these paradigms and their enabling technologies. Generally,these paradigms are similar, sharing such aims as more intelligent/smart decision-making and the optimal use of manufacturing resources, but also show diversity and differences.

The research focus of each paradigm is based on its ideas and enabling technologies. For example, digital manufacturing uses computers to improve manufacturing performance and reduce costs, while cloud manufacturing uses decentralized and networked manufacturing and service-oriented architectures (SOAs).Cyber–physical production systems play a central role in Industry 4.0. All paradigms have played a role when manufacturing sectors have upgraded in specific regions or during specific periods.

These paradigms share one or more common principles with SM and IM, contributing to the foundation of modern SM and IM.To help understand SM and IM research interests, the cooccurrence frequency of paradigm topics to SM or IM was studied from WoS title, abstract, and keyword data, presented in Table 7[6,64–84]. The four most frequent paradigms associated with SM beyond advanced manufacturing are cyber–physical production systems,cloud manufacturing, digital manufacturing, and sustainable manufacturing.In contrast,the four most frequent paradigms associated with IM are flexible manufacturing, holonic manufacturing, CIM, and agile manufacturing. While SM and IM may have different priorities,all subscribe to transforming and upgrading the scale, cost, quality, service, and smartness or intelligence of manufacturing by utilizing the best technologies of their era. In particular, computer modeling, monitoring and control, and information/data analytics are broadly applied within these paradigms.Several technologies common to SM and IM will be further examined in the next section.

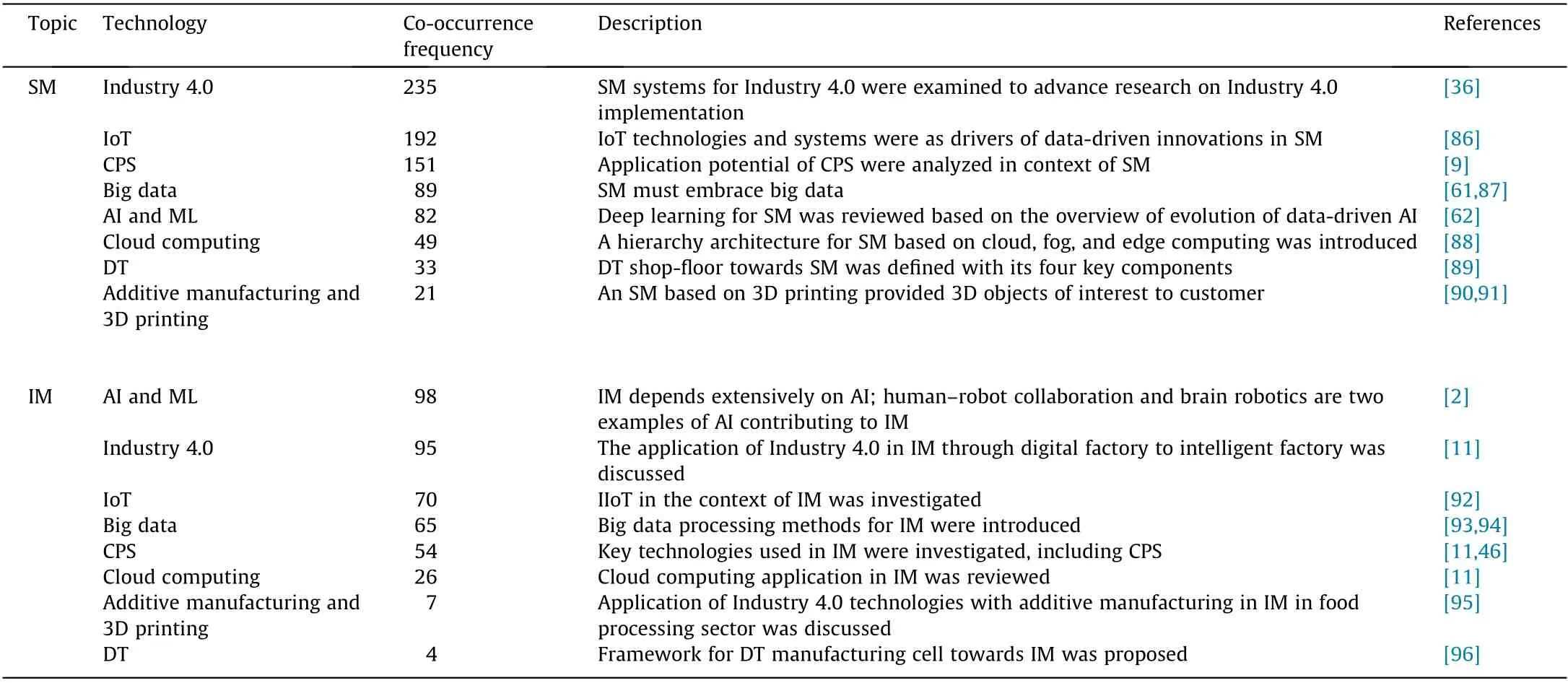

6. Common key technologies and research areas of SM/IM

Emerging technologies common to SM and IM include Industry 4.0, CPS, IoT, Industrial Internet, big data, DT, cloud and fog computing, AI, and ML. To a certain extent, these technologies can be regarded as a new generation of information technologies (IT) [85]. Table 8 [2,9,11,36,46,61,62,86–96] lists common key technologies associated with SM and IM together with their co-occurrence frequency in the title, abstract, or keywords.Other technologies mentioned in the literature include wireless sensor networks (WSNs), augmented reality (AR), mobile internet, and fifth generation cellular network technology (5G)[97–99].

6.1. Industry 4.0 and CPS

Industry 4.0 is a German initiative emphasizing the full integration of traditional manufacturing systems with new IT systems[22,100] and draws attention from both SM and IM researchers.Industry 4.0 highlights horizontal integration through value networks, vertical integration, and end-to-end digital integration across the entire value chain. It is closely related with SM, IM,CPS, and information and communications technology [9,66,101–103]. Thoben et al. [9] provided an overview of Industry 4.0 and SM programs, and analyzed the application potential of CPS,including product design, production, logistics, maintenance, and exploitation.Zheng et al.[36]examined SM systems within Industry 4.0, including proposing a framework for SM systems, demonstrative scenarios, key technologies, and possible applications.Scholars who studied IM within Industry 4.0 regarded CPS, IoT,cloud computing, and the digital factory as key technologies [11].Cheng et al. [104] also analyzed future directions for Industry 4.0 to provide reference for applications in IM. Related topics within IM also include HCPS, human-in-the-loop CPS, and cyber–physical–social systems [1,105–109].

Table 6 Evolution of SM/IM from literature analysis perspective.

Table 7 Other manufacturing paradigms related to SM and IM.

6.2. IoT and big data analytics

IoT is a network of computers, machines, and people that are uniquely identified and can share data [7,80,110,111]. Big data refers to the idea that new data-processing applications are required to analyze data sets collected in the manufacturing environment as they are too large and complex for traditional methods.IoT and BDA are currently hot topics within SM and IM.Yang et al.[86]reviewed IoT technologies as drivers to data-driven innovation in SM, and also proposed the Internet of Manufacturing Things(IoMT). Kusiak [87] argued SM must embrace big data and identified gaps in SM innovation that need to be filled: adoption strategies, improved data collection and sharing, predictive models,connected factories,and control processes.Tao et al.[61]discussed the manufacturing data lifecycle and the role of big data in supporting SM,and argued big data will enable today’s manufacturing paradigm to transform to SM. Bai [92] investigated IIoT in thecontext of IM,and presented an overview for its infrastructure and information interaction among devices. Zhu et al. [112] claimed that the success of IM relied on the timely acquisition,distribution,and utilization of huge amounts of data. Xiao and Liu [93] applied big data processing method in machine tools in the context of IM.Zhong et al. [94] introduced big data analytics for IM shop floors using IoT and wireless technologies.

Table 8 Key technologies related with SM and IM.

6.3. Cloud computing and fog computing

Cloud computing is the provision of scalable, on-demand computer resources, including data storage and computing power,which is accessed remotely by the user through a network[10,68,113–115]. It has enabled cloud manufacturing, a serviceoriented manufacturing paradigm proposed to reduce resource consumption and enhance resource utilization [114,116]. Fog or edge computing is a related concept that extends distributed computing to devices on the edge of the network, enabling new applications or services [117]. Park and Tran [118] studied a cloudbased SM system in which the advanced information technologies such as cognitive agents,cloud computing,and swarm intelligence were used.Qi and Tao[88]introduced a hierarchy reference architecture for SM that deployed the computational and networking capabilities to the edge of the cloud. Zhong et al. [11] reviewed cloud computing applications in IM and, along with Zhou et al.[4], regarded cloud computing as a critical enabling technology for IM.

6.4. Industrial Internet

The Industrial Internet is recognized as the motivation for a new industrial revolution following the original industrial revolution of the mid-18th century and the computer revolution from the 1950s[5]. The vision of the Industrial Internet heavily depends on the adoption of advanced information and communication technologies in traditional industries, including RFID, sensor networks,IoT, CPS, cloud computing, big data, and AI. While the Industrial Internet is an important and independent research subject for SM/IM, representative Industrial Internet architectures have provided significant influence to national approaches to early SM/IM architectures [119]. Zhou et al. [4] characterized the Industrial Internet as a foundation made up of intelligent network,platform,and safety systems that supports IM. Wang et al. [120] stated the Industrial Internet platform is a key enabler for achieving SM with the aim of integrating distributed manufacturing services to complete complicated tasks.Moreover,scholars in the development of Industry 4.0 and towards the application of CPS understand the Industrial Internet similarly. Recently, scholars are referring to the IIoT terminology that seems to bind the Industrial Internet with the IoT [98,121]. The differences between the IoT, the Industrial Internet, and the IIoT are beyond the scope of this work.

6.5. Digital twin

A DT is a virtual representation that fully describes a physical production process or system from multiple levels.Broadly,a DT is an integrated system that can simulate,calculate,monitor,and control processes and system status [122–127]. While it is a significant technology to both SM and IM, more publications associate DTs to SM. Tao and Zhang [89] defined a DT shop-floor as part of the SM paradigm, discussing physical and virtual shop-floors, the service system, and data for four key DT components. Qi et al.[128] investigated combining SM services with a DT to radically change design, production, usage, and other processes. Lu et al.[129] discussed DT-driven SM models, applications, and research issues. Zheng et al. [130] argued a DT will gradually become one key research direction of IM, with rapid development of virtual and data acquisition technology. Zhou et al. [96] proposed an IM framework for a knowledge-driven DT manufacturing cell,supporting autonomous manufacturing by a strategy that combines intelligent perception,simulation,optimization,prediction,and control.

6.6. AI and ML

AI is the technique that enables computers to mimic,strengthen, or replace human intelligence by applying logic, ifthen rules, expert systems, decision tress, and ML [8,131,132].Early successful applications of AI used agents and generic algorithms. ML is a subset of AI that includes statistical techniques to enable machines to improve at tasks with experience.Deep learning is the subset of ML that uses software algorithms that are trained by exposing multilayered neural networks with vast amounts of data.Within SM,Schaffer[20]regarded AI as an important tool, while Wang et al. [62] reviewed deep learning as part of the evolution of data-driven AI in SM, discussing typical deep learning architectures in the context of SM, including convolutional neural network, auto encoder, and recurrent neural networks. Oztemel [39] stated multiple AI technologies must be utilized for manufacturing activities for a manufacturing systems to be intelligent, and they must exhibit characteristics such as learning, reasoning, and decision-making. Wang [2] argued from the perspective of intelligence science that the future of IM depends extensively on AI. He provided human–robot collaboration and brain robotics as two representative examples of AI contributing to IM.

In summary,today’s SM and IM utilize a multitude of technologies and concepts. However, minor differences and preferences in SM versus IM have shaped their exploration and implementation.For example, AI and ML are more frequently associated to IM research, while Industry 4.0 and DTs are more frequently associated to SM research. However, the boundary between today’s SM and IM is blurry as they share all key technologies.

7. Reference architectures and implementation for SM/IM

Two keywords co-occurring frequently with both SM and IM are framework and architecture, indicating their importance to both paradigms. Framework and architectures are widely applied to describe general structures and internal relationships within complex systems. Framework describes the functional elements,the representation of knowledge, and the information flow within a system. Architecture is the assignment of functions to subsystems and the specification of interfaces between subsystems[133,134].

7.1. Reference architectures and standards for SM/IM

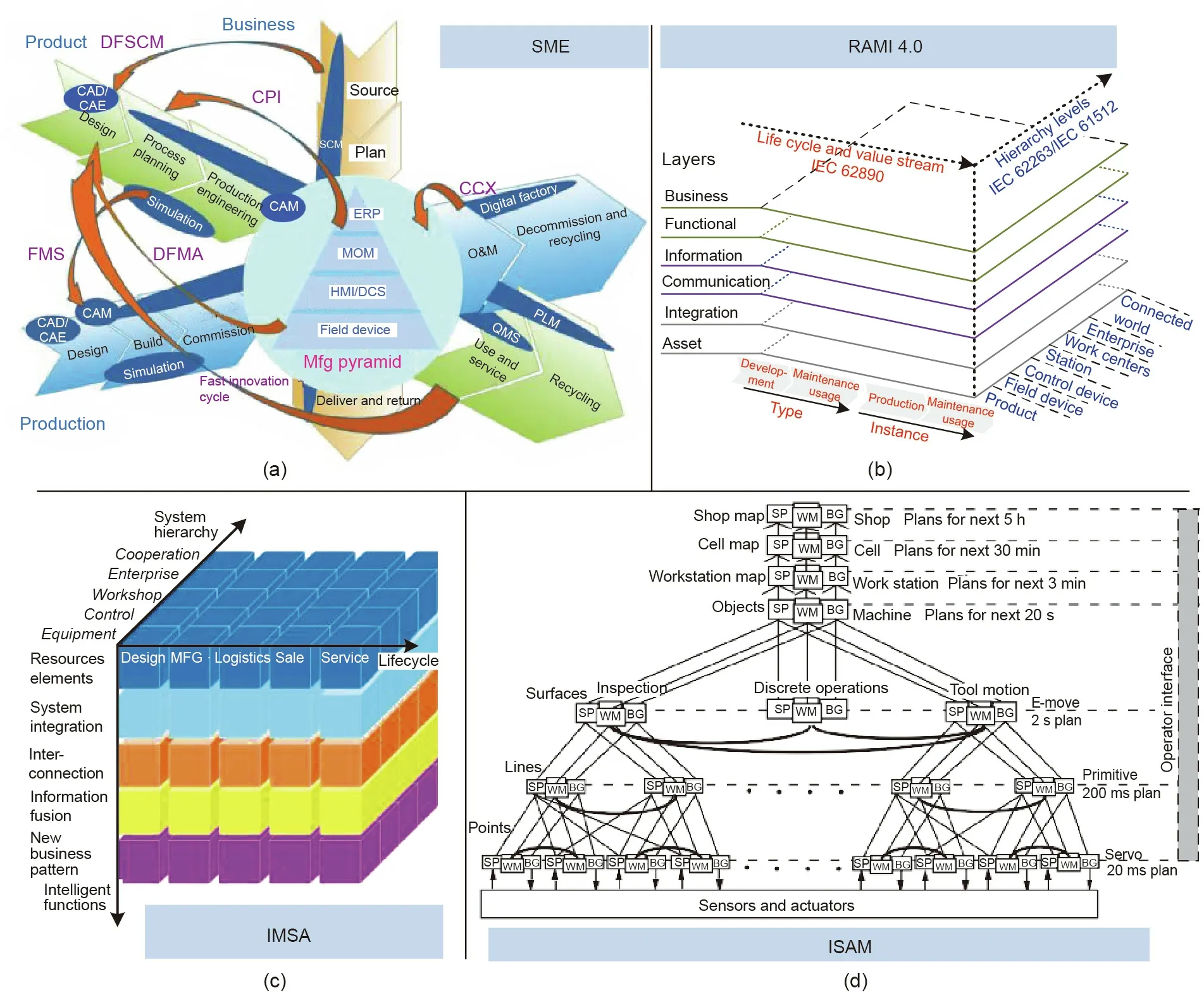

Several SM- and IM-related frameworks or architectures were found in the literature review that proposed systematic implementation and standardization of SM and IM technologies [135]:

• SM Ecosystem (SME) [26,27] by NIST, USA;

• Reference Architecture Model Industrie 4.0 (RAMI 4.0) [136]by ‘‘Standardization and Reference Architecture Platform”Industrie 4.0, Germany;

•IMS architecture(IMSA)[137],by the Ministry of Industry and Information Technology (MIIT) of the People’s Republic of China and the Standardization Administration of China(SAC);

• An intelligent systems architecture for manufacturing(ISAM)—a reference model architecture for IMSs [134], by NIST, USA.

These four representative frameworks or reference architectures are illustrated in Fig. 7 [27,134,136,137]. Other frameworks/architectures proposed include the framework for CPSs (FCPSs) [138], the Industrial Value Chain Reference Architecture(IVRA) [139], the Industrial Internet Reference Architecture (IIRA)[119], and the IoT architectural reference model (IoT-ARM) [140].Although several SM-related reference architectures have been proposed [135,141,142], SME and RAMI 4.0 are discussed in this section as representative. Likewise, of the several reference architectures for IM that have been proposed [11,45,134,143], IMSA and ISAM are discussed in this section as representative.

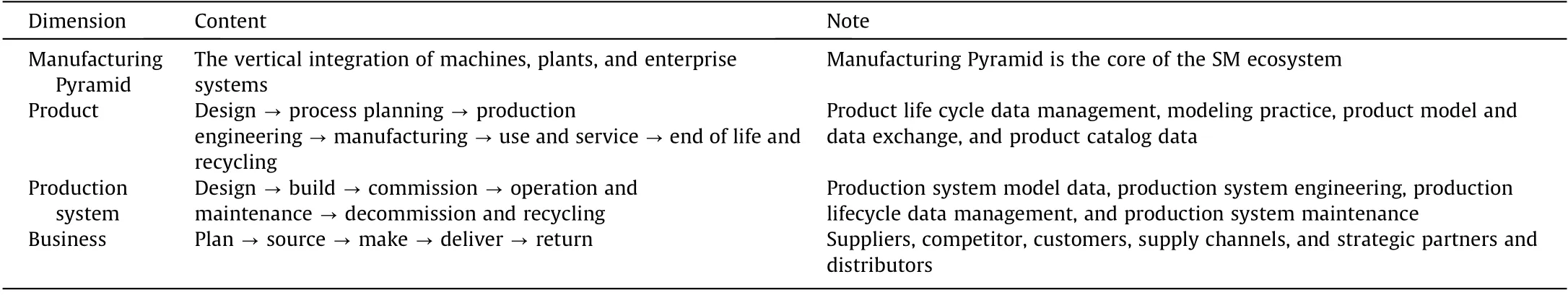

The SME was proposed by NIST in 2016 to standardize the SM system landscape [26,27]. SME encompasses a pyramid built of three manufacturing dimensions:the product,the production systems, and the enterprise (business) systems, as shown in Fig. 7(a)and Table 9 [26,27]. NIST proposed the system architectural paradigm based on a hierarchical control model to cover all areas of SM.In their report Current Standards Landscape for Smart Manufacturing Systems [26], standards were positioned within the SME ecosystem from the perspective of product development lifecycle,production system lifecycle, business cycle for supply chain management, and manufacturing pyramid. Standards for the product lifecycle dimension include modeling practice (e.g., ISO/TC 213 Global Positioning System (GPS)), product model and data exchange (e.g., Initial Graphics Exchange Specification, Drawing Interchange Format), manufacturing model data (e.g., ISO 14649),product catalog data (e.g., ISO 13584), and product lifecycle data management (e.g., Product Lifecycle Management Extensible Markup Language (PLMXML)). Standards for the production system lifecycle dimension include production system model data and practice (e.g., IEC 62832), production system engineering(e.g., SysML, Modelica), production lifecycle data management(e.g., ISO 10303-239), and production system maintenance (e.g.,GEIA 927). General business modeling standards are for interactions among manufacturers, suppliers, customers, partners, and even competitors, including Supply Chain Operations Reference(SCOR), Open Applications Group Integration Specification(OAGIS), and Manufacturing Enterprise Solutions Association’s B2MML. Based on ISA 95, integration standards, the‘‘manufacturing pyramid”divides into device level(e.g.,IEC 61784,MT Connect), SCADA level (e.g., Modbus, ISA 88), manufacturing operations management level (e.g., ISO 22400), and enterprise level(e.g.,ISO 19440,OAGIS).An analysis of the SMS related standards concludes that current manufacturing standards are insufficient to fully enable SM systems [27], requiring standards to address cybersecurity,cloud-based manufacturing services,supply chain integration, and data analytics. Additionally, two barriers to standards adoption that inhibit the growth of SMS include a lack of tracking of standards and standards adoption, and an overlap and redundancy between standards.Therefore,harmonization and collaboration among standards development organizations is necessary.

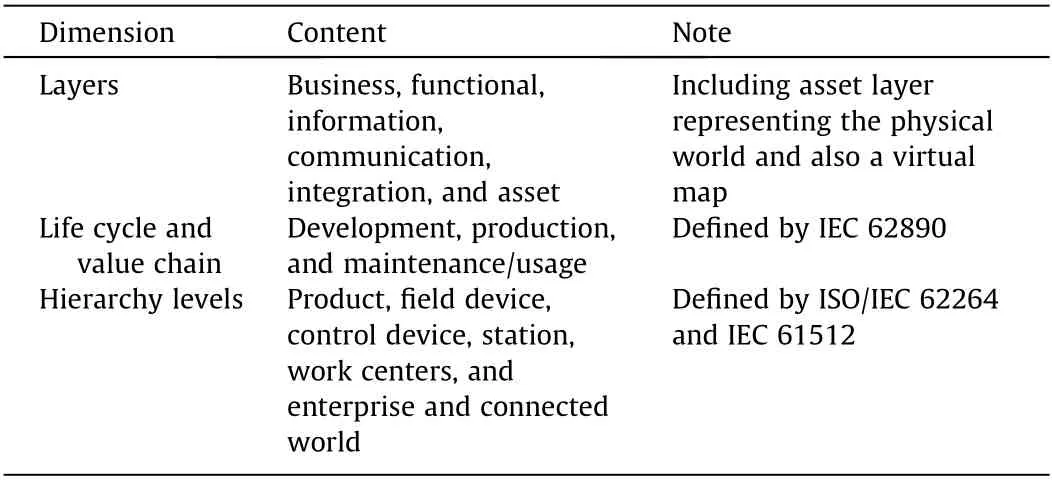

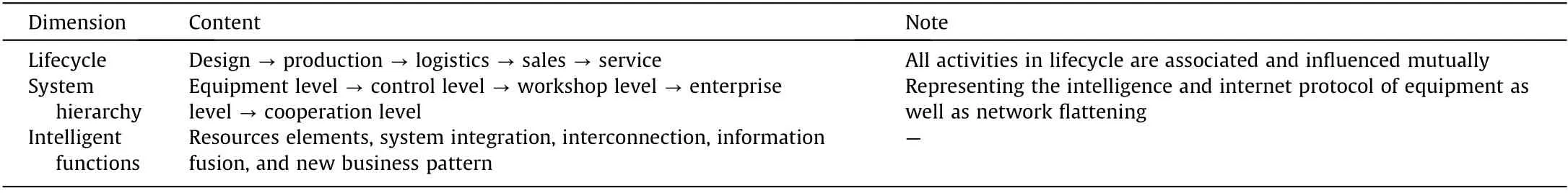

Fig.7. Representative framework/architecture for SM(a)SME[27],(b)RAMI 4.0[136],and for IM(c)IMSA[137],and(d)ISAM[134].CAE:computer aided engineering;CAM:computer-aided manufacturing;CCX:continuous commissioning;CPI:continuous process improvement;DCS:distributed control systems;DFMA:design for manufacturing and assembly;DFSCM:design for supply chain management;ERP:enterprise resource planning;FMS:flexible manufacturing system;HMI:human–machine interface;Mfg:manufacturing;MOM:manufacturing operations management;O&M:operation and maintenance;PLM:product lifecycle management;QMS:quality management system;SCM: supplying chain management; BG: behavior generation; SP: sensory processing; WM: world modeling.

The domains defined in RAMI 4.0 include layers, life cycle, and hierarchy levels as shown in Fig. 7(b) [136] and Table 10 [136].The intent of RAMI 4.0 is to be resilient and easy to expand or link with other SM architectures. In theory, any level of an SM enterprise can find a location in this three-level architecture. Several important standards in the context of RAMI 4.0 include IEC 62890 for life-cycle status, ISO/IEC 62264 for enterprise-control system integration, and IEC 61512 for batch control. Other related standards include IEC 62541, IEC 61784, VDMA 24582, IEC 61987,and ISO/IEC 20140.

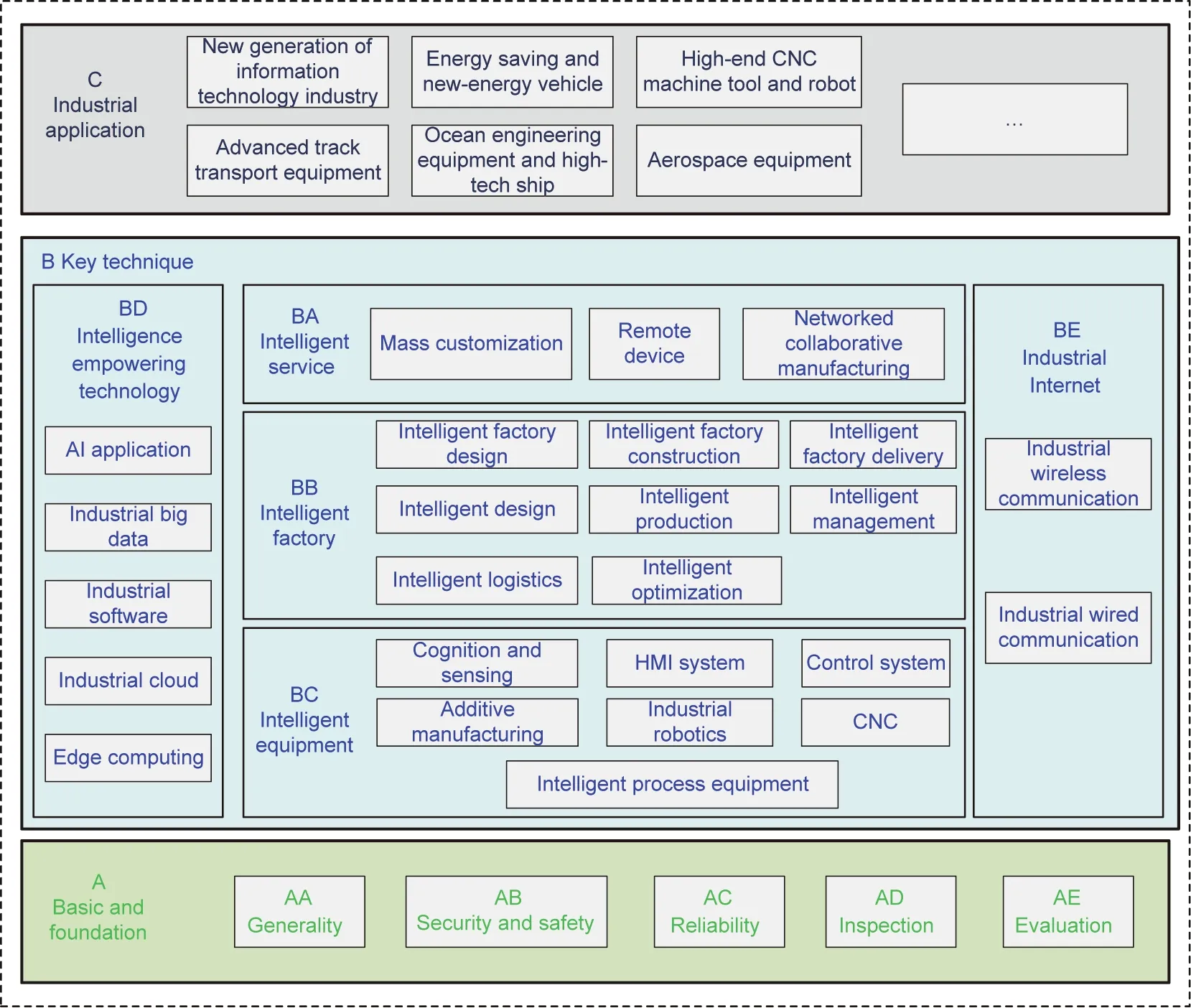

ISAM was defined by Refs.[134,143]as a reference model architecture for IM systems, shown in Fig. 7(d) [134]. It provides a framework for IM standards and engineering guidelines for various manufacturing applications. ISAM is a hierarchically layered set of intelligent processing nodes organized as a nested series of control loops. The IMSA provides a model, terminologies, evaluation indicators, and technology standards for IM [137], as shown in Fig. 7(c) [137] and Table 11 [137]. Further, IMSA indicates that the life cycle,system level,and functioning of intelligent elements determine the scope of every IM-related technology. IMSA proposes a diagram of the structure of the IM standard system to help standards classification, shown in Fig. 8 [144]. The structural diagram of IM standard system includes ‘‘A: basic generality,” ‘‘B:key techniques,” and ‘‘C: industrial application,” which mainly reflects the relationship of different parts of the standards system.As of November 2018,there are about 300 IM standards released or under preparation in China, mainly covering basic generality and aspects of key techniques.

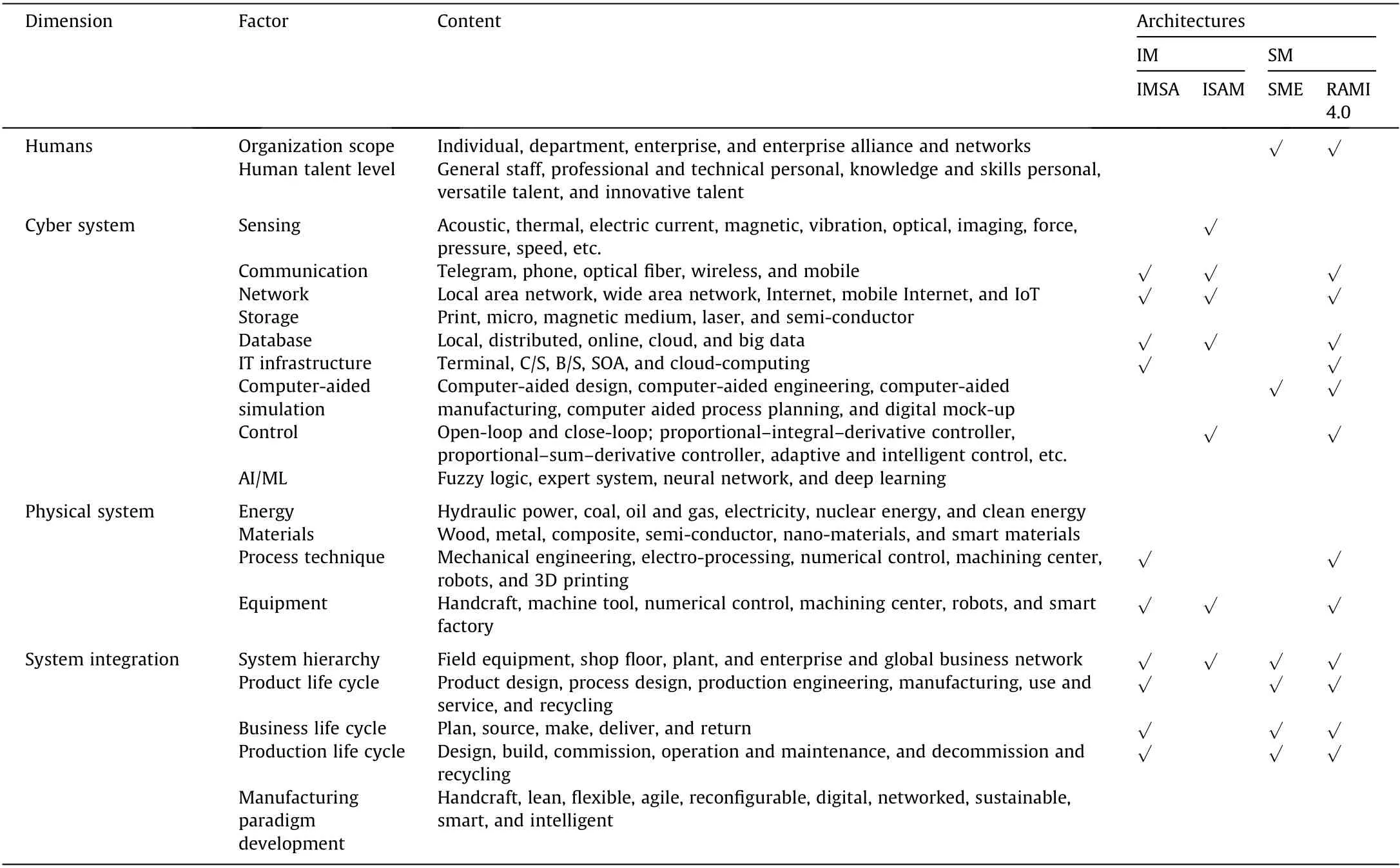

Recently, an HCPS model was proposed as a general reference architecture to better understand the relationship between SM and IM. HCPS is well matched for this comparison as it has well defined dimensions [1]. Table 12 [1,135] maps the representative SM and IM architectures and concludes:

• SME, RAMI 4.0, and IMSA consider system integration and management from different viewpoints. Product and production lifecycle, and supply chain are described in these architectures. However, all reference architectures lack a comprehensive consideration of recent AI/ML technologies,energy,materials,and manufacturing paradigm development,which are also important for the further implementation of SM or IM.

•The attention put to human factors and related improvements to enterprise culture and human resources in related architectures is evolving. For example, in RAMI 4.0, the reference architecture of Industry 4.0, enterprise culture, and human resources is not reflected. But in fact, this aspect is obviously included in the Industry 4.0 maturity index [63], and the Japanese SM/IM reference architecture [139].

• The SME architecture does not fully describe important elements of enterprise infrastructure, IoT, cloud computing,CPS,big data,and DT.The importance of physical systems(industrial technology) such as intelligent robot, threedimensional (3D) printing, and new materials is not also emphasized in SM. RAMI 4.0 does not also suggest a solution for SM implementation as it does not cover all aspects of SM and connects all related standards.

•The architectures and standards are time-sensitive.Standards will need tracking and revision as SM/IM develops and new problems arise and are resolved. Moreover, consideration of industrial complexity is required since industry in many developing countries is still semi-automated or only at a preliminarily stage in the deployment of digital or network technologies.

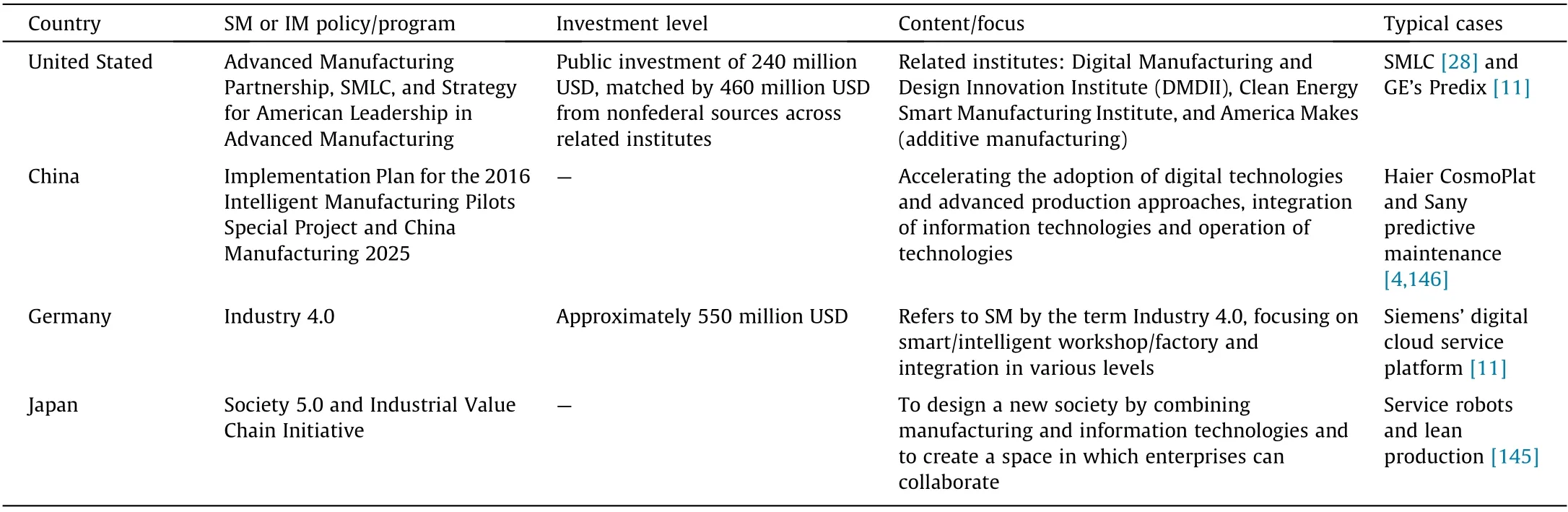

7.2. National focus and typical practical case

Many major countries have launched national plans,initiatives,and projects in SM/IM or Industry 4.0, as listed in Table 13[4,11,28,64,145,146]. The following are the sampling of the similarities and distinguishing features in the paradigm selected,investment level, focus, and development paths between these national plans and projects and their practical implementations:

• Since 2011, United States has released several national plans and initiatives on manufacturing, including Advanced Manufacturing Partnership and Strategy for American Leadership in Advanced Manufacturing. Many policies and programs related with SM/IM are released in the context of advanced manufacturing, so its selected paradigm or preferred terminology for SM/IM is advanced manufacturing. The emphasis in United States in SM/IM is predominantly on the IT aspects of the top layer, such as big data, cloud computing, deep learning and virtual reality, and energy efficiency.One example is the Clean Energy Smart Manufacturing Institute and SMLC [28], which recognize data as a new resource for solving issues in energy consumption and environmental sustainability. Another example is General Electric (GE)’s Predix platform and Industrial Internet Consortium [11].

• Around 2012, Germany released a national strategy for Industry 4.0 with a similar vision of SM/IM. Germany prefersIndustry 4.0 as its terminology for SM/IM. Germany is focusing on smart/intelligent workshop/factory and related research into underlying technologies, such as intelligent sensing,wireless networks, and CPS. One important feature of the Industry 4.0 national plan is its integration within various levels based on the value-added service that can be provided with equipment. One example is Siemens’digital cloud service platform named Sinalytics [11].

Table 9 SM ecosystem architecture proposed by United States [27].

Table 10 RAMI 4.0 architecture proposed by Germany [136].

• In the 1990s, Japanese scholars first proposed international programs on IM. Recently, Japan released Society 5.0 and Industrial Value Chain Initiative (IVI) in the context of SM/IM. Japan focuses on increasing the value of each enterprise by means of cyber–physical production systems via lean management and service orientation, as well as solving the problems of an aging society. One example is their research and adoption of service robots in healthcare. Another is their principle of continuous improvement and respect for people in lean production, which are key elements in Japan’s SM/IM vision [145].

• In 2015, China released several national programs and plans for SM/IM. China’s preferred terminology is IM. China’s strategy of upgrading manufacturing technologies is in parallelrather than in series (i.e., from digitalization to networking and to intelligentization) due to the reality of its unbalanced development. Another feature of China’s IM is userorientation. Examples include Sany’s digital platform for predictive maintenance and Haier’s CosmoPlat [4,146].

Table 11 IMSA architecture proposed by China [137].

Fig. 8. Structural diagram of IM standard system [144]. A, B, C, D, and E are the codes in the IMSA.

Table 12 Mapping SM/IM reference architectures to HCPS dimensions [1,135].

Table 13 National SM or IM related policies/programs [64].

In summary, SM/IM is the collaborative output of information technology, industrial manufacturing technology or operation technology (OT), and human intelligence and creativity, leading into a rapid evolution of the manufacturing system. However,SM/IM is just one tool towards manufacturing industries’ultimate goals of reducing defects while improving quality, improving productivity while reducing cost, reducing downtime by predicting failure before it happens, minimizing waste while enhancing sustainability, and maintaining competitive advantages [64] through understanding, accumulation, and application of domain knowledge of manufacturing process and systems.

As is known, each country, region, or enterprise faces different situations and problems, and of course; each has differing comparative advantages. Therefore, when implementing integrating advanced IT and OTs, the technical path, prior technologies,and selected SM/IM paradigm may differ significantly. From the perspective of philosophy and culture, these differences become distinct by the way knowledge is understood, accumulated, and applied within manufacturing processes, systems,and sectors. For example, a typical Japanese manufacturing enterprise desires to continuously improve via rooting change in organizational culture and human training, and their knowledge acquisition is heavily dependent on individuals. A typical US company acquires new knowledge from data and knowledge migration, and can also be good at subverting and redefining problems. German manufacturing companies are good at the continuous upgrade of equipment and production systems,inserting new knowledge into the equipment, and creating new value for themselves and their customers. These differences in manufacturing philosophy, learned from the comparison of national focus and practical cases in SM/IM, may be useful guidance for countries, regions, and enterprises when they make their own development strategies.

8. Summary and conclusions

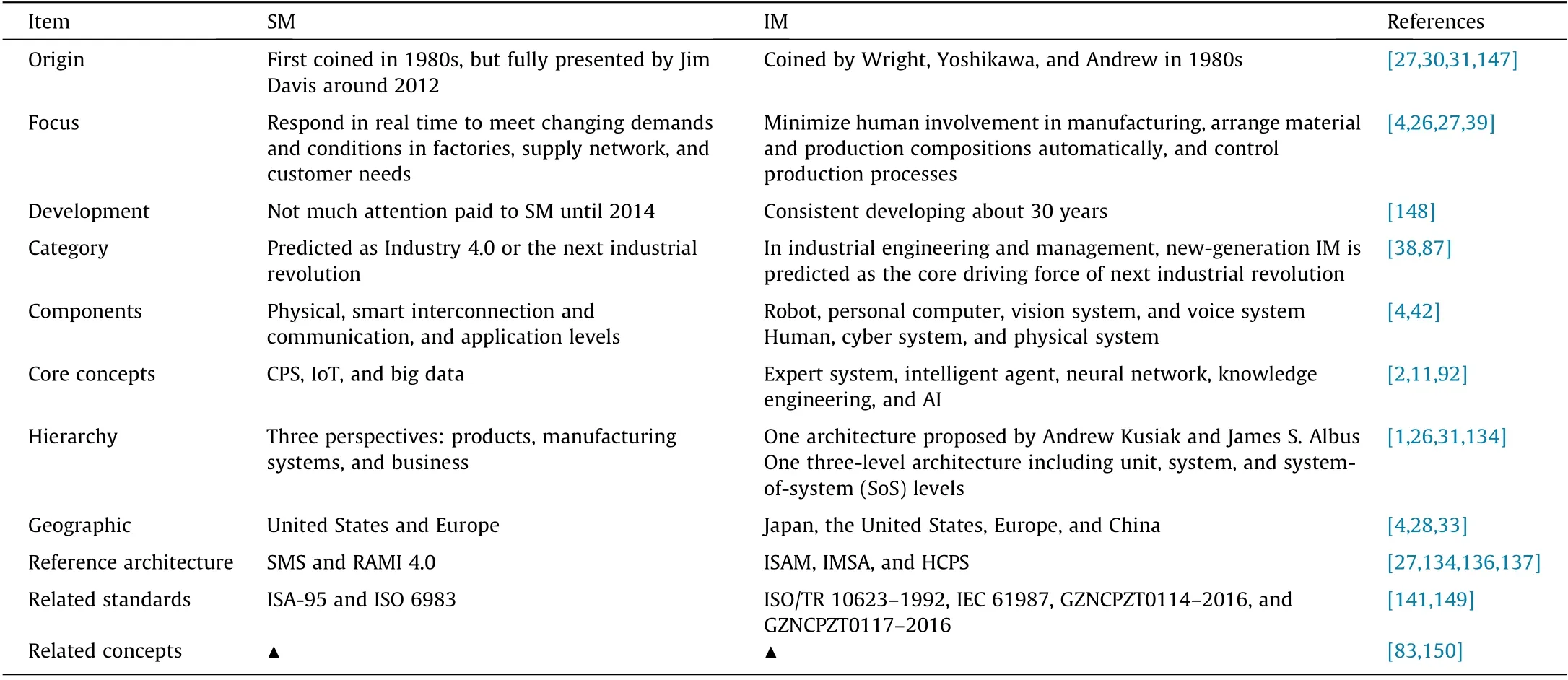

SM and IM are important paradigms to the new industrial revolution (Industry 4.0). Features and research focus are overlapped in the concepts and technology development of SM and IM. Both describe the evolution of manufacturing technology facilitated with advanced information and communication technologies. Academia, industry, and government have shown strong interests in the development of SM and IM.The concepts of SM/IM have been evolving since the first day they were proposed.However, limited considerations have been taken on whether the definitions, thought, connotation, and technical developments in the literature are truly distinct or are shared. To address the gap,the work presented reviewed and compared SM and IM through multiple perspectives, as summarized in Table 14 [1,2,4,11,26–28,30,31,33,38,39,42,83,90,93,134,136,137,141,147–150].

Early concepts of SM and IM were coined almost at the same time, where both were driven by developments in AI during the 1980s. However, SM and IM appear to be two parallel paradigms that evolved independently,and for the most part,attracted attention from different groups until around 2014.This literature review reveals that SM co-occurs more frequently with the concepts of Industry 4.0, data-driven, and big data, showing a close relationship with the research interests of scholars in those areas. In contrast, IM co-occurs more frequently with the concepts of AI algorithm, optimization, agent, and architecture. Under various definitions, different concepts and research topics can be associated to SM or IM at different development phases. The development of digitalization, networking, and intelligentization in manufacturing is common for both paradigms.

From an evolutionary analysis of SM and IM, changes in keywords and most-related paradigms reflect the adoption of the enabling technologies and research focus of SM and IM national level strategies. A comparison of reference architectures and standards indicate that global academia and industry would benefit from strengthened international cooperation between SM and IM communities. Manufacturing societies and organizations should strive to reach a consensus and conduct cooperative research on common issues (e.g., unified standards and reference architectures, workforce training). Distinguished features of national plans and projects and practical implementations have been found in aspects of paradigm/concept selection, investmentlevel, focus, and development paths for SM and IM. Moreover, the pursuit of continuous knowledge acquisition and application, and the goals of reducing defects, improving productivity, saving cost,reducing downtime, minimizing waste, enhancing sustainability,and maintaining a competitive advantage, have been shared by national level plans of manufacturing development in different countries.

Table 14 SM and IM through multiple perspectives: comparison and correlation.

The study of the SM and IM evolution also provides practical guidance to understand and implement SM and IM in enterprises or regions that have relatively low level of SM and IM development. The manufacturing philosophies and their noted consistency may help when targeted development decisions are made, such as choosing proper transformation paradigms and development strategies, and evaluating and selecting suitable technologies. Since manufacturing enterprises are the main implementers of SM and IM, it is suggested that more attention should be paid to key technologies such as CPS, big data, cloud computing, IoT, and AI, and human/staff education based on their unique situation, no matter which SM/IM paradigm is adopted.

Future research to further the understanding and implementation of SM/IM are supposed to include:

• Key technology development. To improve the smartness/intelligence of manufacturing systems,key enabling technologies such as sensing, DT, CPSs, knowledge engineering, and deep learning should be developed concurrently to make their adoption more robust,adaptive,economic,and sustainable.• Human–machine symbiosis. Today’s SM and IM call for a greater role of human–machine symbiosis. There should be in-depth integration and cooperation between humans and intelligent machines(e.g.,CPS)rather than only using machines to replace humans.

•Interdisciplinary,cross-domain,and social integration.The potential of SM and IM can be further unlocked if it is linked to other technologies, such as intelligent transportation, smart energy/grid,smart building,intelligent healthcare,smart city,and intelligent society. Research areas may include multiphysics modeling, social internet, data storage, privacy and security, standards, and ethics.

• Additional comparative survey. Surveys on SM and IM related questions using patent analysis,projecting technology trajectories, and interviewing experts, in order to compare standards and applications, and address the unique challenges of implementing SM/IM in small and mid-size enterprises, may provide further insights. A comparison of SM and IM manufacturing cultures is another potential topic worthy systematically studying.

Acknowledgements

This work was supported by the International Postdoctoral Exchange Fellowship Program (20180025), National Natural Science Foundation of China (51703180), China Postdoctoral Science Foundation (2018M630191 and 2017M610634), Shaanxi Postdoctoral Science Foundation (2017BSHEDZZ73), and FundamentalResearchFundsfortheCentralUniversities(xpt012020006 and xjj2017024).

Compliance with ethics guidelines

Baicun Wang, Fei Tao, Xudong Fang, Chao Liu, Yufei Liu, and Theodor Freiheit declare that they have no conflict of interest or financial conflicts to disclose.

- Engineering的其它文章

- Artificial Intelligence Cracks a 50-Year-Old Grand Challenge in Biology

- Sustainable Practice in Pavement Engineering through Value-Added Collective Recycling of Waste Plastic and Waste Tyre Rubber

- Comparison of Production-Triggering Strategies for Manufacturing Enterprises under Random Orders

- Hydrogen Energy: A Global Trend and China’s Strategy

- The Vision of France, Germany, and the European Union on Future Hydrogen Energy Research and Innovation

- Insight from Japan’s Hydrogen Strategy and Activities